Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

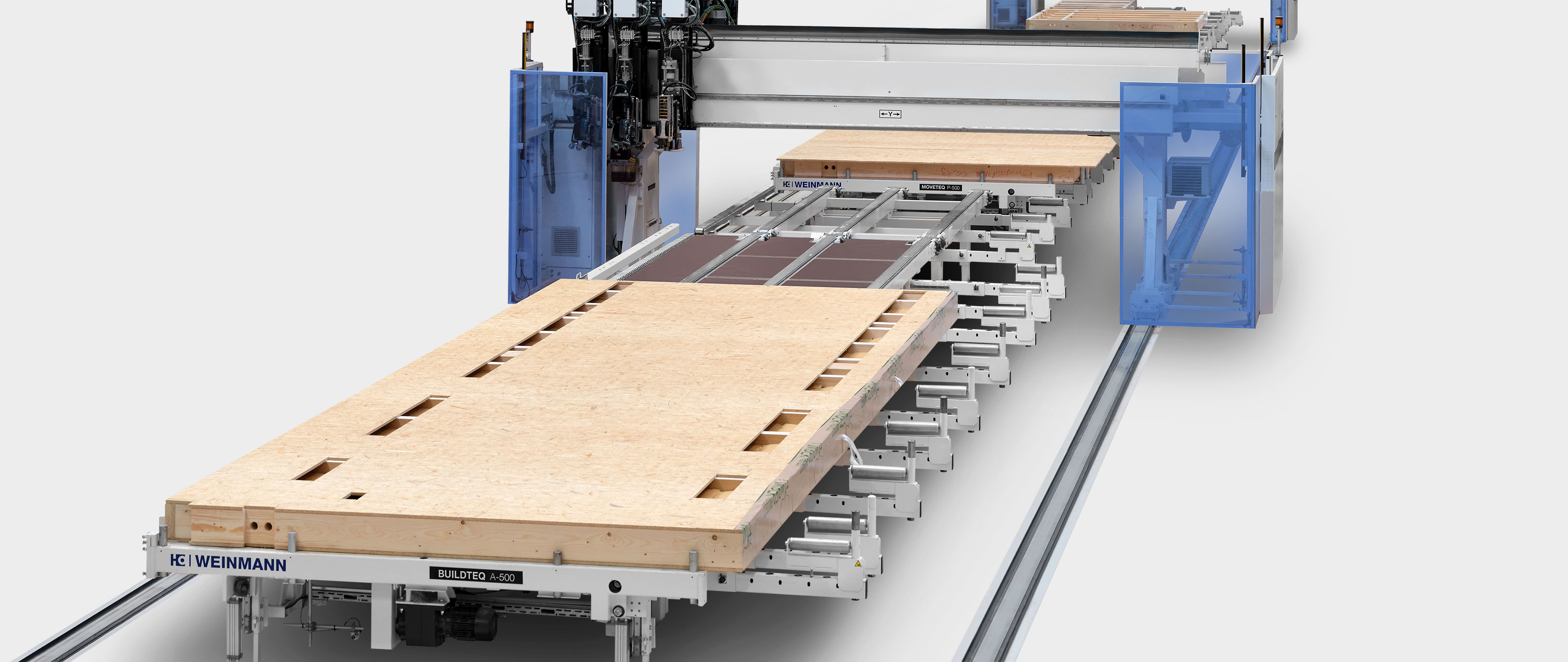

WEINMANN Assembly Tables BUILDTEQ A-500

WEINMANN Assembly Tables BUILDTEQ A-500

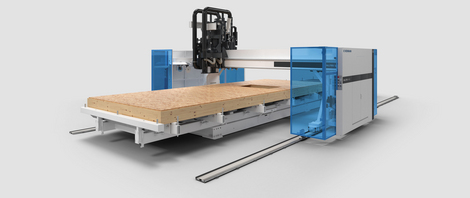

Multifunctional solution for production lines

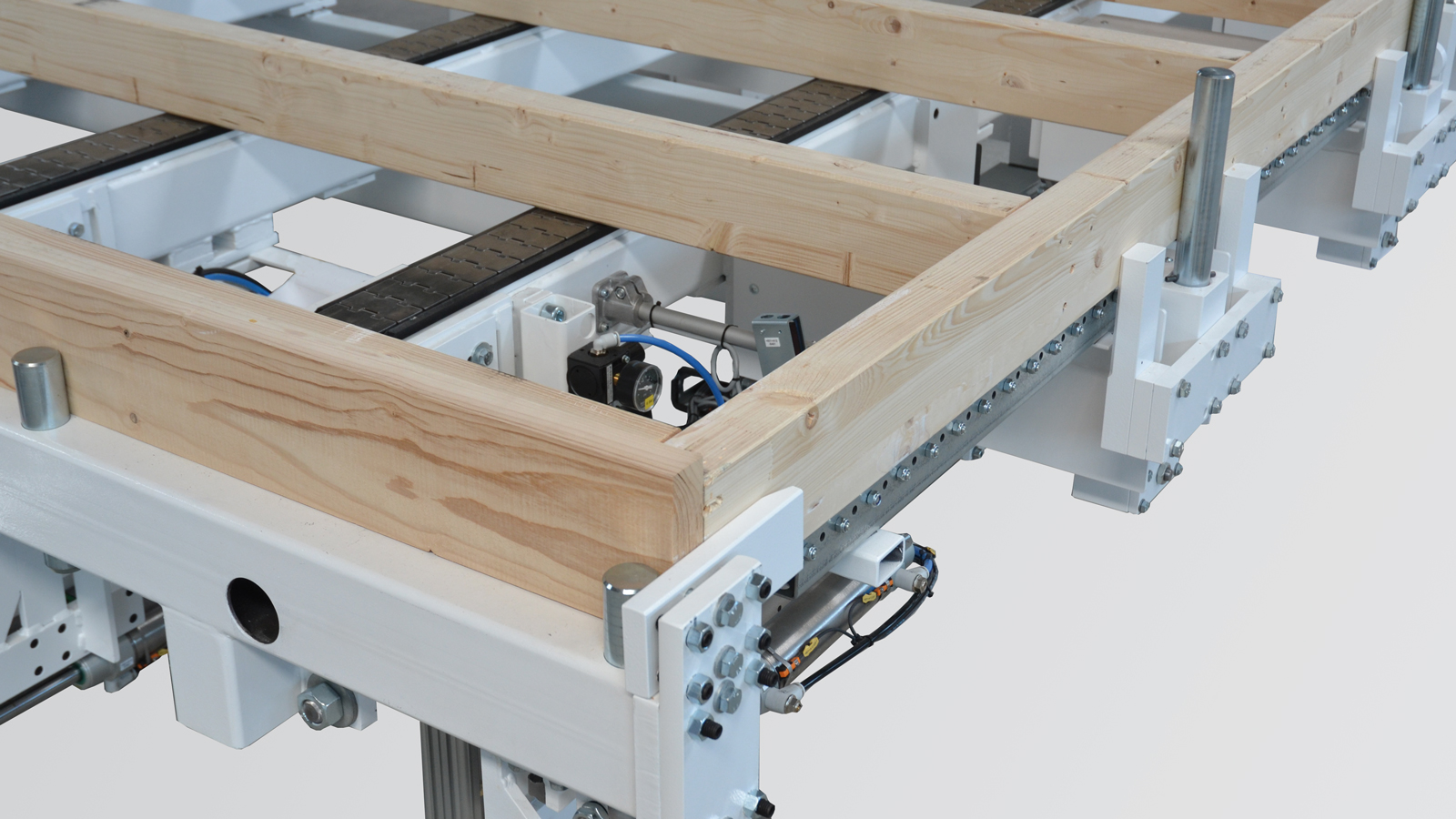

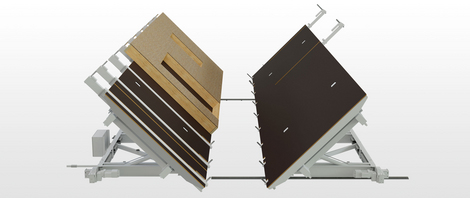

The BUILDTEQ A-500 element tables are truly versatile components in the production line and take over tasks such as turning elements, aligning elements at the correct angle to ensure safe sheathing and processing, transporting elements, and tilting elements for storage.

Highlights

Tailored to customer requirements: The versatile configuration options enable the table to be adapted to suit the customer's needs.

Easy handling of elements: Suitable transport and turning systems form the foundation of smooth production.

For any production line: The industrial table can be easily integrated into any production line thanks to coordinated interfaces.

Images

Features

-

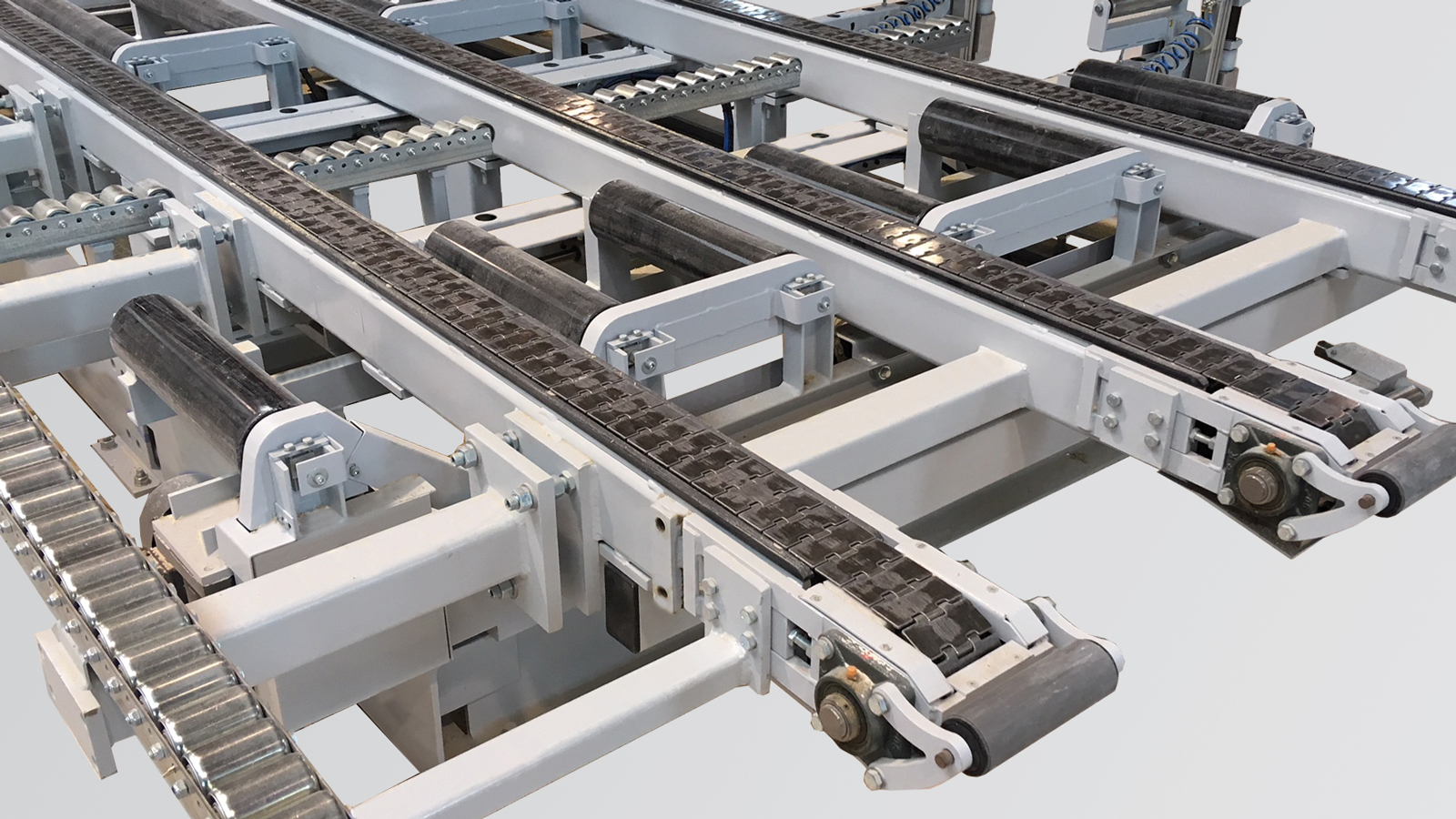

Wide range of applications, as both longitudinal and transverse transport are possible

-

Two transport variants available:

Manual element transport via quadruple track roller

Motorized element transport with hinged slat conveyors -

NC-controlled beam aligner for high level of processing quality

-

Improved comfort thanks to an ergonomic processing height

-

Can be used in transport logistics for elements: The wall table moves to different production lines in the hall and transfers the elements or retrieves them from the relevant production line.

-

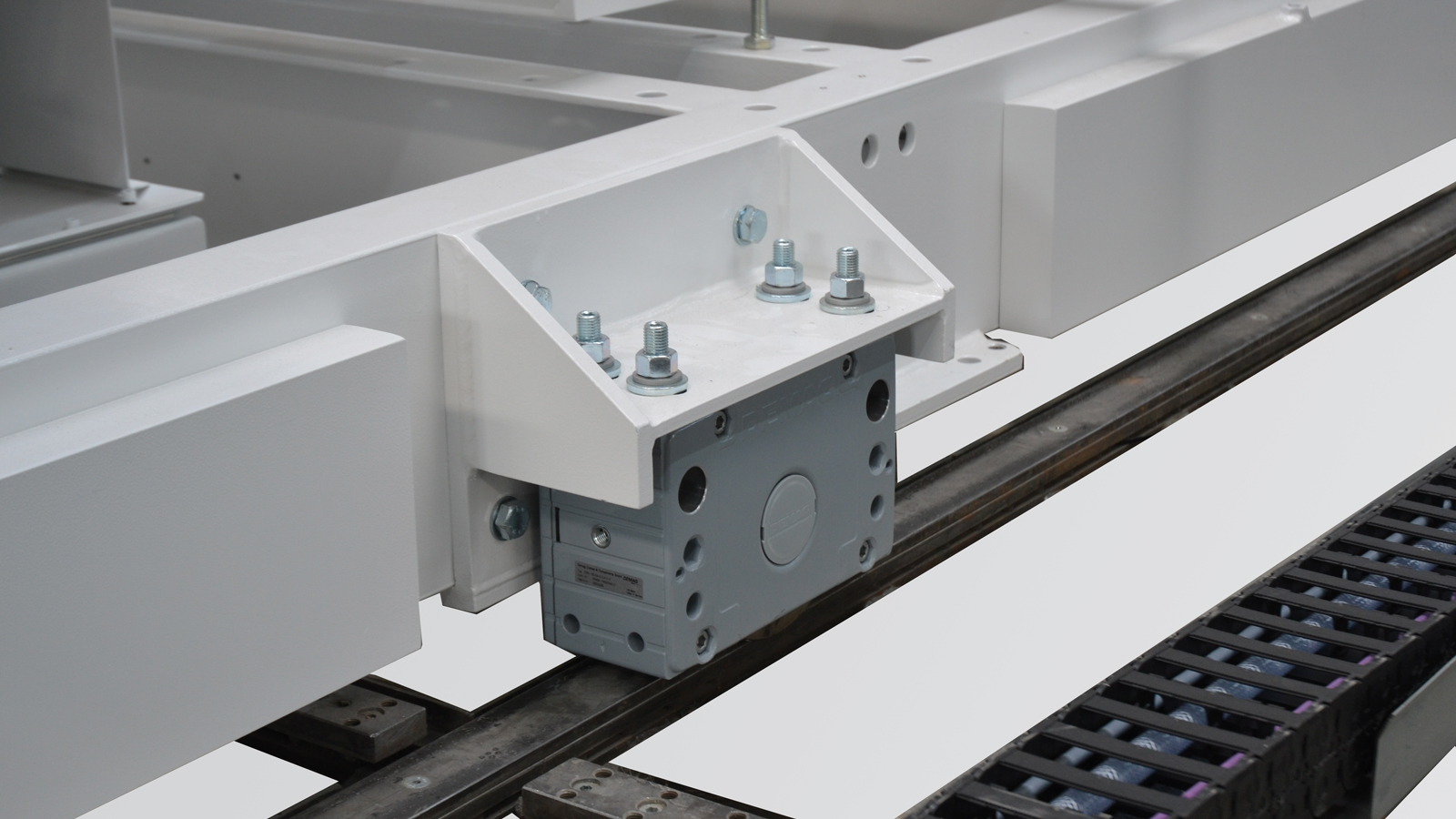

Automated processes are stored in the controller: all functions, such as moving the table or opening the voltage, are executed automatically

Technical Data

| Working height [mm] | 730 |

| Clamping range [m] | 1.2 - 3.2 (Option: until 3.8) |

| Element length min [m] | 1.5 |

| Element length max [m] | 12 (Over length is possible on request) |

| Element weight [t] | 3.5 (Option: until 6) |

All technical data are without engagement!

(Previous product name: Wall Table WTW)

Here's how your colleagues produce

Brochures