Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Panel dividing saws SAWTEQ S-65

Panel dividing saws SAWTEQ S-65

The complete panel dividing saw for daily production

The SAWTEQ S‑65 delivers precision from the first cut. Panels move steadily through the saw, producing uniform results on every job. The intuitive software keeps operation simple and efficient. Reliable cutting performance works together with comfortable, ergonomic handling. The design supports efficient energy use, and every essential function is integrated, creating a balanced solution for panel processing.

Product available exclusively in Bangladesh, India, Sri Lanka .

Highlights

Compact design with air-cushioned tables for easy panel movement. Side pressure device ensures precise cutting and consistent process quality. CADSaw interface provides intuitive operation with clear next-step visualization.

Robust clamps position panels accurately at the cutting line. Upper clamping elements lower horizontally and a secure grip whether cutting a single panel or multiple panels together. Built for continuous multi-shift operation.

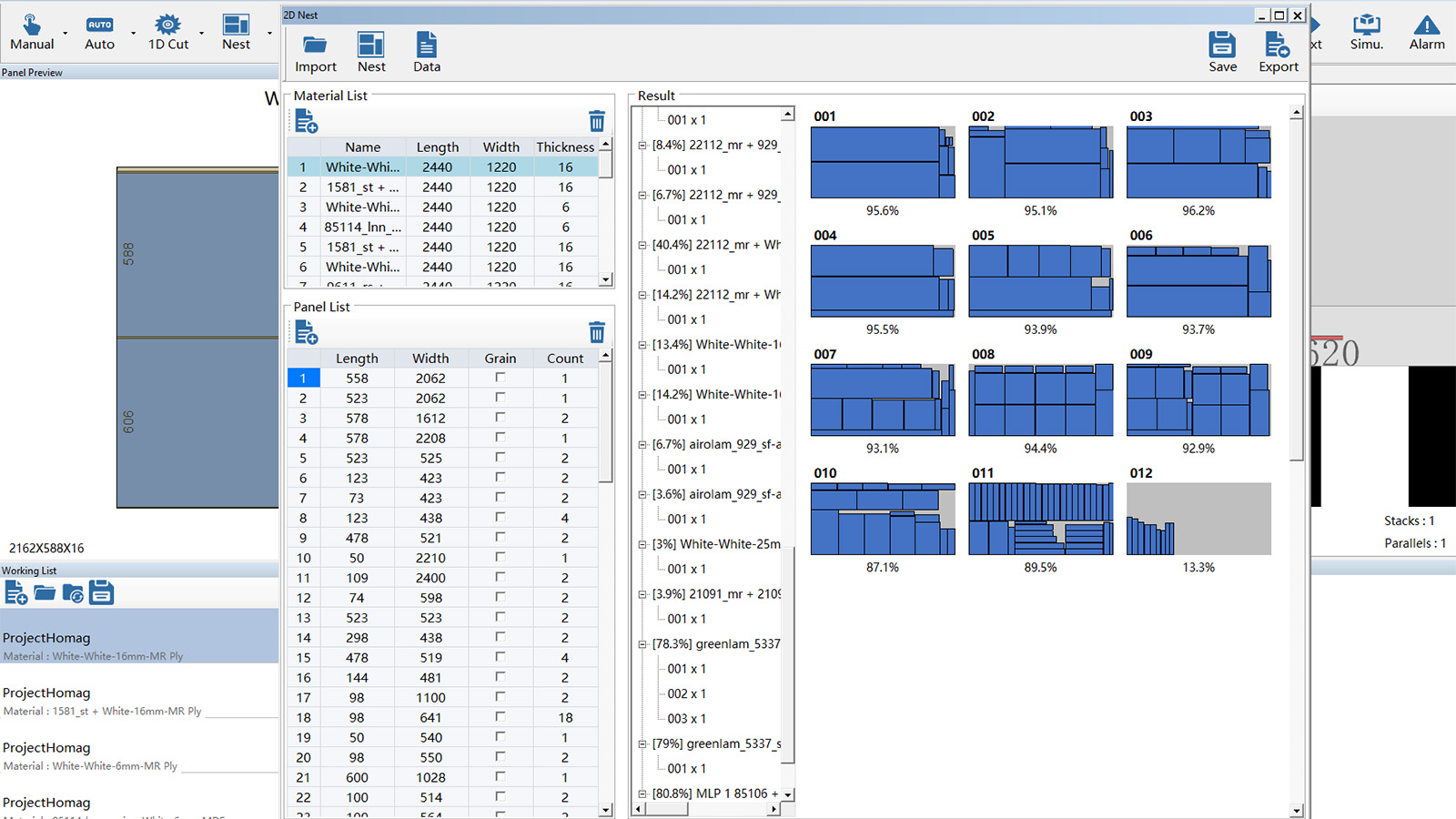

With nesting mode in CADSaw, cutting pattern optimization is built directly into the saw. Part and panel lists for each order can be entered or imported, and CADSaw promptly generates optimized layouts. This minimizes material waste and increases productivity, making it ideal for small to medium-sized orders.

Features

-

Precise Panel Cutting: Clean, accurate cuts on wood-based panels with consistent quality in every production run.

-

CADSaw – OGI Operation: Graphic guidance shows all cutting steps in order, making operation simple and reducing errors.

-

Simulation Mode: Visual preview of cutting patterns before production to prevent mistakes and save material.

-

Nesting Mode: Optimised cutting layouts directly in CADSaw to minimise waste and boost productivity.

-

Labeling with Part Graphics: Labels with text, graphics, and barcodes created in sync with cutting for easy identification.

Technical Data

| Saw blade projection [mm] | 60 |

| Cutting length [mm] | 2,900 |

| Saw carriage speed [m/min] | up to 30 |

| Program fence speed [m/min] | up to 30 (forwards 20 m/min) |

| Main saw motor [kW] | 5.5 (7.5 optional) |

| Monitor | 24" full-HD multi-touch display |

| Operating software | CADSaw |