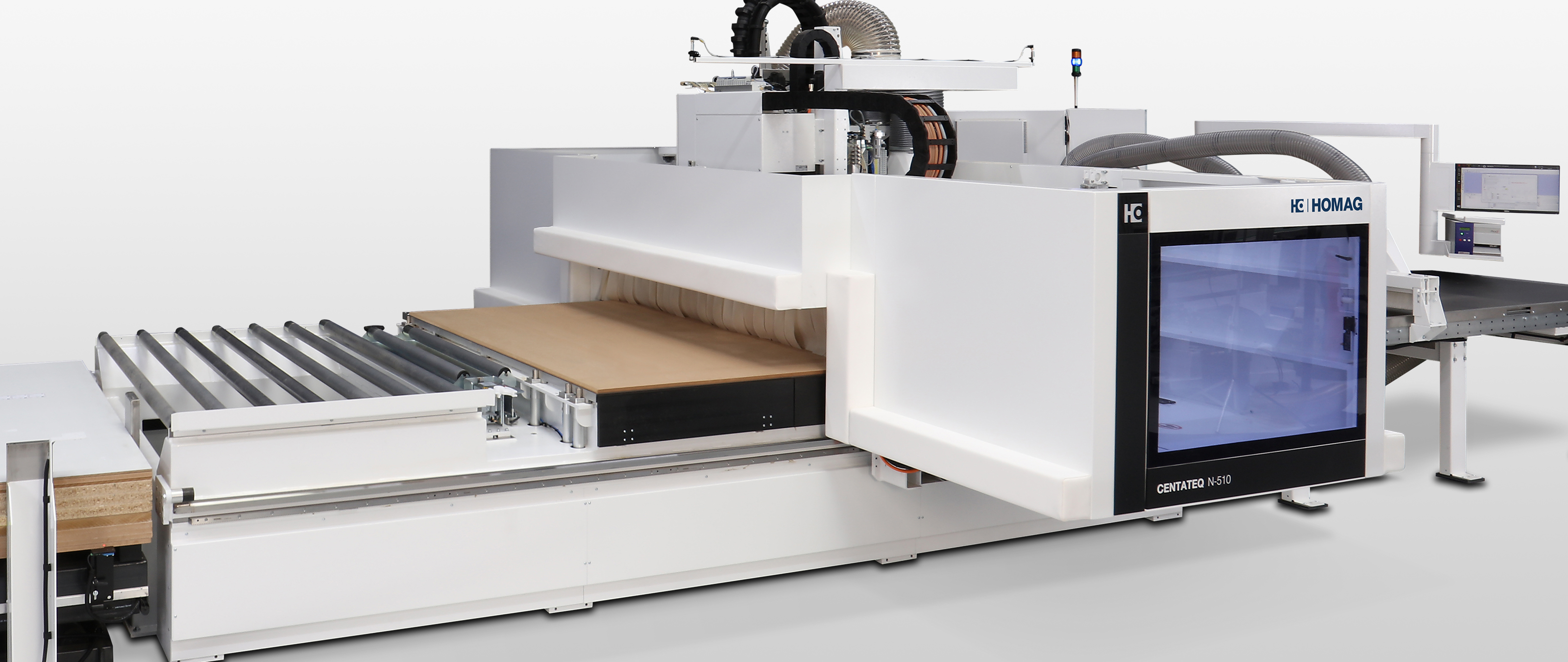

CNC Machining Centers CENTATEQ N-510

CNC Machining Centers CENTATEQ N-510

The individual nesting concepts for the top class

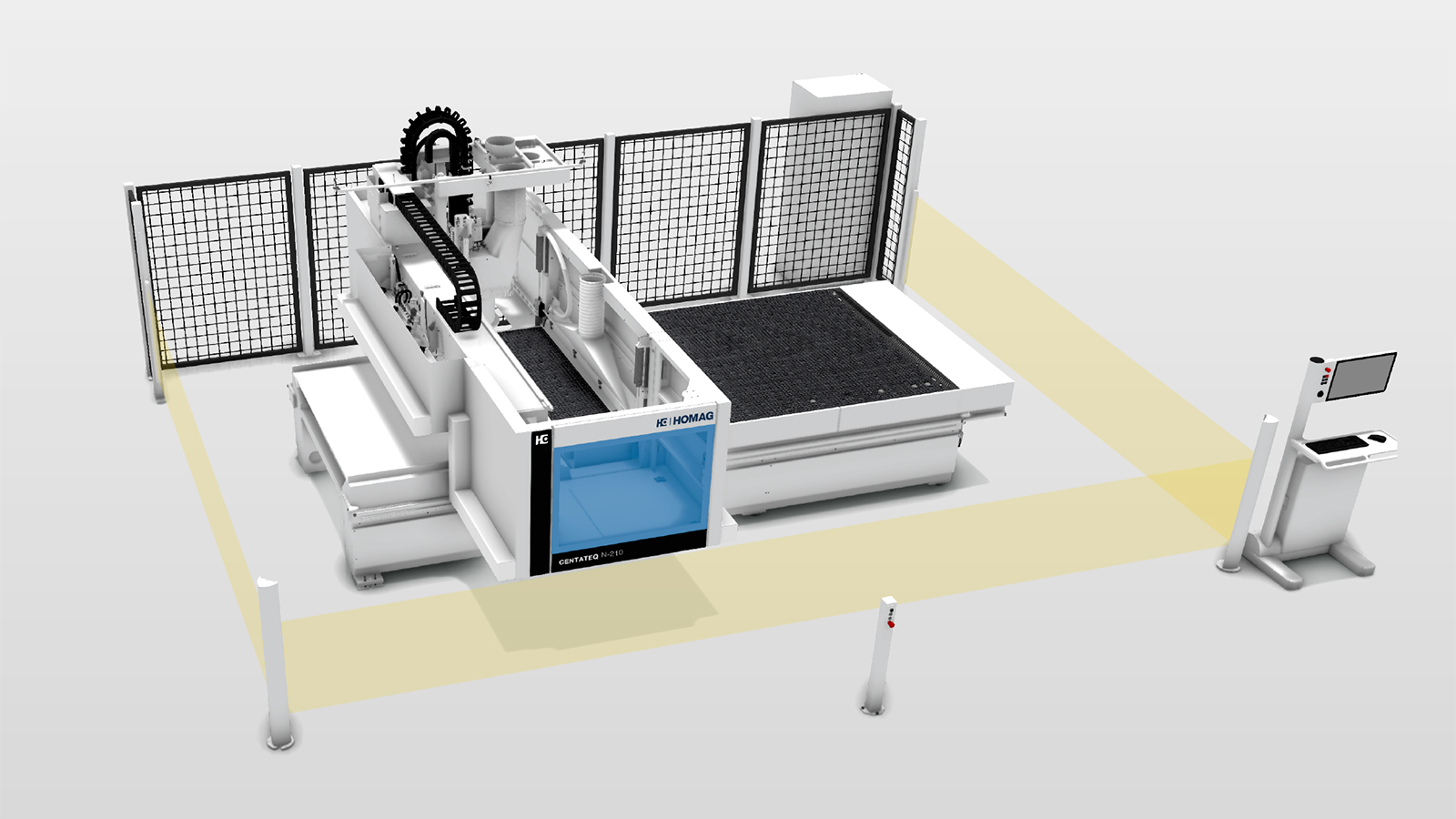

Our nesting machines enable waste-optimized processing and dividing of panel-shaped materials. The classic area of application is the production of carcass furniture or the dividing and finishing of furniture fronts. The machine offers further flexibility when processing individual parts on vacuum clamps. Automation concepts that are easy to connect via Plug & Play offer the option of retrofitting the machine. Differently equipped drilling gears and tool changers offer a high degree of versatility.

Highlights

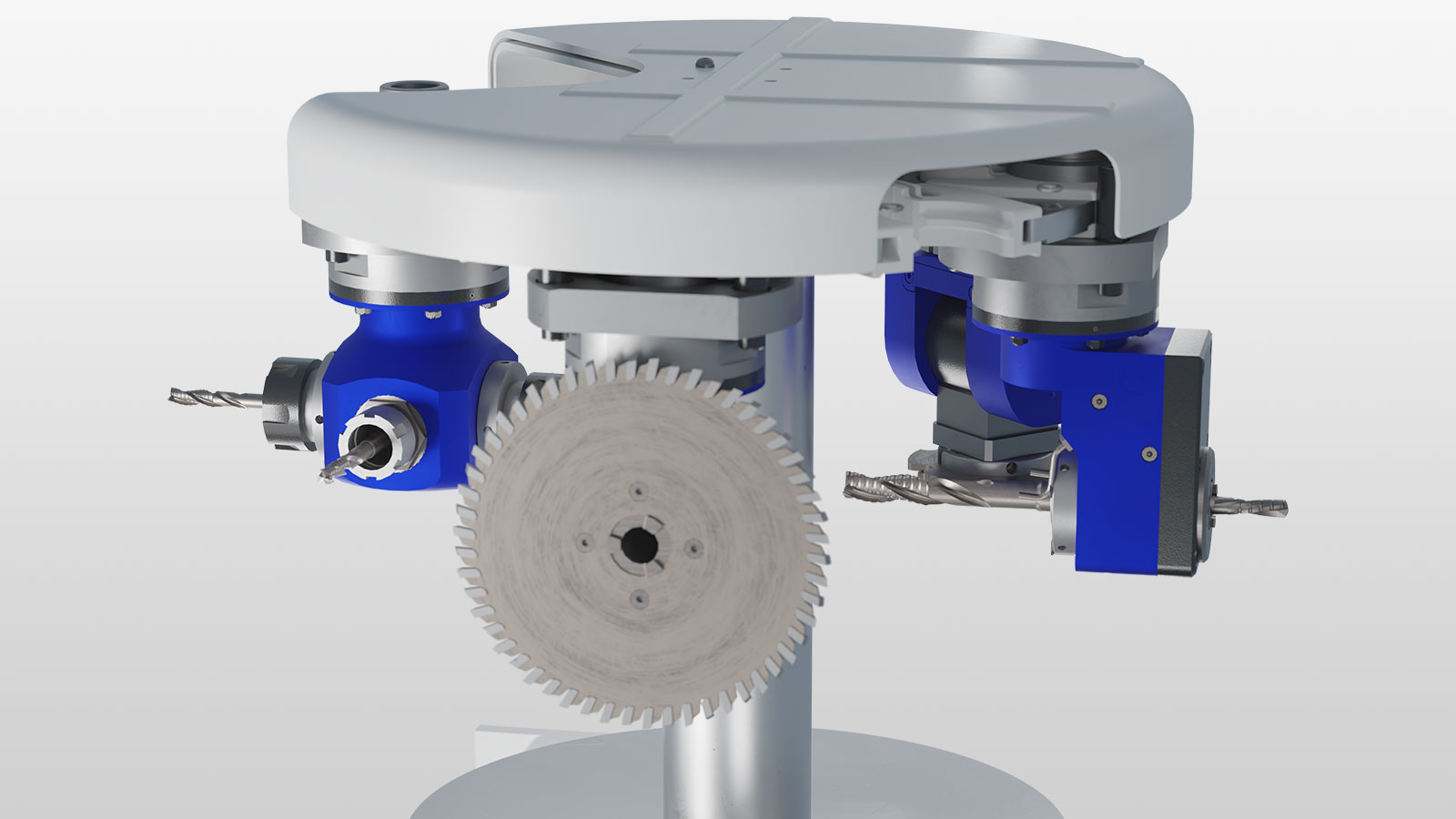

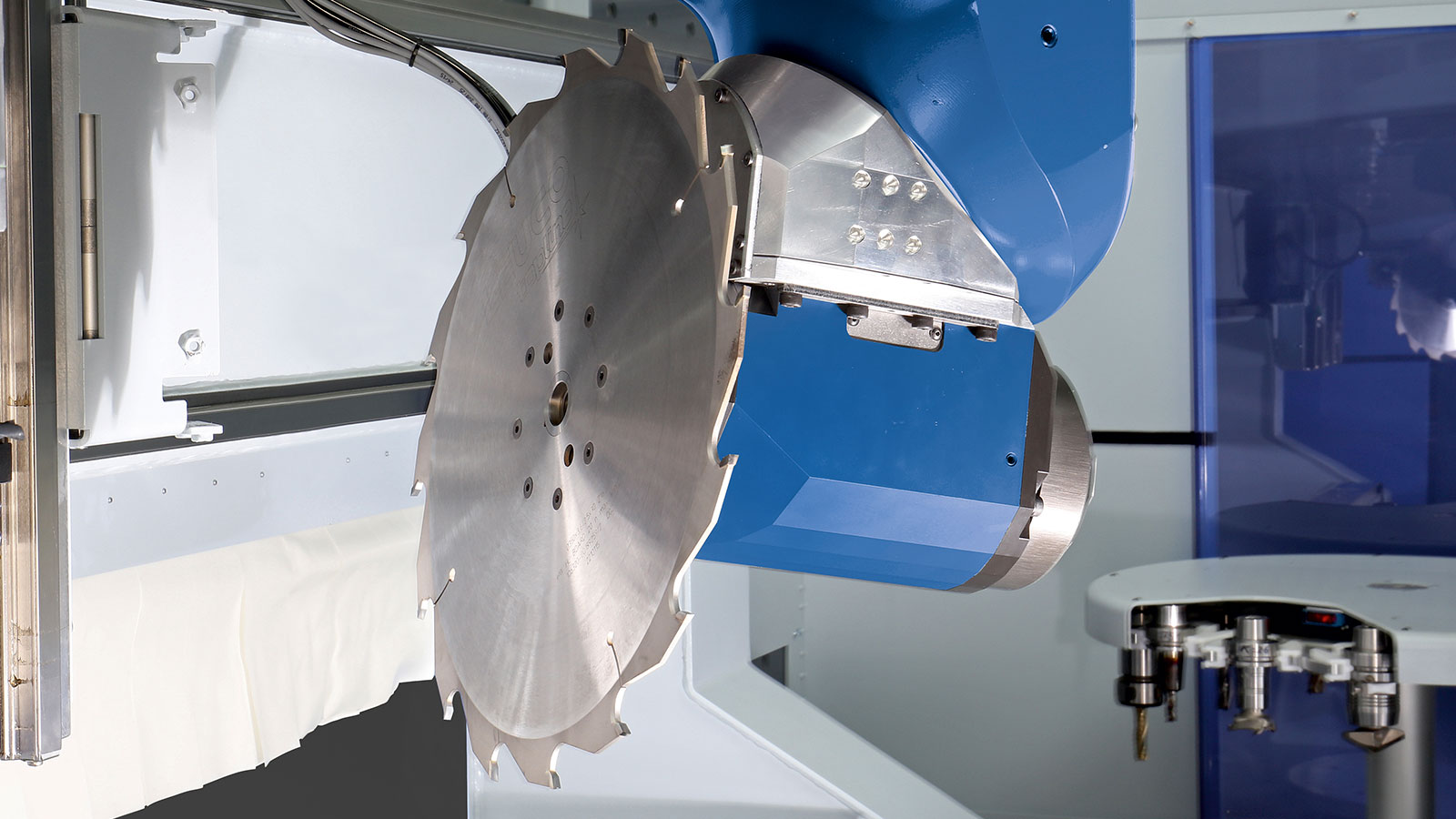

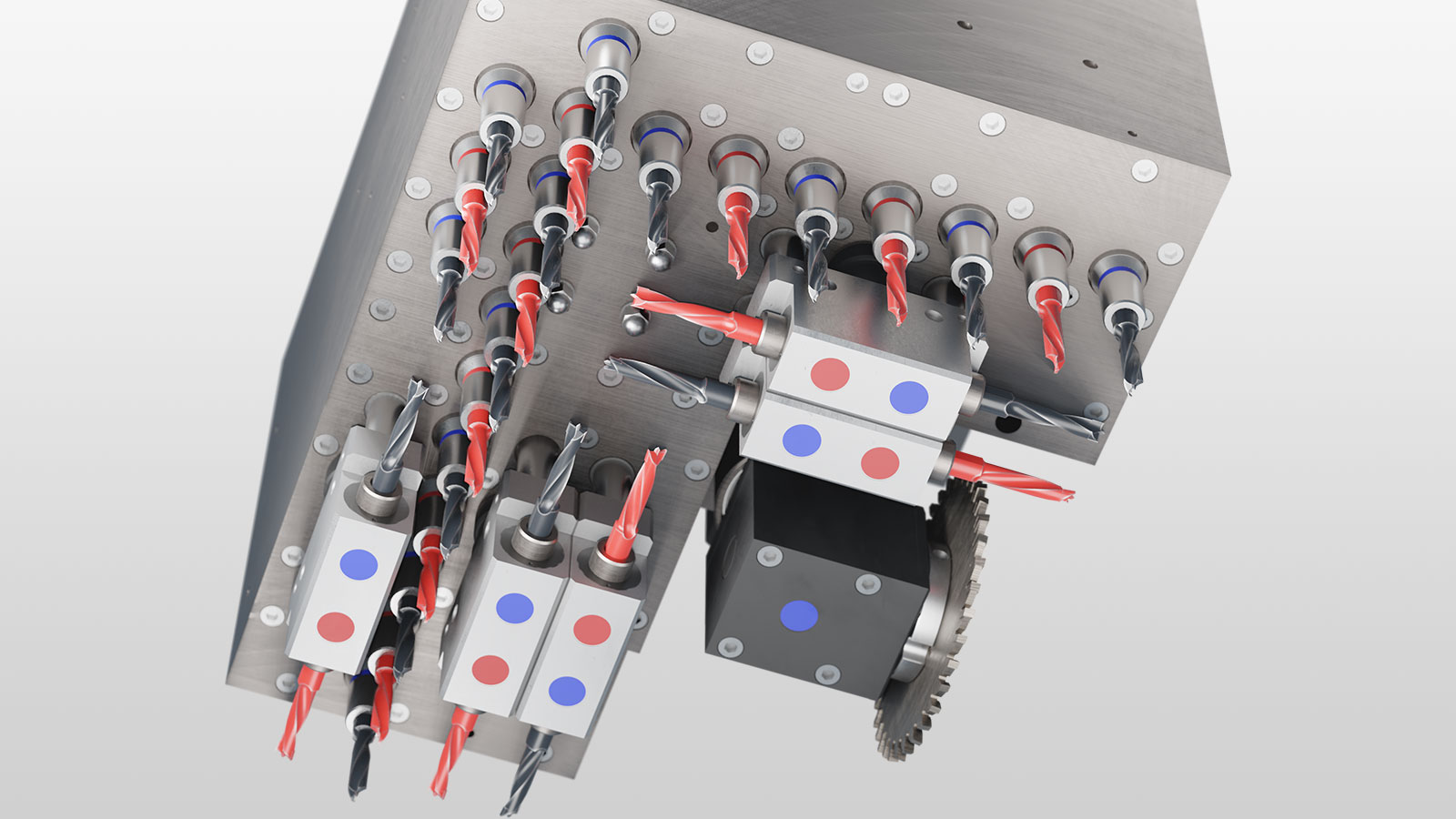

18 DIFFERENT DRILLING GEARS - Various combinations of vertical and horizontal spindles and grooving saws are possible.

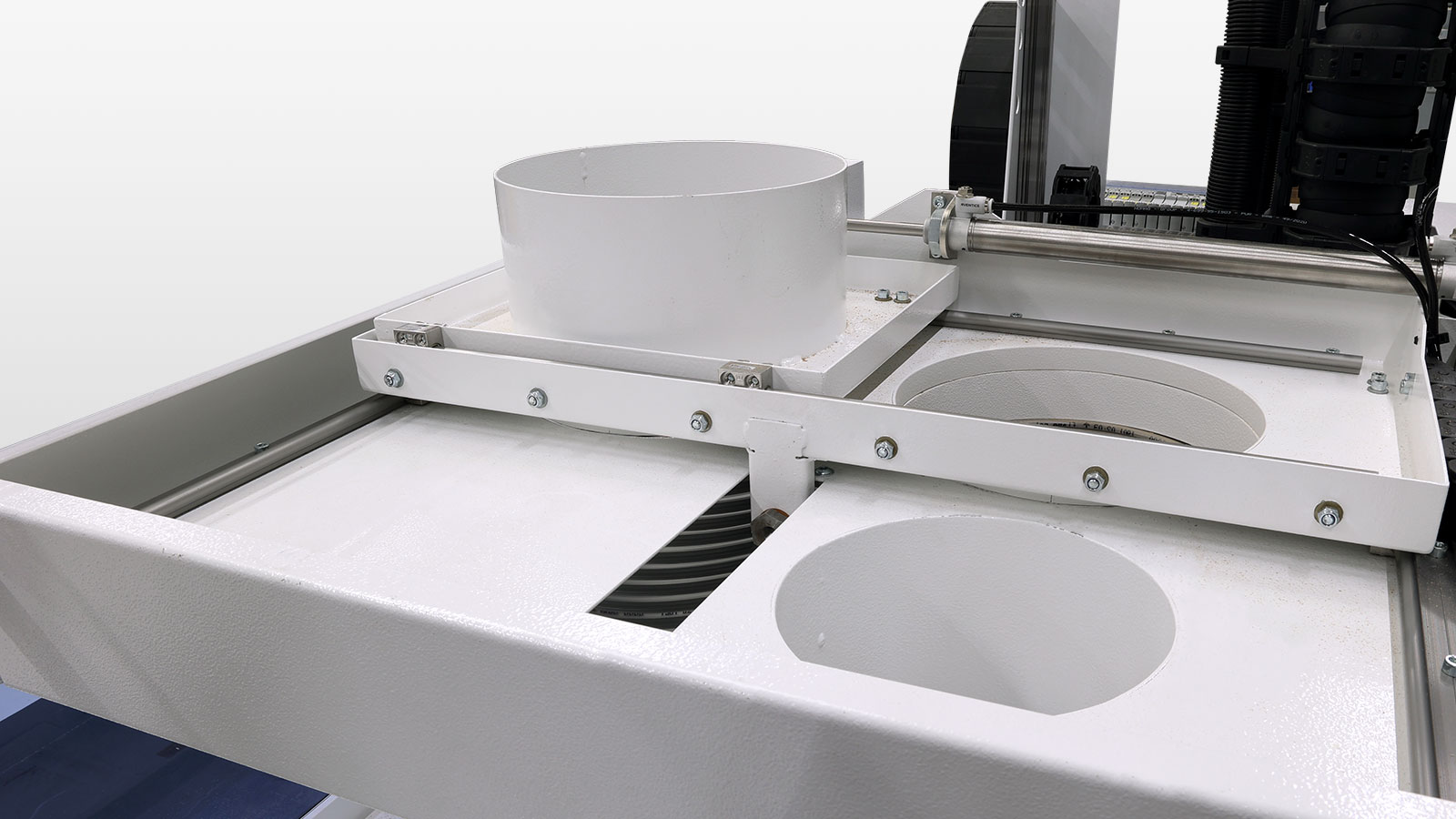

Multi-position extraction for simple integration into production and reduced costs for peripherals

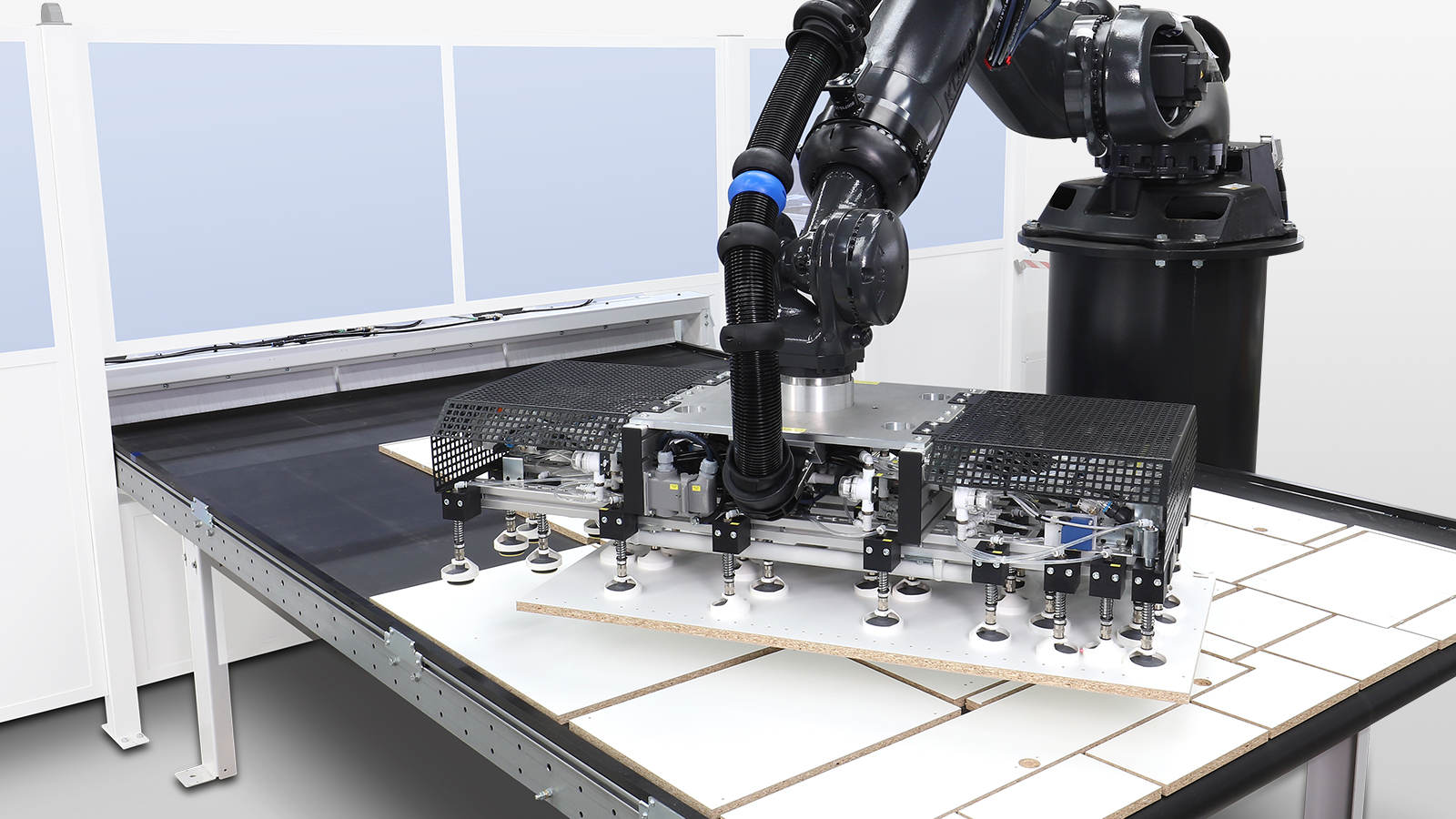

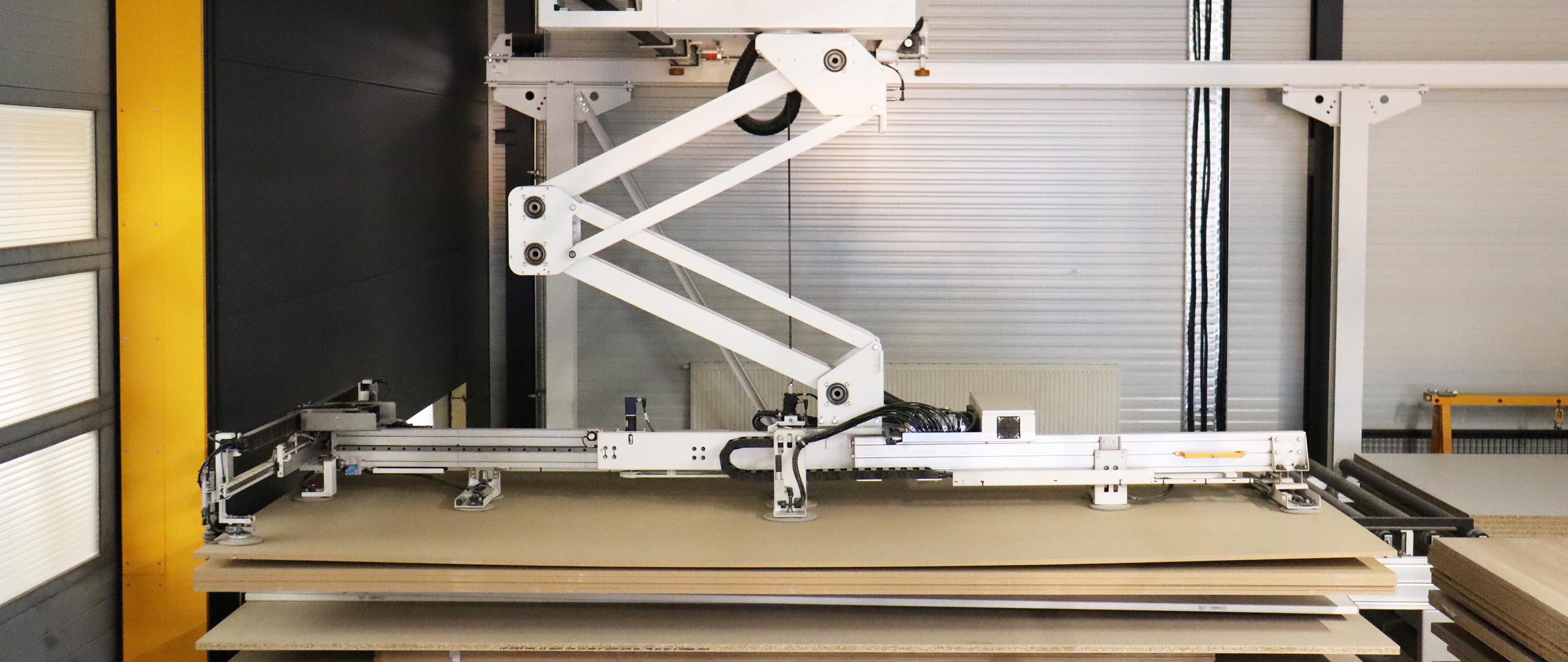

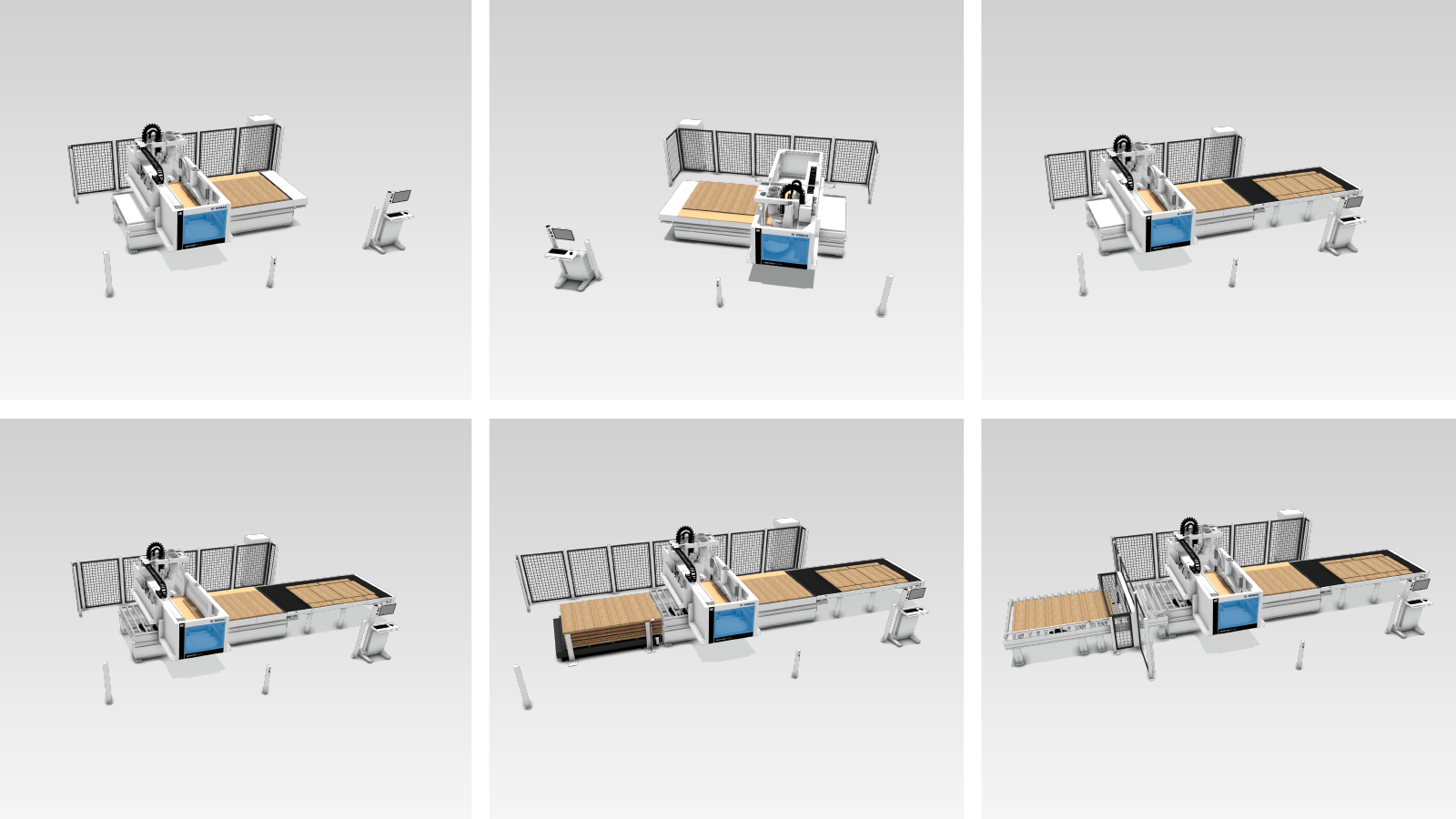

Our plug & play features allow us to gradually expand the machine right from the start. Whether the workpieces are to be fed by hand, roller conveyor, pallet truck or storage - we always have the right concept for your requirements.

The focus of the two-level safety concept consisting of a light barrier and strip bumper is the interaction and interplay between the machine and the machine operator. The system can also produce independently, quickly and with high dynamic parameters without intervention.

Images

Features

-

Heavy industrial welded steel construction in moving gantry design

-

Front and rear stop rulers on prismatic guides

-

3-, 4-, or 5-axis machining

-

Milling spindle with vibration sensor for maximum service life

-

Industrial drilling gear with patented spindle clamping for long service life and durability

-

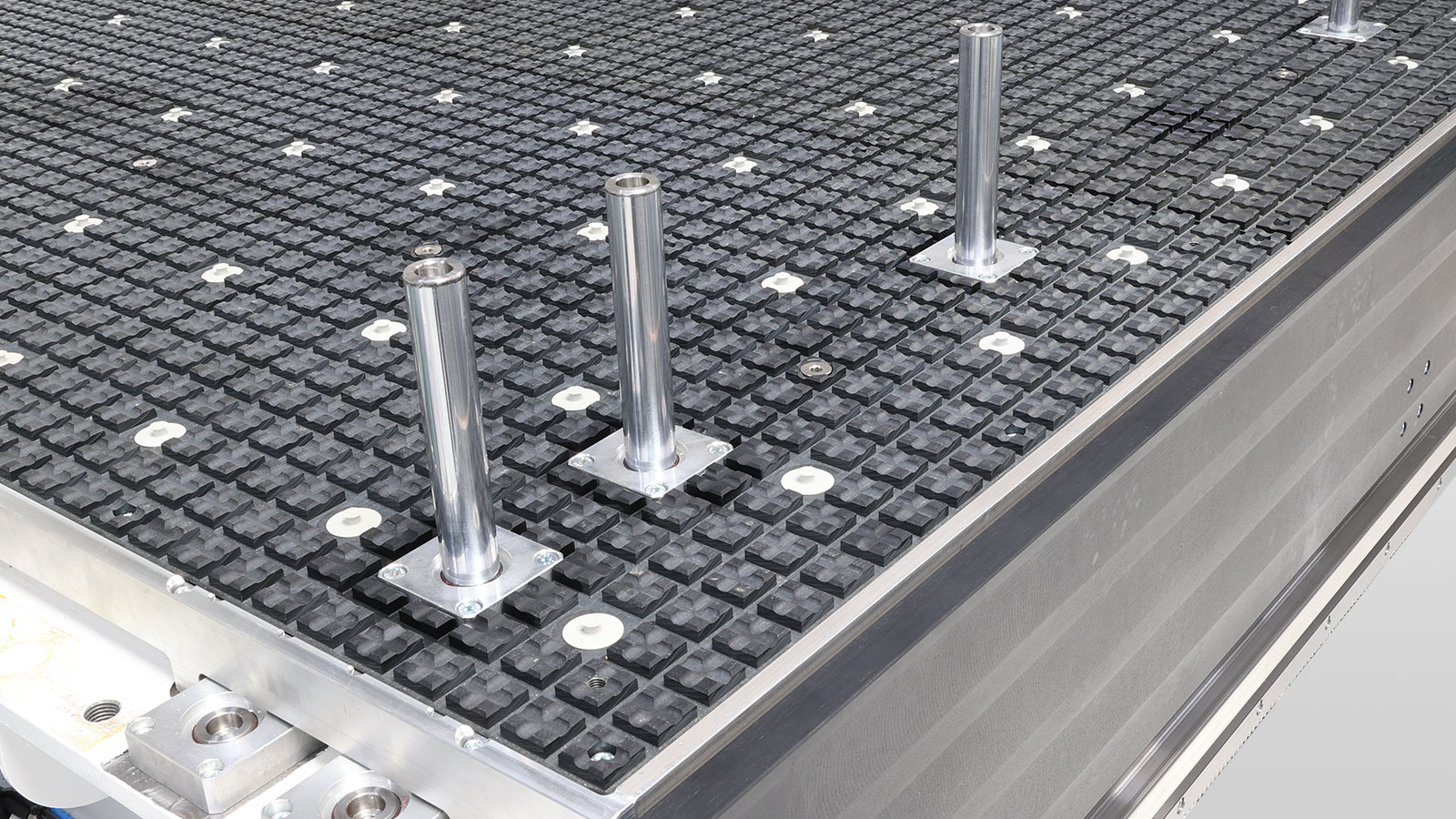

Up to 84 vacuum zones in the highest configuration level

-

Smallest field size for vacuum zones X = 630 mm and Y = 315 mm

-

Stop bolts in the table for aligning individual parts

-

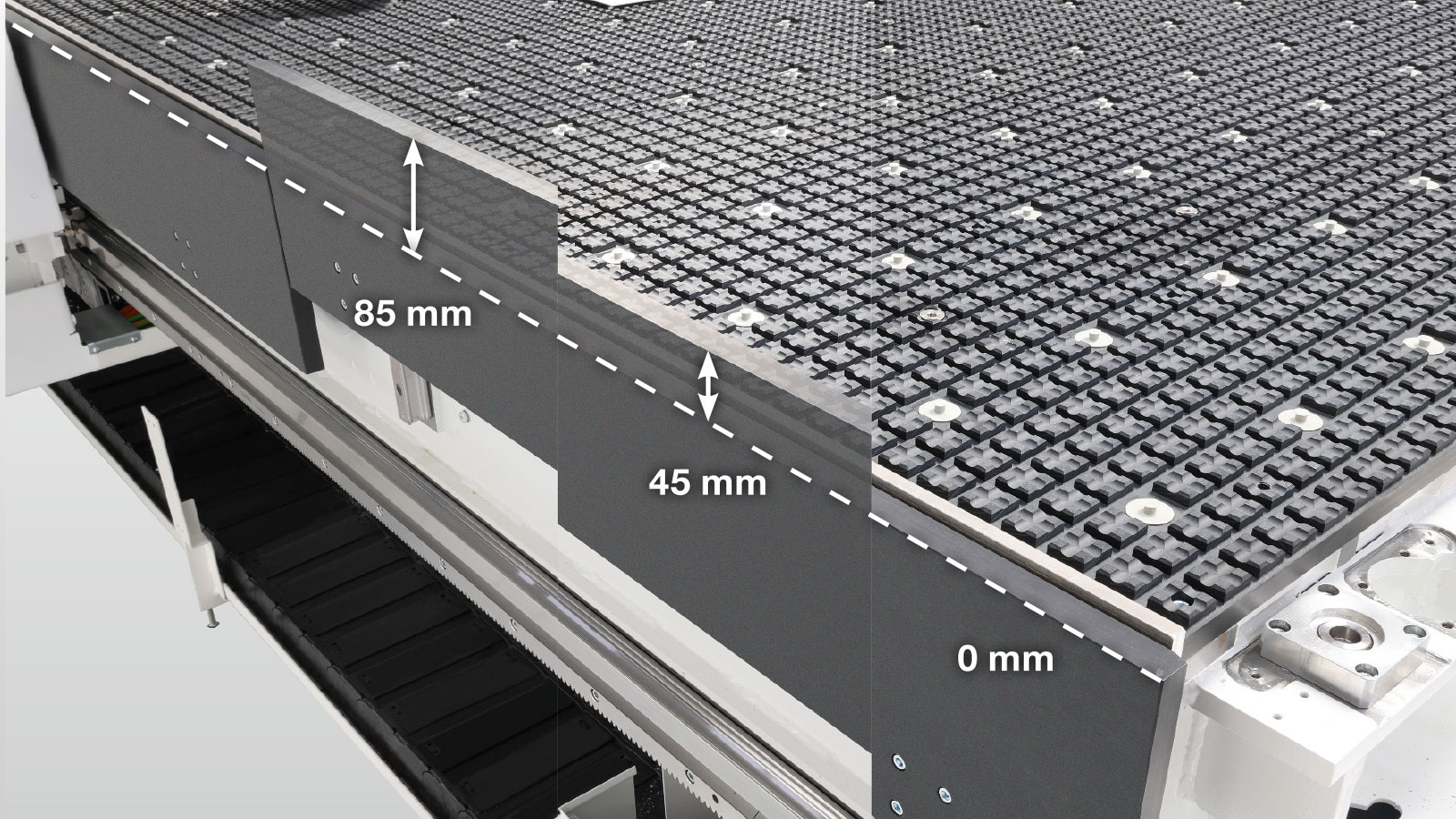

Simultaneous insertion and removal for even shorter handling times and greater productivity

-

Automated material handling from 3-60 mm panel thickness

-

Open system with interfaces to standard software solutions

Technical Data

Local and web-based apps for design, optimization, material organization and labelling

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

HOMAG CENTATEQ N-510 | The new nesting generation

Our nesting machines allow for machining and dividing of panel-shaped materials with waste reduction as a focus.

Brochures