Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

WEINMANN Timber Frame Production Lines Roof and ceiling production line

WEINMANN Timber Frame Production Lines Roof and ceiling production line

Manufacture all roof and ceiling elements with a single system

The roof and ceiling production line can be used to manufacture roof and ceiling elements, including those with complex beam constructions. The CNC-controlled machines enable a flexible and efficient work flow. Your personal contact optimizes the processes based on your requirements, taking into account material manipulation, logistics and material flows, as well as optimum interaction between all the components.

Highlights

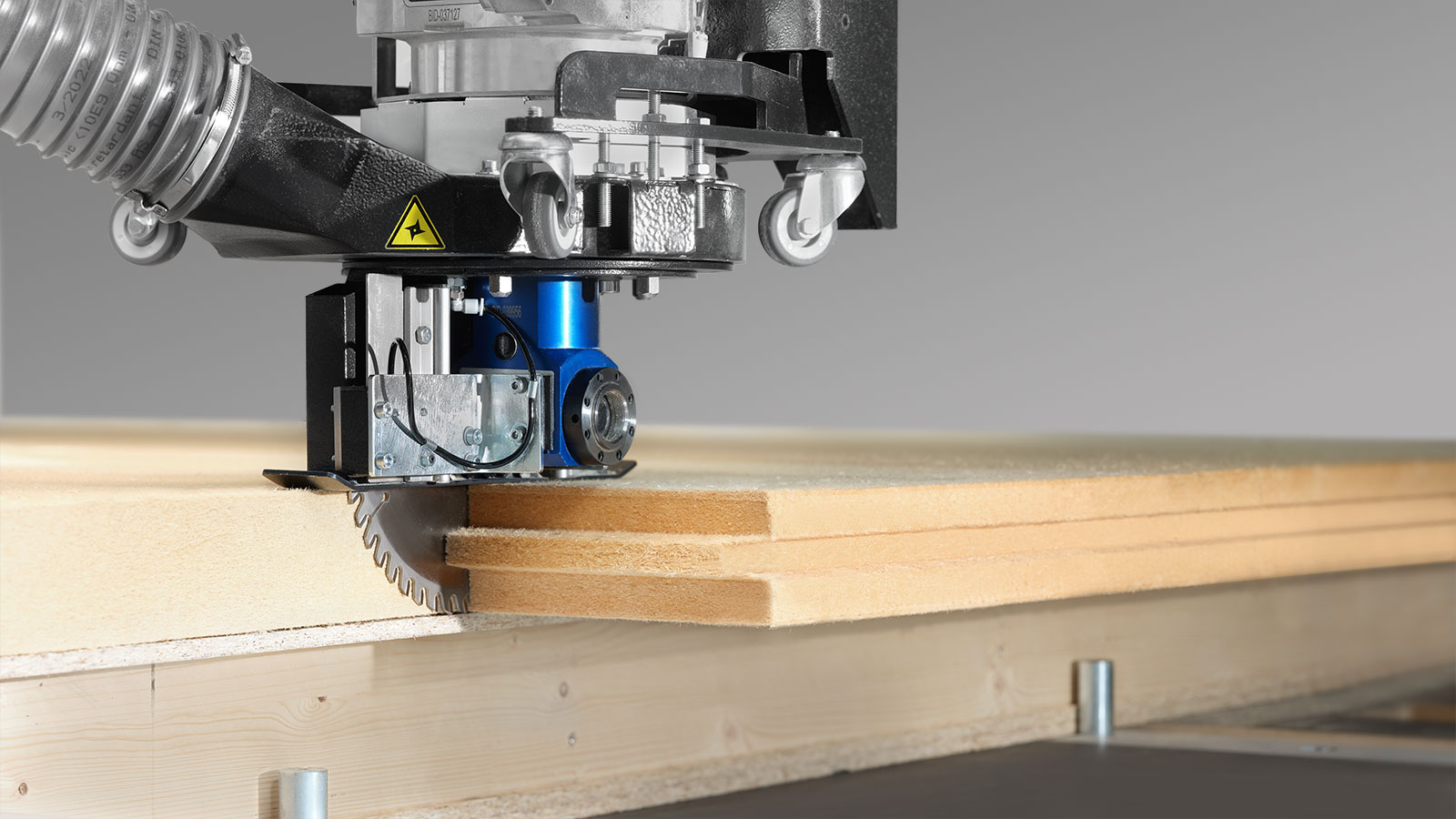

High flexibility and versatility: Fastening and processing of many different materials such as OSB, Fermacell, soft fiber or wood fiber.

Efficient production process thanks to high production speed and intelligent processes from cutting to loading of elements.

Production systems can be highly customized so that the solution is perfectly tailored to your needs.

Features

-

No measurement is required as the NC-controlled insertion tables are equipped with automatically adjustable bolts that determine the position of the rafters and beam layer

-

The multifunction bridge secures and processes an extremely wide range of materials: OSB, Fermacell, soft fiber, wood fiber

-

Transport of the roof and ceiling elements into storage using special storage and handling systems

-

Integrated data flow with standardized software ensures optimum machine availability and productivity

-

Intuitive operation including numerous help functions and wizard with the innovative powerTouch control system

-

WALLTEQ M-380 multifunction bridge with LatTec option:

Fully automatic positioning and attachment of battens and shuttering on a beam or rafter framework -

Both longitudinal and lateral travel and transport paths are possible, offering a wide range of possibilities when organizing work sequences

-

Handling systems for careful and ergonomic movement of materials: transportation, assembly, removal, intermediate storage, loading

Technical Data

| Element thickness [mm] | 75 - 500 |

| Element width [m] | 0.4 - 2.6 Optionally more possible |

| Element length [m] | 6 / 8 / 10 / 12 m |

| Element weight max. [kg] | 3.500 |

| System output | customer-specific |

All technical data are without engagement!

Here's how your colleagues produce

Brochures