Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

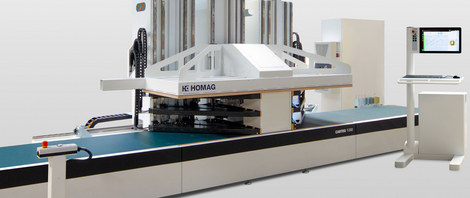

Case Clamps CABTEQ T-250

Case Clamps CABTEQ T-250

Flexible pressing technology in a continuous process with automatic clamping unit

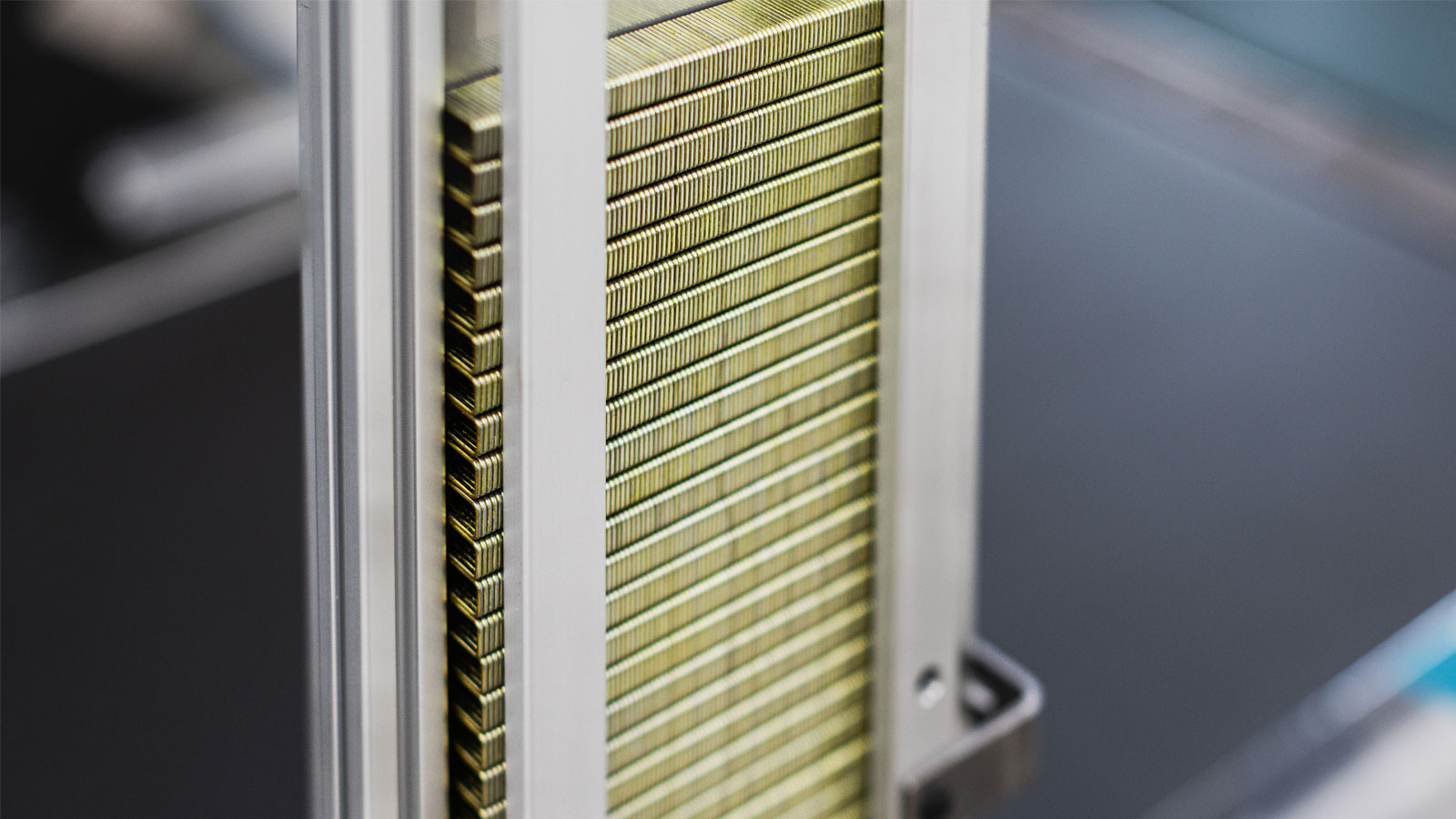

The CABTEQ T-250 automatically presses every carcase gently and to the highest quality. No matter whether sensitive surfaces, thin-walled materials or mitred furniture. The result is absolutely right-angled, rigid and cleanly pressed cabinets. The CABTEQ T-250 is also equipped with a clamping unit. This inserts the clamps perpendicular to the rear wall or at an angle between the rear wall and the side/bottom of the cabinet.

Highlights

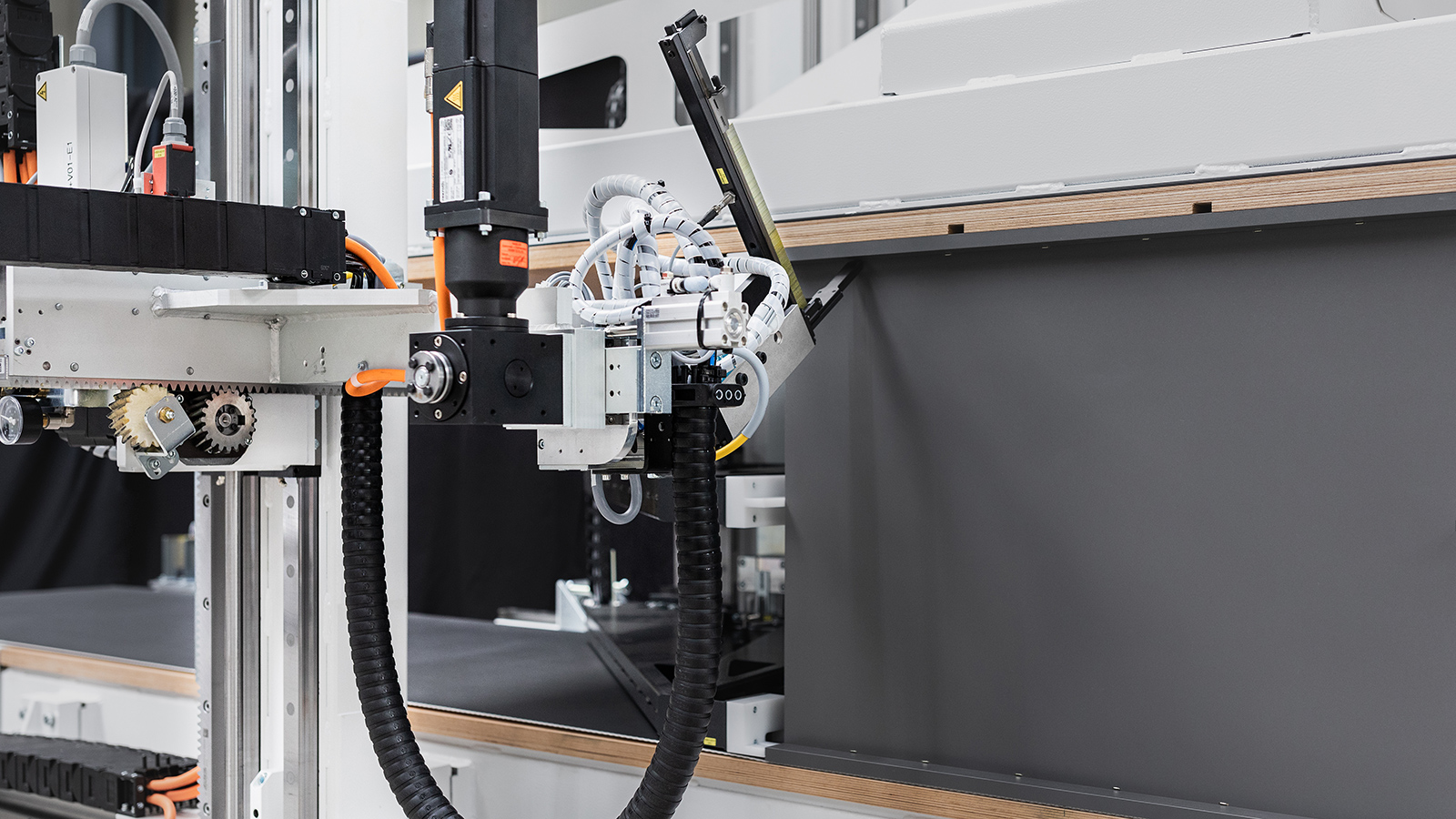

The CABTEQ T-250 features an extended base frame. An x-axis is attached to this, which acts as a guide for the "clamp unit" assembly assistance. Other units can be used, for example for fastening the rear panel with "screwdrivers".

The throughfeed press is also equipped with a clamp unit. This inserts the clamps perpendicular to the back panel or at an angle between the back panel and the side/bottom of the enclosure and is the most commonly installed option for fastening the back panels. State-of-the-art 4-axis servomotor technology is used here.

Images

Features

-

Less manpower required thanks to automated back panel fastening of the stapling unit.

-

Reproducible quality thanks to automated back panel fastening of the clamping unit.

-

Precisely adjustable pressing force allows pressing of carcasses with sensitive surfaces, thin-walled or small carcasses.

-

The main dimensions of length and height are scanned by sensors when the carcase is fed in and enable automatic positioning of the top pressure and the side pressure elements.

-

Electrical instead of pneumatic weight compensation of the upper pressure enables energy savings of up to 50 percent.

-

Pressing is centered on the zero line on the operator side. This means that the body is completely accessible to the operator.

-

Time efficiency thanks to automatic reloading of the clamps in the magazine, which can hold up to 10,000 clamps, while the furniture is being processed.

Technical Data

| Carcass dimensions |

|

| Length in the pressing room [mm] | 250 - 2,500 |

| Depth in the pressing room [mm] | 120 - 800 |

| Height in the pressing room [mm] | 220 - 1,320 |

| Pressure |

|

| vertikal [kN] | max. 30 |

| horizontal [kN] | max. 15 |

| Feed speed Transports [m/min] | 12 - 40 |

| Working height [mm] | 500 |

| Weight [t] | 6.0 |

| Operating pressure [bar] | 6 |

| Transport interface | yes |

| Control | powerTouch |

(Previous product name: Electric throughfeed case clamp MDE 160)

Software

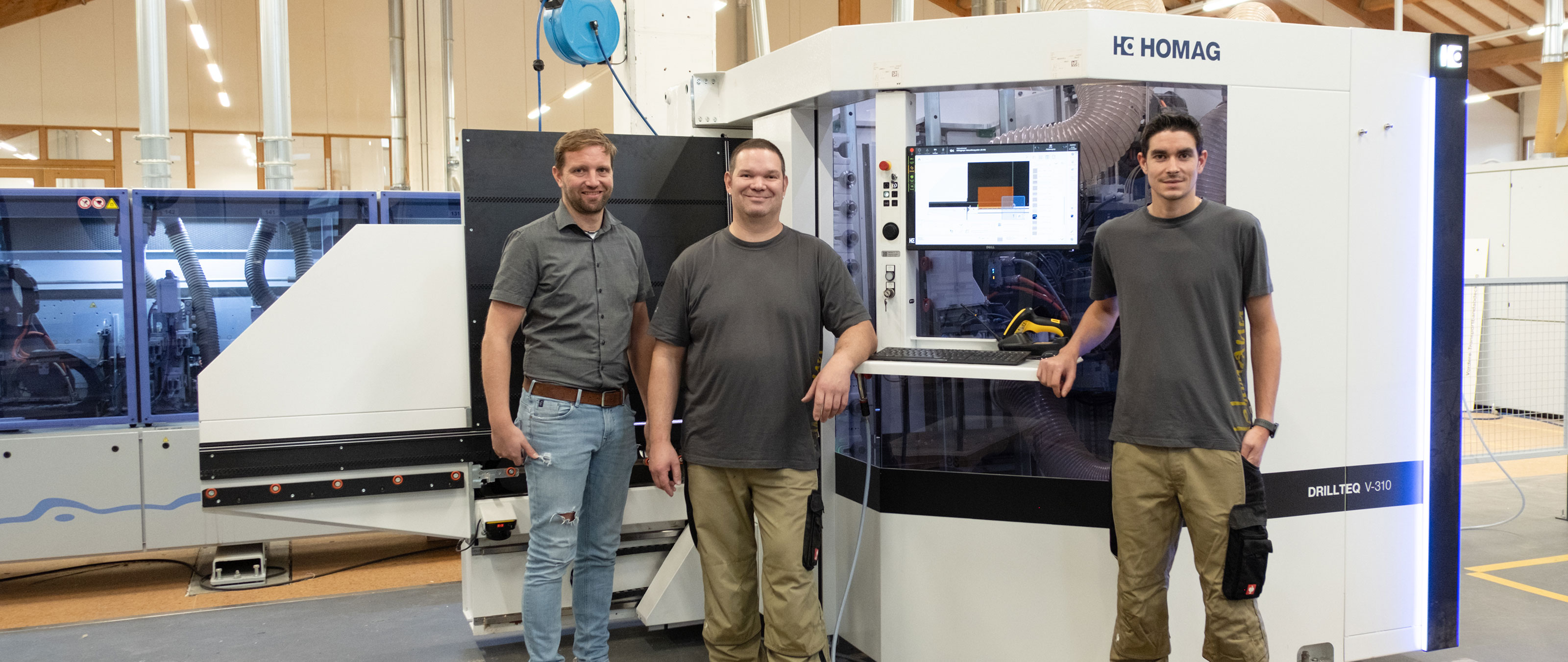

Here's how your colleagues produce

Brochures

Product Comparison

Case clamps