Service: Innovations for greater safety, efficiency and digital networking

HOMAG is optimizing the future of wood processing

The wood processing industry is facing new challenges with increasing demands on cybersecurity, the desire for greater efficiency in production and the increasing digitalization shaping the industry. HOMAG Service is responding to these developments with bespoke solutions for modernizing machines, intelligent spare parts management, AI-supported maintenance and a secure remote maintenance solution.

With the latest updates, HOMAG is ensuring the following:

- Greater security and performance — through the cybersecurity update with Windows 10

- Higher efficiency — thanks to faster machines and innovative automation solutions

- Simplified ordering of spare parts — with the integration of eParts into the eShop

- Smart machine monitoring — through predictive diagnostics

- Secure remote maintenance for existing and new machines — with the serviceRemote Bridge

These innovations help customers to operate their machines in a future-proof and cost-effective manner — with the highest standards of productivity, availability and user-friendliness.

The following presents the latest innovations from HOMAG in detail.

Predictive diagnostics

Predictive diagnostics for maximum machine availability

HOMAG is expanding its service offering with an intelligent diagnostic solution

Unscheduled machine downtimes are costly in production. With predictive diagnostics, the new add-on to the HOMAG hotline contract, problems and wear can be detected at an early stage, thereby reducing unscheduled downtimes.

Intelligent data analysis for preventive maintenance

By analyzing machine data, HOMAG can identify potential problems at an early stage and provide individual solution proposals, based on many years of service experience.

Customers receive monthly reports with recommendations for improvements and immediate notifications in the event of an impending production outage. These measures enable HOMAG to contribute to reducing machine downtimes through predictive diagnostics.

This solution is currently available for selected machines in the German-speaking world and offers a smart way to make production more efficient and more predictable. The expansion of this product to other countries is planned for Q3 2025.

New level of remote service with sR Bridge

HOMAG is unveiling a new technology for secure machine networking — HOMAG is launching serviceRemote Bridge to meet the increasing requirements for data security.

The new hardware enables the secure, future-oriented remote maintenance of machines — easy to install and immediately ready for use.

Why serviceRemote Bridge?

Maximum data security — GDPR-compliant and Cyber Resilience Act-compliant solution for secure remote maintenance for new and existing machines

Easy installation — compact hardware that the customer can install and commission itself

Future-proof — replaces the existing remote maintenance solutions and always stays up-to-date with regular software updates

sR Bridge establishes a direct connection between the customer's machines and HOMAG Remote Service. Machine software updates can be easily downloaded online and installed on machines. HOMAG supports customers with detailed installation instructions to make installation easy.

serviceRemote Bridge from HOMAG is a secure, modern and user-friendly solution for the remote maintenance of machines. It enables easy installation and regular software updates for maximum data security. The direct connection between the customer's machines and HOMAG Remote Service enables efficient production, while the customer retains full control of its data and can control the activation, implementation and termination of the remote service itself.

eShop meets eParts

HOMAG is improving spare parts management and linking its time-tested eParts part identification tool with HOMAG eShop which has been in use for over 15 years. This advanced development enables customers to find the right spare parts even faster and order them immediately online. They benefit from full price transparency and exclusive benefits, such as a 3% online discount on spare parts in Germany and Austria, free delivery, express order by 3 pm for next-day delivery and a best-price guarantee. HOMAG guarantees fair prices for genuine spare parts and reimburses 100% of the difference if customers find an identical spare or wearing part cheaper elsewhere. This advanced development is aimed at simplifying the entire ordering process and increasing the efficiency and reliability of production.

Modernization projects

HOMAG supports its customers with innovative modernization solutions to make their machines future-proof — from improved cybersecurity measures to smart automation systems.

Cybersecurity update: Windows 10 for greater security and performance

Security is a top priority, especially in an increasingly networked production environment. HOMAG offers comprehensive modernization on Windows 10 Enterprise LTSC. Selected software components are updated to improve system stability, performance and IT security.

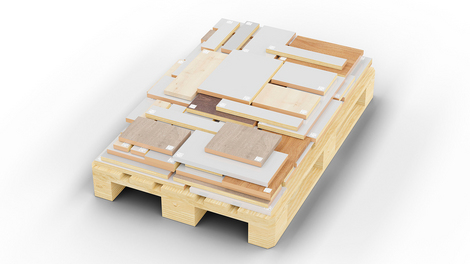

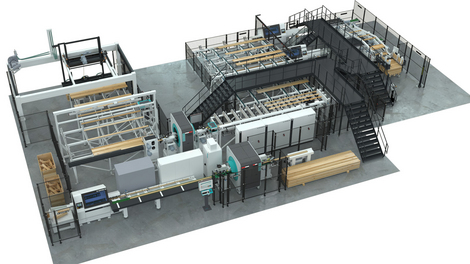

In addition, HOMAG has a wide range of other modernization solutions for existing machine pools. For example, the machine processes on the SAWTEQ panel dividing saw with integrated STORETEQ storage system, can be specifically optimized — with cutting cycles that are up to 7% faster for noticeably higher productivity.

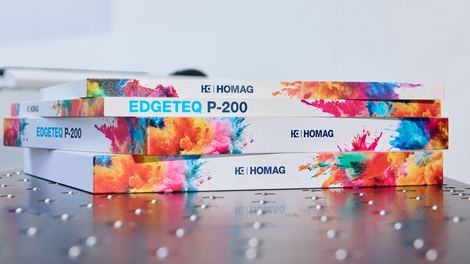

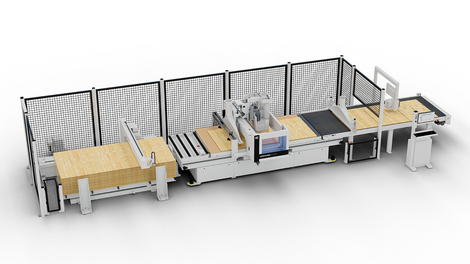

For EDGETEQ edge banding machines, HOMAG offers solutions in all performance and automation levels — from workpiece return to fully automatic destacking systems.

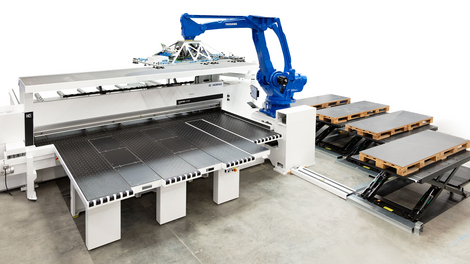

Even more efficiency can be achieved by using modern robotics, especially in CNC processing cells. Robot cells enable high-availability production, improve ergonomics and process reliability, reduce damage to parts and ensure continuous production.

These solutions show that HOMAG is setting new standards for safe, automated and economical production.