Machine Finder

Filter

0 results

No matching products found

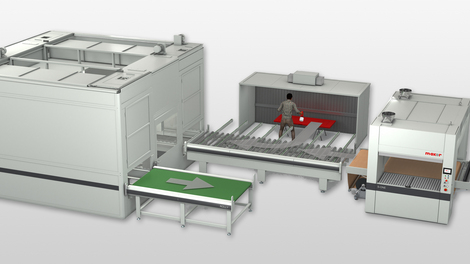

Spray Machines

Pressurized Spray Machine - Makor Start One C

- Entry into Flatline Automated Spray Finishing.

- Compact design. 3+1 fluid circuits.

- Pressurized spray cabin.

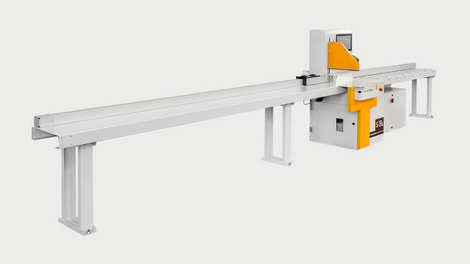

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperPush 200

- Maximum cutting accuracy of up to 0.01mm

- Automatic onboard defect and cut-list optimization

- Enclosed cutting center provides absolute operator safety

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperPush 250

- Pusher fed driven saw

- Lateral chain infeed

- Accurate to 0.01mm

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperPush 150

- Entry level optimized cutting.

- Total operator safety.

- Robust pusher for large work pieces.

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperCut 100

- High speed optimizing and defecting.

- Dual operator loading area.

- Accurate and square cutting.

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperCut 300

- High speed optimizing saw designed for rough lumber.

- Automatic width detection.

- NC controlled drive system.

Automatic Cross-Cut Saws

Cross Cut Saw Salvador SuperCut 500

- Lightning fast cutting.

- Capable of handling roughest of lumber.

- Servo controlled cutting center.

CNC Drilling and Dowel inserting Machines

Boring Machines Ironwood BR Series

- Versatile Drilling.

- Enhanced Safety Features.

- Easy Tool Change.

Automatic Cross-Cut Saws

Up-cut Saws Ironwood CUT Series

- Advanced Safety Features.

- Hands-Free Operation.

- Accurate Crosscutting.

Jointer & Planer

Dual Surface Planers Ironwood DSP Series

- Advanced Safety Features.

- Smooth & Reliable Feed.

- Optimal High-Speed Performance.

Jointer & Planer

Jointers Ironwood JT Series

- Quick Set Up.

- Enhanced Safety Features.

- Low-Maintenance Operation.

Spray Machines

Pressurized Spray Machine Makor Next Two

- Twin Arm - Automated Spray Finishing.

- New Generation, Medium level production.

- Pressurized spray cabin.

Jointer & Planer

Planers Ironwood P Series

- Smooth & Quiet Operation

- Easy To Use Controls

- Helical Cutting Power

Automatic Cross-Cut Saws

Straight Line Rip Saws Ironwood SLR Series

- Ultimate Glue Line Accuracy

- Variable Speed Drives

- Advanced Anti-Kickback Safety Features

Profile & Spindle Moulders

Shapers Ironwood S Series

- Plug & Play Power feeders.

- Safe Operations.

- Versatile Cutting Operations.

Sanding Machines

Wide Belt Sanders Ironwood S Series

- Ease Of Use.

- Vibration-Free Calibration Sanding.

- Strength & Stability.

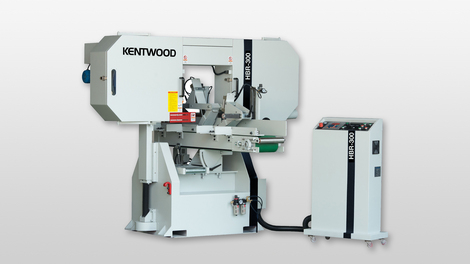

Moulding & Profiling

Moulder Kentwood M-100

- Small footprint perfect for any shop.

- Cast iron frame for reduced vibration and increased quality.

- Advanced safety features.

Moulding & Profiling

Moulder Kentwood M-200

- Available with manual or CNC set-up.

- Independently driven spindles.

- 4-8 spindle configurations.

Moulding & Profiling

Moulder Kentwood M-300

- 24” touchscreen equipped with ProLink digital software.

- Profile memory and CNC controlls allows for rapid set up times.

- Tool room and office interlink.

Moulding & Profiling

Moulder Kentwood M-500

- Heavy duty feed system.

- High speed single knife finishing.

- Increased horsepower.

Moulding & Profiling

Moulder Kentwood M-600

- Straight and profiled jointers

- Highspeed processing

- Automatic board sensors for speed regulation

Moulding & Profiling

Moulder Kentwood M-2000

- 6,000-12,000 RPM HSK 85W Spindles.

- Rapid Set Up Hoods.

- 24” ProLink APC.

Moulding & Profiling

Moulder Kentwood HBR Series

- Cast iron wheels reduce vibration.

- Hydraulic blade tensioning.

- Automatic blade height and table tilt adjustment.

Sanding Machines

Sander Alpha-Brush Extreme CCBBDD

- 6 head brush sanders, working width 1350mm.

- 2 x Cross – 2 x Barrel – 2 x Disk configuration. Dual or Single Grit sanding strips.

- For Medium to Large production level process

Sanding Machines

Sander Alpha-Brush Extreme CBD

- 3 head brush sanders, working width 1350mm.

- Cross – Barrel – Disk configuration. Dual or Single Grit sanding strips.

- Great Entry Market machine for small to medium wood shops.

Spray Machines

Pressurized Spray Machine Makor Excellent CM80

- Two Arm (independently driven) - Automated Reciprocating Sprayer.

- New Generation, High Quality Application, High Productivity.

- 3 Zone Pressurized Spray Cabin.

Spray Machines

Drying Oven Makor Flexi Oven

- Variable Time - Drying and Curing System.

- Central lift system with Right and Left Tower.

- Programable drying recipes. Variable height shelving.

Spray Machines

Spraying Cartesian Robot - Makor Evolution Series

- 5 axis cartesian movement for high quality application.

- Pinnacle in automation and quality!

- Innovative 3D part scanning.

Spray Machines

Drying Oven Makor Ultradry 1&2

- UV cure technology.

- Available in 1 or 3 lamp configurations.

- Curing mono and bi-component UV paints.

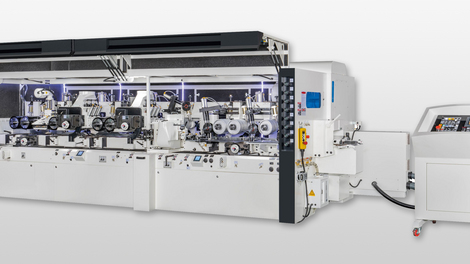

Edge Banding Machines

Automatic Contour Edegbander Vector Revolution 180

- Cartridge Glue Nozzle System

- Vacuum Table

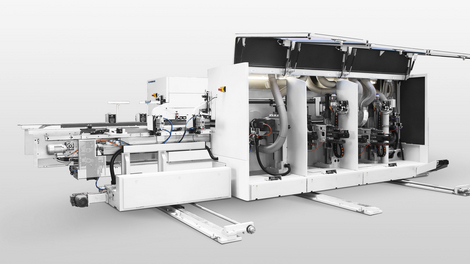

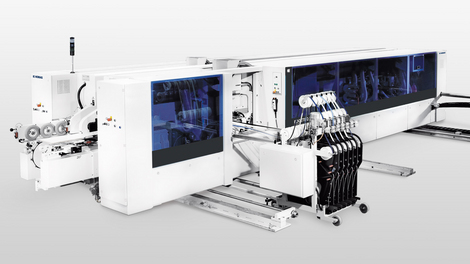

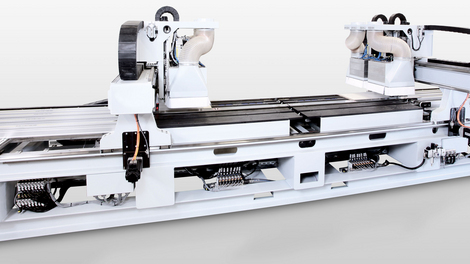

Double End Tenoners

Double-End Tenoner TENONTEQ D-500: Entry-level machines for flooring production

- Multifunctional and cost-effective

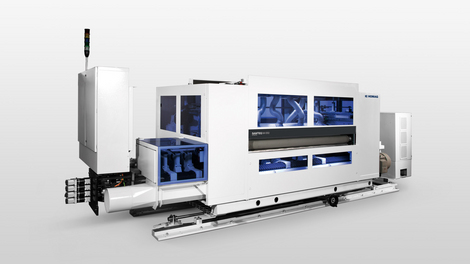

Double End Tenoners

Double-End Tenoner TENONTEQ D-600: Medium performance range for flooring production

- Compact and flexible solutions for longitudinal and crosswise profiling

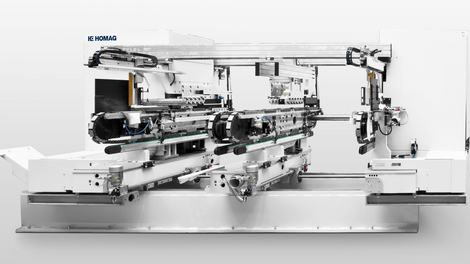

Double End Tenoners

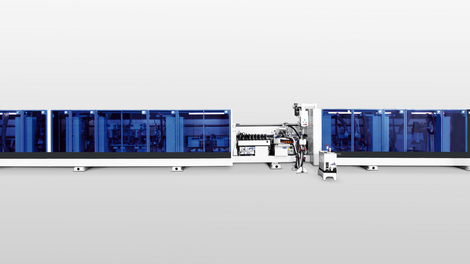

Double-End Tenoner TENONTEQ D-800: High-end solutions for flooring production

- For exacting requirements for performance and flexibility

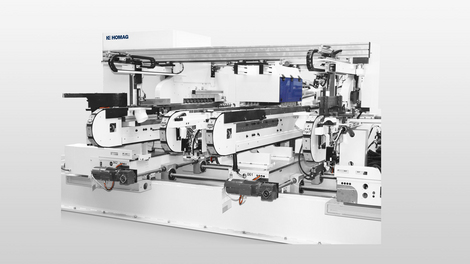

Double End Tenoners

Double-End Tenoner TENONTEQ D-500: for furniture production and interior furnishings

- A compact introductory solution for double-sided dimensioning work

Double End Tenoners

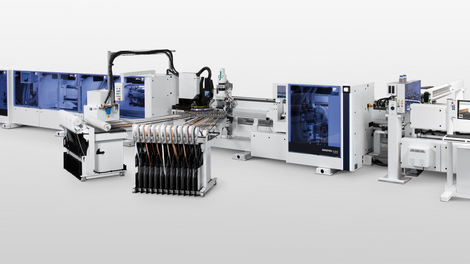

Double-End Tenoner TENONTEQ D-600: for manufacturing doors, fronts and panels

- Two throughfeeds - longitudinal and crosswise - process the four sides of your workpieces

Double End Tenoners

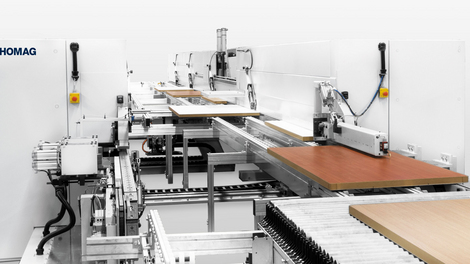

Double-End Tenoner TENONTEQ S/D-800: for furniture and component production

- Single-sided and double-sided power machines for specialized requirements

Multi Rip Saws

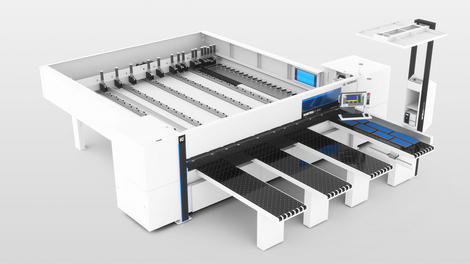

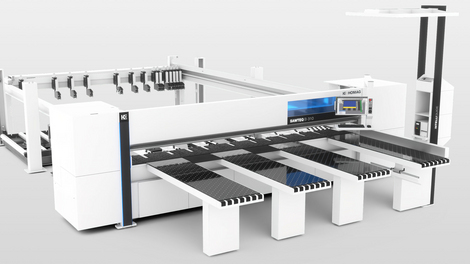

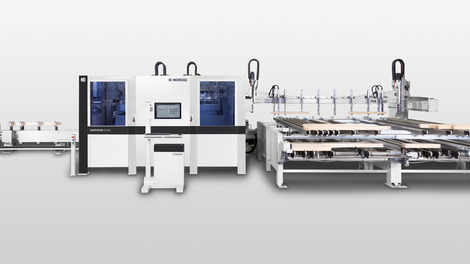

Multi rip saw SAWTEQ M-500 / 320 / 330: Longitudinal division in line with requirements

- Single-row or double-row configurations

Multi Rip Saws

Multi rip saw SAWTEQ M-500: Throughfeed sawing that saves materials

- A division technique offering material savings of up to 6%

Multi Rip Saws

Multi rip saw SAWTEQ M-500: Longitudinal division of large panel materials

- The path to increased profitability

Multi Rip Saws

Multi rip saw SAWTEQ M-500: Longitudinal division of panels into narrow formats

- Division using polygon shaft technology

Multi Rip Saws

Multi rip saw SAWTEQ M-700: Maximum precision for throughfeed cutting

- Minimal tolerance ranges for longitudinal division techniques

Multi Rip Saws

Multi rip saw SAWTEQ C-600: Flexible cross cut saws

- Throughfeed saw for industrial furniture and floor manufacturers

Multi Rip Saws

Multi rip saws SAWTEQ C-700: Flexible crosswise division for the upper performance range

- A throughfeed saw for producing furniture and flooring parts in high batch quantities

Multi Rip Saws

Multi rip saws SAWTEQ C-720: Flexible crosswise division designed especially for the furniture industry

- A throughfeed saw for cost-effective production of furniture workpieces

Edge Banding Machines

Shaped part edge banding / post-processing machines

- The flexible solution for all shaped parts

Edge Banding Machines

XES 200 PUR service station

- The all-rounder that complements your edge banding machine for easy processing of PUR glue

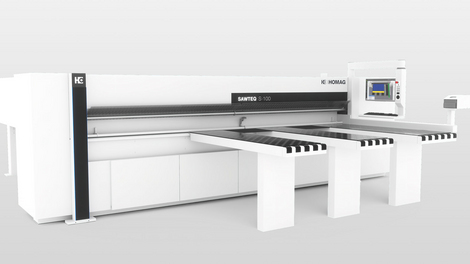

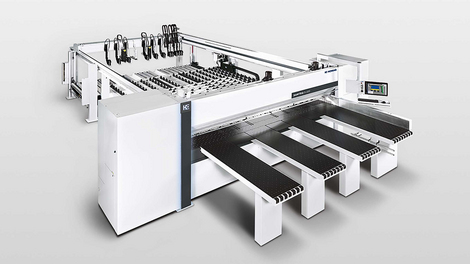

Panel dividing saws

Panel dividing saw SAWTEQ O-100 (India)

- Simply better, right from the start. For a more precise and efficient cutting process.

Panel dividing saws

Panel dividing saw SAWTEQ S-100

- Saw for single panels and small series

- For newcomers and upgraders: super price, super performance

- Semi-automatic cutting: ergonomic, reliable, efficient

Panel dividing saws

Panel dividing saw SAWTEQ S-160

- High-precision cutting with premium quality cut

- High performance and high output with fast cutting cycle time

- CADmatic with assistance graphic for intuitive, ergonomic machine operation

Panel dividing saws

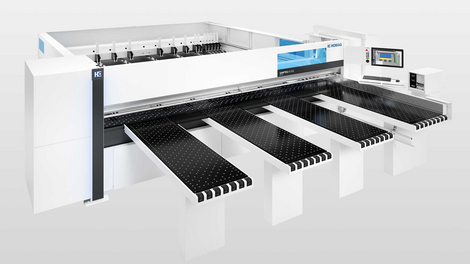

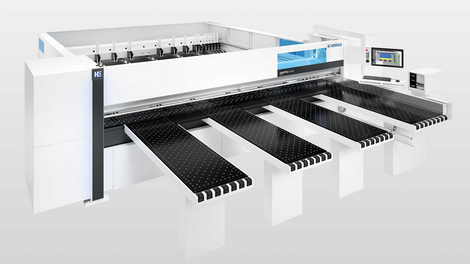

Panel dividing saw SAWTEQ S-200

- Attractively priced, efficient and upgradeable

- Cutting lengths up to 4,300 mm

- Low-noise and virtually maintenance-free saw carriage

Panel dividing saws

Panel dividing saw SAWTEQ S-210 with lifiting table

- High throughput on a small footprint

- Highly ergonomic due to lifting table feed

- Almost maintenance-free 4-column lifting table

Panel dividing saws

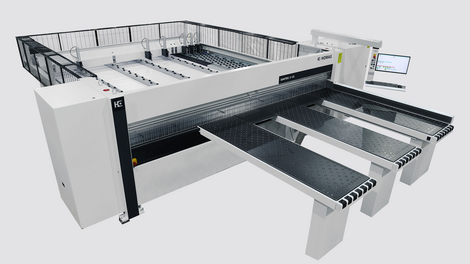

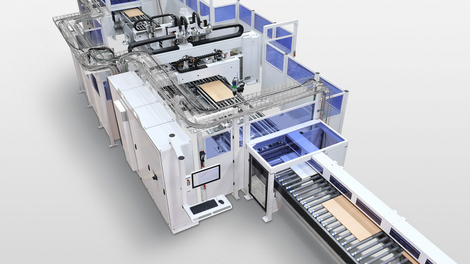

Panel dividing saw SAWTEQ S-200 flexTec

- Unmanned operation possible until stack change

- Quick changeover between operator and automatic mode

- Up to 850 parts per shift

New

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-200 plastics

- A small, but powerful plastics saw for fast processing of smaller batches.

Panel dividing saws

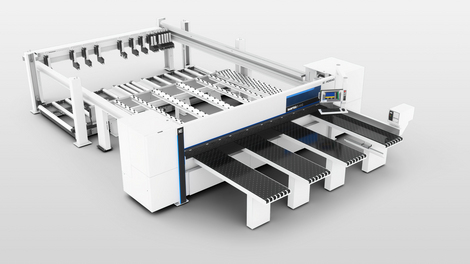

Panel dividing saw SAWTEQ S-300

- Designed for smooth material flow and precise logistics process

- Also suitable for networked production processes

- Operational flexibility thanks to custom configurations

Bestseller

Panel dividing saws

Panel dividing saw SAWTEQ S-310 with lifting table

- Short production times and high throughput due to automatic feeding

- Designed for smooth material flow and precise logistics process

- Ready for networked production processes

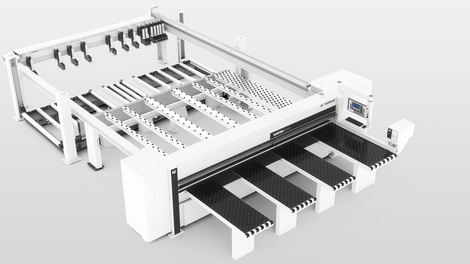

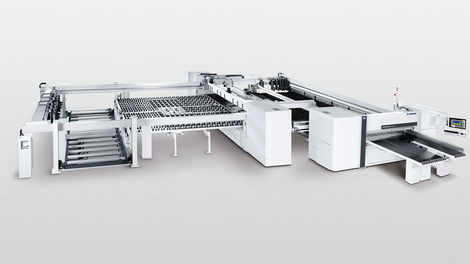

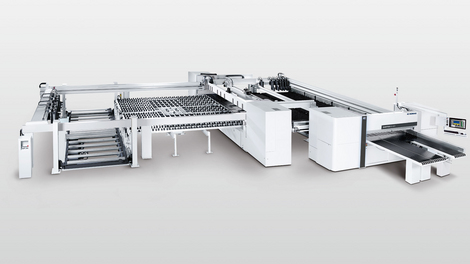

Panel dividing saws

Panel dividing saw SAWTEQ A-300 | A-310 as angular saw unit

- Rip and cross cuts in one pass: this saw is an excellent solution for volume production involving cutting panels in books.

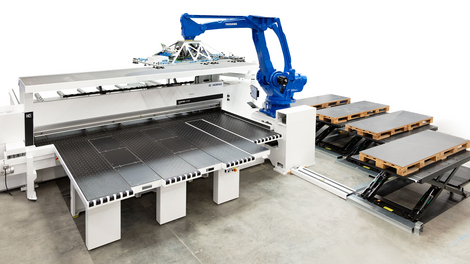

Panel dividing saws

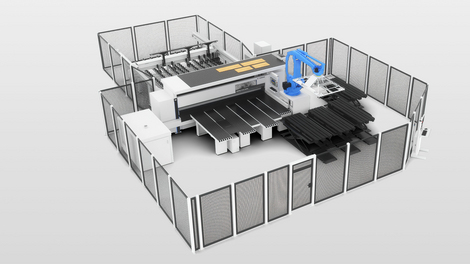

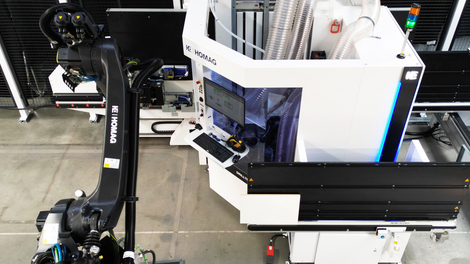

Panel saw SAWTEQ S-300 | S-310 flexTec

- In robot operation: Highly efficient batch size 1 production with up to 1000 parts per shift

- Low unit costs per part

- Partially unmanned operation

Panel dividing saws

Panel dividing saw SAWTEQ S-320 flexTec

- Production capacity of up to 3,000 parts per shift

- Automation through robot management

- Unlimited recuts

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-300 plastics

- The classic among the horizontal plastics saws provides great cutting precision and produces even small quantities profitably.

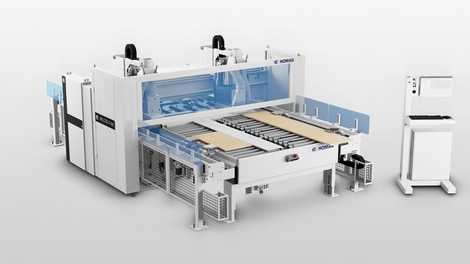

Panel dividing saws

Panel dividing saw SAWTEQ S-400

- Designed to cut large volumes of panels to finish cut quality

- High throughput capability: saw blade projection of 110 mm or 125 mm

- Extra power with 18 KW main saw motor (optional 24 KW)

Panel dividing saws

Panel dividing saw SAWTEQ S-410 with lifting table

- In the SAWTEQ S-410, HOMAG offers a horizontal panel saw with automatic feed system that really speeds up the cutting process.

Panel dividing saws

Panel dividing saw SAWTEQ A-400 | A-410 as angular saw unit

- The SAWTEQ SAWTEQ A-400 | A-410 delivers a high level of precision in continuous operation, coupled with an impressive processing speed.

Panel dividing saws

Panel saw SAWTEQ S-400 | S-410 flexTec

- In robot operation: Highly efficient batch size 1 production with up to 1000 parts per shift

- Low unit costs per part

- Partially unmanned operation

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-400 plastics

- This panel dividing saw is every bit as versatile as your demands are varied and can handle nearly all types of plastic panels – also when dealing with larger quantities and cutting in books.

Panel dividing saws

Panel dividing saw SAWTEQ S-500

- Advantage through size is the motto of the SAWTEQ S-500 – an innovative, robust high-performance saw for mass producers.

Panel dividing saws

Panel dividing saw SAWTEQ S-510 with lifting table

- A real powerhouse with automatic feeding: the SAWTEQ S-510 can easily be integrated in highly efficient production processes and can even accelerate them.

Panel dividing saws

Panel dividing saw SAWTEQ A-500 | A-510 as angular saw unit

- Plenty of output in a short time: the fully automated angular saw unit of the 5 series sets the benchmark in industrial manufacturing and is particularly powerful.

Panel dividing saws for plastics processing

Panel dividing saw SAWTEQ S-500 plastics

- Cutting plastic panels on a large scale – this is what the SAWTEQ S-500 plastics saw is designed for, and it sets the benchmark for this in the premium segment.

Panel dividing saws

Panel dividing saw SAWTEQ A-610 as angular saw unit

- The largest and most powerful angular saw unit made by HOMAG is a real powerhouse for volume production.

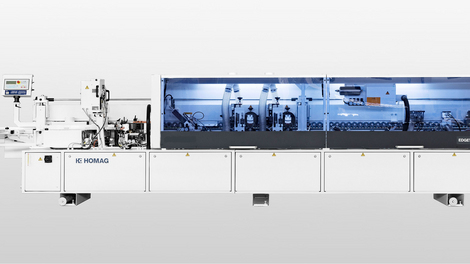

Edge Banding Machines

Edge banding machines EDGETEQ S-200: 8 m/min | 11 m/min feed speed

- Glue change in under 3 minutes

- Regulated motors for edge feeding

- Strip separation by suction cups

New

Edge Banding Machines

Edge Banding Machines EDGETEQ S-230

- Perfect edge banding with our EDGETEQ S-230 Series

Edge Banding Machines

Edge banding machines EDGETEQ S-240: 11 m/min feed speed

- Entry-level machine for demanding requirements

Edge Banding Machines

Edge banding machines EDGETEQ S-300

- 14 m/min feed rate

- Multi-level technology with automatic adjustment

- Connection to software and apps

Edge Banding Machines

Edge banding machines EDGETEQ S-340

- Joint trimming unit guarantees the ideal formatting of the panel

- Quick Melt gluing unit guarantees the optimal edge banding

- Snipping unit equipped with 2 motors offers a highly precise cut

Edge Banding Machines

Edge Banding Machines EDGETEQ S-358

- Powerful motors on all units provide unrestricted power

- Joint trimming unit perfectly formats the panels

- Quick melt gluing unit is ideal for optimal edge adhesion

Edge Banding Machines

Edge banding machines EDGETEQ S-360

- Complete edge processing with our EDGETEQ S-360.

Edge Banding Machines

Edge banding machines EDGETEQ S-370

- The next generation of Edge banding machines.

Edge Banding Machines

Edge banding machines EDGETEQ S-380 | profiLine: 8–20 m/min feed speed

- Feed speed up to 20 m/min

- Portal return connection

- Individualization in the profiLine modular system

Edge Banding Machines

Edge banding machines EDGETEQ S-500 Optimat and profiLine

- Feed rate: 16–20, 25, 30, 35 m/min

- Process PUR, EVA and airTec or laserTec using just one machine

- Minimum workpiece width: 60 mm (40 mm)

Bestseller

Edge Banding Machines

Edge banding machines EDGETEQ D-610 profiLine

- High-performance machines offering compact to tailored solutions

Edge Banding Machines

Edge banding machines EDGETEQ S-800 profiLine

- Delivering accurate processing and the perfect aesthetic in combination with any edging material

Edge Banding Machines

Edge banding machines EDGETEQ S-810 powerLine: Individual equipment configuration

- Delivering accurate processing and the perfect aesthetic in combination with any edging material

Edge Banding Machines

Edge banding machines EDGETEQ D-810 powerLine: Maximum Power

- Unique high-performance machines

Edge Banding Machines

Shaped part throughfeed machines EDGETEQ S-810/CF: Rapid processing of large quantities

- Complete processing of shaped parts in a single run

Edge Banding Machines

Postforming machines EDGETEQ S-810: One machine – five processing stations

- Pre-coated panel in – postforming part out

Edge Banding Machines

Softforming machines: Creative edge design

- An extensive range of profiles and edge materials

Edge Print

EDGETEQ P-200 digital edge printing

- Prints decors, images, logos and text

- Direct printing on MDF boards

- Apply design ideas directly

New

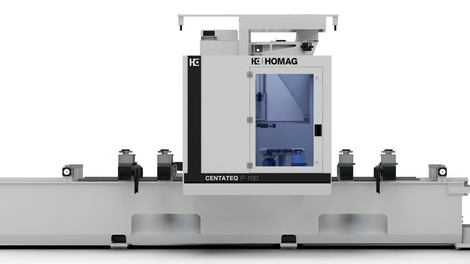

CNC Machining Centers

CNC Processing Center CENTATEQ P-100

- Universal CNC technology with 3, 4 or 5 axes

- Stable moving gantry design

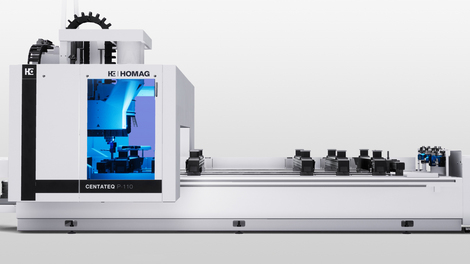

CNC Machining Centers

CNC Processing Center CENTATEQ P-110

- Universal CNC technology with 3, 4 or 5 axes

- Completely free accessibility for optimum operation

- Stable moving gantry design

Bestseller

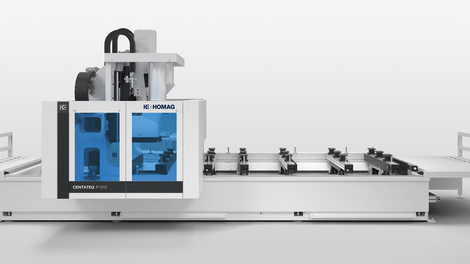

CNC Machining Centers

CNC Processing Center CENTATEQ P-210

- Flexible CNC technology with 3, 4 or 5 axes

- Gluing technology and automation available for the trade

- Stable moving gantry design

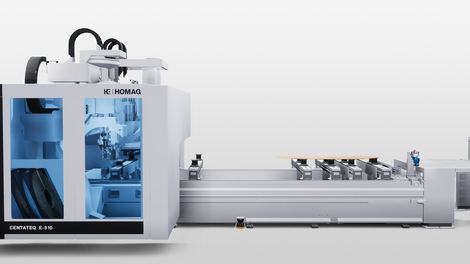

CNC Machining Centers

CNC Processing Center CENTATEQ P-310 | E-310

- Processing options from 5-axis to edge

- Scalable in performance, easy to operate

- Performance and convenience combined in one machine

CNC Machining Centers

CENTATEQ P-510|610 + E-510 processing centers

- High-end CNC processing centers with SORB TECH machine body for the highest demands

- Individually configurable according to your needs

CNC Machining Centers

CENTATEQ E-700 processing centers

- High-performance edge banding on two processing tables

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-100

- Enable optimized processing of panel materials

- Various possibilities for the automation of material handling

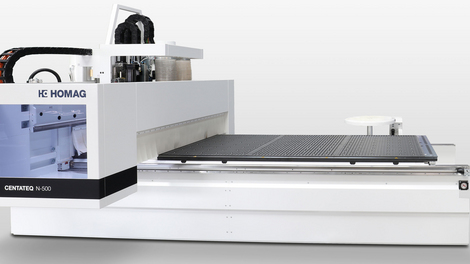

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-210

- A new take on nesting processing.

- 3- and 4-axis machining

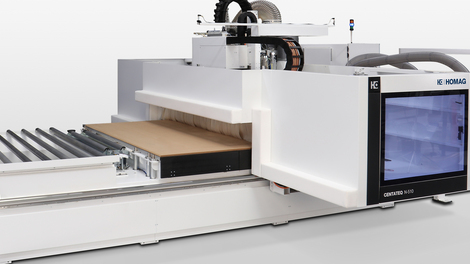

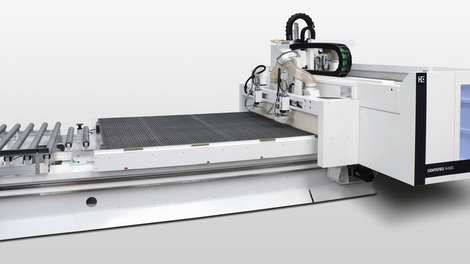

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-500

- Compact class Flexible handling concepts 3-, 4-axis machining

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-510

- Where the top class starts – more flexibility, maximum efficiency

- 3, 4 or 5-axis processing

- Z-height up to 260 mm

CNC Machining Centers

CNC-Gantry Processing Center CENTATEQ N-600

- Nesting with 3-, 4- or 5-axis technology

CNC Machining Centers

CENTATEQ T-Series processing centers

- Synchronous or parallel processing on two processing tables

CNC Machining Centers

CENTATEQ S-800|900 processing centers

- Solutions for complex requirements in window production

- From the individual machine to the connected cell

WEINMANN Multifunction Bridge

Multifunction bridge WALLTEQ M-300

- For entry into the world of automatic creation of elements

- Ideal for woodworking shops with high processing flexibility

- Sawing of materials up to 80 mm

Bestseller

WEINMANN Multifunction Bridge

Multifunction Bridge WALLTEQ M-500

- Individually configurable solution

- A wide range of processing options for the elements

- Extended mounting options for sheathing

WEINMANN Multifunction Bridge

Multifunction Bridge WALLTEQ M-300 insuFill /M-500

- Fully automated insulation of timber construction elements

- Efficient use of materials and reduced dust exposure for employees

- Logging of the blow-in quantity

WEINMANN Timber Frame Production Lines

Compact Line

- Easy to integrate thanks to low space requirements

- High overall productivity

- Flexible batch size production

WEINMANN Timber Frame Production Lines

Wall production line

- High-precision production of wall elements

- Efficient production process due to high speed

- Can be expanded to different levels of automation

WEINMANN Timber Frame Production Lines

Roof and ceiling production line

- Enables the manufacture of roof and ceiling elements

- An integrated system — from cutting to loading

- Can be individually adapted to customer requirements

WEINMANN Framing Station

Frame Work Station FRAMETEQ F-300

- Cost-effective entry-level solution for automated frame work production

- High flexibility since the system can be expanded on a modular basis

- Optimized production of standard walls and gable elements

WEINMANN Framing Station

Frame Work Station FRAMETEQ F-500

- High level of performance due to high degree of automation

- Versatile expansion options even with robot technology

- Optimized production of standard walls and gable elements

WEINMANN Framing Station

FRAMETEQ F-700 framing station

- Production of complex and demanding frame works.

- Ideally suited for fully automatic production processes.

- Versatile expansion options even with robot technology.

Cardboard-box Cutting and Closing Machines

Cardboard-box closing machine PAQTEQ S-200

- Perfect packaging, fully automatic

Cardboard-box Cutting and Closing Machines

Cardboard-box cutting machine PAQTEQ C-250

- Individual packaging like a custom-made suit

- Efficient and sustainable product protection

- Stand-alone operation or integrated into a complex packaging line

Case Clamps

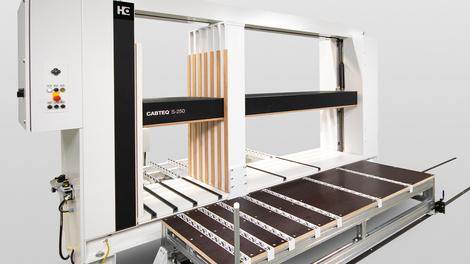

Stationary Case clamp CABTEQ S-200

- Intuitive operation

- Pressing areas with tolerance compensation in the top pressure

- Simple installation of the machine thanks to Plug & Play

Case Clamps

Stationary Case clamp CABTEQ S-250

- Pressing areas with tolerance compensation in the top pressure

- Sensor detection for a gentle pressing process

- Optionally selectable plug-in station and carcass upright for an ergonomic working environment

Case Clamps

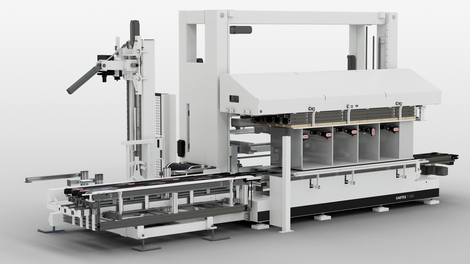

Electric throughfeed case clamp CABTEQ T-200

- Our solution as an introduction to throughfeed pressing technology

- Automatic positioning of the press elements by sensory recognition of the main dimensions at the infeed of the carcase.

Case Clamps

Electric throughfeed case clamp CABTEQ T-250

- Automatic positioning of the press elements by sensory detection

- Precise, fully autom. adjustment by using precise ballscrew drives

- Optional clamping unit for fully automatic fastening of the back panels

Case Clamps

Electric joining press CABTEQ T-500

- Automated joining process for assembling carcasses

- Precisely adjustable pressing force allows pressing of carcasses with sensitive surfaces, thin-walled or small carcasses

- Operator support during the assembly process for carcases thanks to the vacuum-operated holding arms for shelves and rear panel

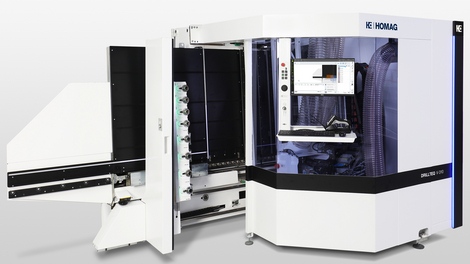

CNC Drilling and Dowel inserting Machines

CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-110

- Horizontal drilling and doweling

CNC Drilling and Dowel inserting Machines

CNC-Dowel hole drilling machine DRILLTEQ C-100 NBS 033 (India)

- Perfect dowel hole drilling with our DRILLTEQ C-100 NBS 033

CNC Drilling and Dowel inserting Machines

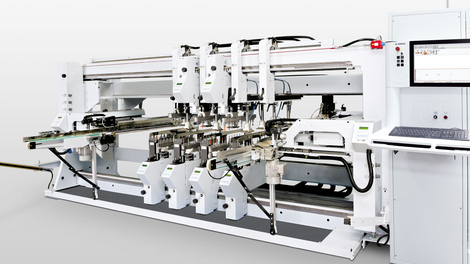

CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-510

- Horizontal drilling, doweling and milling

- Vertical drilling, milling

- Special configuration for inclined machining between 42° - 45°

CNC Drilling and Routing Machining Centers

Vertical CNC Processing Center DRILLTEQ V-200

- A flexible all-rounder for processing in just 5 m²

CNC Drilling and Routing Machining Centers

DRILLTEQ V-310 vertical CNC processing center

- Maximum cabinet processing. Minimum space requirements. A space-saving miracle that requires just 11 m² of floor space.

Bestseller

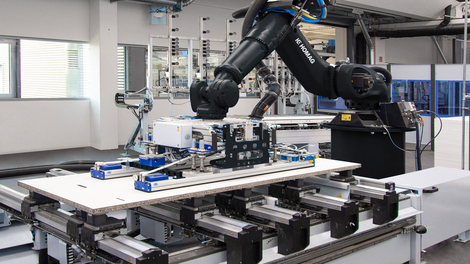

Robot Solutions for the Furniture Industry

Robot FEEDBOT D-310

- Add-on for the DRILLTEQ V-310 CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

New

Robot Solutions for the Furniture Industry

Robot FEEDBOT D-300

- Retrofitting for DRILLTEQ V-500 CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

CNC Automatic Drilling and Fitting Machines

Throughfeed Processing Centers DRILLTEQ L-200

- Ideal for the cabinet side processing

CNC Automatic Drilling and Fitting Machines

Throughfeed Processing Center DRILLTEQ L-500

- 6-sided processing without compromises

CNC Drilling and Routing Machining Centers

CNC-Processing Center DRILLTEQ H-230

- 6-sided processing for complete carcase production

- High flexibility thanks to manual handling

CNC Drilling and Routing Machining Centers

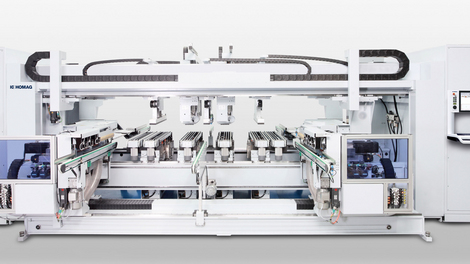

CNC-Processing Center DRILLTEQ H-330

- Full panel processing where routing and drilling units perform in highspeed. 6 sided-processing along 2 working fields

- 4 CNC-controlled clamping devices ensure permanently firm and precise positioning of the workpieces – regardless of the speed

- Optional top electric spindles with automatic tool changer make processing more possibilities.

CNC Drilling and Routing Machining Centers

CNC-Processing Center DRILLTEQ H-600

- High processing speeds of up to 130 m/min.

- 6-sided machining for complete carcass production

- High output thanks to double part processing of mirrored workp.

Througfeed Drilling Machines

Throughfeed Drilling Machine DRILLTEQ C-500

- The high-performance drilling machine from a batch size of more than 250 pieces – enormous repeat accuracy with the same high quality standards.

Througfeed Drilling Machines

Drilling System DRILLTEQ C-800

- Up to 730 individually retrievable drilling spindles ensure dynamic batch size one manufacturing.

Sorting Buffering and Collating Systems

Collating storage system

- Automatically on two levels - 2-bridge-system

Sorting Buffering and Collating Systems

Collating center SORTEQ R-200

- Limitless sorting from batch size 1

Sorting Buffering and Collating Systems

Sorting line

- Gentle material transport without suction technology

Robot Solutions for the Furniture Industry

Robot FEEDBOT C-300

- Add-on for a CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

- Production cell with a robot for automatic material handling

WEINMANN Handling and storage systems timber construction

Robot FEEDBOT F-500

- Automated insertion of studs and belts in the frame work

- Delivers tailor-made results thanks to a high degree of precision

- Reduces the physical exertion required by employees

WEINMANN Handling and storage systems timber construction

Robot FEEDBOT W-500

- Automated placement of panels on the frame work

- Delivers tailor-made results due to a high degree of precision

- Reduces physical exertion of employees

Robot Solutions for the Furniture Industry

Robot SORTBOT R-300

- Solution for horizontal or vertical sorting

- More Output without Waiting Times

Robot Solutions for the Furniture Industry

Robot PAQBOT I-300

- Insert station with robot for automatic filling of cardboard-boxes

Sorting Buffering and Collating Systems

Buffering system

- Buffering for the adjustment of the material flow

Feed and Stacking

Feed and stacking system FEEDTEQ G-200 | STACKTEQ G-200

- Gantry-design feed and stacking system

Feed and Stacking

Feed and stacking system FEEDTEQ L-500 | STACKTEQ L-500

- Compact feed and stacking system

WEINMANN Handling and storage systems timber construction

Swing jib crane FEEDTEQ H-300

- Quick and easy material handling

- High degree of work ergonomics and easy operation

- Optimized material provision

WEINMANN Handling and storage systems timber construction

Handling portal FEEDTEQ H-500

- Ergonomic material provision in production lines

- Quick and easy handling over large working areas

- Suitable lifting devices for the right material

WEINMANN Assembly Tables

Up-lifting and distribution trolleys BUILDTEQ A-500

- Ergonomic transport of wall panels

Storage systems timber construction

Wall magazine STOCKTEQ V-300 | V-500

- Enables a production-optimized workflow

- Comprehensive safety system

- Customized magazine capacity

Storage systems timber construction

Window installation track STOCKTEQ V-330 | V-530

- Wide magazine track with sufficient space for installing windows and doors

- Enables ergonomic work processes

- Comprehensive safety system

Storage systems timber construction

Distribution and warehouse trolley STOCKTEQ D-300 | D-500

- Enables easy distribution and loading of finished wall elements

- Precise positioning of the carriage on the wall tracks of the magazine

- High level of occupational safety

Storage systems timber construction

Stake magazine STOCKTEQ V-100

- Temporary storage of elements

- Easy loading and removal with the overhead crane

- Ideal for small businesses

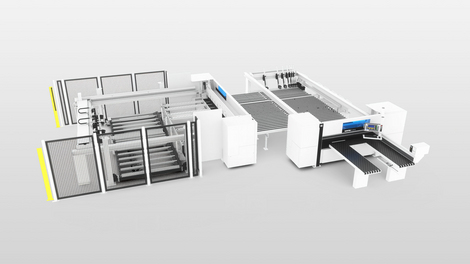

Storage Systems

Single-axis feeder STORETEQ F-100

- Fully automatic board handling: Increases your productivity and saves time

- Fits in any workshop: The space-optimized feeder requires hardly any floor space

- Intuitive operation: You operate the feeder conveniently directly a your HOMAG saw

New

Storage Systems

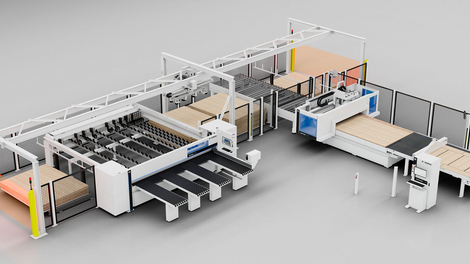

Storage system STORETEQ P-300 | P-500

- Transparent storage management

- Optimal material flow and consumption up to offcuts

- Low search times and increased productivity

Storage Systems

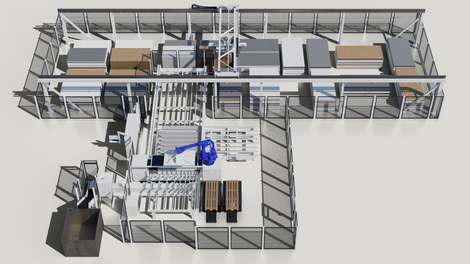

Storage system STORETEQ P-310|P-510 and P-320|P-520

- Optimal and resource-saving storage area

- Transparently managed stocks in the smallest of spaces

- Highly efficient and intelligent logistics

WEINMANN Handling and storage systems timber construction

Feeding portal STORETEQ H-100

- Fully automatic feeding of the FRAMETEQ

- Efficient use of resources

- Pre-storage and feeding of standard studs

WEINMANN Handling and storage systems timber construction

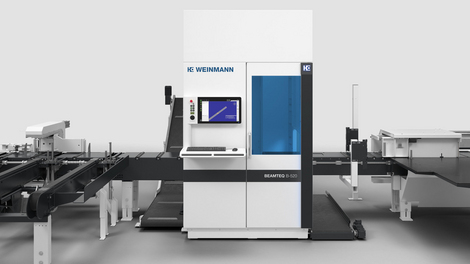

Linear portal STORETEQ H-300

- Fully automatic feeding of the BEAMTEQ with beams up to 6 m

- Enables increased cutting performance

- Up to six storage positions for beam packages

WEINMANN Handling and storage systems timber construction

Feeding portal STORETEQ H-700

- Fully automatic feeding of the BEAMTEQ with beams up to 13.7 m

- Enables increased cutting performance

- Individually configurable storage positions for wood stacks

WEINMANN Assembly Tables

Self Assembly Table BUILDTEQ A-100

- Attractive entry-level solution thanks to self-assembly

- Can also be expanded on a modular basis in combination with a multifunction bridge

- Can be used universally for all elements

WEINMANN Assembly Tables

Carpentry Table BUILDTEQ A-300

- Ideal for small and medium-sized carpentry businesses

- High level of occupational safety thanks to non-slip sheathing

- Can be used flexibly for all elements

WEINMANN Assembly Tables

Butterfly turning table

- Fast and safe turning of elements

- Enables processing of both element sides

- Can be integrated and expanded in plants

WEINMANN Assembly Tables

Element table BUILDTEQ A-500

- Ideal for use in industrial production lines

- Versatile configuration options

- High productivity thanks to semi-automated processes

WEINMANN Assembly Tables

Roof and floor table BUILDTEQ A-600

- The specialist for roof and ceiling elements

- NC-controlled axes allow fully automatic positioning of beams

- High level of occupational safety thanks to non-slip sheathing

WEINMANN Carpentry Machines

Sawing Center BEAMTEQ B-520

- Fast cutting, perfect precision: optimum output

- Up to 4500 running meters/8 h for simple cutting

- Sawing and milling with no setup times

WEINMANN Carpentry Machines

Carpentry Machine BEAMTEQ B-560

- Powerful and precise beam processing

- Up to 2200 running meters/8 h for complex beam processing

- Up to 200 mm processing depth

New

WEINMANN Carpentry Machines

Carpentry Machine BEAMTEQ B-660

- Powerful and precise beam processing of all six sides in one throughfeed

- Up to 2200 running meters/8 h for complex beam processing

- Up to 200 mm processing depth

New

Production Management

Factory Management System

- MES product developed by HOMAG

- Combines German advanced technology and localized interface

- Modularity for personalized digital transformation

Results from 0 to 0 of 0