Maximilian Schuhmann has been a co-owner of the Möbel und Raum joinery for 15 years. There's nothing unusual about that – if it wasn't for the fact that he is 31 years old. The founder, Thomas Schuhmann, gave his son a share in the company at the tender age of 16. An unusual step, there's no doubt about that. But it shows what makes the people from Lower Franconia in Germany so special: a sense of responsibility, a willingness to take risks, vision, communication – but one after the other.

A little dynasty of joiners: The "Hummel" joiners.

In 2023, Möbel und Raum is celebrating its 25-year anniversary, but the history of the joinery goes back a long way. Named after their original building in Schönderling, the Hummel joiners have been creating experiences made of wood for more than 150 years: first as traveling joiners, later in the fine village joinery. In 1998, Thomas Schuhmann ventured into self-employment – with plenty of ideas on board and his wife Lucie at his side.

As an operations manager for store fittings, he gained a lot of experience. Above all, what can go wrong. He tried to avoid these mistakes himself, successfully. After two years, the business moved to the neighboring Schondra – to its own production hall. Since 2018, son Maximilian has not only been a co-owner, but also a managing director. His father gives him a free hand as much as possible. There has been no adverse effect on sales, which have almost doubled in recent years.

Expertise in shop fitting – and beyond.

Thomas Schuhmann doesn't beat around the bush: "We are consumers." Whether it's textiles, shoes, gastronomy or sports – to satisfy their customers, the Lower Franconians bring in their entire experience: Who is buying? How do they buy? Where do the people come from? How do we bring them to the store? And how do we bring sales to the store? The answers aren't plucked from the air, they are based on facts throughout Germany – well thought out from start to finish and produced to precision.

In addition to shop fitting, there is also demand for classic joinery work in Märzgrund in Schondra: kitchens, bedrooms, living rooms. The Schuhmanns are in complete agreement: this is the only way for the trainees to learn their craft. And work is only enjoyable over the long term with a little variety. It is good that Möbel und Raum is in the process of building up another pillar with timber house construction. At the moment, they are producing several residential units for which, adventurous as always, they take over almost all of the trades themselves.

And as if the work itself were not varied enough, father and son are constantly making sure that no feeling of daily grind creeps in: changing workstations, training on all machines and celebrating together. Whether this is at the Kilianifest fair with the giant ferris wheel in 2018, at the company's own event location "Jahr100Raum" or on the legendary trainee excursions – with which every year of training begins.

Training as the foundation for success.

The trainees don't know where they are going until the annual excursion actually sets off. The excitement rises every minute until the one-week project finally starts. Then the young people arrive in the Basque Country, on a houseboat in Amsterdam or at Lake Garda. The trip unites them, creates common memories and educates them. Yes, you have read that correctly: the program primarily includes general education, social competence and company values: a high level of own initiative, entrepreneurial thinking and responsible action – with respectful cooperation.

Communication plays a central role here: active language, no cursing, no nicknames, no workplace bullying. A proper image is important – in the business, at the customer's premises and in the region. Every employee is given the right clothing, from T-shirts to work trousers and jackets to a high-visibility vest. These issues seem to take root: not only are the fun factor and cohesion extremely high at Möbel und Raum, but also the speed and quality standards.

It is an advantage to learn from the bottom up what matters every day. Two budding product designers, one trainee in office management, two students on dual study programs and six future joiners are currently doing this. Female employees are not uncommon at Möbel und Raum – something that is not typical of the industry: 17 of the 44 employees are women. How did the Lower Franconians manage this? With clear prospects. Maximilian Schuhmann presents the joinery profession in the schools of the region. He shows where the journey can take people – education, years spent as a journeyman, training, leadership positions.

He and his father have thus inspired a number of young people for the career and business. 76 people have completed their training in Märzgrund, around 20 of whom are now part of the team. In addition, an impressive further training rate of more than 40% makes not just the company stronger. Even though some of the foremen, technicians and engineers now take up responsibility in other companies, they are still part of the joinery's strong network.

This is also why the focus of training is on individual challenge and support. What are the strengths? Where are the weaknesses? Together, they can find the right application area – for which each person takes full responsibility. And, in return, they receive trust and freedom. This type of motivation is working. This is demonstrated equally by the outstanding atmosphere and the high-quality work.

Human success stories.

It is important to the family that everyone in the company goes their way. Fabian Eckstein, for example, completed his training together with Maximilian Schuhmann. He is now a plant manager and, according to his former apprentice colleague, works "as if it were his own shop." Thanks to people like him, the Schuhmanns can also take a three-week break to develop new ideas that will make Möbel und Raum even more successful in the future.

The business continues seamlessly because everyone takes responsibility. This is what Nina Weber-Romeis does too. She originally comes from the gastronomy sector. A few months ago, she started working half-days in the warehouse. She is now taking on more and more joinery activities, thinking about processes and operating her first machines independently. Flexible working hours and colleagues from outside the field: Thomas Schuhmann is impressed by how smoothly both work – also thanks to the continuously intuitive operation of the machine pool.

The whole world speaks one language: HOMAG.

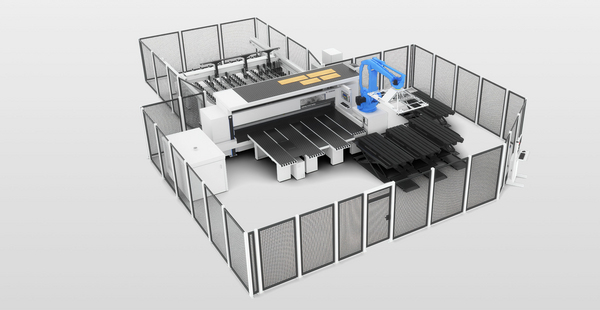

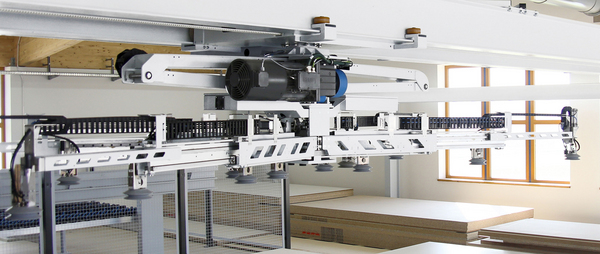

"We want to work with the best machines. And this isn't possible without HOMAG," says Maximilian Schuhmann. He and his father trust the technology from Schopfloch. This is also due to the relationship with the HOMAG sales organization – in the person of Karl-Heinz Brauneisen and Daniel Medler. When Thomas Schuhmann wanted to invest in a new saw in 2017, Karl-Heinz Brauneisen brought his entire market knowledge and technical know-how into play to inspire the founder with an automated panel storage system. At first glance this was a risky step; looking back it was absolutely the correct decision. The investment has made a lot of things possible: more flexibility, higher speed, stronger growth.

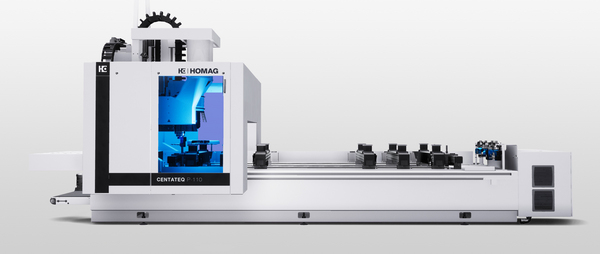

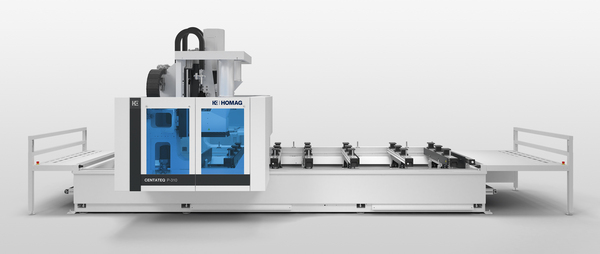

The machine pool is now so large that there are no bottlenecks. On the contrary, Möbel und Raum frequently produce items for fellow joiners with capacity problems – also thanks to the high level of CAD expertise in the technical center. This received another strong boost last year. To make it as easy as possible for all employees, the engineers plan everything in advance. The rest is made possible by the HOMAG user interface. "If I can operate one HOMAG machine, I can operate all of them," says Maximilian Schuhmann from experience. In his semester abroad in Los Angeles, HOMAG machines helped with the integration – just as they do today in Märzgrund. Four Ukrainian women work in production. The simple change of language into English makes this possible. Thomas Schuhmann is supporting the women in the jungle of German bureaucracy: from checking accounts through administrative formalities to finding housing.

Thinking outside the box.

At Möbel und Raum they are forward-looking – including when it comes to energy. Thomas Schuhmann makes it clear: "We consume energy, so we also produce energy." The solar systems alone have been producing five times their own consumption since 2009. This allows the joinery to look to the future with confidence: Maximilian Schuhmann wants to continue to invest, create affordable housing in the region and remain flexible. Who knows which business areas are yet to open up. His father's plans, on the other hand, are clear: "Family, social projects – and vacation," he notes with a wink.

Maßarbeit – Issue 9 | 2023

“We want to work with the best machines. And this isn't possible without HOMAG.”Maximilian Schuhmann, Managing Director

Möbel und Raum joinery

Products: Shop fittings, interior fittings, house construction

Location: Schondra, Germany

Founded: 1998

Employees: 47

First HOMAG machine: 1998

HOMAG machine pool:

- KAL370 AMBITION 2492 edge banding machine (today: EDGETEQ S-500) with LOOPTEQ O-300 return

- BOF 311 VENTURE 10 XL CNC processing center (today: CENTATEQ P-310)

- BHP Vantage 43M CNC processing center (today: CENTATEQ P-110)

- BHX200 CNC processing center (today: DRILLTEQ V-500)

- CENTATEQ P-210 CNC processing center

- PROFI HPP400/43/43/X panel dividing saw (today: SAWTEQ S-400)

- SBC-113/C SANDY wide-belt sanding machine (today: SANDTEQ W-300)

- STORETEQ S-200 (STORETEQ P-300)