Find HOMAG Automation (BARGSTEDT & LIGMATECH) products here ➤ HOMAG

The HOMAG Group is the world's leading provider of integrated solutions for production in the woodworking industry and woodworking shops.

Here you will find the proven former HOMAG Automation woodworking machines (BARGSTEDT and LIGMATECH) in the usual quality under the HOMAG brand.

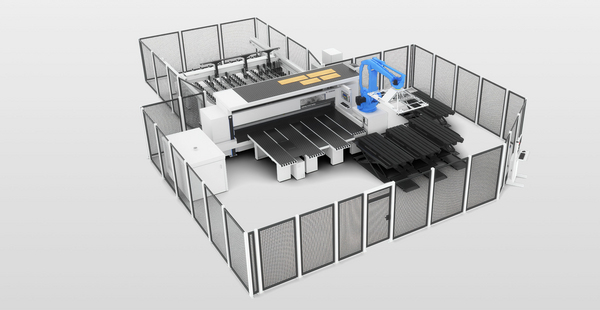

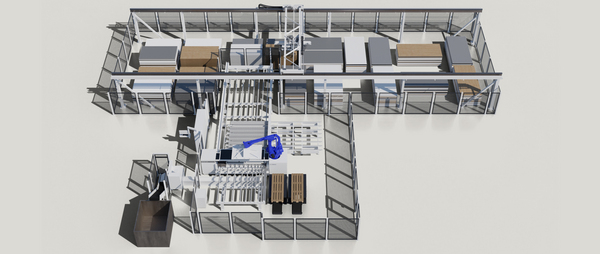

HOMAG Automation Panel Storage Systems (BARGSTEDT)

HOMAG Automation Sorting Buffering and Collating Systems (BARGSTEDT)

HOMAG Automation Assembly Technology (LIGMATECH)

HOMAG Automation Packaging Technolgy (LIGMATECH)

HOMAG Automation Technology (LIGMATECH)

Modernizations and updates for software and controls can be found under Service .

Service for BARGSTEDT and LIGMATECH Woodworking Machinery

You are looking for a contact person in the service?

You are looking for YOUR SOLUTION for your production?

Spareparts for BARGSTEDT and LIGMATECH Machinery you find in the eShop .

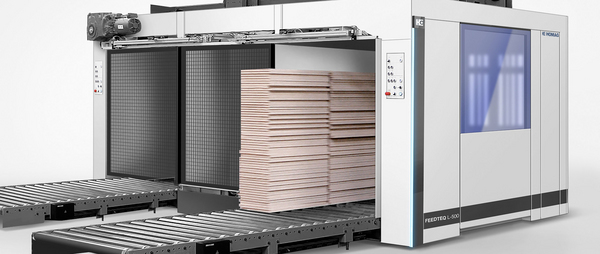

Single-axis feeder STORETEQ F-100

Fully automatic board handling: Increases your productivity and saves time

Fits in any workshop: The space-optimized feeder requires hardly any floor space

Intuitive operation: You operate the feeder conveniently directly a your HOMAG saw

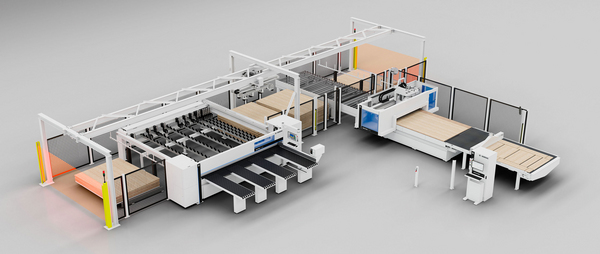

Sorting Buffering and Collating Systems

Sorting line

Gentle material transport without suction technology

Robot SORTBOT R-300

Solution for horizontal or vertical sorting

More Output without Waiting Times

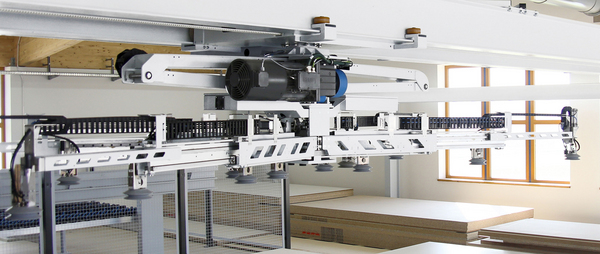

Robot Solutions for the Furniture Production

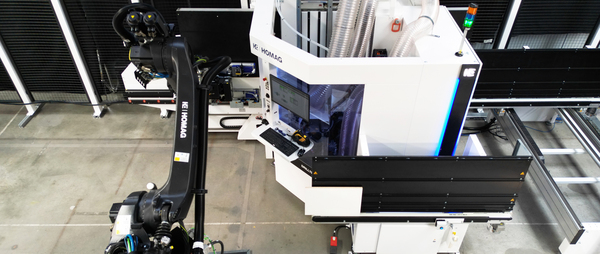

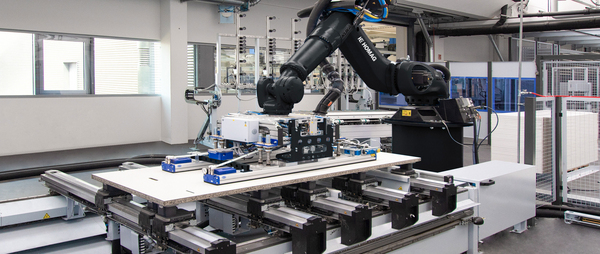

Robot FEEDBOT D-310

Add-on for the DRILLTEQ V-310 CNC-processing center

Safe, precise, automatic handling of workpieces for more efficient production

Robot FEEDBOT D-300

Retrofitting for DRILLTEQ V-500 CNC-processing center

Safe, precise, automatic handling of workpieces for more efficient production

Robot FEEDBOT C-300

Add-on for a CNC-processing center

Safe, precise, automatic handling of workpieces for more efficient production

Production cell with a robot for automatic material handling

Robot SORTBOT R-300

Solution for horizontal or vertical sorting

More Output without Waiting Times

Robot PAQBOT I-300

Increased performance thanks to precise, fast insertion

Process stability minimizes manual intervention and ensures quality

Easy integration thanks to trenchless concept

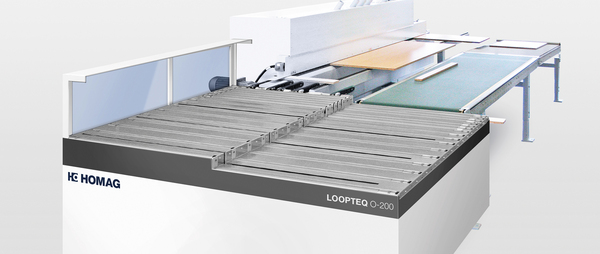

Return conveyor LOOPTEQ O-200

The entry to a comfortable material flow

For small, narrow and mediumsized workpieces

Pays off from 9 hours working time per week

Return conveyor LOOPTEQ O-300

For a wide spectrum in the material flow

For small and light up to large and heavy workpieces

Pays off from 15 hours working time per week

Return System LOOPTEQ O-400

Combination of stacking system and workpiece return

Designed for production halls with limited space

Designed for large parts up to 3,100 x 1,300 mm

Return conveyor LOOPTEQ O-600

Combination of stacking system and workpiece return

For a wide variety of parts and a high degree of automation

Interlinked material flow with high capacity

Stationary Case clamp CABTEQ S-200

Intuitive operation

Pressing areas with tolerance compensation in the top pressure

Simple installation of the machine thanks to Plug & Play

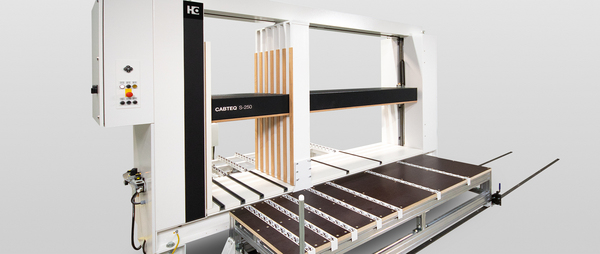

Stationary Case clamp CABTEQ S-250

Pressing areas with tolerance compensation in the top pressure

Sensor detection for a gentle pressing process

Optionally selectable plug-in station and carcass upright for an ergonomic working environment

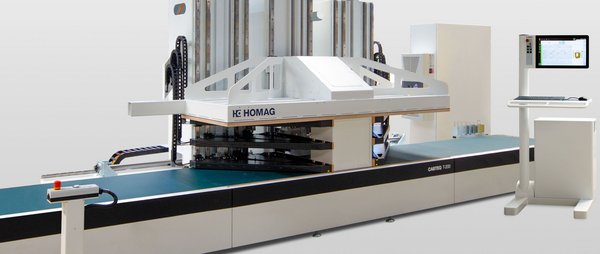

Throughfeed case clamp CABTEQ T-200

Our solution as an introduction to throughfeed pressing technology

Automatic positioning of the press elements by sensory recognition of the main dimensions at the infeed of the carcase.

Throughfeed case clamp CABTEQ T-250

Automatic positioning of the press elements by sensory detection

Precise, fully autom. adjustment by using precise ballscrew drives

Optional clamping unit for fully automatic fastening of the back panels

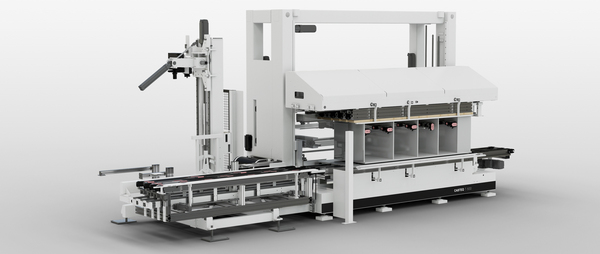

Automatic joining press CABTEQ T-500

Automated joining process for assembling carcasses

Precisely adjustable pressing force allows pressing of carcasses with sensitive surfaces, thin-walled or small carcasses

Operator support during the assembly process for carcases thanks to the vacuum-operated holding arms for shelves and rear panel

Cardboard-box Cutting and Closing Machines

Robot PAQBOT I-300

Increased performance thanks to precise, fast insertion

Process stability minimizes manual intervention and ensures quality

Easy integration thanks to trenchless concept

Here's how your colleagues produce

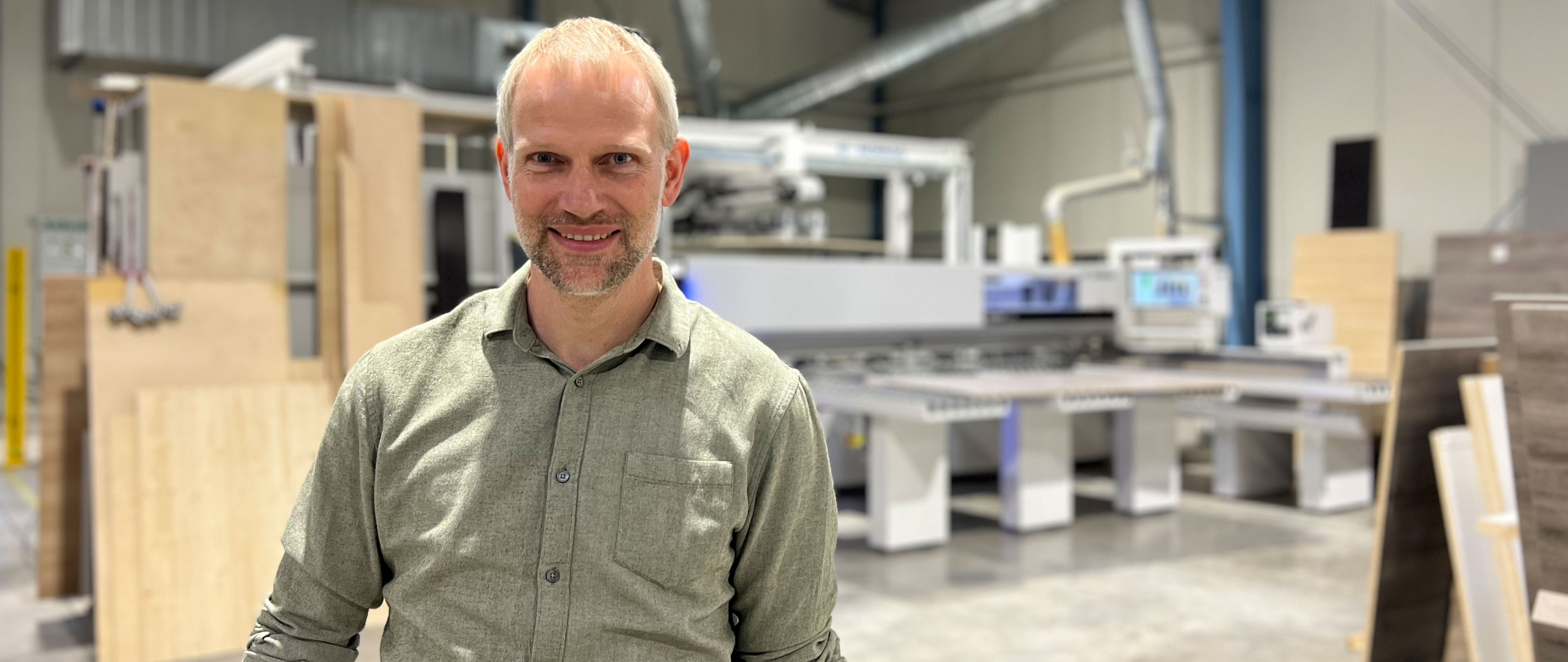

Panel dividing saw meets single-axis feeder

Interior Millwork

Automation - Trade

Read more

Suite Dreams. A portrait of Felix Graf GmbH.

Interior Millwork

Shopfitting & Furnishing

Automation - Trade

Read more

Automation perfectly implemented

Automation - Trade

Interior Millwork

Shopfitting & Furnishing

Read more

Panel dividing saw meets single-axis feeder

Interior Millwork

Automation - Trade

Panel dividing saw meets single-axis feeder

Optimized cutting at abc-Tischler: Panel dividing saw meets single-axis feeder

Read more

Interior Millwork

Automation - Trade

Read more

Interior Millwork

Automation - Trade

Suite Dreams. A portrait of Felix Graf GmbH.

Interior Millwork

Shopfitting & Furnishing

Automation - Trade

Suite Dreams. A portrait of Felix Graf GmbH.

A portrait of Felix Graf GmbH.

Read more

Interior Millwork

Shopfitting & Furnishing

Automation - Trade

Read more

Interior Millwork

Shopfitting & Furnishing

Automation - Trade

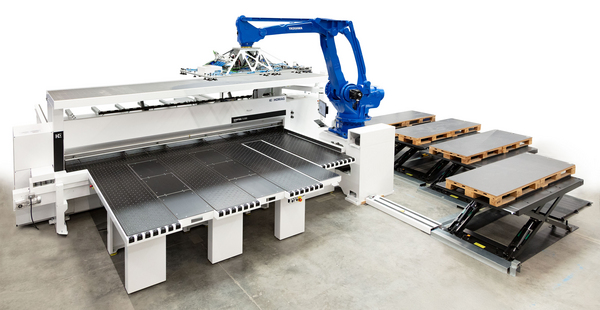

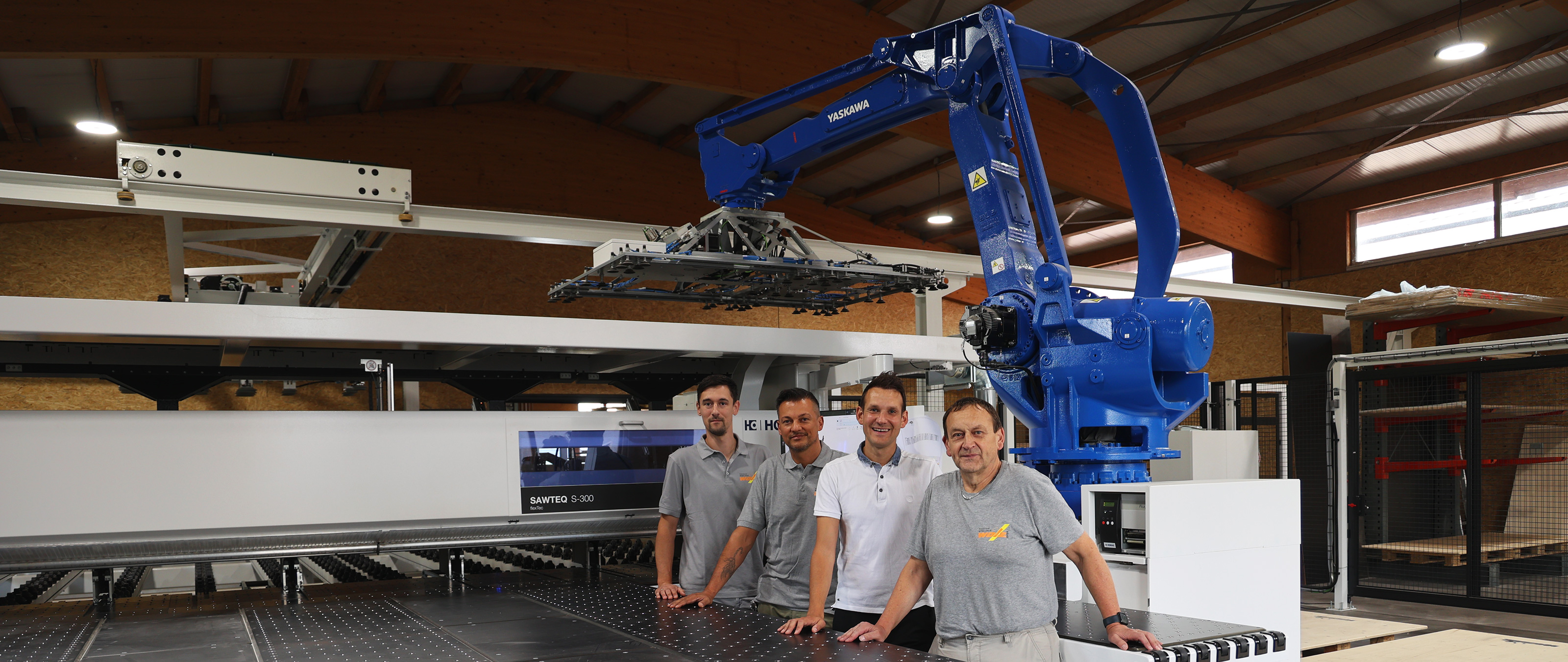

Automation perfectly implemented

Automation - Trade

Interior Millwork

Shopfitting & Furnishing

Automation perfectly implemented

The SAWTEQ S-300 flexTec robot saw with the STORETEQ P-300 storage system increases output at Wolz

Read more

Automation - Trade

Interior Millwork

Shopfitting & Furnishing

Read more

Automation - Trade

Interior Millwork

Shopfitting & Furnishing