Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

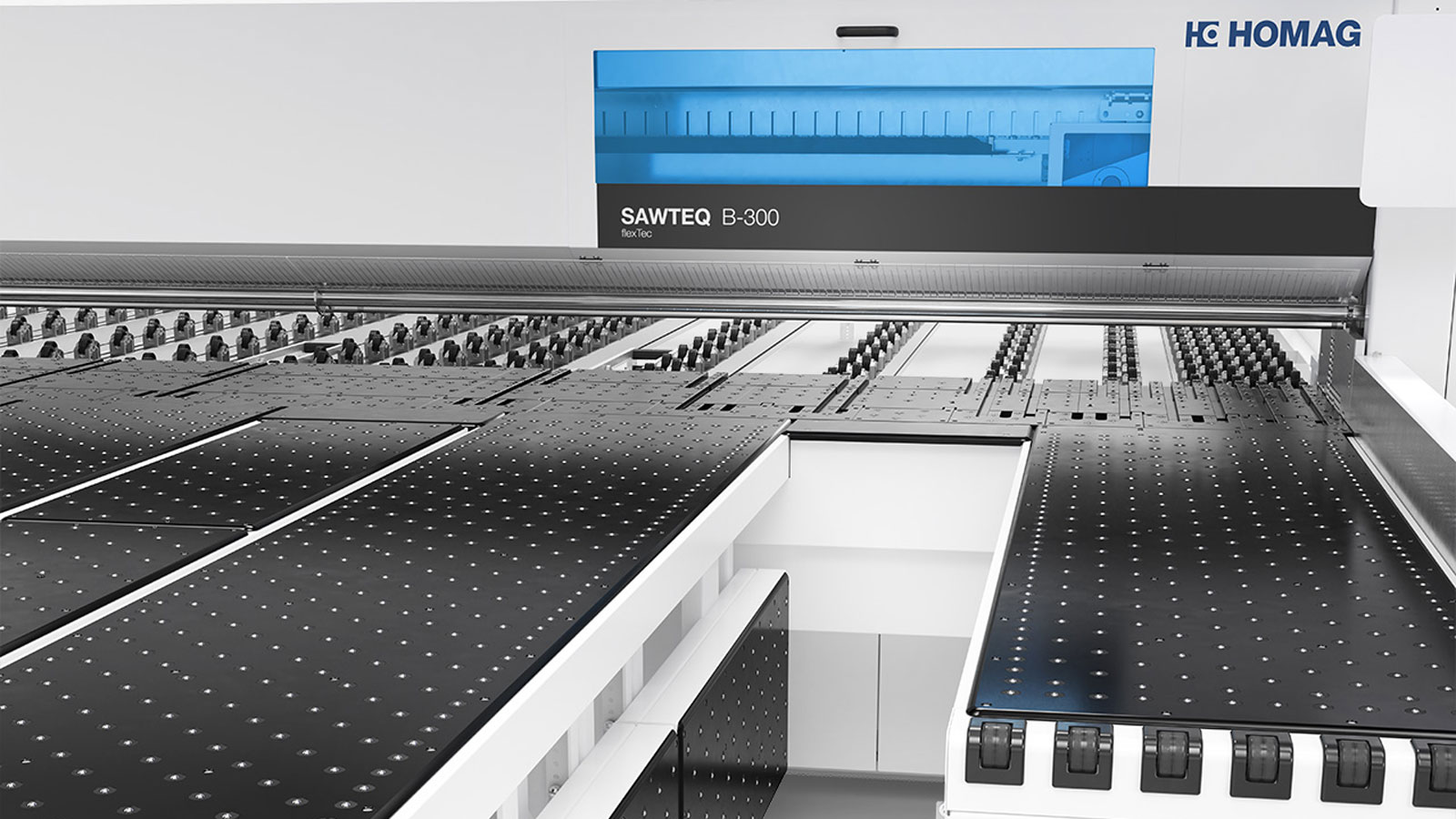

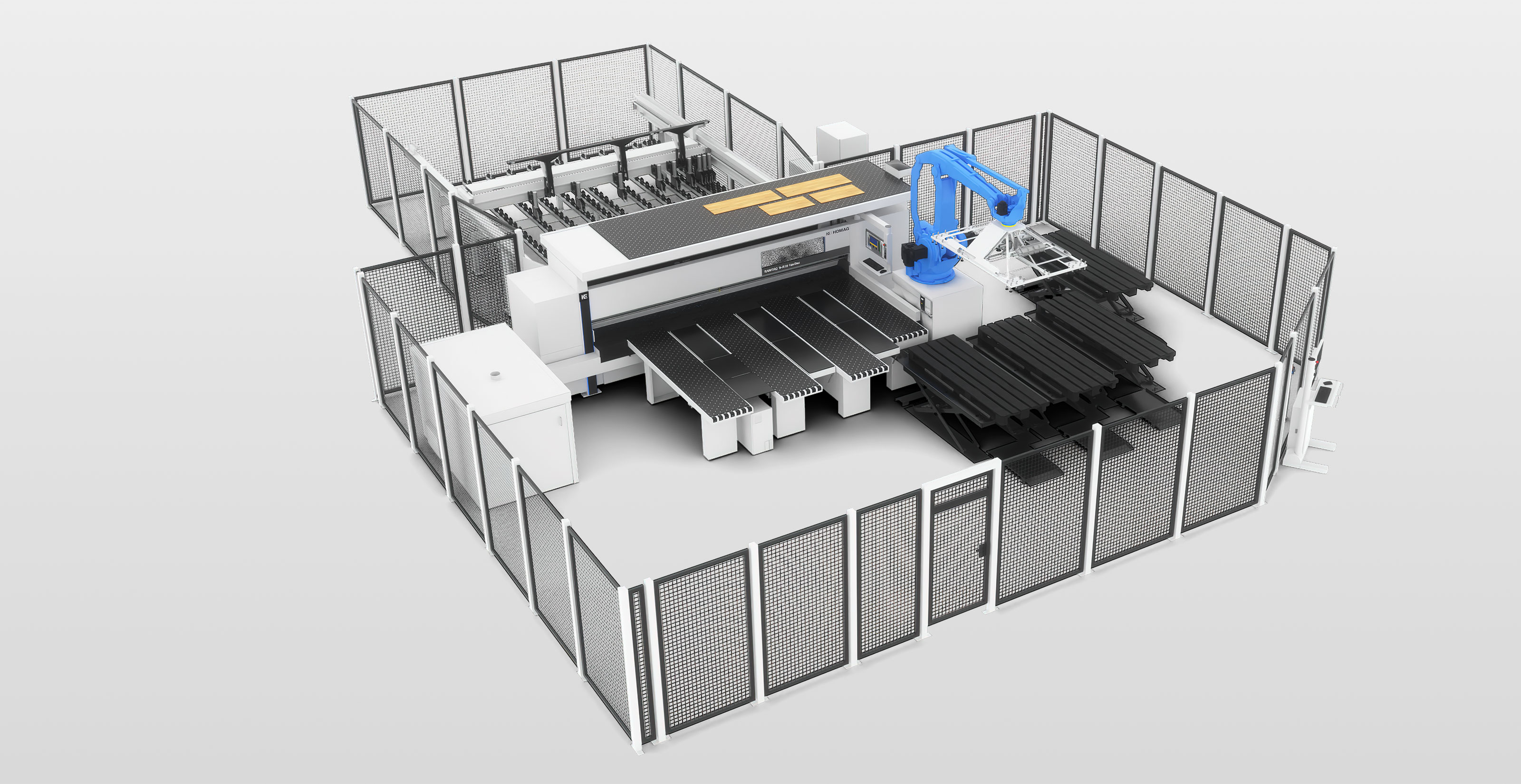

Panel dividing saws SAWTEQ S-300 | S-310 flexTec

Panel dividing saws SAWTEQ S-300 | S-310 flexTec

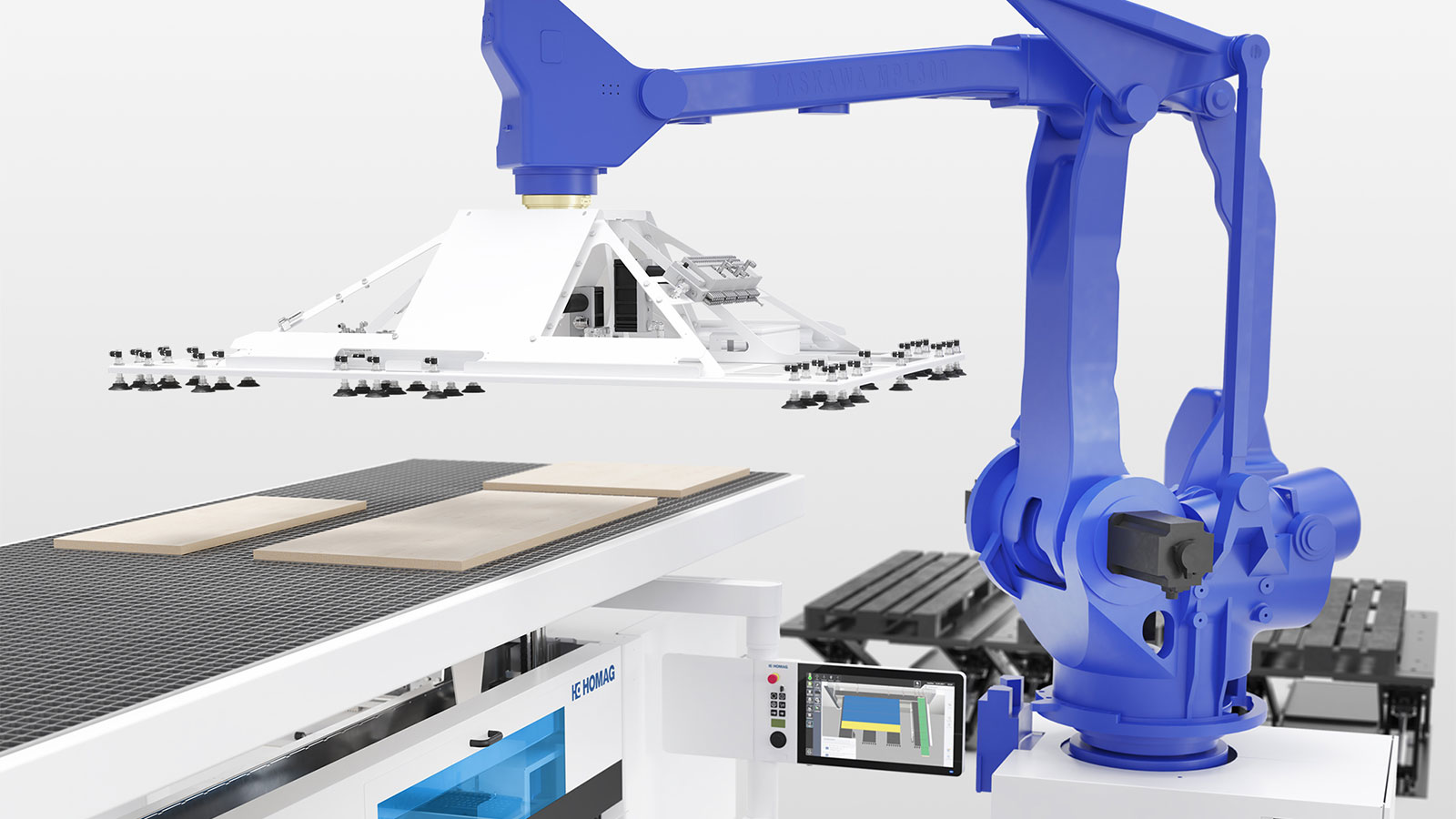

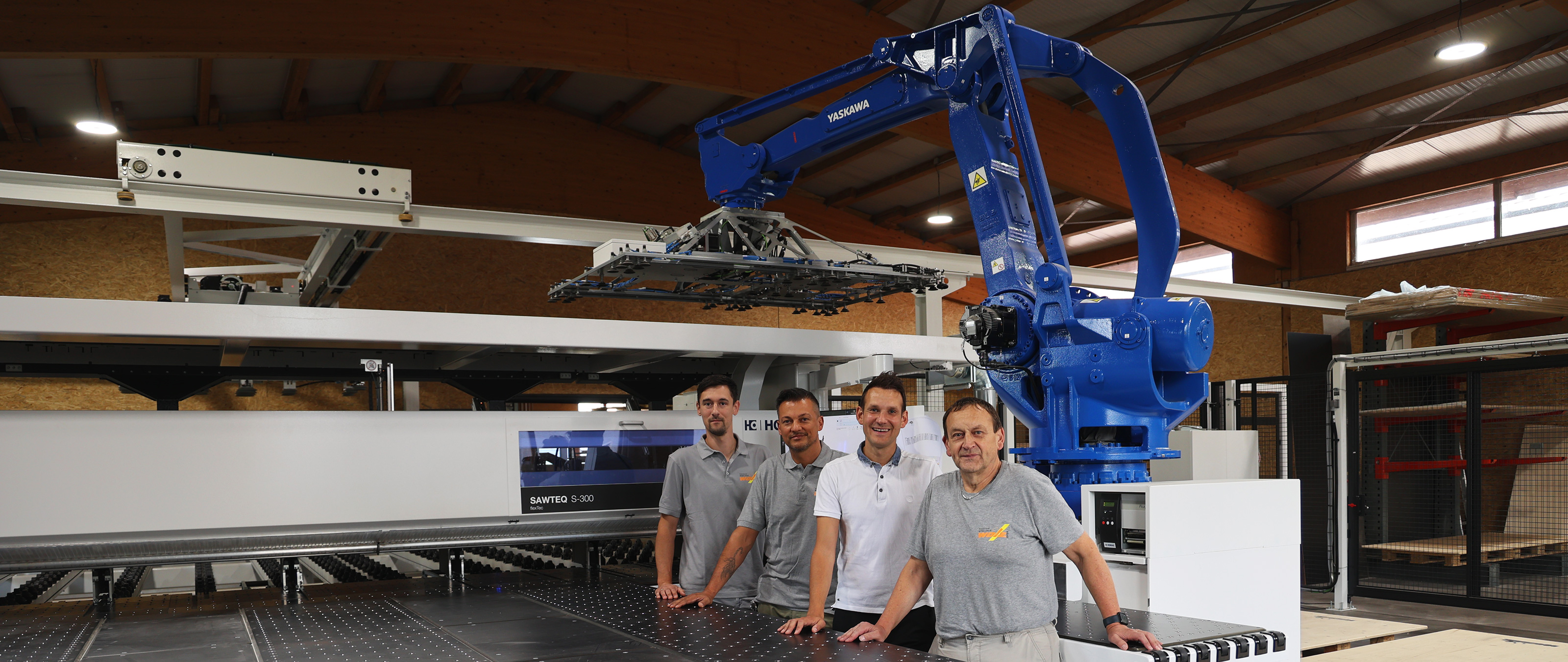

Robot performance and operating

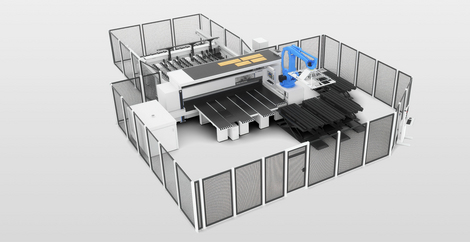

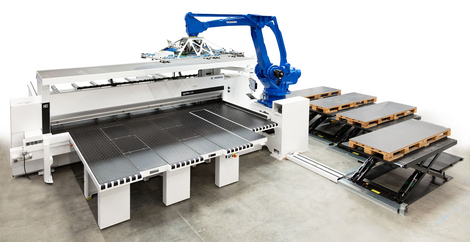

The SAWTEQ S-300 | S-310 flexTec is equipped with an integrated robot and are technically capable of fully automated batch size 1 production over longer distances. Alternatively, the saw can be operated manually as usual – totally flexibly and as needed: for cutting books, for example.

Images

Features

-

Robot with suction traverse – At the heart of these saws is a tried-and tested industrial robot with a specially developed suction traverse. The robot is responsible for all the handling of the panels, strips and parts. This is fully automatic, highly flexible, error-free and efficient.

-

Parts buffer

-

Fully automatic labeling

-

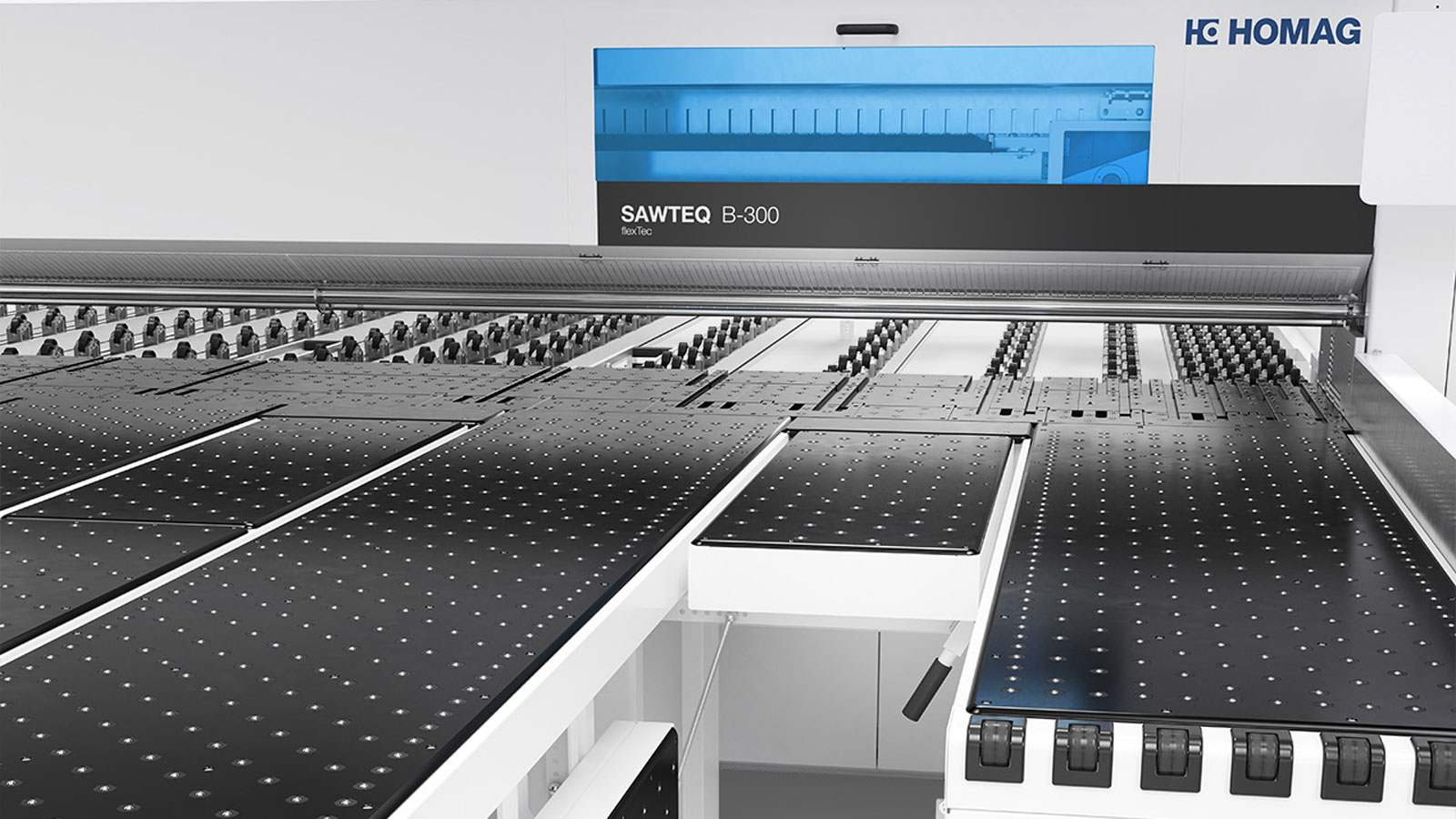

Fold-down air cushion tables – The gaps between the air cushion tables are each equipped with two fold-down tables

-

Automatic outfeed fence – Pushes panel remnants from the rear machine table to the front

-

Patented: central side pressure device

Technical Data

| Saw blade projection [mm] | 80 (95 as option) |

| Cutting length [mm] | 3,800 / 4,300 |

| Saw carriage speed [m/min] | up to 150 (170 as option) |

| Program fence speed [m/min] | up to 90 |

| Main saw motor [kW] | 50 Hz: 11 (18 or 24 as option) 60 Hz: 11 (21 or 28 as option) |

| Monitor | 24" full-HD multi-touch display |

| Operating software | CADmatic 5 |

(Previous product name: SAWTEQ B-300 flexTec)

Here's how your colleagues produce

Brochures

Product Comparison

flexTec saws for cutting