CNC machining centers, CNC processing centers and CNC routers for woodworking

Freestyle Technology – The New CENTATEQ P-110

Read more!CNC Machining Centers

Filter

0 results

No matching products found

CNC Machining Centers

If you want to buy a new or used CNC router, you expect the machine to solve your manufacturing challenges. HOMAG CNC machining centers offer cutting-edge technology from the world market leader for all woodworking technology for manufacturers of all sizes.

The world market leader HOMAG presents its CNC processing centers:

We offer superior technology and equipment for the highly efficient production of furniture, interior fittings, construction elements, and millwork, for panel processing, plastics and solid wood processing.

Advantages of our CNC machining centres

- The right clamping system for every task:

console or flat table, grid table, clamping table, multi-table, twin table, pod and rail table, console table - Available in 3, 5, or 5 axis options

- Heavy machine frame made of a welded steel construction and stable mobile gantry construction

- Scalable performance through customized assembly of the CNC machining center with milling spindles, drilling gears and tool changers.

- Quick and easy access to the processing units and aggregates.

- Maximum visibility into the machine during processing, while at the same time providing protection and reliable safety features for the operator

- Easy refilling of hot melt glue adhesive

- Easy and quick loading and exchange of edging materials

- Energy-efficient extraction with low connection power

- Reduced power consumption through stand-by operation at the touch of a button

Fields of application of a CNC machining center

With our CNC woodworking machines we offer YOUR solution. With a CNC machining center from HOMAG, you are perfectly prepared for all tasks.

- staircase production

- furniture production

- kitchen and bath cabinets

- millwork

- window production

- door production

- formed parts

- interior finishing

- plastics processing

Equipment features of our CNC routers

As different as the required production demands are, so wide is the range of equipment features and technology. We are able to offer you everything to get the most from your machinery: from tool changers, aggregates, edge processing, console tables, grid tables, vacuum suction cups to tailor-made clamping solutions for our CNC router.

Process technologies:

- sawing

- cutting

- connecting

- separate

- milling

- drilling

- glue edges

- edge finishing

- measuring

- 3D machining

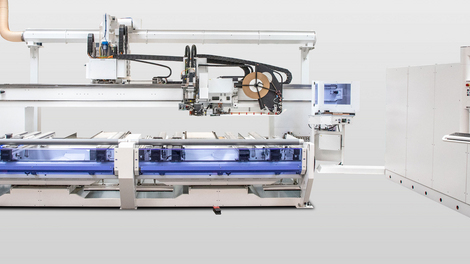

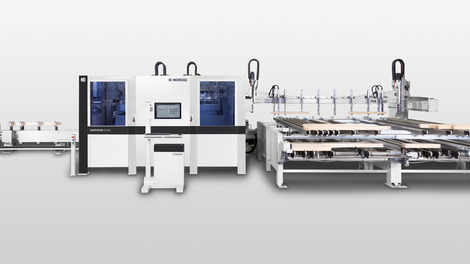

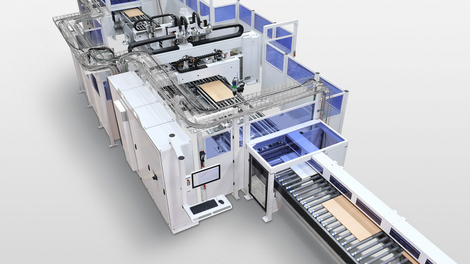

Automation of your CNC machining center

With intelligent solutions, we are able to help you extend your CNC machining center into manufacturing cells with automatic material handling and more. From entry into automation to unlimited workpiece handling:

- attached loaders/feeders

- robot handling

- labeling

- production cell control

- plant visualization/system visualization

Partnership, solution-oriented, innovative - CNC machining centers from HOMAG.

CNC Machining Centers

CNC Processing Center Greda Poker V5

- Hopper feeder and automatic unloading system.

- Full 5-axis machining allows for limitless processing.

- Sanding heads provide finished part quality.

CNC Machining Centers

CNC Processing Center Greda Mitika V5

- Hopper feeder and automatic unloading system.

- Full 5-axis machining allows for limitless processing.

- sanding heads provide finished part quality.

CNC Machining Centers

CNC Machining Center Greda Venus

- 4 working stations for high volume production.

- Configurable with a variety of aggregates.

- Fully enclosed working center.

CNC Machining Centers

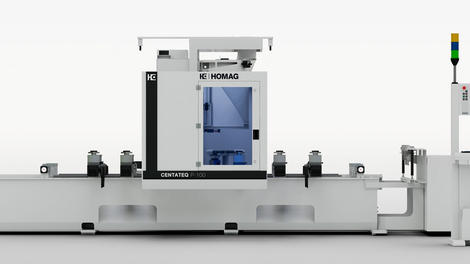

CNC Processing Center CENTATEQ P-100

- Universal CNC technology with 3, 4 or 5 axes

- Flexible cantilever design

CNC Machining Centers

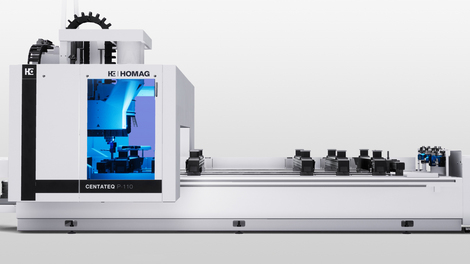

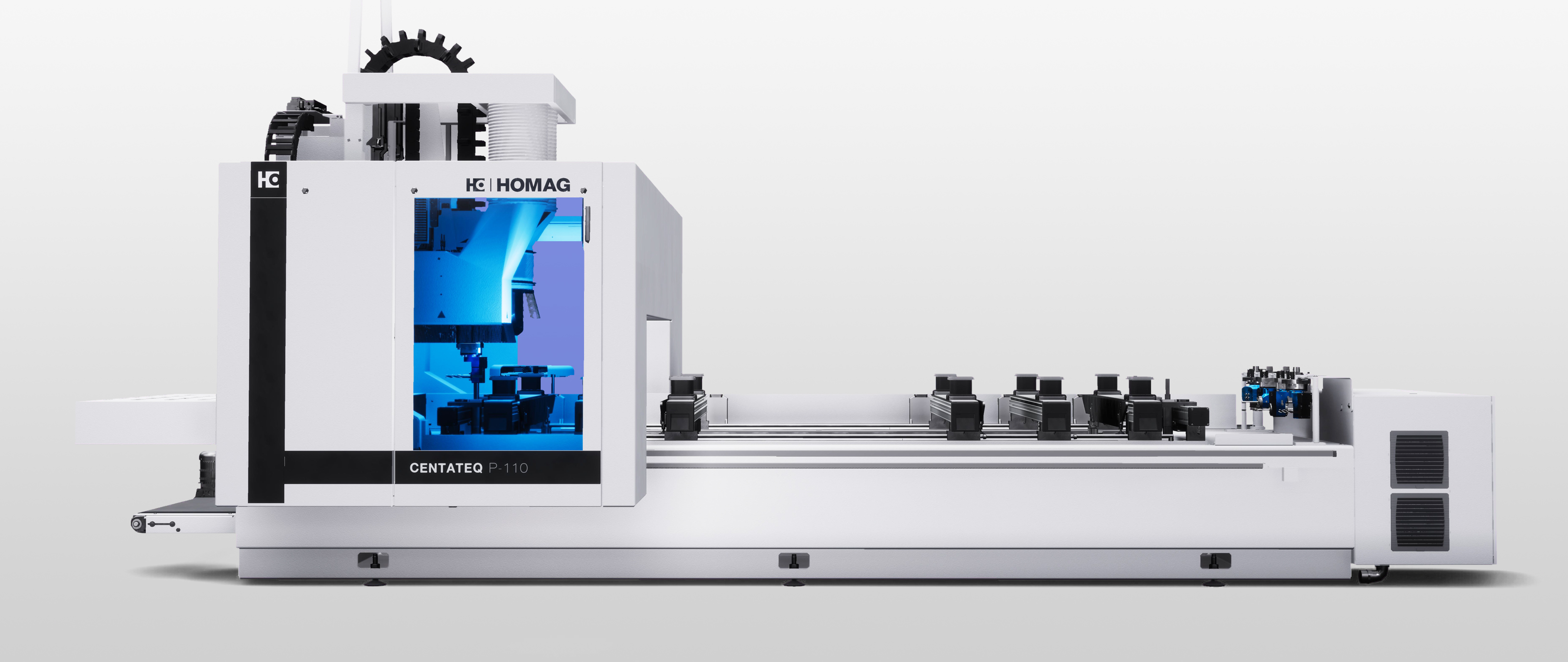

CNC Processing Center CENTATEQ P-110

- Universal CNC technology with 3, 4 or 5 axes

- Completely free accessibility for optimum operation

- Stable moving gantry design

Bestseller

CNC Machining Centers

CNC Processing Center CENTATEQ P-210

- Flexible CNC technology with 3, 4 or 5 axes

- Gluing technology and automation available for the trade

- Stable moving gantry design

CNC Machining Centers

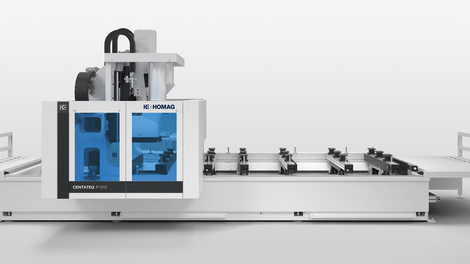

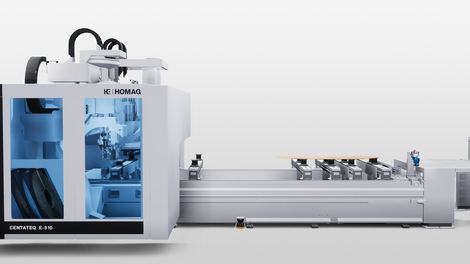

CNC Processing Center CENTATEQ P-310 | E-310

- Processing options from 5-axis to edge

- Scalable in performance, easy to operate

- Performance and convenience combined in one machine

CNC Machining Centers

CENTATEQ P-510|610 + E-510 processing centers

- High-end CNC processing centers with SORB TECH machine body for the highest demands

- Individually configurable according to your needs

CNC Machining Centers

CENTATEQ E-700 processing centers

- High-performance edge banding on two processing tables

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-100

- Enable optimized processing of panel materials

- Various possibilities for the automation of material handling

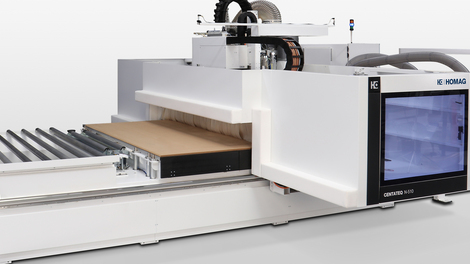

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-210

- A new take on nesting processing.

- 3- and 4-axis machining

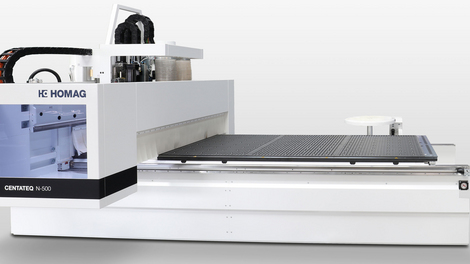

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-500

- Compact class Flexible handling concepts 3-, 4-axis machining

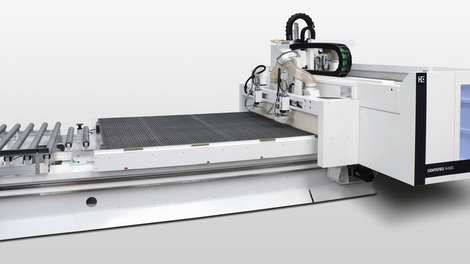

CNC Machining Centers

CNC Gantry-Processing Center CENTATEQ N-510

- Where the top class starts – more flexibility, maximum efficiency

- 3, 4 or 5-axis processing

- Z-height up to 260 mm

CNC Machining Centers

CNC-Gantry Processing Center CENTATEQ N-600

- Nesting with 3-, 4- or 5-axis technology

CNC Machining Centers

CENTATEQ T-Series processing centers

- Synchronous or parallel processing on two processing tables

CNC Machining Centers

CENTATEQ S-800|900 processing centers

- Solutions for complex requirements in window production

- From the individual machine to the connected cell

CNC Drilling and Routing Machining Centers

Vertical CNC Processing Center DRILLTEQ V-200

- A flexible all-rounder for processing in just 5 m²

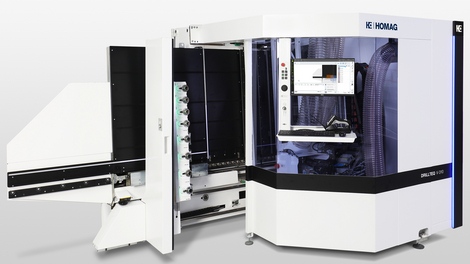

CNC Drilling and Routing Machining Centers

DRILLTEQ V-310 vertical CNC processing center

- Maximum cabinet processing. Minimum space requirements. A space-saving miracle that requires just 11 m² of floor space.

Bestseller

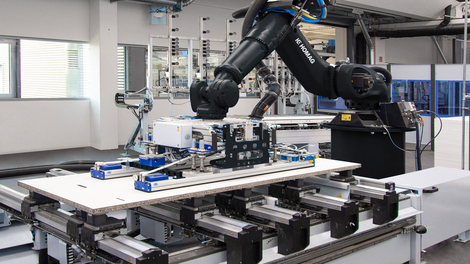

Robot Solutions for the Furniture Industry

Robot FEEDBOT C-300

- Add-on for a CNC-processing center

- Safe, precise, automatic handling of workpieces for more efficient production

- Production cell with a robot for automatic material handling

CNC Automatic Drilling and Fitting Machines

Throughfeed machining centers for drilling and fitting setting technology for industrial batch size 1 machining. Individually configured to the requirement, for drilling, milling, fitting setting.

- Reliable technology designed for continuous operation

- For sides, bottoms, fronts, to ensure parts are ready to install with all necessary fittings

- Scalable performance due to multi-stage machining and distribution of work contents to several machining stations

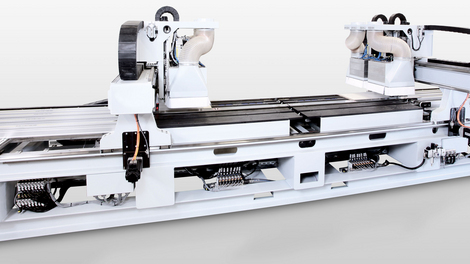

CNC Automatic Drilling and Fitting Machines

Throughfeed Processing Centers DRILLTEQ L-200

- Ideal for the cabinet side processing

CNC Automatic Drilling and Fitting Machines

Throughfeed Processing Center DRILLTEQ L-500

- 6-sided processing without compromises

CNC Drilling and Dowel inserting Machines

Our HOMAG DRILLTEQ D drilling machines have mainly 2 tasks: Horizontal drilling and doweling. They are fast, reliable and easy to operate

Advantages of our drilling and dowel inserting machines:

- Uniform woodWOP programming for all CNC machines

- intelliGuide operator assistance system with LED light bar for displaying the workpiece contact positions

- Expandable with units for drilling in the surface and for horizontal and vertical milling

- Simple program selection via barcode scanner

- Reliable technology for gluing with automatic cleaning and program-controlled glue quantity

- Precise machining due to continuous support on the smooth machine table

Fields of application of the drilling and dowel inserting machines

With our machines we offer you the right solution for every challenge:

- Flat drilling operations

- Classic dowel hole drilling in the front face

- Continuous back wall groove

- Drilling machining to complement a nesting machine

- Flat milling machining for integrated and high-quality hinges or fittings

CNC Drilling and Dowel inserting Machines

Boring Machines Ironwood BR Series

- Versatile Drilling.

- Enhanced Safety Features.

- Easy Tool Change.

CNC Drilling and Dowel inserting Machines

CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-110

- Horizontal drilling and doweling

CNC Drilling and Dowel inserting Machines

CNC-Dowel hole drilling machine DRILLTEQ C-100 NBS 033 (India)

- Perfect dowel hole drilling with our DRILLTEQ C-100 NBS 033

CNC Drilling and Dowel inserting Machines

CNC-Drilling and Dowel Inserting Machine DRILLTEQ D-510

- Horizontal drilling, doweling and milling

- Vertical drilling, milling

- Special configuration for inclined machining between 42° - 45°

Results from 0 to 0 of 0