Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

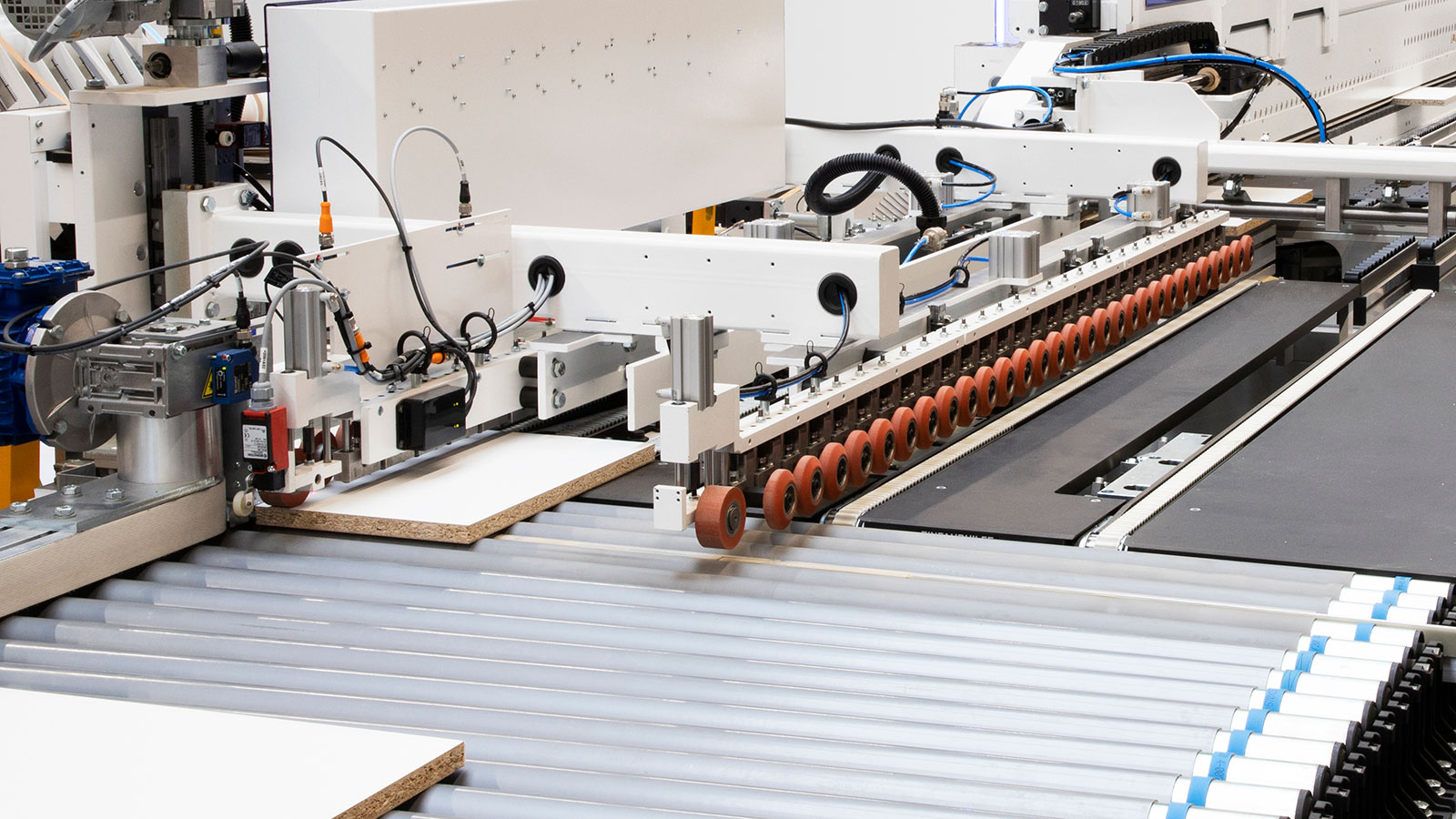

Edge Banding Machines EDGETEQ S-500 Optimat | profiLine

Edge Banding Machines EDGETEQ S-500 Optimat | profiLine

One machine. Unlimited possibilities

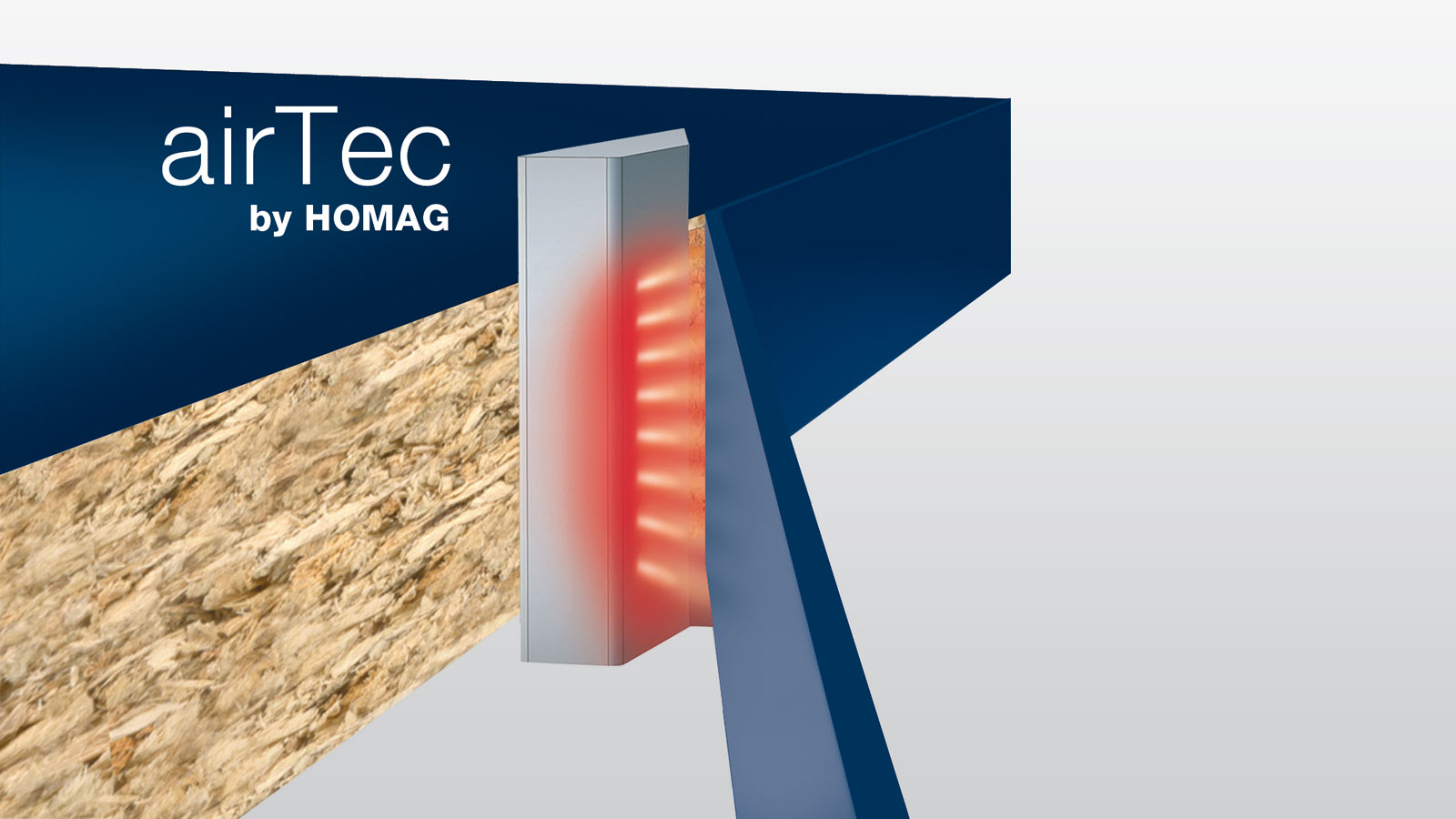

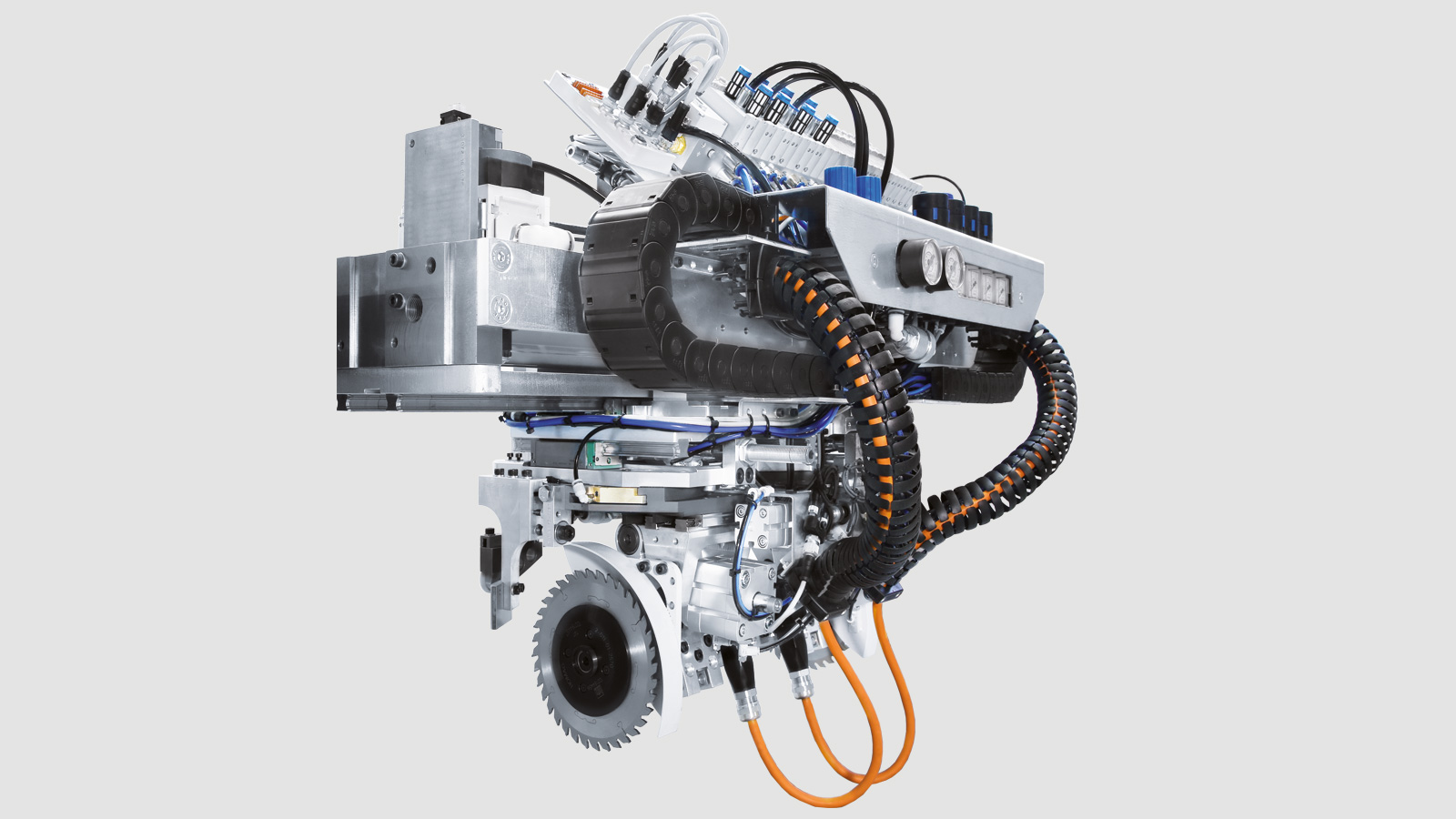

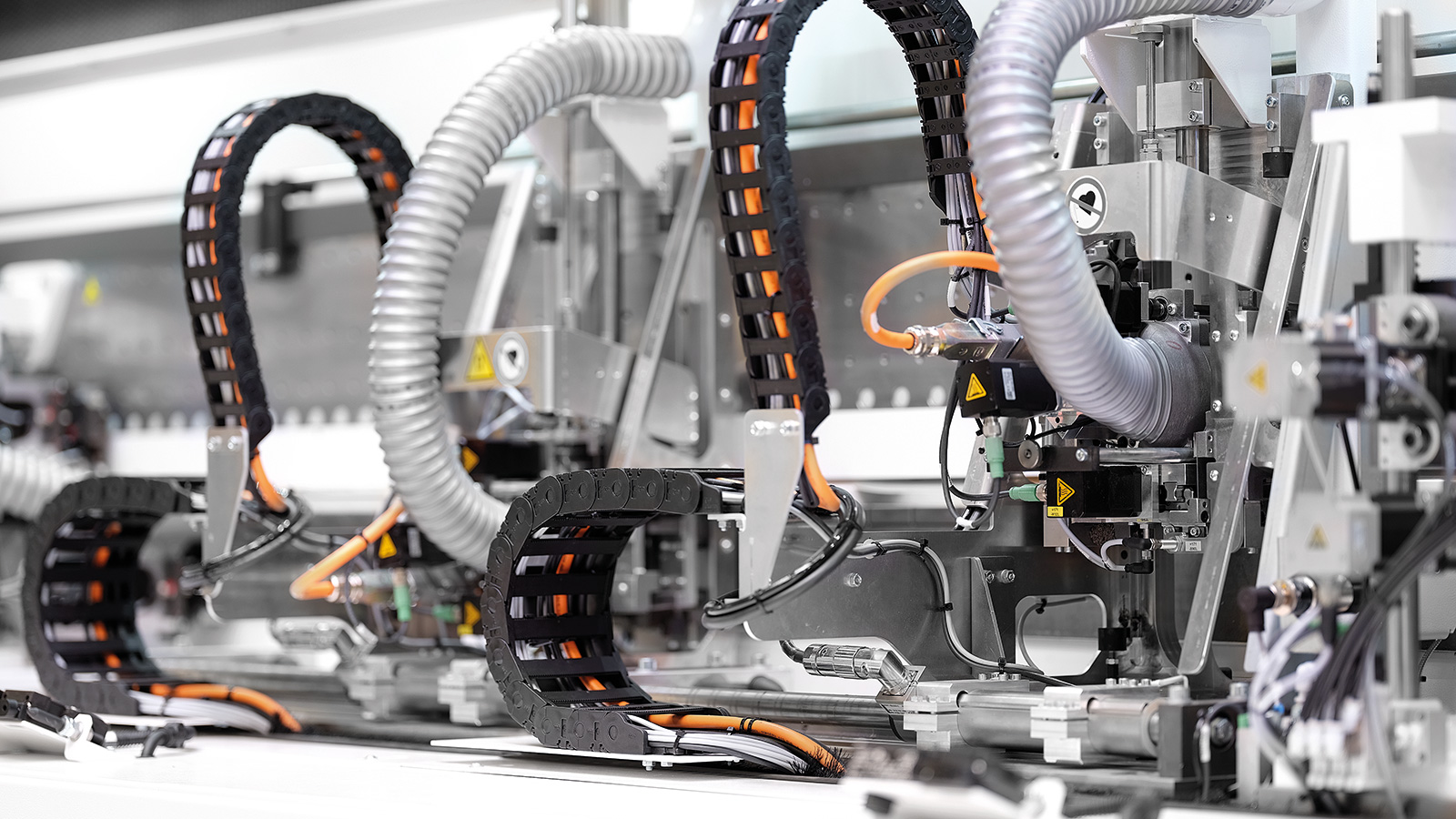

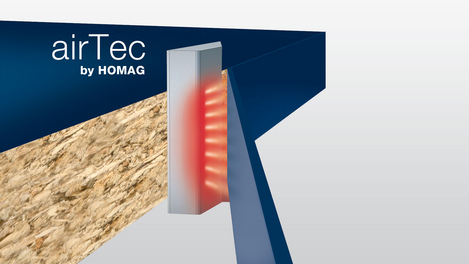

The single-sided EDGETEQ S-500 machines offer precise gluing and perfect post-processing of edges. PUR and airTec can be used if required. The feed rate can be set to 16–20, 25 or 35 m/min, enabling productivity to keep up with demand at woodworking shops or businesses with higher performance requirements. Automation and further functionality can be added on an individual basis for these edge banding machines.

Highlights

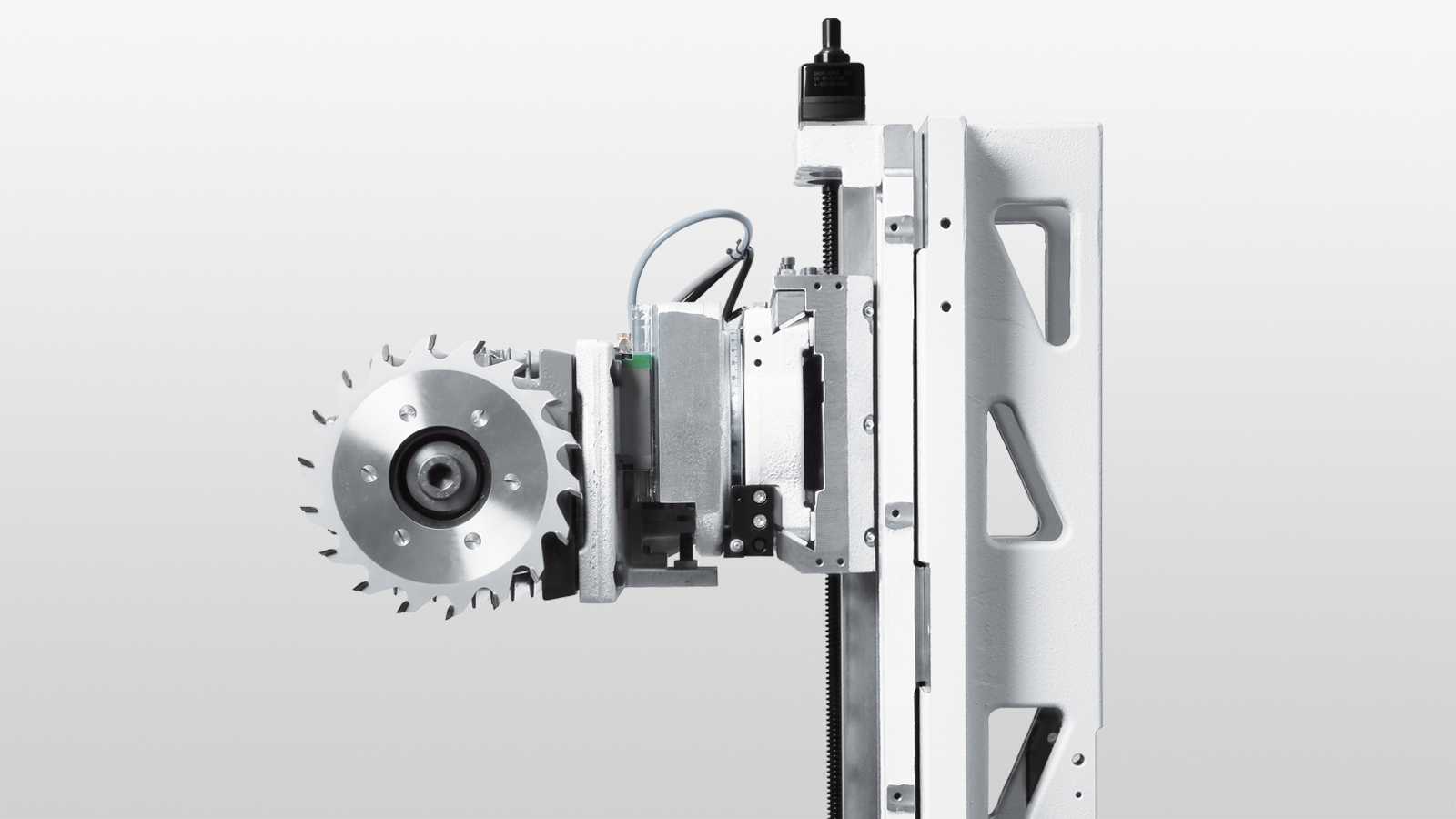

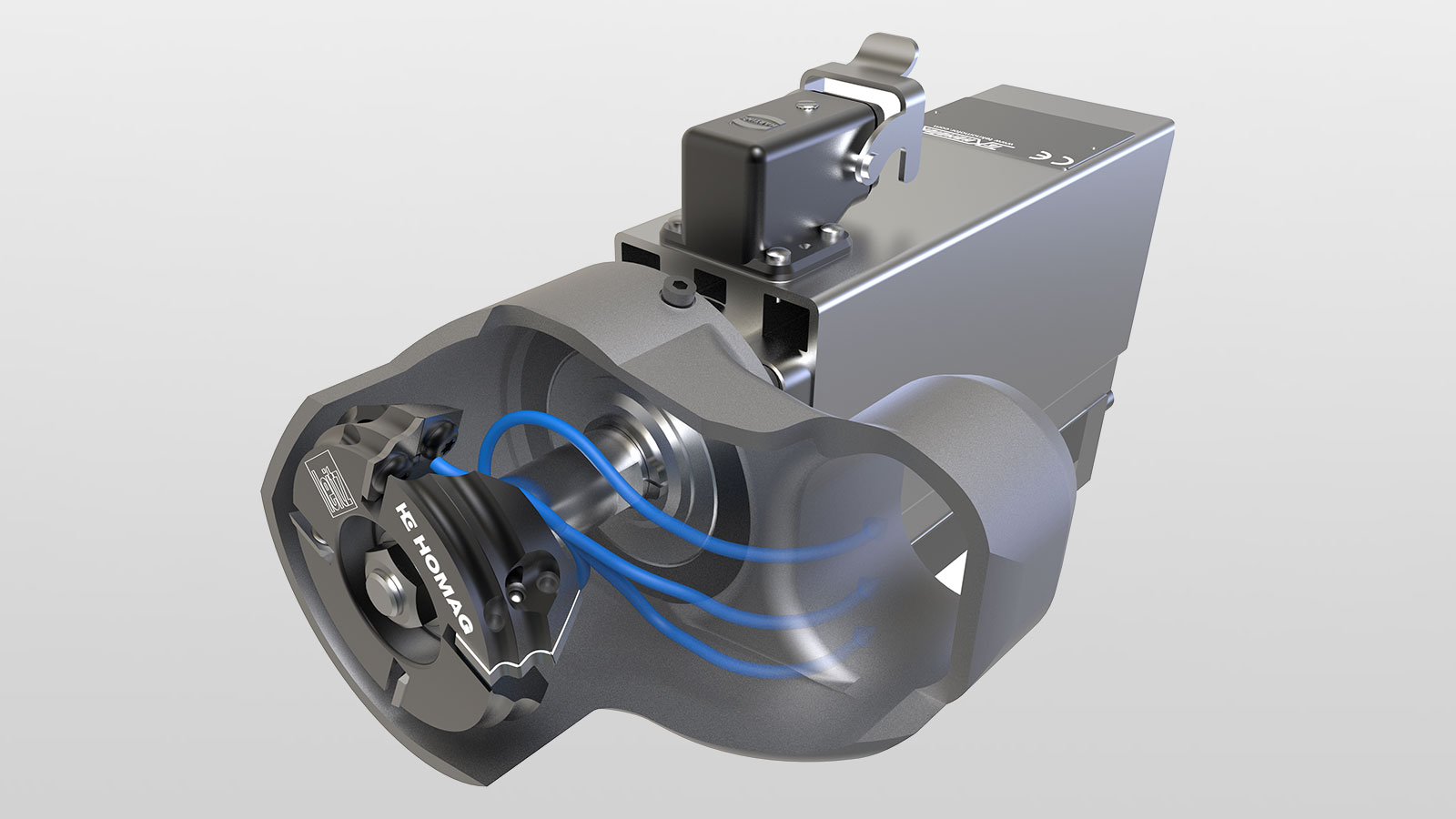

Optimal processing quality with the FK30 profile trimming unit. The motion sequence is controlled by linear motors. The high acceleration of the linear motors when rounding the edge enables optimal processing quality.

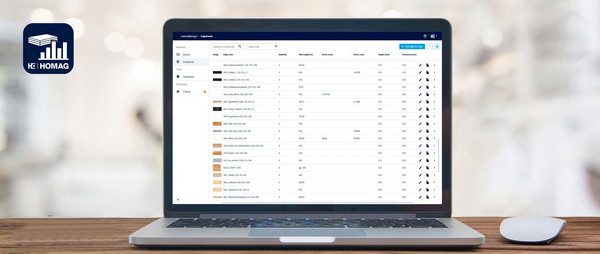

Intuitive touch operation. Control machine functions directly via woodCommander using the multi-touch, widescreen monitor. The ergonomic design as well as numerous help and assistant functions take ease of operation to the next level.

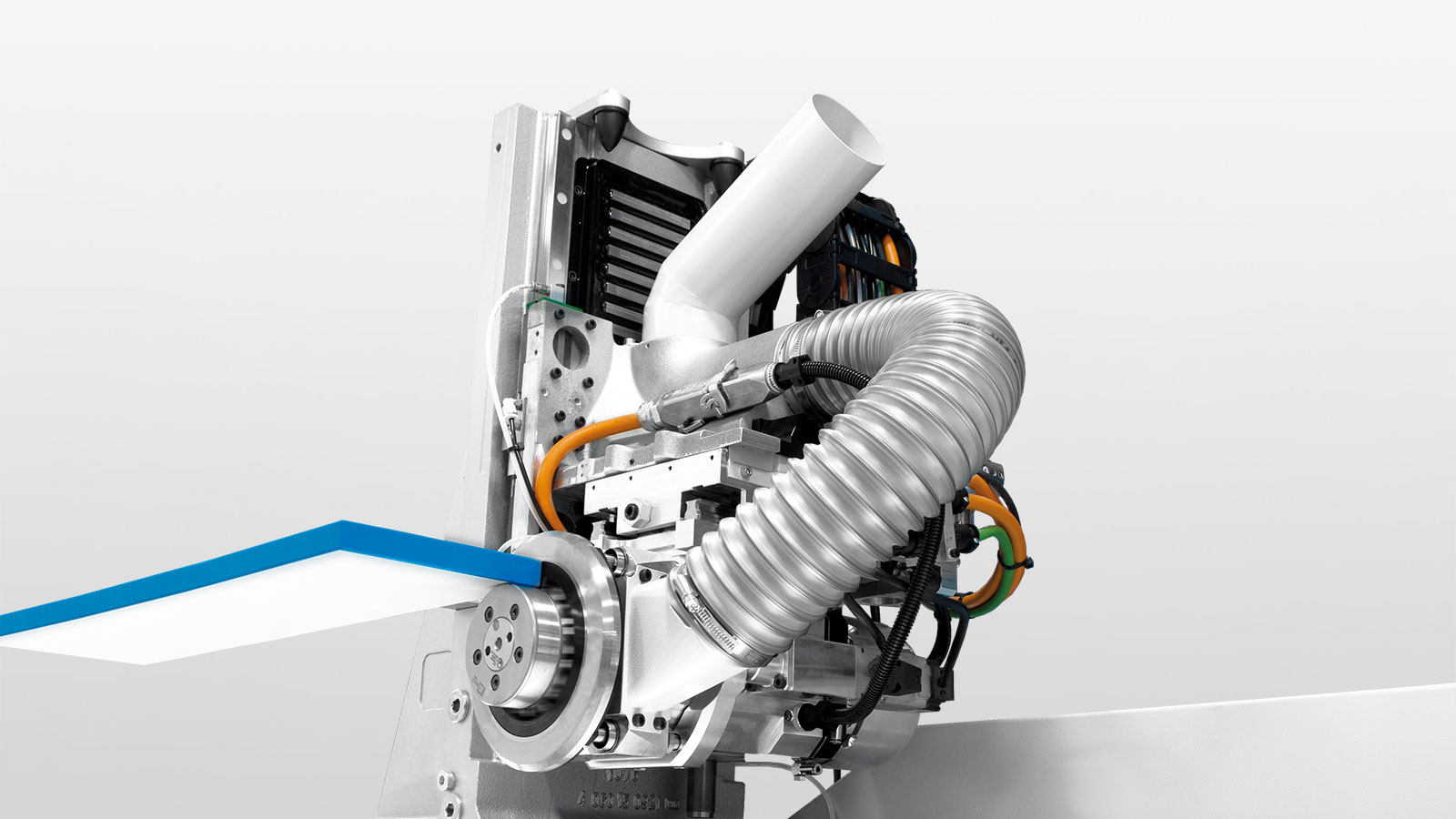

Controlled chip collection. The chips are suctioned off in the interior and fed to the extraction hood in a targeted manner. Reduced wear and tear and lower service costs increase profitability and service life. The reduced suction speed lowers energy consumption and costs.

Images

Features

-

woodCommander 6: Software for quick selection of the processing programs and the edge material

-

The multi-profile technology can be used to automatically switch between profiles and a chamfer. In addition to short setup times, you can achieve reproducible quality at the highest level.

-

Processing of rolls of material up to 3 mm, of strips up to 12 mm alternative of solid strips up to 20 mm

-

Workpieces with protective film/high gloss: For perfect high-gloss parts, important components such as the motorized top roll pressure element and the automatic adjustment of the glue joint scraper come into play.

-

Workpieces with hinge holes (nesting process) or pointed/blunt-angled parts: Depending on the unit configuration, different tracing elements are installed. They are ideal for processing parts with hinge holes, such as those produced in nesting, as well as pointed or blunt-angled parts.

-

With the narrow parts package, particularly narrow workpieces up to 40 mm can be processed precisely

-

Low energy costs plus material savings with ecoPlus

Technical Data

EDGETEQ S-500 | |

|---|---|

| Feed speed adjustable [m/min] | 16 – 20 (25, 30, 35) |

Workpiece width [mm] * with workpiece thickness 8 - 22 mm |

60 (40) |

| Workpiece thickness [mm] | 8 – 60 / 12 – 60 (8 – 100) |

| Edge thickness, coils [mm] | 0.3 – 3 |

| Edge thickness, strips / solid wood strips [mm] | 0.3 – 12 (20) |

* dependent on the workpiece thickness

Software

Here's how your colleagues produce

Brochures

Product Comparison

Edge banding machine