Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

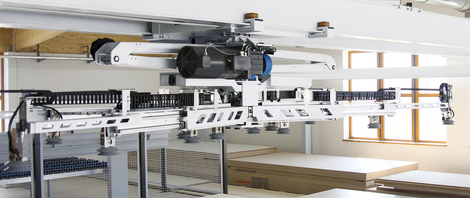

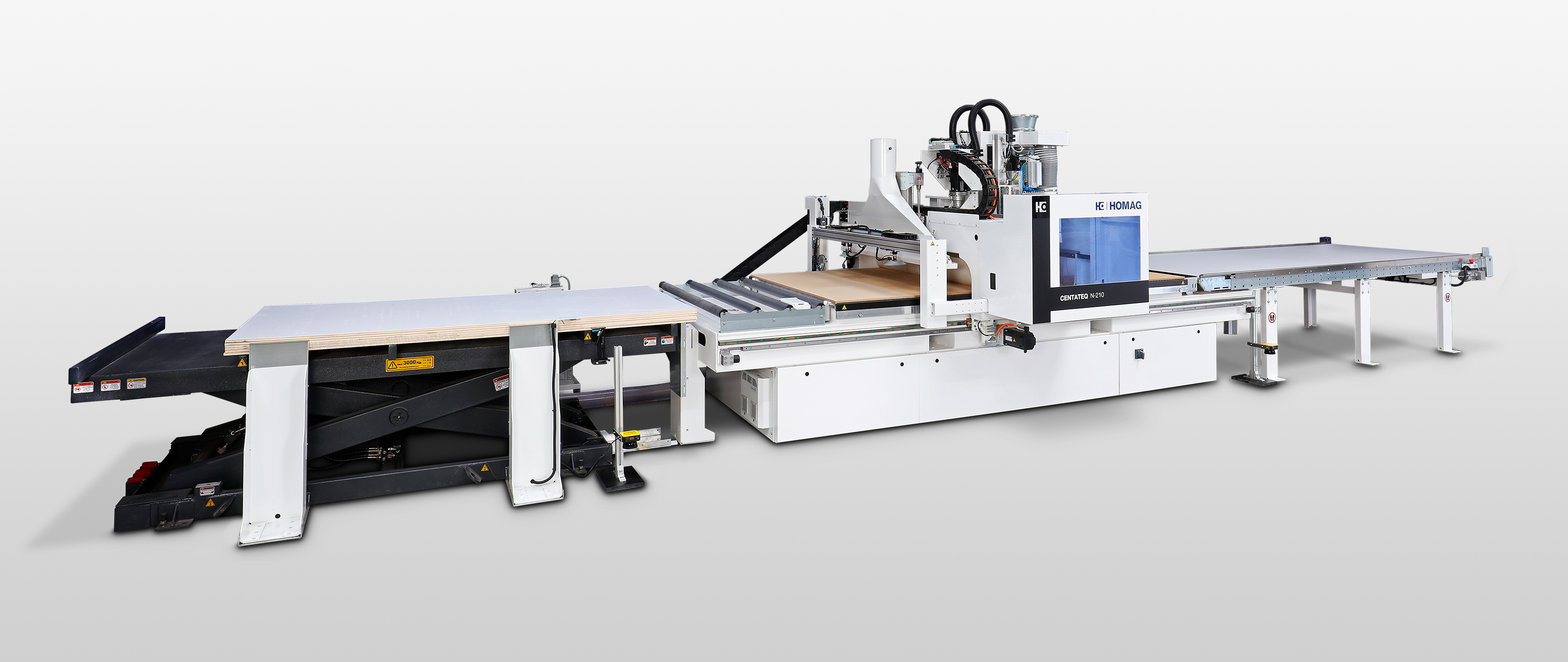

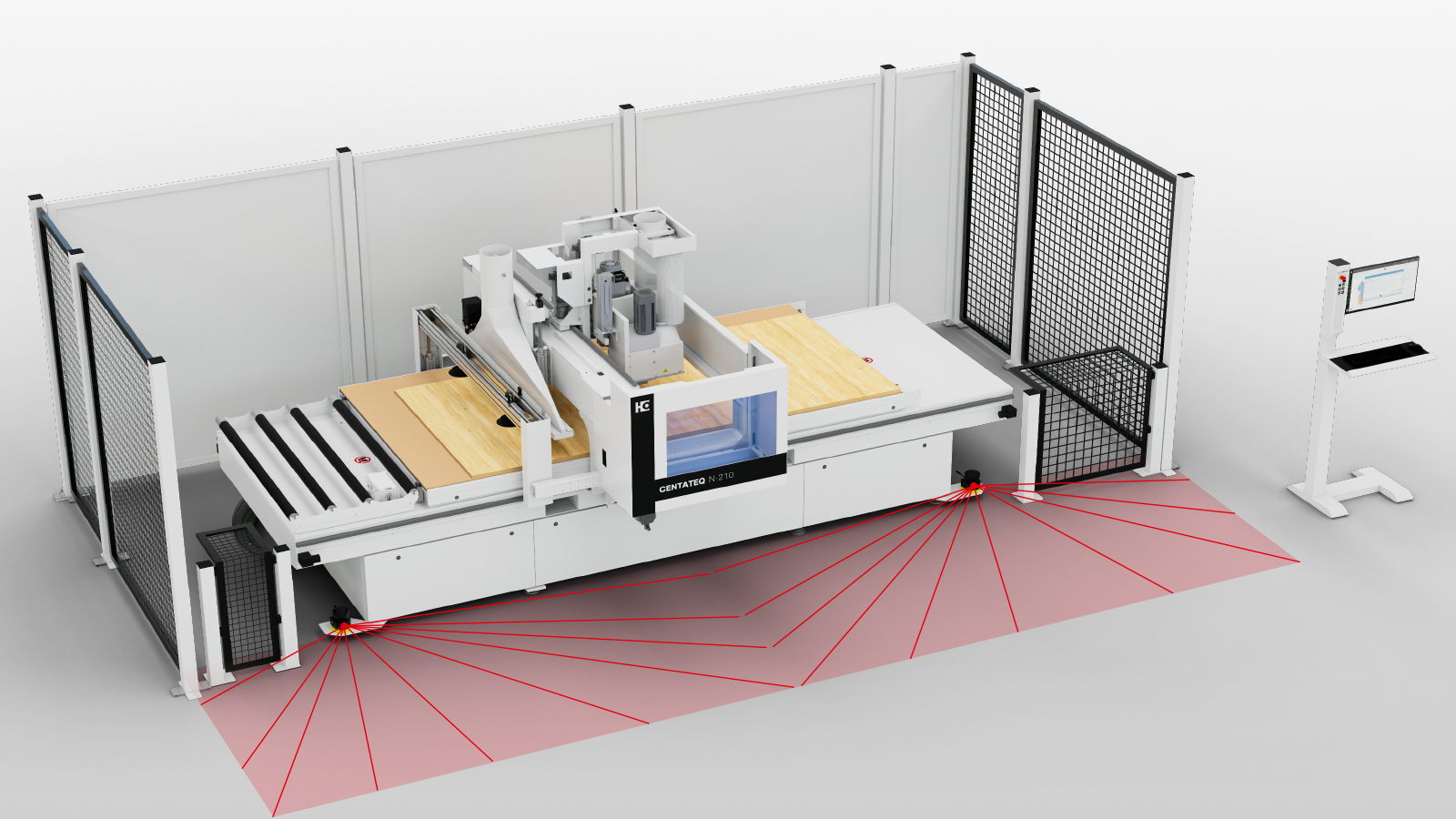

CNC Machining Centers CENTATEQ N-210

CNC Machining Centers CENTATEQ N-210

The next generation of entry-level nesting processing.

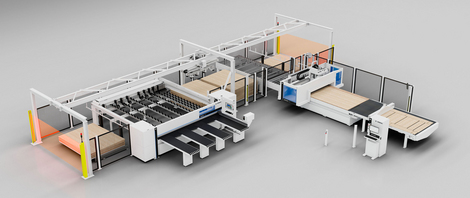

The new generation of the CENTATEQ N-210 represents the entry into the nesting sector. A major step was the reduction of the installation area by 25 % compared to the previous version. Tight spaces at the customer's premises are no longer an obstacle. The machine has been extended to include intelligent optimization with streamlined functions. The new generation works as a stand-alone machine or as part of an automated concept. The machining operations can be realized with a wide mix of units and tools. The functionality of this machine is rounded off with automation options.

Highlights

Safescan safety concept - the focus is on output and productivity. The machine stops when entering the safety area. After leaving the safety area and confirmation at the operating terminal, the machine continues processing.

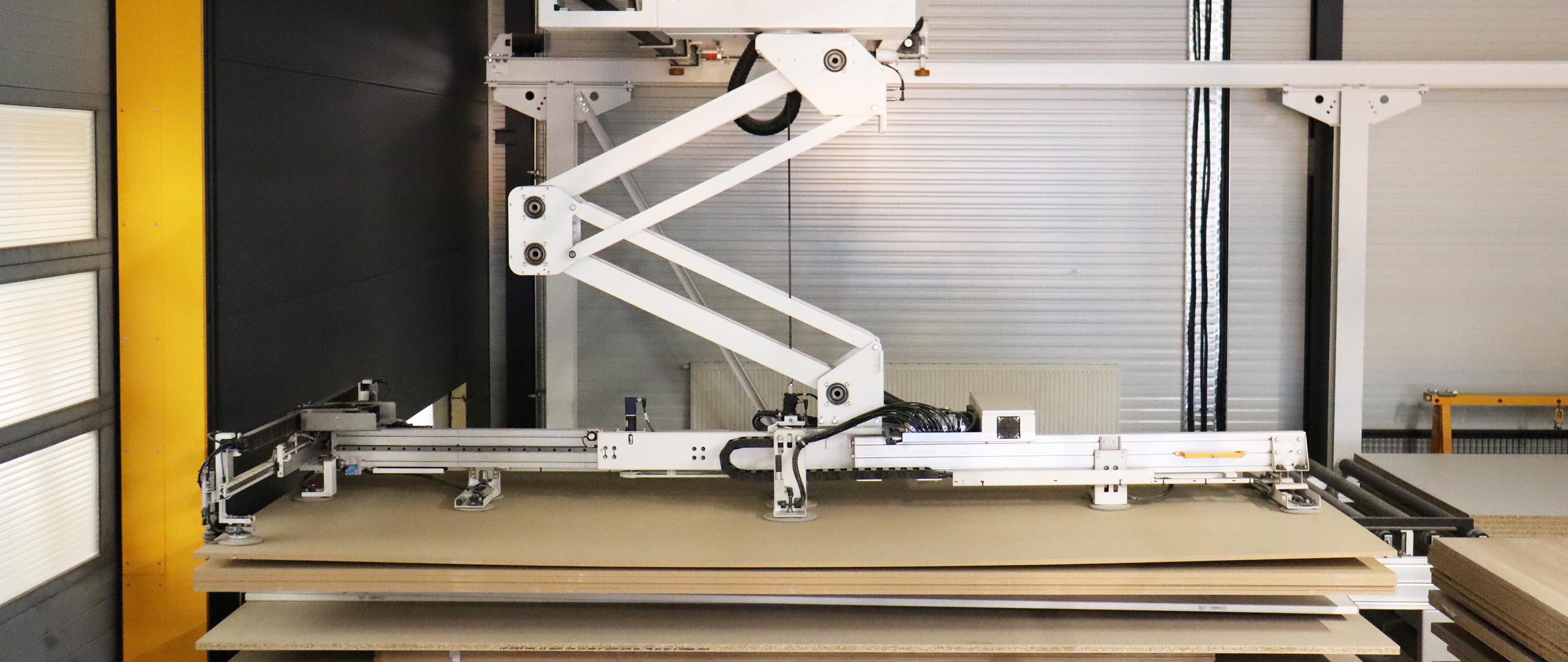

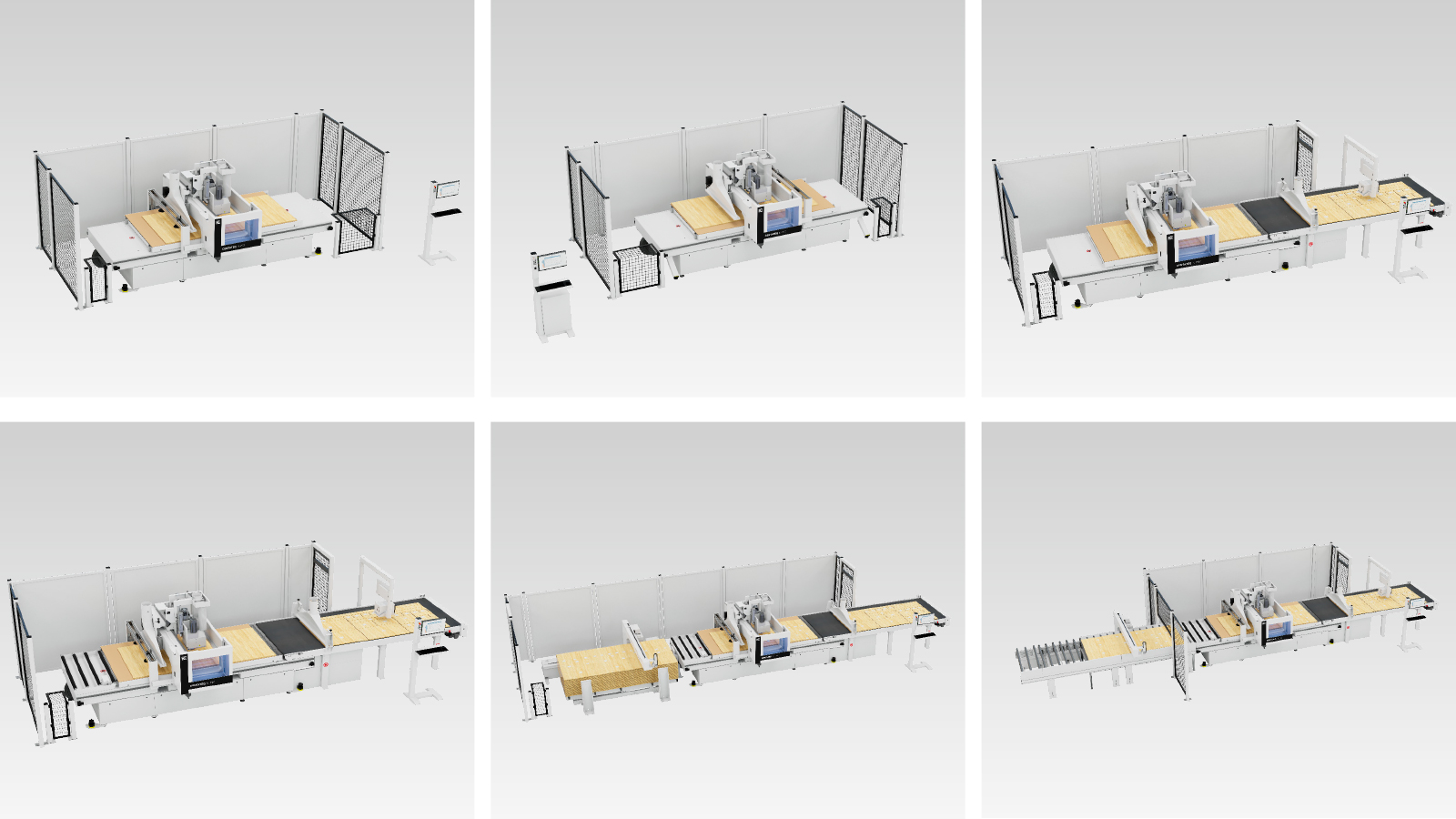

Our plug & play features allow us to gradually expand the machine right from the start. Whether the workpieces are to be fed by hand, roller conveyor, pallet truck or storage - we always have the right concept for your requirements.

Images

Features

-

Compact machine concept with integrated switch cabinet and 25% smaller footprint.

-

Barrier-free safety system without step mats for easy accessibility.

-

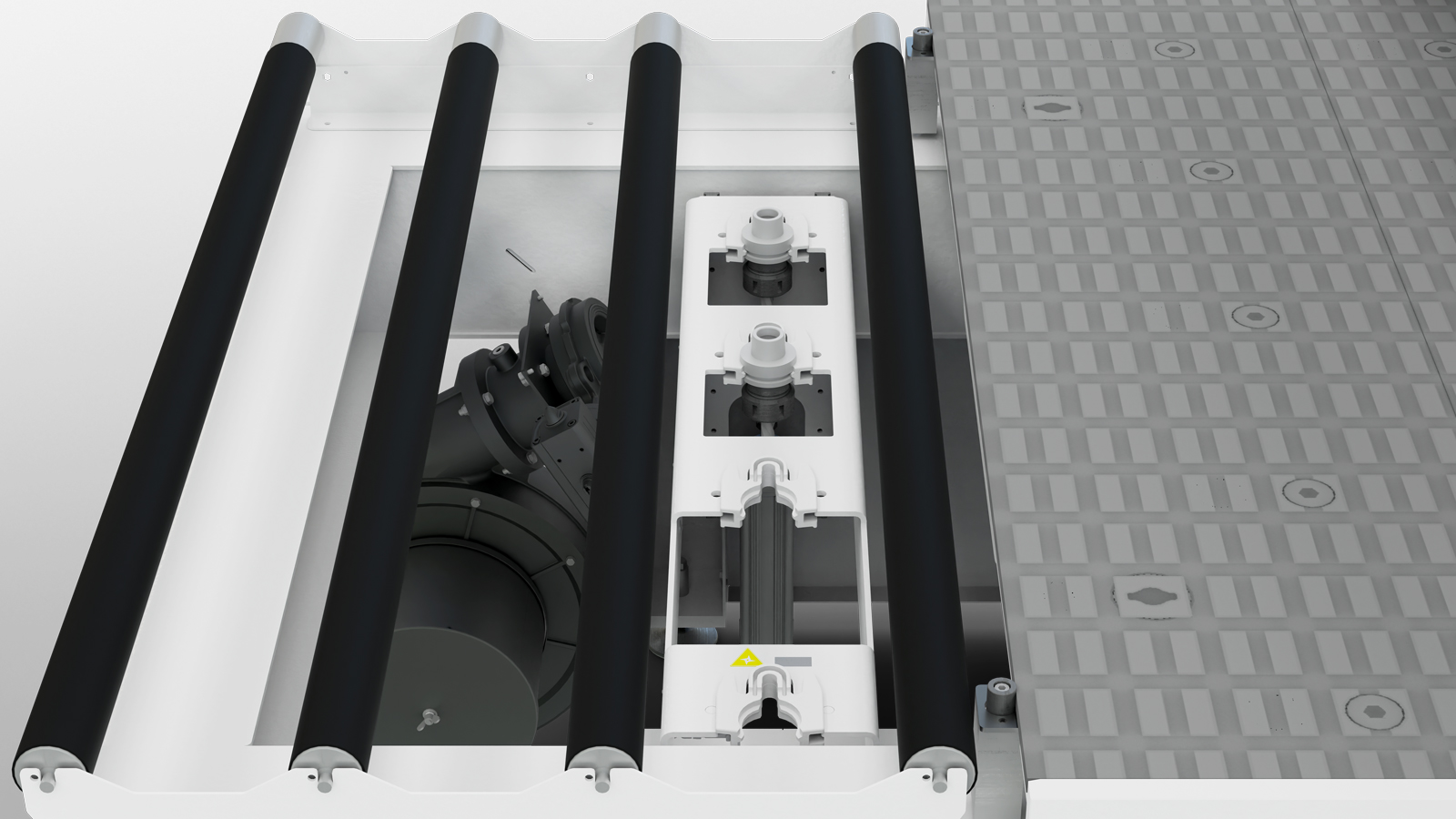

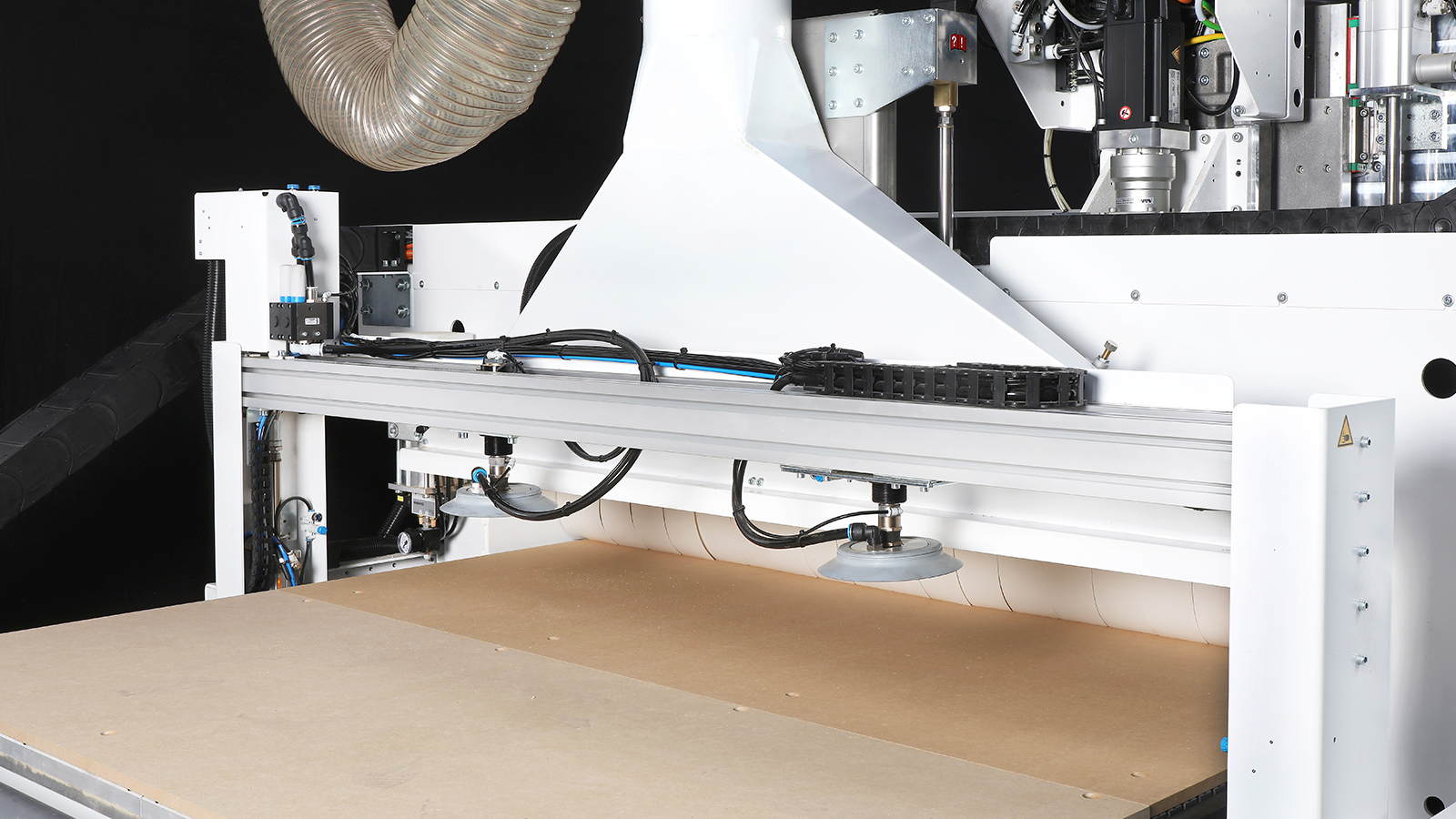

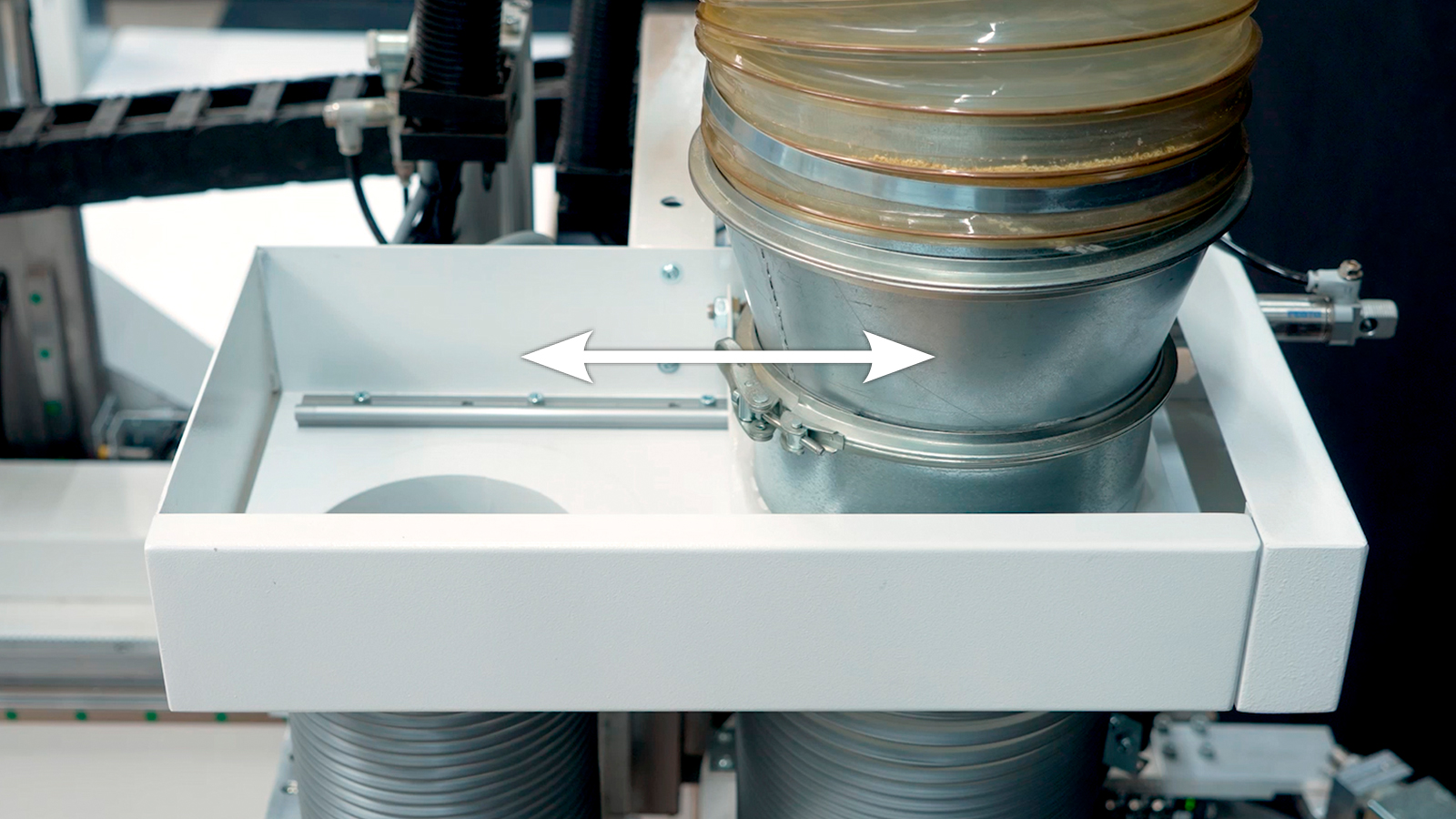

Automatically selectable vacuum field divisions of the table. Adapted to standard market panel sizes.

-

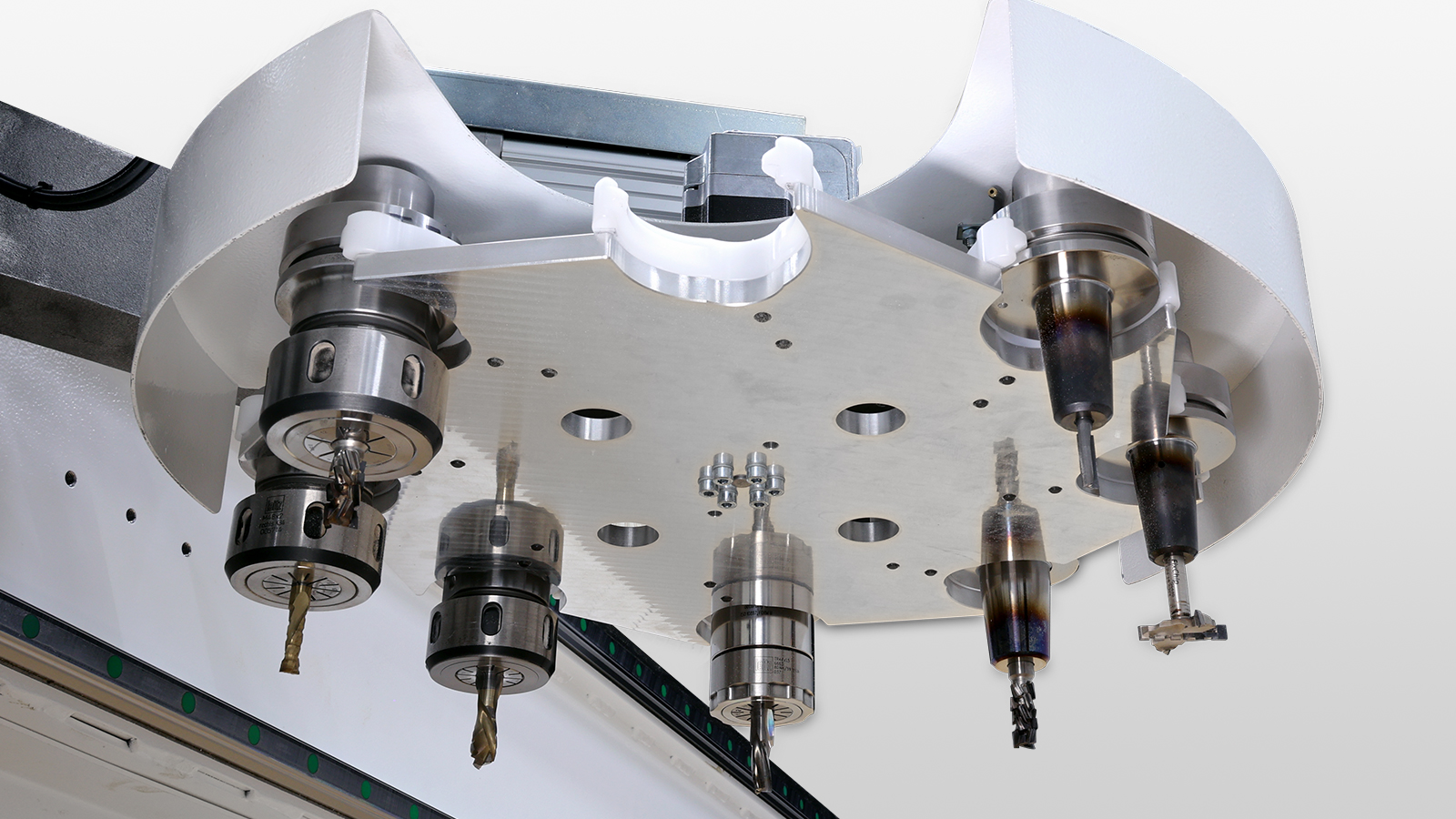

Tool changer traveling in X and Y direction on the main spindle for short tool change times.

-

14 automation options from the stand-alone machine to the fully automated cell.

-

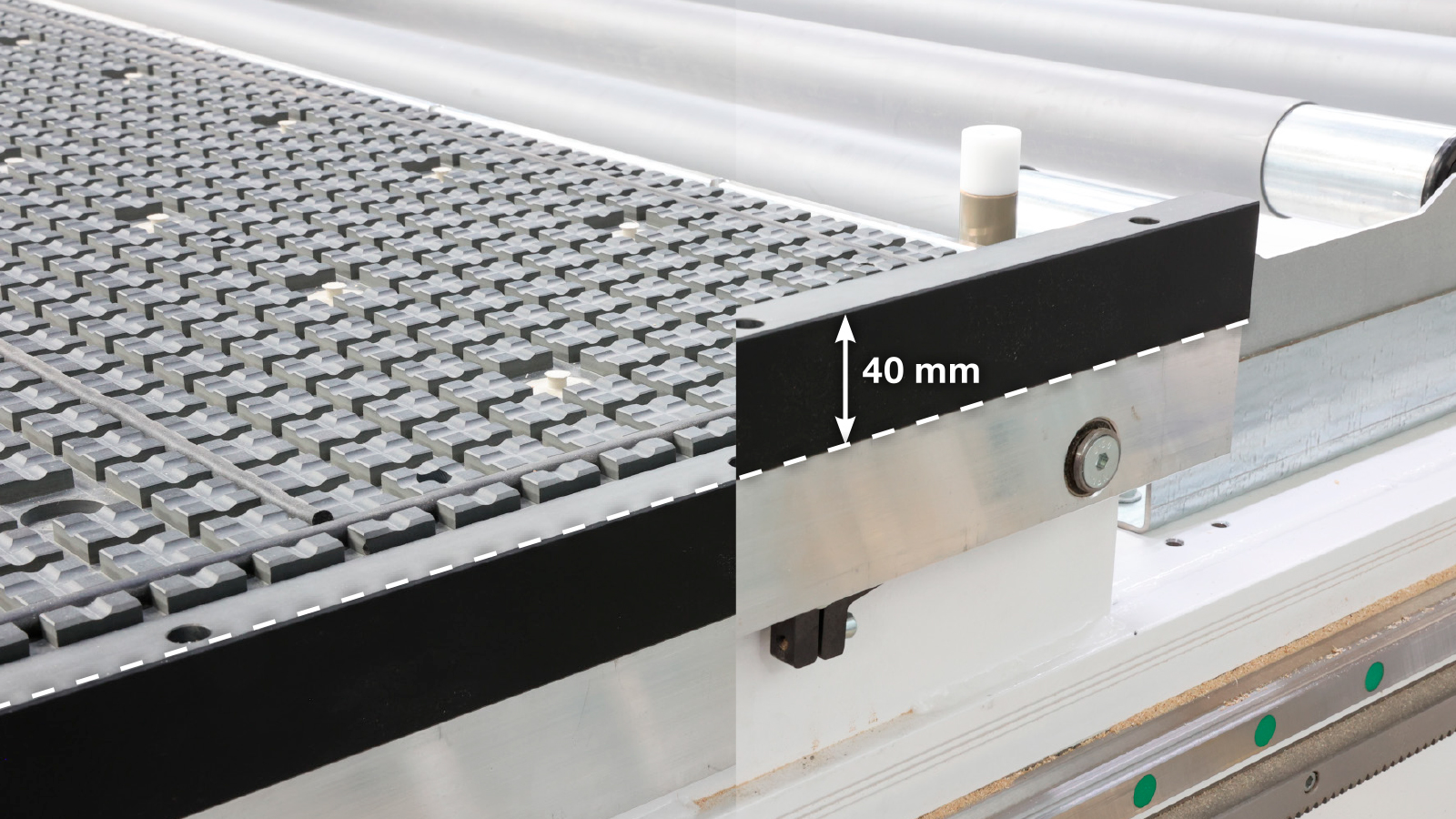

Matrix table - cross-segment positioning of suction cups without restriction.

-

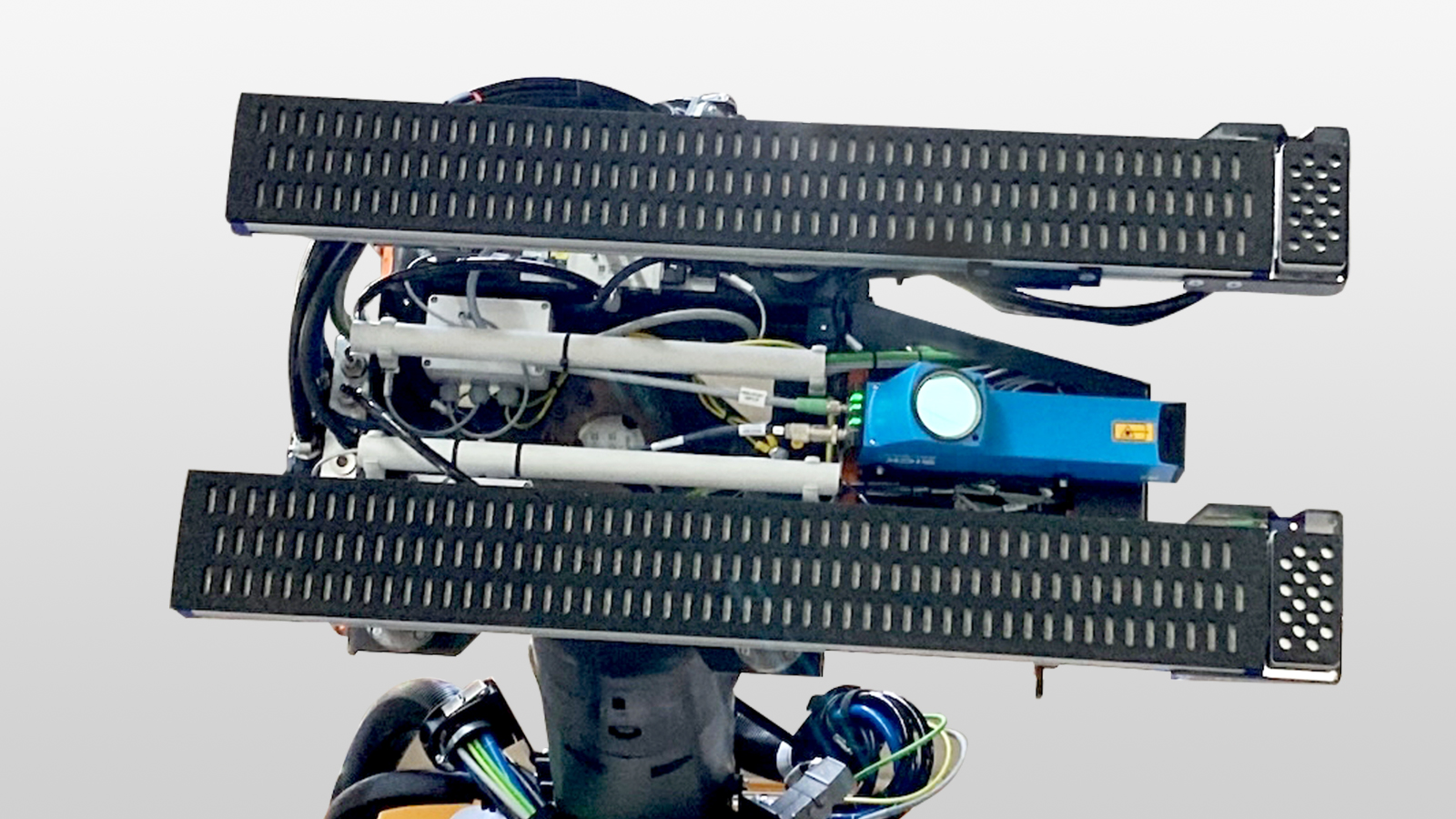

Multi-position suction on the main spindle and drilling gear for easy integration into production and reduced costs for peripherals.

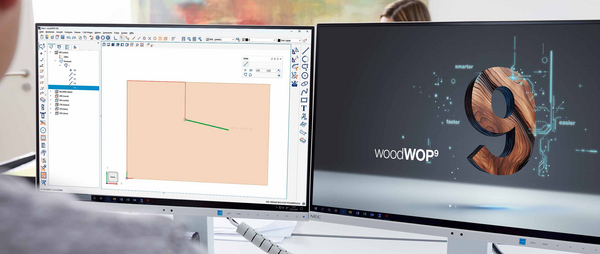

Software

Here's how your colleagues produce

Brochures