Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

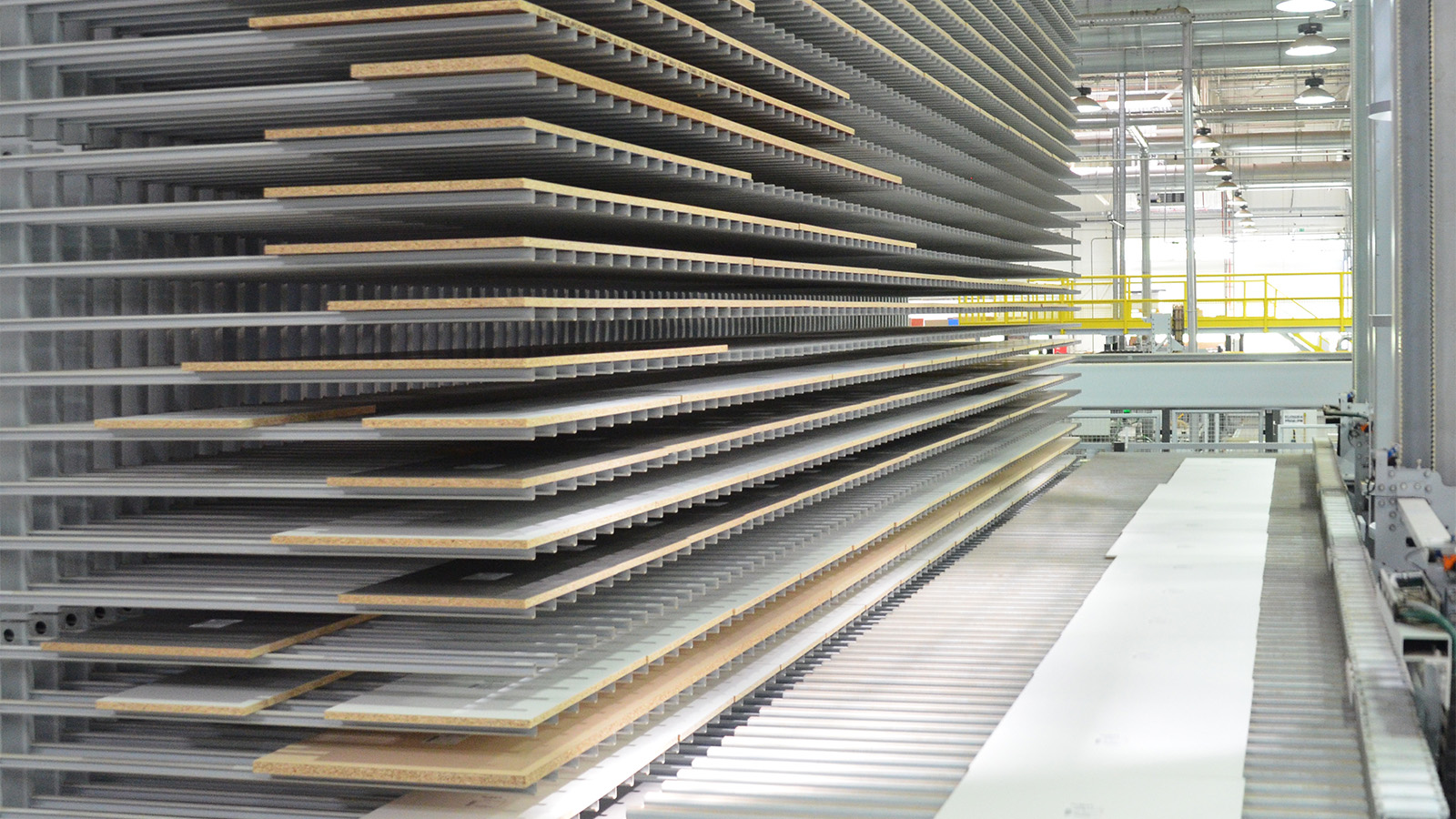

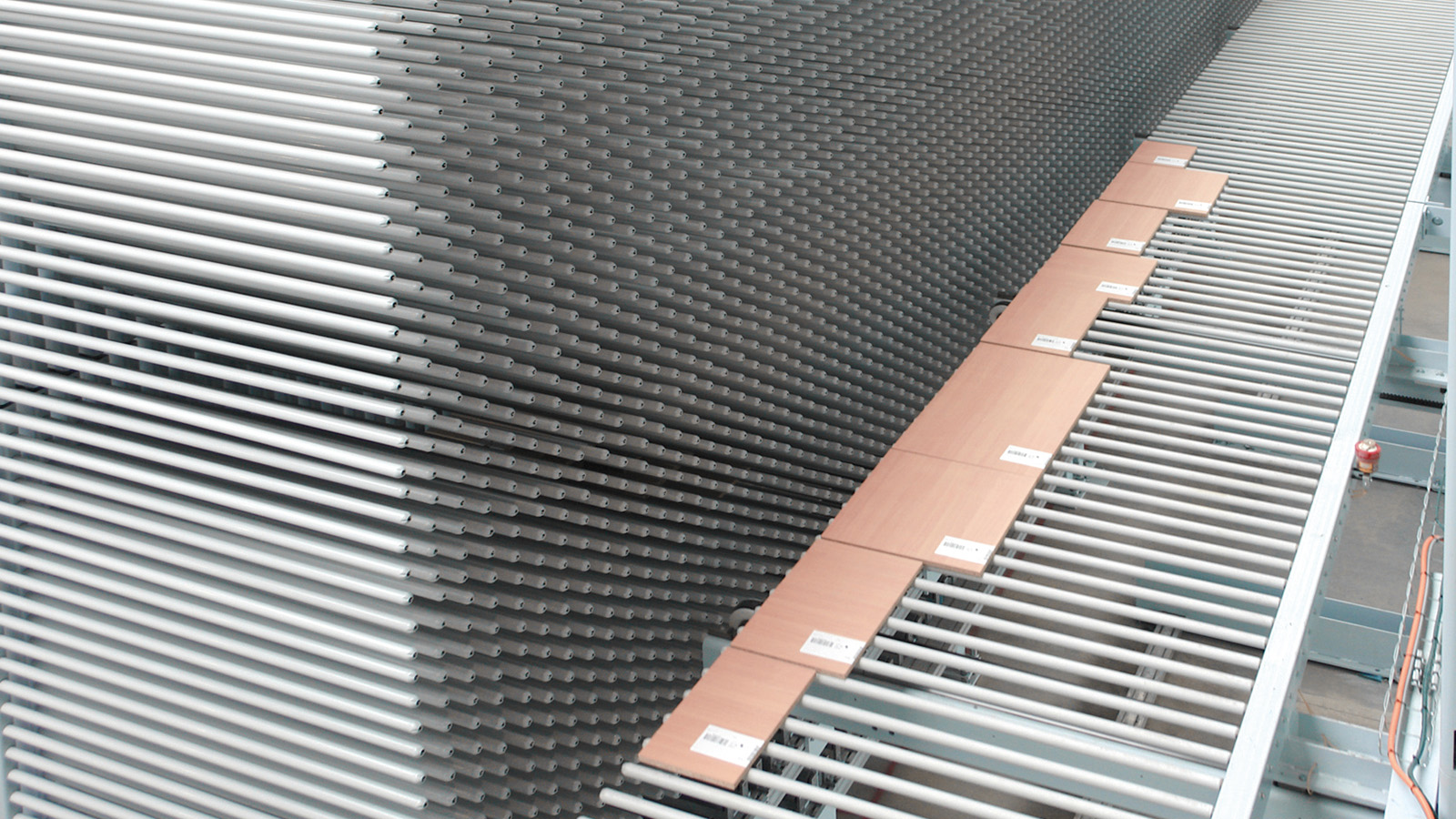

Sorting Buffering and Collating Systems Buffering system

Sorting Buffering and Collating Systems Buffering system

Buffering for the adjustment of the material flow

The buffering system serves to decouple the power peaks in cutting and the adjustment of the material stream to the edge banding. The result: Maximum capacity utilization for the whole production process.

Images

Features

-

Material flow is equalized due to different buffering zones and in- and outfeed transports

-

Storing and removal of components in layers or rows

-

Optimum preparation of the following machine due to manipulation of the material order

-

Optimization of the material flow due to sorting possibilities in layers

-

Optimum use of space thanks to the ideal positioning of the material

-

Direct access to each shelf - removal lists can flexibly be changed until the last panel

Here's how your colleagues produce

Brochures