New woodCommander6 software generation

WoodCommander6: The simplest edge control system ever

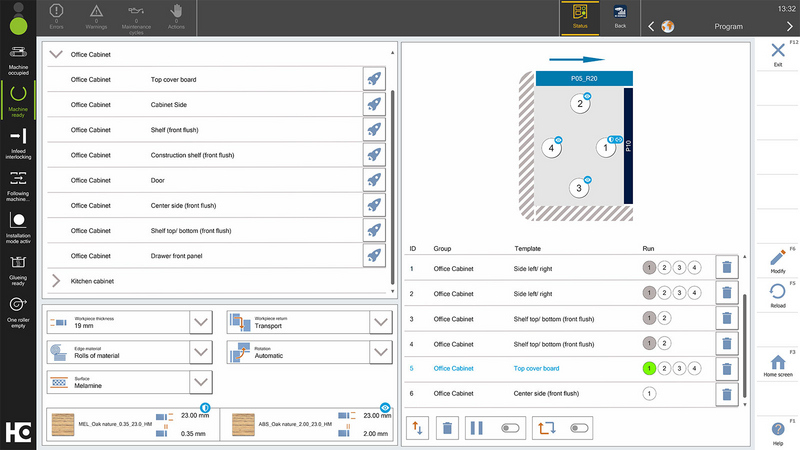

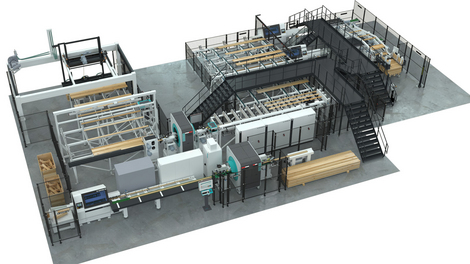

The new generation of woodCommander 6 software is the simplest edge control system ever. It is designed to select processing programs and edge material and enables the reliable and fast recording of production parameters as well as the workpiece-oriented creation of machine programs. With clever grouping of levels of information, fewer clicks are required to produce the desired results. Relevant parameters can be displayed dependent on the situation. Preview images from the 3D simulation enable faster program changes.

The real 3D workpiece simulation, the display of the dimensions directly on the 3D workpiece and the automatic check of impermissible parameter combinations lead to a high level of operating safety. Having fewer test workpieces also results in time and cost savings. The processing steps resulting from the simulated effect on the workpiece as well as the switchable tool track must be captured at first glance.

The machine operator has enormous flexibility thanks to the user-specific arrangement of parameters, the integrated user rights management and widgets for programs or edge material, for example.

What's new is that the operator only needs to know his workpiece; woodCommander 6 does everything else. This is our way of dealing with the current shortage of skilled workers. The new software eliminates the need for presorting workpieces, increases efficiency, saves costs and increases quality through fewer errors. It is based on the workpiece instead of the throughfeed, while linking edges and processing programs reduces the number of clicks required. Even inexperienced operators can master complex machines by simply selecting the workpiece information, which considerably reduces the entry barrier.

NEW: Simple user interface

The reduced user interface enables even inexperienced operators to operate highly automated machines safely and efficiently. This innovation aims to support operators without the necessary qualifications in different countries and industries.

The implementation of a lowest user level, which only displays basic editing programs and blocks access to additional functions, ensures that only authorized personnel can change settings. This means that even inexperienced operators can operate the machine reliably and efficiently.

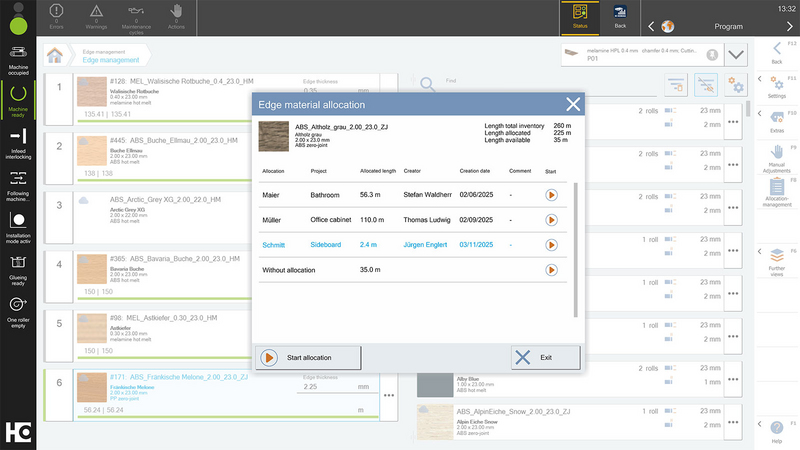

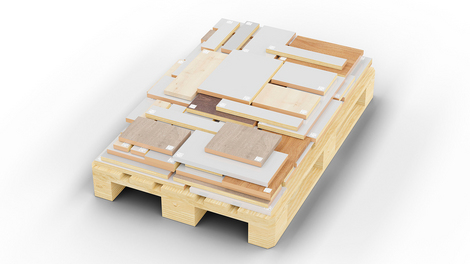

NEW: Allocate edge material

The situation often used to arise that the edge material for a planned piece of furniture was already processed for another job before the job started. This problem is now a thing of the past.

The new function enables you to allocate edge material for your projects. This ensures that the material is available for the specific order and not used elsewhere. As soon as a roll of the allocated edge material is inserted in the machine, the operator receives a prompt. The operator can decide whether they want to process the allocation or use the remaining available material. This function ensures that every order is processed with the right materials, exactly as the customer wants.

The new function offers increased security and efficiency in order processing by ensuring the availability of the required material and improving the quality of the end products.

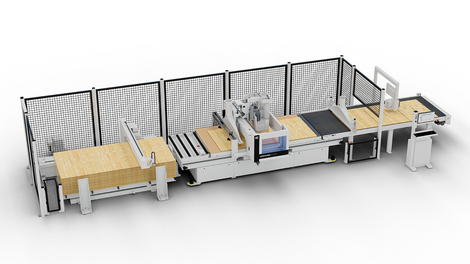

NEW: HOMAG Select

The new production software sets standards in the manufacturing industry and enables more efficient, user-friendly production of workpieces.

It is no longer necessary to have specific experience of a machine. The focus is on workpiece orientation, which makes the production of workpieces considerably easier. In addition, the software enables the simple, intuitive creation and management of workpieces (digital twin) with no data connection.

Thanks to the categorization of workpiece templates according to customer-specific production or design philosophy, it is possible to start workpieces with just one click. The workpieces and their feed are visualized, including the edges and processing steps used. A new production list also provides an overview of all workpieces being processed and shows the current processing status for each workpiece.

The intelligent, fully automatic selection of programs and processing parameters rounds off the functionality of the software.