Machine Finder

Machine Finder

Whether you are involved in furniture production, component manufacturing, timber house construction, or solid wood processing, we offer precisely coordinated solutions ranging from individual machines to complete production lines. From craftsmanship to industry. Our products are used to create high-quality furniture, kitchens, timber houses, windows, wooden floors, and stairs.

Filter

0 results

No matching products found

Spray Machines

Pressurized Spray Machine - Makor Start One C

- Entry into Flatline Automated Spray Finishing.

- Compact design. 3+1 fluid circuits.

- Pressurized spray cabin.

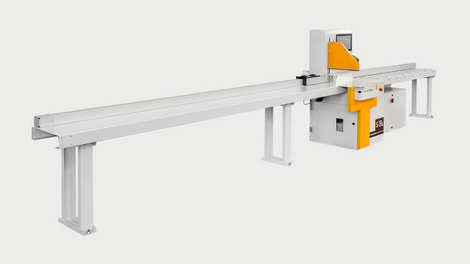

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperPush 200

- Maximum cutting accuracy of up to 0.01mm

- Automatic onboard defect and cut-list optimization

- Enclosed cutting center provides absolute operator safety

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperPush 250

- Pusher fed driven saw

- Lateral chain infeed

- Accurate to 0.01mm

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperPush 150

- Entry level optimized cutting.

- Total operator safety.

- Robust pusher for large work pieces.

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperCut 100

- High speed optimizing and defecting.

- Dual operator loading area.

- Accurate and square cutting.

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperCut 300

- High speed optimizing saw designed for rough lumber.

- Automatic width detection.

- NC controlled drive system.

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperCut 500

- Lightning fast cutting.

- Capable of handling roughest of lumber.

- Servo controlled cutting center.

CNC Drilling and Dowel inserting Machines

Boring Machines Ironwood BR Series

- Versatile Drilling.

- Enhanced Safety Features.

- Easy Tool Change.

Automatic Cross-Cut Saws

Up-cut Saws Ironwood CUT Series

- Advanced Safety Features.

- Hands-Free Operation.

- Accurate Crosscutting.

Jointer & Planer

Dual Surface Planers Ironwood DSP Series

- Advanced Safety Features.

- Smooth & Reliable Feed.

- Optimal High-Speed Performance.

Jointer & Planer

Jointers Ironwood JT Series

- Quick Set Up.

- Enhanced Safety Features.

- Low-Maintenance Operation.

Spray Machines

Pressurized Spray Machine Makor Next Two

- Twin Arm - Automated Spray Finishing.

- New Generation, Medium level production.

- Pressurized spray cabin.

Jointer & Planer

Planers Ironwood P Series

- Smooth & Quiet Operation

- Easy To Use Controls

- Helical Cutting Power

Automatic Cross-Cut Saws

Straight Line Rip Saws Ironwood SLR Series

- Ultimate Glue Line Accuracy

- Variable Speed Drives

- Advanced Anti-Kickback Safety Features

Profile & Spindle Moulders

Shapers Ironwood S Series

- Plug & Play Power feeders.

- Safe Operations.

- Versatile Cutting Operations.

Sanding Machines

Wide Belt Sanders Ironwood S Series

- Ease Of Use.

- Vibration-Free Calibration Sanding.

- Strength & Stability.

CNC Machining Centers

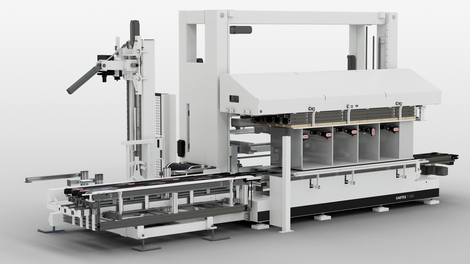

CNC Processing Center Greda Poker V5

- Hopper feeder and automatic unloading system.

- Full 5-axis machining allows for limitless processing.

- Sanding heads provide finished part quality.

CNC Machining Centers

CNC Processing Center Greda Mitika V5

- Hopper feeder and automatic unloading system.

- Full 5-axis machining allows for limitless processing.

- sanding heads provide finished part quality.

CNC Machining Centers

CNC Machining Center Greda Venus

- 4 working stations for high volume production.

- Configurable with a variety of aggregates.

- Fully enclosed working center.

Moulding & Profiling

Moulder Kentwood M-100

- Small footprint perfect for any shop.

- Cast iron frame for reduced vibration and increased quality.

- Advanced safety features.

Moulding & Profiling

Moulder Kentwood M-200

- Available with manual or CNC set-up.

- Independently driven spindles.

- 4-8 spindle configurations.

Moulding & Profiling

Moulder Kentwood M-300

- 24” touchscreen equipped with ProLink digital software.

- Profile memory and CNC controlls allows for rapid set up times.

- Tool room and office interlink.

Moulding & Profiling

Moulder Kentwood M-500

- Heavy duty feed system.

- High speed single knife finishing.

- Increased horsepower.

Moulding & Profiling

Moulder Kentwood M-600

- Straight and profiled jointers

- Highspeed processing

- Automatic board sensors for speed regulation

Moulding & Profiling

Moulder Kentwood M-2000

- 6,000-12,000 RPM HSK 85W Spindles.

- Rapid Set Up Hoods.

- 24” ProLink APC.

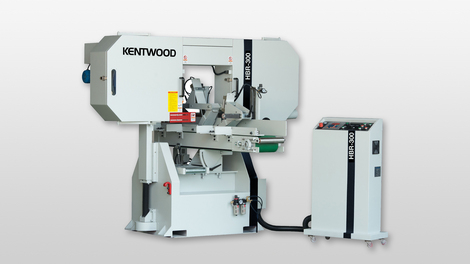

Moulding & Profiling

Moulder Kentwood HBR Series

- Cast iron wheels reduce vibration.

- Hydraulic blade tensioning.

- Automatic blade height and table tilt adjustment.

Sanding Machines

Sander Alpha-Brush Extreme CCBBDD

- 6 head brush sanders, working width 1350mm.

- 2 x Cross – 2 x Barrel – 2 x Disk configuration. Dual or Single Grit sanding strips.

- For Medium to Large production level process

Sanding Machines

Sander Alpha-Brush Extreme CBD

- 3 head brush sanders, working width 1350mm.

- Cross – Barrel – Disk configuration. Dual or Single Grit sanding strips.

- Great Entry Market machine for small to medium wood shops.

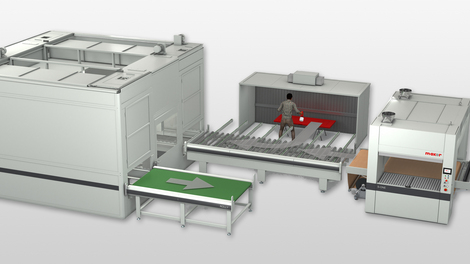

Spray Machines

Pressurized Spray Machine Makor Excellent CM80

- Two Arm (independently driven) - Automated Reciprocating Sprayer.

- New Generation, High Quality Application, High Productivity.

- 3 Zone Pressurized Spray Cabin.

Spray Machines

Drying Oven Makor Flexi Oven

- Variable Time - Drying and Curing System.

- Central lift system with Right and Left Tower.

- Programable drying recipes. Variable height shelving.

Spray Machines

Spraying Cartesian Robot - Makor Evolution Series

- 5 axis cartesian movement for high quality application.

- Pinnacle in automation and quality!

- Innovative 3D part scanning.

Spray Machines

Drying Oven Makor Ultradry 1&2

- UV cure technology.

- Available in 1 or 3 lamp configurations.

- Curing mono and bi-component UV paints.

Sanding Machines

Sander Heesemann MFA 10 Series

- The Mid-Upper-level Industrial Range Series of machines from Karl Heesemann Sanders.

- Recipe based programming with Touchscreen Controller. Industry 4.0 ready.

- The frame allows up to 8 working heads in “Free Range” configuration. 1350mm & 1600mm working widths.

Sanding Machines

Sander Heesemann HSM New Edition

- Entry into the Industrial Range Series of machines from Karl Heesemann Sanders.

- Recipe based programming with Touchscreen Controller. Industry 4.0 ready.

- Available in *17 pre-configured layouts. 1350mm working width.

Sanding Machines

Sander Heesemann MFA IMPRESSION Series

- The mid-level Industrial Range Series of machines from Karl Heesemann Sanders.

- Recipe based programming with Touchscreen Controller. Industry 4.0 ready.

- The frame allows up to 5 working heads in “Free Range” configuration. 1350mm working width.

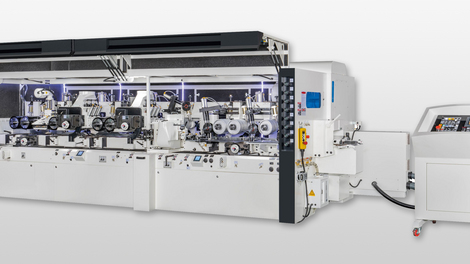

Edge Banding Machines

Automatic Contour Edegbander Vector Revolution 180

- Cartridge Glue Nozzle System

- Vacuum Table

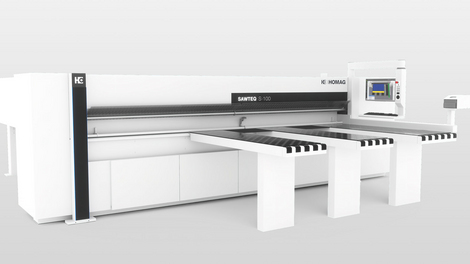

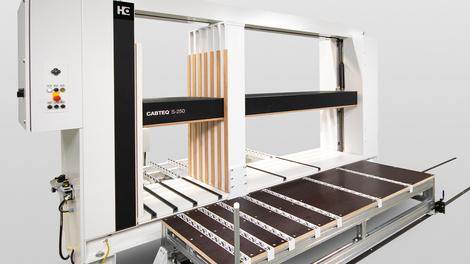

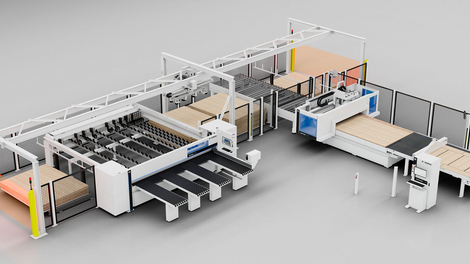

Panel dividing saws

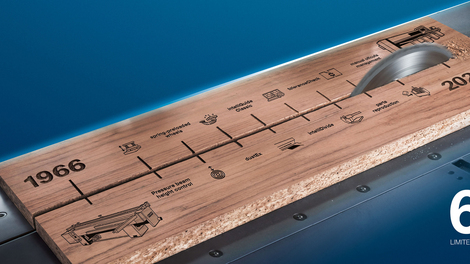

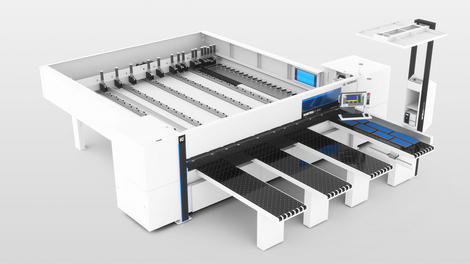

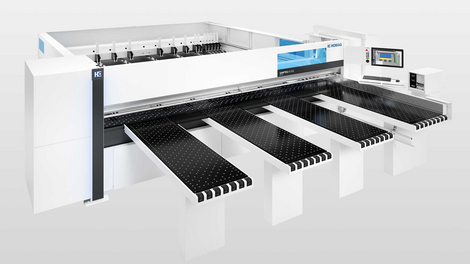

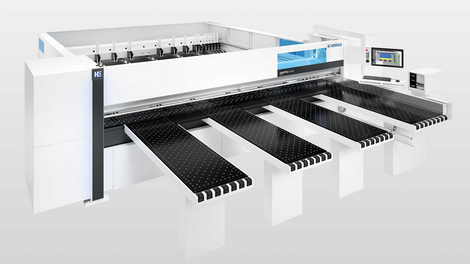

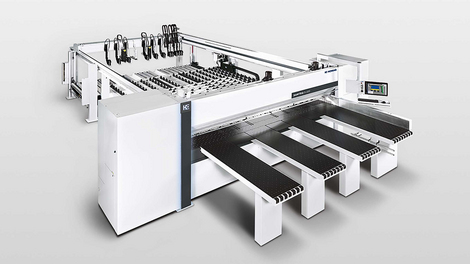

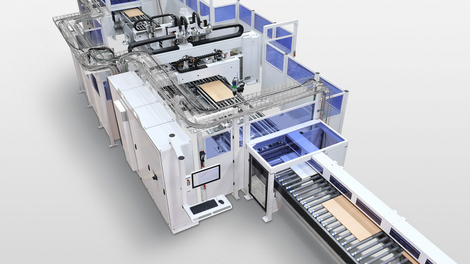

Panel dividing saw SAWTEQ Edition60

- For the SAWTEQ S-300/310 and S-400/410 series

- Special edition

- Limited to 60 machines

New

Panel dividing saws

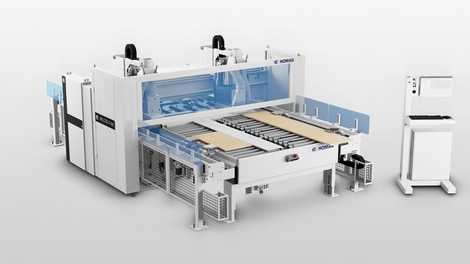

Panel dividing saw SAWTEQ S-65

- Delivers precise cuts with consistent quality in every production run.

- Integrates essential functions into a compact, reliable panel dividing saw.

- Combines solid cutting performance, ergonomic design, and efficient operation.

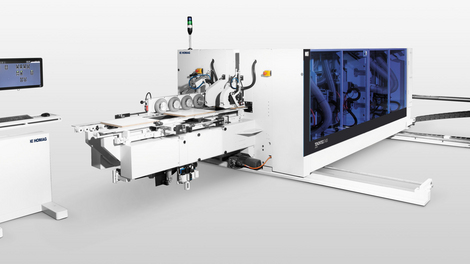

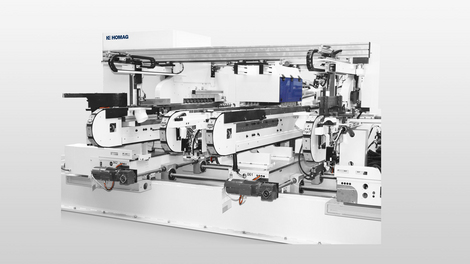

Double End Tenoners

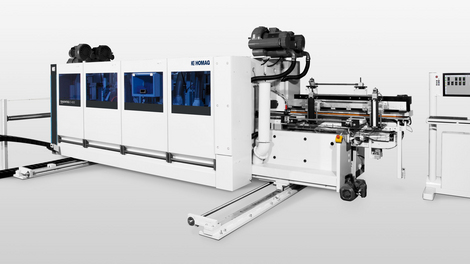

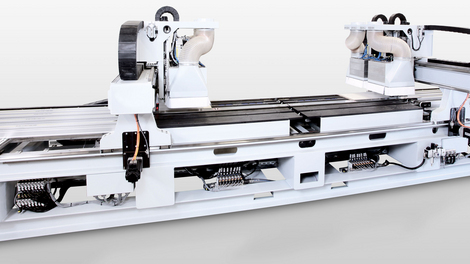

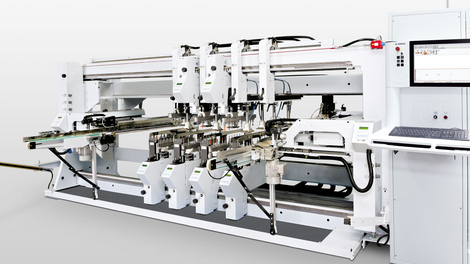

Double-End Tenoner TENONTEQ D-500: Entry-level machines for flooring production

- Multifunctional and cost-effective

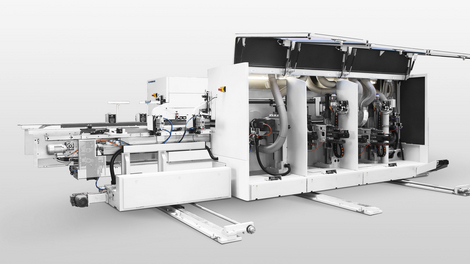

Double End Tenoners

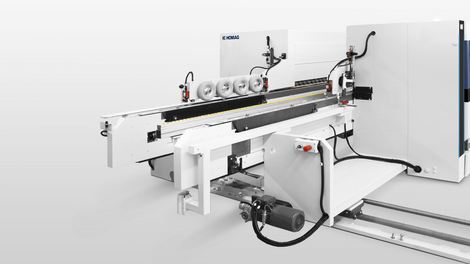

Double-End Tenoner TENONTEQ D-600: Medium performance range for flooring production

- Compact and flexible solutions for longitudinal and crosswise profiling

Double End Tenoners

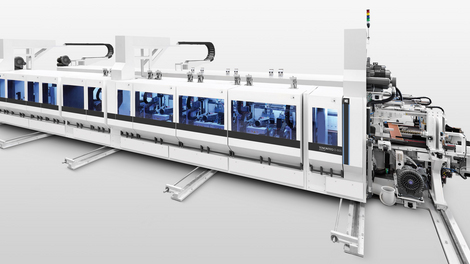

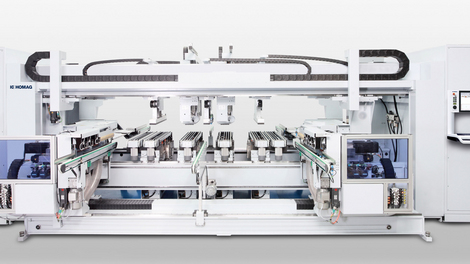

Double-End Tenoner TENONTEQ D-800: High-end solutions for flooring production

- For exacting requirements for performance and flexibility

Double End Tenoners

Double-End Tenoner TENONTEQ D-500: for furniture production and interior furnishings

- A compact introductory solution for double-sided dimensioning work

Double End Tenoners

Double-End Tenoner TENONTEQ D-600: for manufacturing doors, fronts and panels

- Two throughfeeds - longitudinal and crosswise - process the four sides of your workpieces

Double End Tenoners

Double-End Tenoner TENONTEQ S/D-800: for furniture and component production

- Single-sided and double-sided power machines for specialized requirements

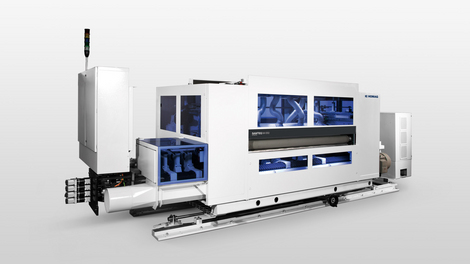

Multi Rip Saws

Multi rip saw SAWTEQ M-500 / 320 / 330: Longitudinal division in line with requirements

- Single-row or double-row configurations

Multi Rip Saws

Multi rip saw SAWTEQ M-500: Throughfeed sawing that saves materials

- A division technique offering material savings of up to 6%

Multi Rip Saws

Multi rip saw SAWTEQ M-500: Longitudinal division of large panel materials

- The path to increased profitability

Multi Rip Saws

Multi rip saw SAWTEQ M-500: Longitudinal division of panels into narrow formats

- Division using polygon shaft technology

Multi Rip Saws

Multi rip saw SAWTEQ M-700: Maximum precision for throughfeed cutting

- Minimal tolerance ranges for longitudinal division techniques

Multi Rip Saws

Multi rip saw SAWTEQ C-600: Flexible cross cut saws

- Throughfeed saw for industrial furniture and floor manufacturers

Multi Rip Saws

Multi rip saws SAWTEQ C-700: Flexible crosswise division for the upper performance range

- A throughfeed saw for producing furniture and flooring parts in high batch quantities

Multi Rip Saws

Multi rip saws SAWTEQ C-720: Flexible crosswise division designed especially for the furniture industry

- A throughfeed saw for cost-effective production of furniture workpieces

Edge Banding Machines

Shaped part edge banding / post-processing machines

- The flexible solution for all shaped parts

- The ideal machines for small quantities

- Impressive price-performance ratio

Edge Banding Machines

XES 200 PUR service station

- Storage of application units in a vacuum

- Holding device for 2 application units

- Small and compact, less than 1 m²

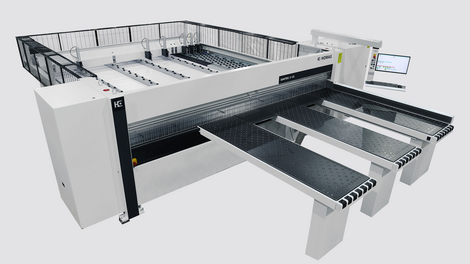

Panel dividing saws

Panel dividing saw SAWTEQ S-100

- Saw for single panels and small batches

- For beginners and those making a change: First-class performance at an attractive price

- Semi-automatic cutting: Ergonomic, safe, efficient

Panel dividing saws

Panel dividing saw SAWTEQ S-160

- High-precision cutting with premium quality cut

- High performance and high output with fast cutting cycle time

- CADmatic with assistance graphic for intuitive, ergonomic machine operation

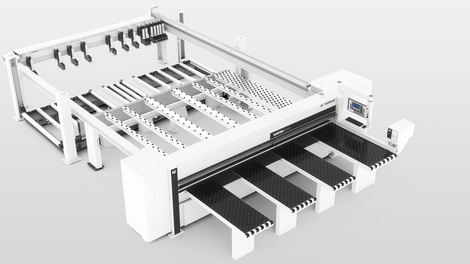

Panel dividing saws

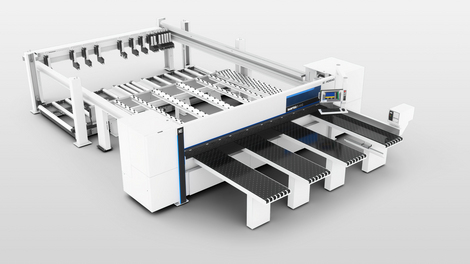

Panel dividing saw SAWTEQ S-200

- Attractive price, powerful and precise

- Modular design for growing requirements

- Can be connected to feed and storage systems

Panel dividing saws

Panel dividing saw SAWTEQ S-210 with lifiting table

- More speed and material throughput

- Ergonomic, fast and efficient feeding from the rear

- Modular design for growing requirements

Panel dividing saws

Panel dividing saw SAWTEQ S-200 flexTec

- Unmanned operation possible until stack change

- Quick changeover between operator and automatic mode

- Up to 850 parts per shift

New

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-200 plastics

- A small, but powerful plastics saw for fast processing of smaller batches.

Panel dividing saws

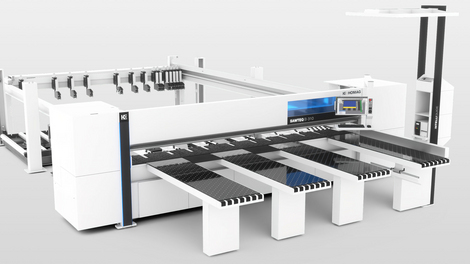

Panel dividing saw SAWTEQ S-300

- Amazing variety of applications thanks to customizable equipment

- Perfect for networked production processes

- Ergonomic, sustainable and efficient

Bestseller

Panel dividing saws

Panel dividing saw SAWTEQ S-310 with lifting table

- Amazing variety of applications thanks to customizable equipment

- Ergonomic, fast and efficient feeding from the rear

- Ready for networked production processes

Panel dividing saws

Panel dividing saw SAWTEQ A-300 | A-310 as angular saw unit

- Rip and cross cuts in one pass: this saw is an excellent solution for volume production involving cutting panels in books.

Panel dividing saws

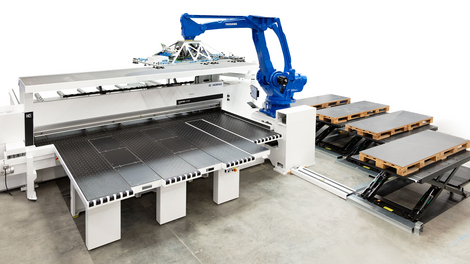

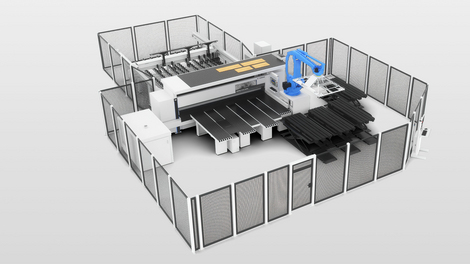

Panel saw SAWTEQ S-300 | S-310 flexTec

- In robot operation: Highly efficient batch size 1 production with up to 1000 parts per shift

- Low unit costs per part

- Partially unmanned operation

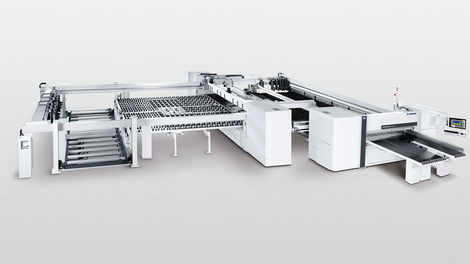

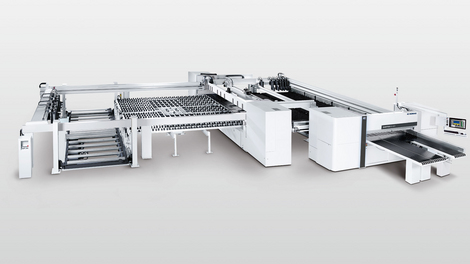

Panel dividing saws

Panel dividing saw SAWTEQ S-320 flexTec

- Production capacity of up to 3,000 parts per shift

- Automation through robot management

- Unlimited recuts

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-300 plastics

- The classic among the horizontal plastics saws provides great cutting precision and produces even small quantities profitably.

Panel dividing saws

Panel dividing saw SAWTEQ S-400

- Amazing variety of applications thanks to customizable equipment

- High throughput for book and series cutting

- Perfect for networked production processes

Panel dividing saws

Panel dividing saw SAWTEQ S-410 with lifting table

- Amazing variety of applications thanks to customizable equipment

- High throughput for book and series cutting

- Ergonomic, fast and efficient feeding from the rear

Panel dividing saws

Panel dividing saw SAWTEQ A-400 | A-410 as angular saw unit

- The SAWTEQ SAWTEQ A-400 | A-410 delivers a high level of precision in continuous operation, coupled with an impressive processing speed.

Panel dividing saws

Panel saw SAWTEQ S-400 | S-410 flexTec

- In robot operation: Highly efficient batch size 1 production with up to 1000 parts per shift

- Low unit costs per part

- Partially unmanned operation

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-400 plastics

- This panel dividing saw is every bit as versatile as your demands are varied and can handle nearly all types of plastic panels – also when dealing with larger quantities and cutting in books.

Panel dividing saws

Panel dividing saw SAWTEQ S-500

- Innovative high-performance saw for series production

- Uncompromising and robust technology for large books of panels

- Perfect for high material throughputs

Panel dividing saws

Panel dividing saw SAWTEQ S-510 with lifting table

- Innovative high-performance saw for series production

- Uncompromising and robust technology for large books of panels

- Ergonomic, fast and efficient feeding from the rear

Panel dividing saws

Panel dividing saw SAWTEQ A-500 | A-510 as angular saw unit

- Plenty of output in a short time: the fully automated angular saw unit of the 5 series sets the benchmark in industrial manufacturing and is particularly powerful.

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-500 plastics

- Cutting plastic panels on a large scale – this is what the SAWTEQ S-500 plastics saw is designed for, and it sets the benchmark for this in the premium segment.

Panel dividing saws

Panel dividing saw SAWTEQ A-610 as angular saw unit

- The largest and most powerful angular saw unit made by HOMAG is a real powerhouse for volume production.

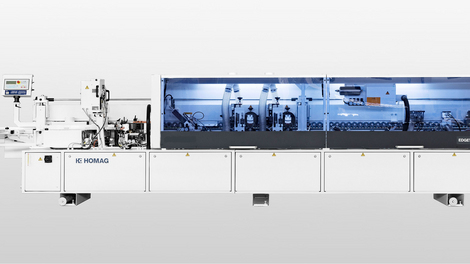

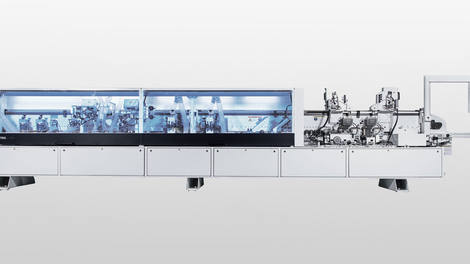

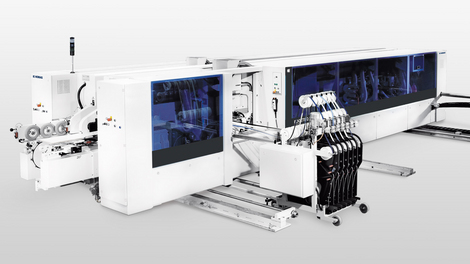

Edge Banding Machines

Edge banding machines EDGETEQ S-200: 8 m/min | 11 m/min feed speed

- Glue change in under 3 minutes

- Regulated motors for edge feeding

- Strip separation by suction cups

Edge Banding Machines

Edge Banding Machines EDGETEQ S-230

- Perfect edge banding with our EDGETEQ S-230 Series

Edge Banding Machines

Edge banding machines EDGETEQ S-240: 11 m/min feed speed

- Entry-level machine for demanding requirements

Edge Banding Machines

Edge banding machines EDGETEQ S-300

- 14 m/min feed rate

- Multi-level technology with automatic adjustment

- Connection to software and apps

Edge Banding Machines

Edge banding machines EDGETEQ S-340

- Joint trimming unit guarantees the ideal formatting of the panel

- Quick Melt gluing unit guarantees the optimal edge banding

- Snipping unit equipped with 2 motors offers a highly precise cut

Edge Banding Machines

Edge banding machines EDGETEQ S-356

- Top belt pressure

- Easy removal of the application unit

- Manual adjustments

Edge Banding Machines

Edge Banding Machines EDGETEQ S-358

- Powerful motors on all units provide unrestricted power

- Joint trimming unit perfectly formats the panels

- Quick melt gluing unit is ideal for optimal edge adhesion

Edge Banding Machines

Edge banding machines EDGETEQ S-360

- Complete edge processing with our EDGETEQ S-360.

Edge Banding Machines

Edge banding machines EDGETEQ S-370

- The next generation of Edge banding machines.

Edge Banding Machines

Edge banding machines EDGETEQ S-380 | profiLine: 8–20 m/min feed speed

- Feed speed up to 20 m/min

- Portal return connection

- Individualization in the profiLine modular system

Edge Banding Machines

Edge banding machines EDGETEQ S-500 Optimat and profiLine

- Feed rate: 16–20, 25, 30, 35 m/min

- Process PUR, EVA and airTec or laserTec using just one machine

- Minimum workpiece width: 60 mm (40 mm)

Bestseller

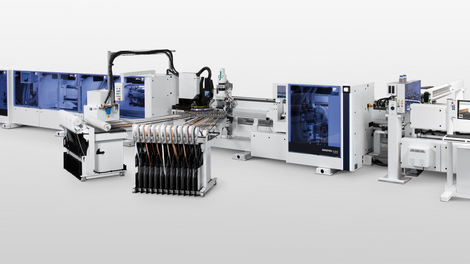

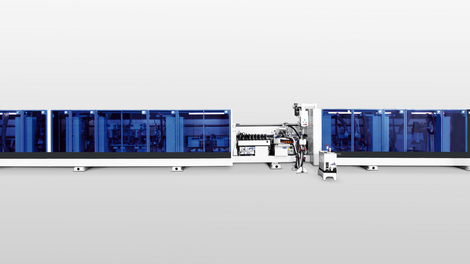

Edge Banding Machines

Edge banding machines EDGETEQ D-610 profiLine

- Feed rate up to 50 m/min

- Double-sided edge processing

- Production of medium to large series

Edge Banding Machines

Edge banding machines EDGETEQ S-800 profiLine

- Feed rate 15-40 m/min

- Flexible production of furniture parts down to batch size 1

- Customized system concepts according to your requirements

Edge Banding Machines

Edge banding machines EDGETEQ S-810 powerLine: Individual equipment configuration

- Delivering accurate processing and the perfect aesthetic in combination with any edging material

Edge Banding Machines

Edge banding machines EDGETEQ D-810 powerLine: Maximum Power

- Unique high-performance machines

Edge Banding Machines

Shaped part throughfeed machines EDGETEQ S-810/CF: Rapid processing of large quantities

- Complete processing of shaped parts in a single run

Edge Banding Machines

Postforming machines EDGETEQ S-810: One machine – five processing stations

- Pre-coated panel in – postforming part out

Edge Banding Machines

Softforming machines: Creative edge design

- An extensive range of profiles and edge materials

Edge Print

EDGETEQ P-200 digital edge printing

- Prints decors, images, logos and text

- Direct printing on MDF boards

- Apply design ideas directly

New

Return Conveyors

Return conveyor LOOPTEQ O-200

- The entry to a comfortable material flow

- For small, narrow and mediumsized workpieces

- Pays off from 9 hours working time per week

Return Conveyors

Return conveyor LOOPTEQ O-300

- For a wide spectrum in the material flow

- For small and light up to large and heavy workpieces

- Pays off from 15 hours working time per week

Return Conveyors

Return System LOOPTEQ O-400

- Combination of stacking system and workpiece return

- Designed for production halls with limited space

- Designed for large parts up to 3,100 x 1,300 mm

New

Return Conveyors

Return conveyor LOOPTEQ O-600

- Combination of stacking system and workpiece return

- For a wide variety of parts and a high degree of automation

- Interlinked material flow with high capacity

Return Conveyors

Edge circulation unit LOOPTEQ C-500

- Fully automatic edge circulation

- Performance increase of up to 100%

- Maximum performance 15 cycles/minute

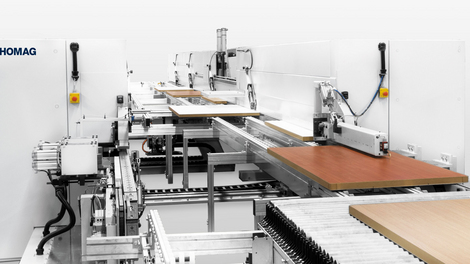

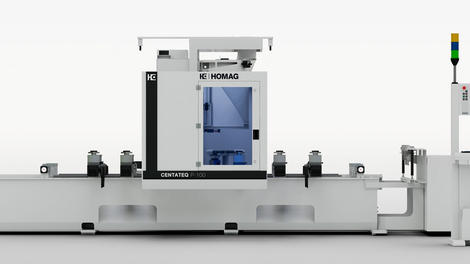

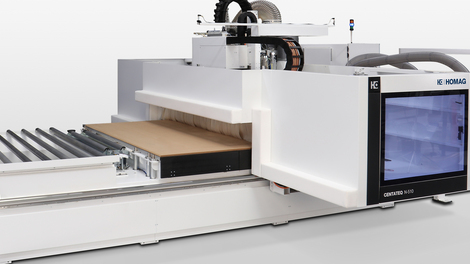

CNC Machining Centers

CNC Processing Center CENTATEQ P-100

- Universal CNC technology with 3, 4 or 5 axes

- Flexible cantilever design

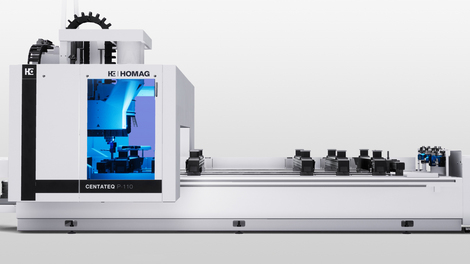

CNC Machining Centers

CNC Processing Center CENTATEQ P-110

- Universal CNC technology with 3, 4 or 5 axes

- Completely free accessibility for optimum operation

- Stable moving gantry design

Bestseller

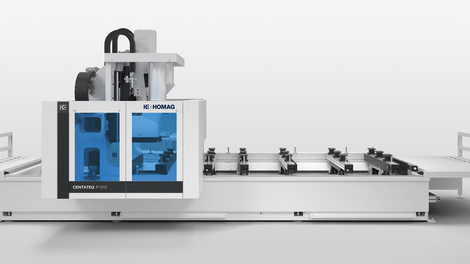

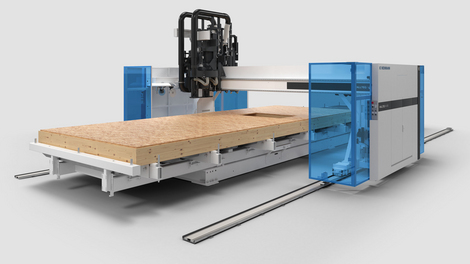

CNC Machining Centers

CNC Processing Center CENTATEQ P-210

- Flexible CNC technology with 3, 4 or 5 axes

- Gluing technology and automation available for the trade

- Stable moving gantry design

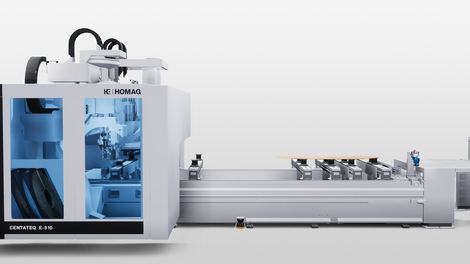

CNC Machining Centers

CNC Processing Center CENTATEQ P-310 | E-310

- Processing options from 5-axis to edge

- Scalable in performance, easy to operate

- Performance and convenience combined in one machine

CNC Machining Centers

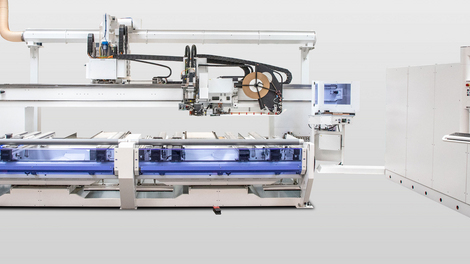

CENTATEQ P-510|610 + E-510 processing centers

- High-end CNC processing centers with SORB TECH machine body for the highest demands

- Individually configurable according to your needs

CNC Machining Centers

CENTATEQ E-700 processing centers

- High-performance edge banding on two processing tables

CNC Machining Centers

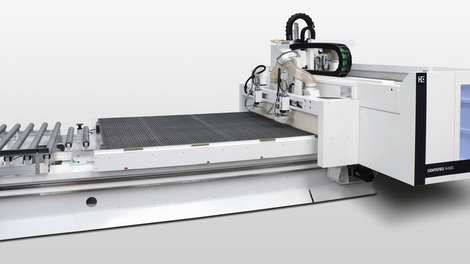

CNC Gantry-Processing Center CENTATEQ N-100

- Enable optimized processing of panel materials

- Various possibilities for the automation of material handling

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-210

- A new take on nesting processing.

- 3- and 4-axis machining

CNC Machining Centers

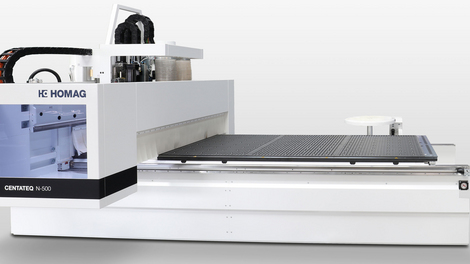

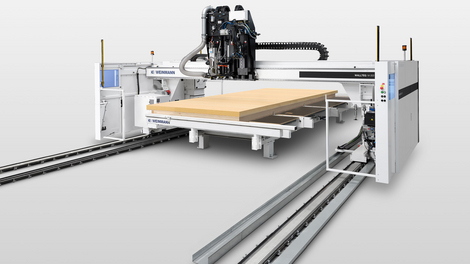

CNC Gantry-Processing Center CENTATEQ N-500

- Compact class Flexible handling concepts 3-, 4-axis machining

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-510

- Where the top class starts – more flexibility, maximum efficiency

- 3, 4 or 5-axis processing

- Z-height up to 260 mm

CNC Machining Centers

CNC-Gantry Processing Center CENTATEQ N-600

- Nesting with 3-, 4- or 5-axis technology

CNC Machining Centers

CENTATEQ T-Series processing centers

- Synchronous or parallel processing on two processing tables

CNC Machining Centers

CENTATEQ S-800|900 processing centers

- Solutions for complex requirements in window production

- From the individual machine to the connected cell

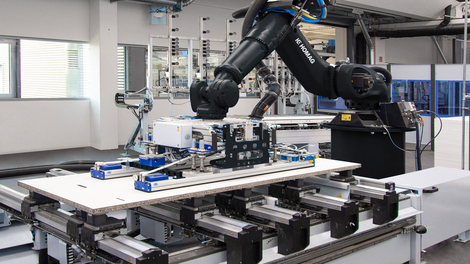

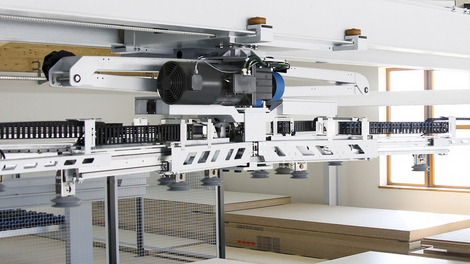

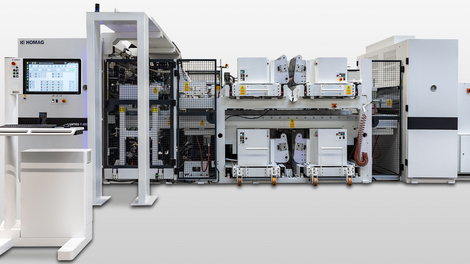

WEINMANN Multifunction Bridge

Multifunction bridge WALLTEQ M-300

- For entry into the world of automatic creation of elements

- Ideal for woodworking shops with high processing flexibility

- Sawing of materials up to 80 mm

Bestseller

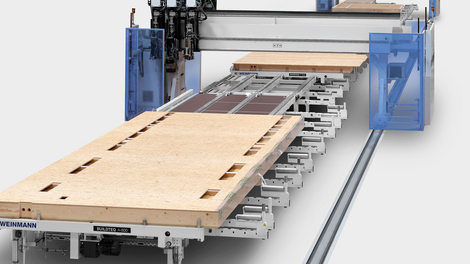

WEINMANN Multifunction Bridge

Multifunction Bridge WALLTEQ M-500

- Individually configurable solution

- A wide range of processing options for the elements

- Extended mounting options for sheathing

WEINMANN Multifunction Bridge

Multifunction Bridge WALLTEQ M-300 insuFill /M-500

- Fully automated insulation of timber construction elements

- Efficient use of materials and reduced dust exposure for employees

- Logging of the blow-in quantity

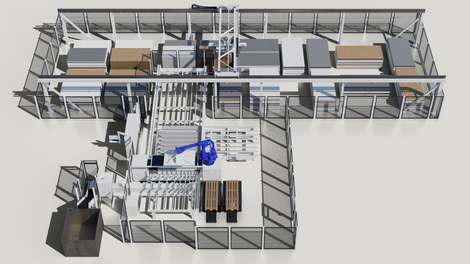

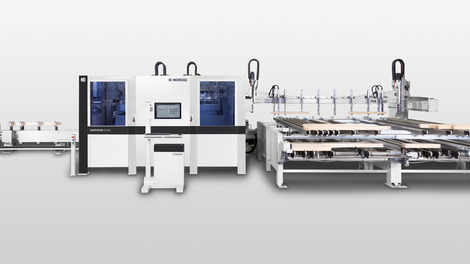

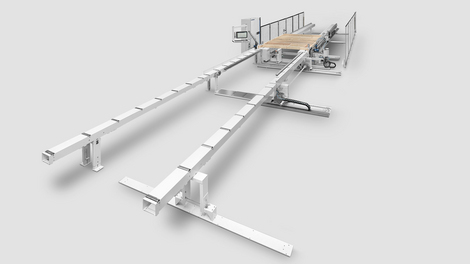

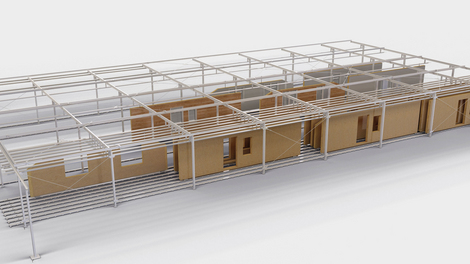

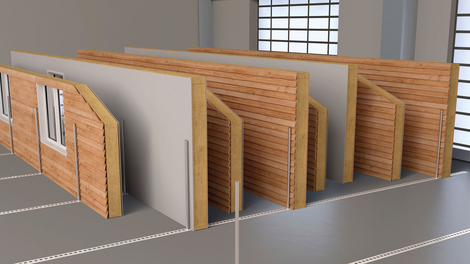

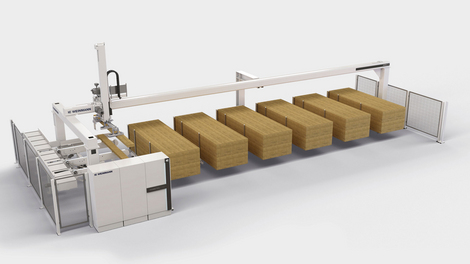

WEINMANN Timber Frame Production Lines

Compact Line

- Easy to integrate thanks to low space requirements

- High overall productivity

- Flexible batch size production

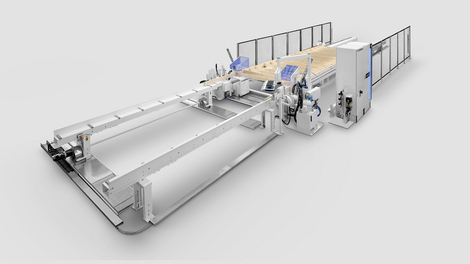

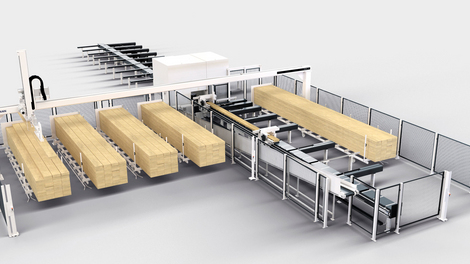

WEINMANN Timber Frame Production Lines

Wall production line

- High-precision production of wall elements

- Efficient production process due to high speed

- Can be expanded to different levels of automation

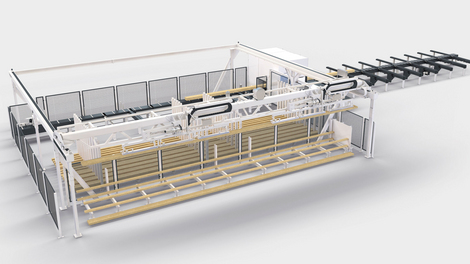

WEINMANN Timber Frame Production Lines

Roof and ceiling production line

- Enables the manufacture of roof and ceiling elements

- An integrated system — from cutting to loading

- Can be individually adapted to customer requirements

WEINMANN Framing Station

Frame Work Station FRAMETEQ F-300

- Cost-effective entry-level solution for automated frame work production

- High flexibility since the system can be expanded on a modular basis

- Optimized production of standard walls and gable elements

WEINMANN Framing Station

Frame Work Station FRAMETEQ F-500

- High level of performance due to high degree of automation

- Versatile expansion options even with robot technology

- Optimized production of standard walls and gable elements

WEINMANN Framing Station

FRAMETEQ F-700 framing station

- Production of complex and demanding frame works.

- Ideally suited for fully automatic production processes.

- Versatile expansion options even with robot technology.

Cardboard-box Cutting and Closing Machines

Cardboard-box cutting machine PAQTEQ C-250

- Individual packaging like a custom-made suit

- Efficient and sustainable product protection

- Stand-alone operation or integrated into a complex packaging line

Cardboard-box Cutting and Closing Machines

PAQTEQ F-200 – Carton folding machine

- Automatic folding, raising and gluing of the bottom cardboard box

- Ideal for series production

- Perfect cardboard boxes – no more manual reworking

Cardboard-box Cutting and Closing Machines

Cardboard-box closing machine PAQTEQ S-200

- Perfect packaging, fully automatic

- Self-calibrating machine, no data entry required

- Suitable for series as well as batch size 1 operation

Case Clamps

Stationary Case clamp CABTEQ S-200

- Intuitive operation

- Pressing areas with tolerance compensation in the top pressure

- Simple installation of the machine thanks to Plug & Play

Case Clamps

Stationary Case clamp CABTEQ S-250

- Pressing areas with tolerance compensation in the top pressure

- Sensor detection for a gentle pressing process

- Optionally selectable plug-in station and carcass upright for an ergonomic working environment

Case Clamps

Throughfeed case clamp CABTEQ T-200

- Our solution as an introduction to throughfeed pressing technology

- Automatic positioning of the press elements by sensory recognition of the main dimensions at the infeed of the carcase.

Case Clamps

Throughfeed case clamp CABTEQ T-250

- Automatic positioning of the press elements by sensory detection

- Precise, fully autom. adjustment by using precise ballscrew drives

- Optional clamping unit for fully automatic fastening of the back panels

Case Clamps

Automatic joining press CABTEQ T-500

- Automated joining process for assembling carcasses

- Precisely adjustable pressing force allows pressing of carcasses with sensitive surfaces, thin-walled or small carcasses

- Operator support during the assembly process for carcases thanks to the vacuum-operated holding arms for shelves and rear panel

CNC Drilling and Dowel inserting Machines

CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-110

- Horizontal drilling and doweling

CNC Drilling and Dowel inserting Machines

CNC-Dowel hole drilling machine DRILLTEQ C-100 NBS 033 (India)

- Perfect dowel hole drilling with our DRILLTEQ C-100 NBS 033

CNC Drilling and Dowel inserting Machines

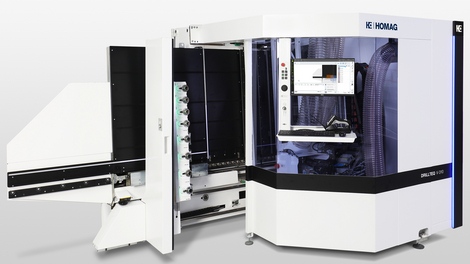

CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-510

- Horizontal drilling, doweling and milling

- Vertical drilling, milling

- Special configuration for inclined machining between 42° - 45°

CNC Drilling and Routing Machining Centers

Vertical CNC Processing Center DRILLTEQ V-200

- A flexible all-rounder for processing in just 5 m²

CNC Drilling and Routing Machining Centers

DRILLTEQ V-310 vertical CNC processing center

- Maximum cabinet processing. Minimum space requirements. A space-saving miracle that requires just 11 m² of floor space.

Bestseller

Robot Solutions for the Furniture Industry

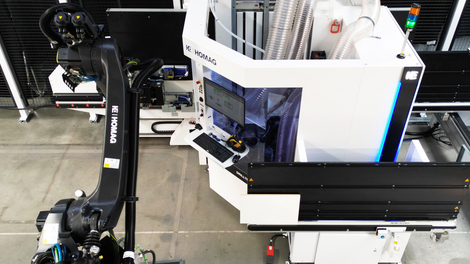

Robot FEEDBOT D-310

- Add-on for the DRILLTEQ V-310 CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

New

Robot Solutions for the Furniture Industry

Robot FEEDBOT D-300

- Retrofitting for DRILLTEQ V-500 CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

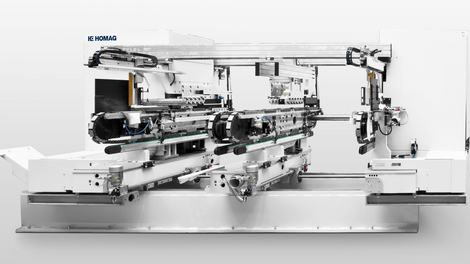

CNC Automatic Drilling and Fitting Machines

Throughfeed Processing Centers DRILLTEQ L-200

- Ideal for the cabinet side processing

CNC Automatic Drilling and Fitting Machines

Throughfeed Processing Center DRILLTEQ L-500

- 6-sided processing without compromises

CNC Drilling and Routing Machining Centers

CNC Drilling and Routing Machining Centers

- 6-sided processing for complete carcase production

- High flexibility thanks to manual handling

CNC Drilling and Routing Machining Centers

CNC-Processing Center DRILLTEQ H-330

- Full panel processing in highspeed

- 4 CNC-controlled clamping devices

- Optional top electric spindles with automatic tool changer

CNC Drilling and Routing Machining Centers

CNC-Processing Center DRILLTEQ H-600

- High processing speeds of up to 130 m/min.

- 6-sided machining for complete carcass production

- High output thanks to double part processing of mirrored workp.

Througfeed Drilling Machines

Throughfeed Drilling Machine DRILLTEQ C-500

- The high-performance drilling machine from a batch size of more than 250 pieces – enormous repeat accuracy with the same high quality standards.

Througfeed Drilling Machines

Drilling System DRILLTEQ C-800

- Up to 730 individually retrievable drilling spindles ensure dynamic batch size one manufacturing.

Sorting Buffering and Collating Systems

Collating storage system

- Automatically on two levels - 2-bridge-system

Sorting Buffering and Collating Systems

Collating center SORTEQ R-200

- Limitless sorting from batch size 1

Sorting Buffering and Collating Systems

Sorting line

- Gentle material transport without suction technology

Robot Solutions for the Furniture Industry

Robot FEEDBOT C-300

- Add-on for a CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

- Production cell with a robot for automatic material handling

WEINMANN Handling and storage systems timber construction

Robot FEEDBOT F-500

- Automated insertion of studs and belts in the frame work

- Delivers tailor-made results thanks to a high degree of precision

- Reduces the physical exertion required by employees

WEINMANN Handling and storage systems timber construction

Robot FEEDBOT W-500

- Automated placement of panels on the frame work

- Delivers tailor-made results due to a high degree of precision

- Reduces physical exertion of employees

Robot Solutions for the Furniture Industry

Robot SORTBOT R-300

- Solution for horizontal or vertical sorting

- More Output without Waiting Times

Robot Solutions for the Furniture Industry

Robot PAQBOT I-300

- Increased performance thanks to precise, fast insertion

- Process stability minimizes manual intervention and ensures quality

- Easy integration thanks to trenchless concept

Sorting Buffering and Collating Systems

Buffering system

- Buffering for the adjustment of the material flow

Feed and Stacking

Feed and stacking system FEEDTEQ G-200 | STACKTEQ G-200

- Gantry-design feed and stacking system

Feed and Stacking

Feed and stacking system FEEDTEQ L-500 | STACKTEQ L-500

- Compact feed and stacking system

WEINMANN Handling and storage systems timber construction

Swing jib crane FEEDTEQ H-300

- Quick and easy material handling

- High degree of work ergonomics and easy operation

- Optimized material provision

WEINMANN Handling and storage systems timber construction

Handling portal FEEDTEQ H-500

- Ergonomic material provision in production lines

- Quick and easy handling over large working areas

- Suitable lifting devices for the right material

WEINMANN Assembly Tables

Up-lifting and distribution trolleys BUILDTEQ A-500

- Ergonomic transport of wall panels

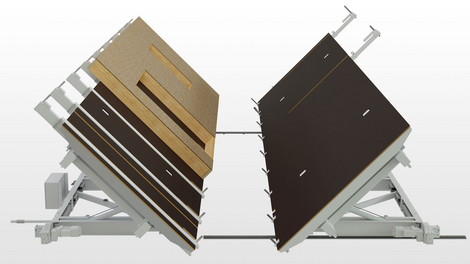

Storage systems timber construction

Wall magazine STOCKTEQ V-300 | V-500

- Enables a production-optimized workflow

- Comprehensive safety system

- Customized magazine capacity

Storage systems timber construction

Window installation track STOCKTEQ V-330 | V-530

- Wide magazine track with sufficient space for installing windows and doors

- Enables ergonomic work processes

- Comprehensive safety system

Storage systems timber construction

Distribution and warehouse trolley STOCKTEQ D-300 | D-500

- Enables easy distribution and loading of finished wall elements

- Precise positioning of the carriage on the wall tracks of the magazine

- High level of occupational safety

Storage systems timber construction

Stake magazine STOCKTEQ V-100

- Temporary storage of elements

- Easy loading and removal with the overhead crane

- Ideal for small businesses

Storage Systems

Single-axis feeder STORETEQ F-100

- Fully automatic board handling: Increases your productivity and saves time

- Fits in any workshop: The space-optimized feeder requires hardly any floor space

- Intuitive operation: You operate the feeder conveniently directly a your HOMAG saw

New

Storage Systems

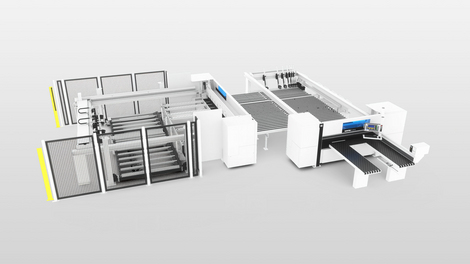

Storage system STORETEQ P-300 | P-500

- Transparent storage management

- Optimal material flow and consumption up to offcuts

- Low search times and increased productivity

Storage Systems

Storage system STORETEQ P-310|P-510 and P-320|P-520

- Optimal and resource-saving storage area

- Transparently managed stocks in the smallest of spaces

- Highly efficient and intelligent logistics

WEINMANN Handling and storage systems timber construction

Feeding portal STORETEQ H-100

- Fully automatic feeding of the FRAMETEQ

- Efficient use of resources

- Pre-storage and feeding of standard studs

WEINMANN Handling and storage systems timber construction

Linear portal STORETEQ H-300

- Fully automatic feeding of the BEAMTEQ with beams up to 6 m

- Enables increased cutting performance

- Up to six storage positions for beam packages

WEINMANN Handling and storage systems timber construction

Feeding portal STORETEQ H-700

- Fully automatic feeding of the BEAMTEQ with beams up to 13.7 m

- Enables increased cutting performance

- Individually configurable storage positions for wood stacks

WEINMANN Assembly Tables

Self Assembly Table BUILDTEQ A-100

- Attractive entry-level solution thanks to self-assembly

- Can also be expanded on a modular basis in combination with a multifunction bridge

- Can be used universally for all elements

WEINMANN Assembly Tables

Carpentry Table BUILDTEQ A-300

- Ideal for small and medium-sized carpentry businesses

- High level of occupational safety thanks to non-slip sheathing

- Can be used flexibly for all elements

WEINMANN Assembly Tables

Butterfly turning table

- Fast and safe turning of elements

- Enables processing of both element sides

- Can be integrated and expanded in plants

WEINMANN Assembly Tables

BUILDTEQ A-400 wall table

- Ideally suited for lightweight construction methods (light timber market)

- For reliable production of open wall elements

- Individually configurable

WEINMANN Assembly Tables

Element table BUILDTEQ A-500

- Ideal for use in industrial production lines

- Versatile configuration options

- High productivity thanks to semi-automated processes

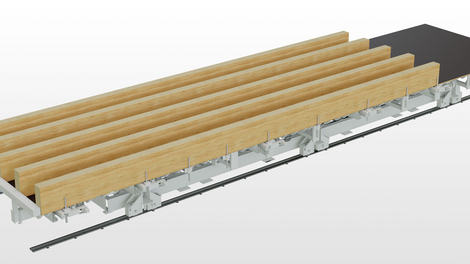

WEINMANN Assembly Tables

Roof and floor table BUILDTEQ A-600

- The specialist for roof and ceiling elements

- NC-controlled axes allow fully automatic positioning of beams

- High level of occupational safety thanks to non-slip sheathing

WEINMANN Carpentry Machines

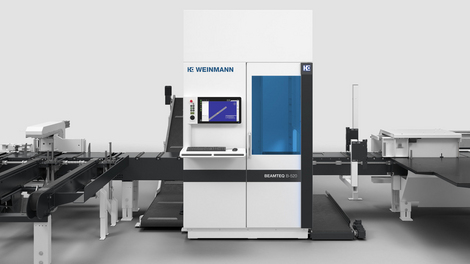

Sawing Center BEAMTEQ B-520

- Fast cutting, perfect precision: optimum output

- Up to 4500 running meters/8 h for simple cutting

- Sawing and milling with no setup times

WEINMANN Carpentry Machines

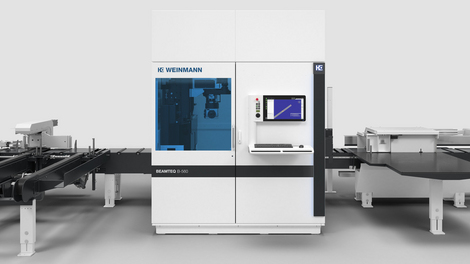

Carpentry Machine BEAMTEQ B-560

- Powerful and precise beam processing

- Up to 2200 running meters/8 h for complex beam processing

- Up to 200 mm processing depth

New

WEINMANN Carpentry Machines

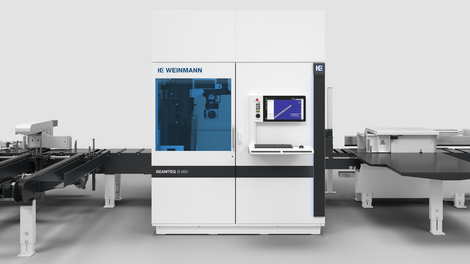

Carpentry Machine BEAMTEQ B-660

- Powerful and precise beam processing of all six sides in one throughfeed

- Up to 2200 running meters/8 h for complex beam processing

- Up to 200 mm processing depth

New

Production Management

Factory Management System

- MES product developed by HOMAG

- Combines German advanced technology and localized interface

- Modularity for personalized digital transformation

Results from 0 to 0 of 0