Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Edge Banding Machines EDGETEQ S-380 | profiLine

Edge Banding Machines EDGETEQ S-380 | profiLine

A highly flexible all-rounder

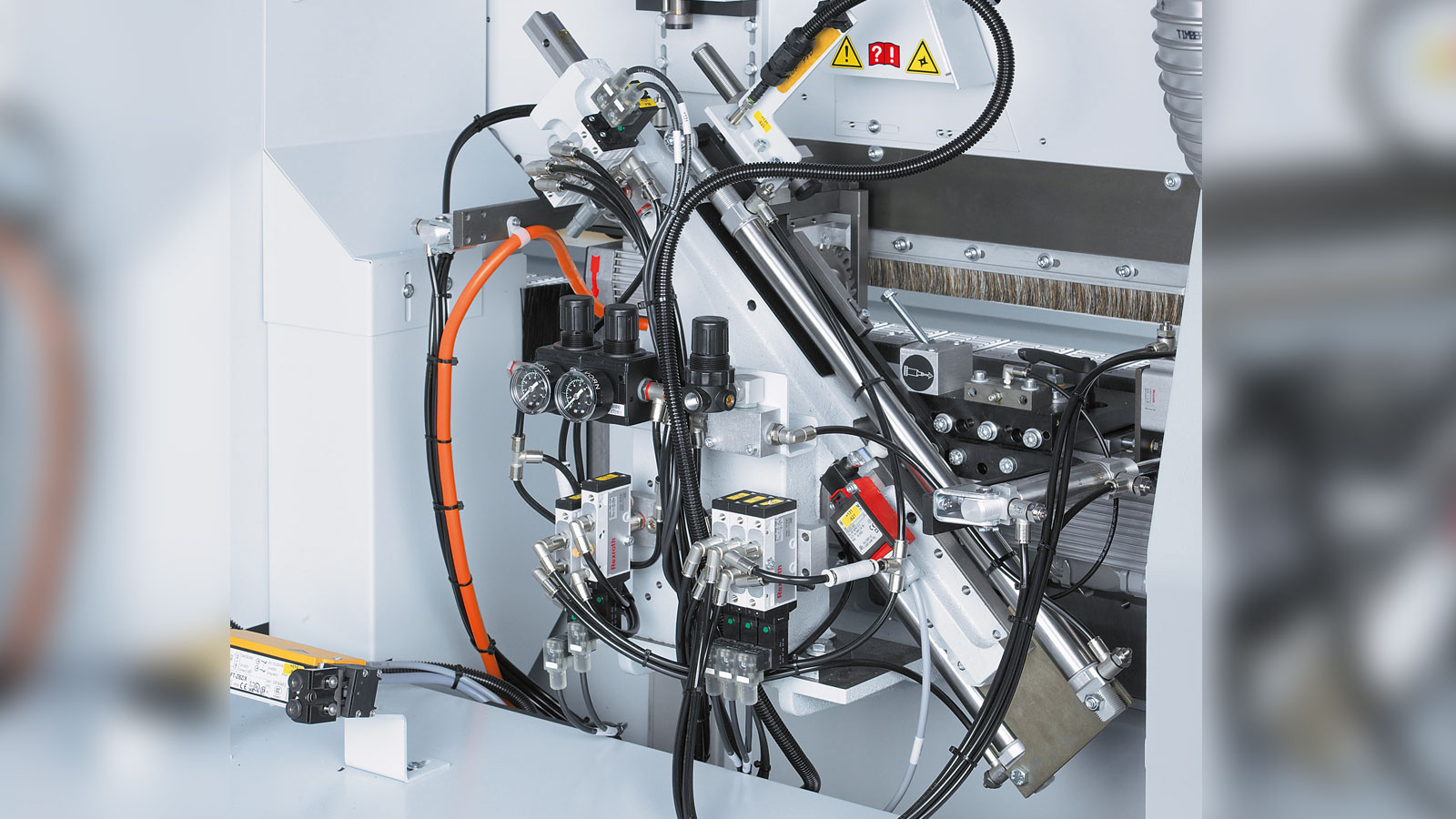

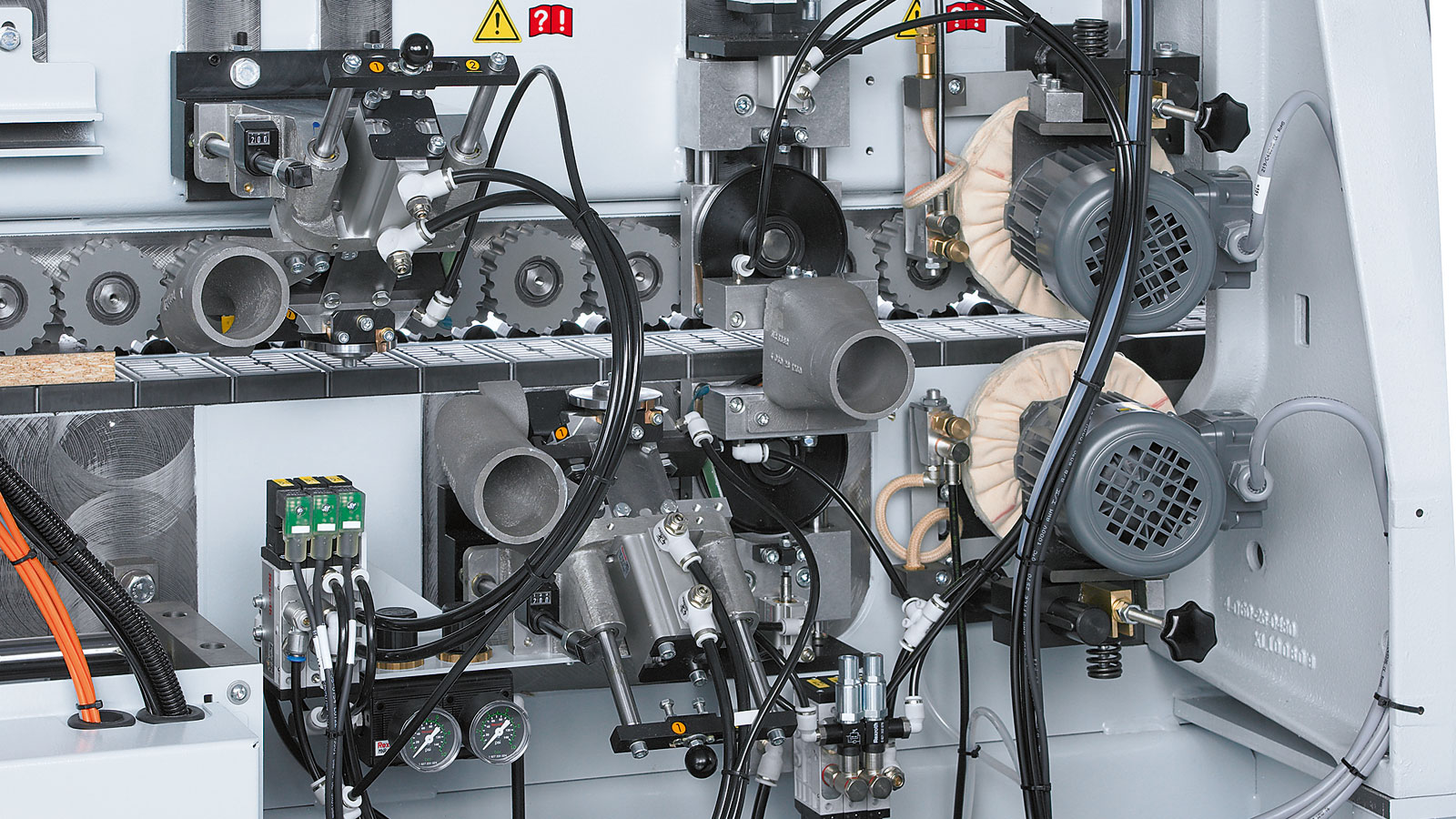

These machines feature a comprehensive range of units, high feed speeds and high-performance motors. The glue application system allows you to switch easily between two colors or glue types (EVA, PU). What's more, the multifunction profile trimming offers rapid processing of radii and longitudinal edges. For frequent material changes, the multi-stage trimming unit and multi-stage scraper can be used. The profiLine modules offer you maximum flexibility. You define the task and we develop a machine that is perfectly tailored to your requirements.

Highlights

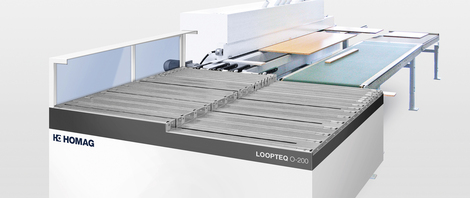

Portal return conveyor LOOPTEQ O-400 - Flexibility and a small footprint make the LOOPTEQ O-400 the perfect addition to your production.

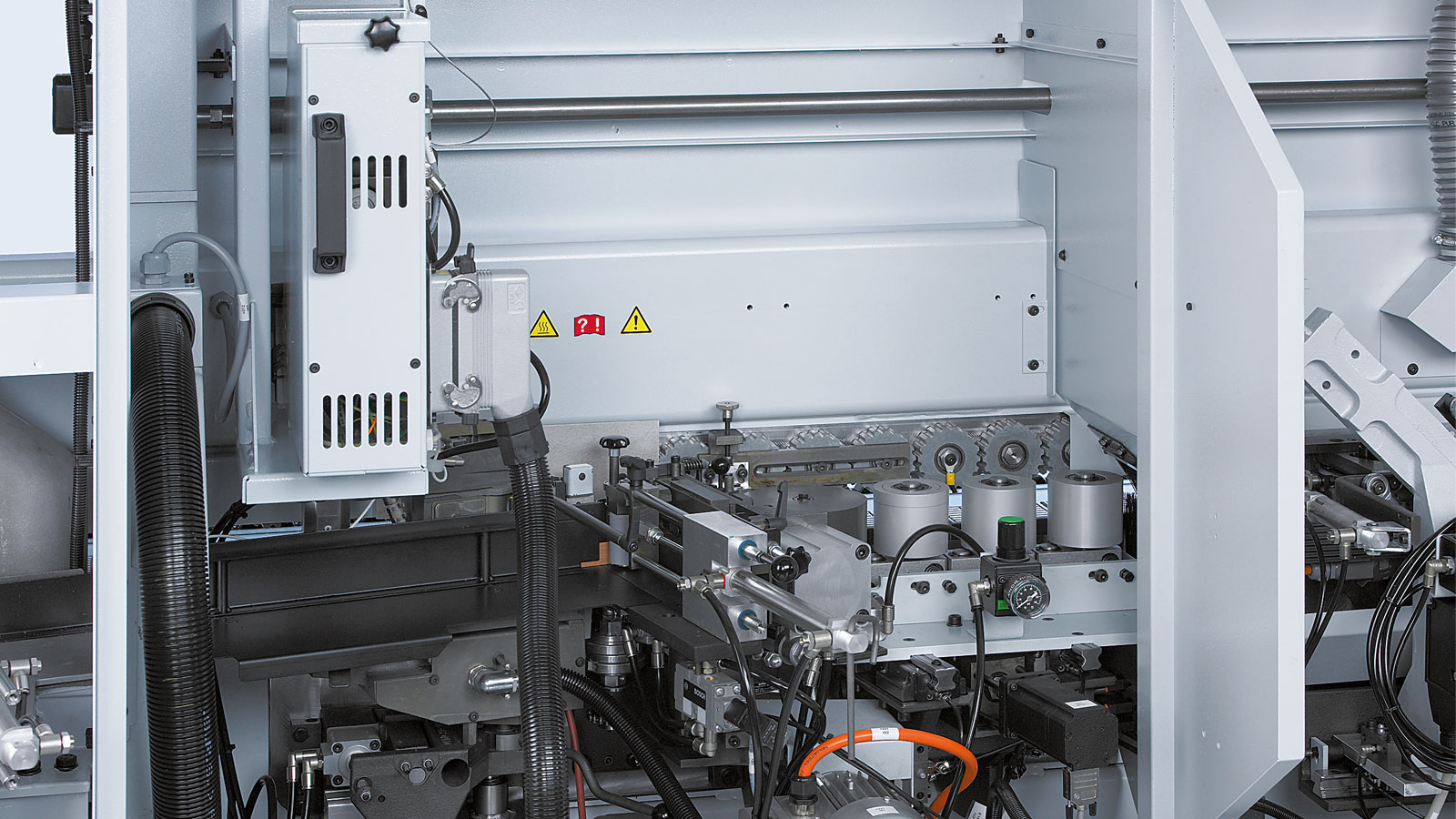

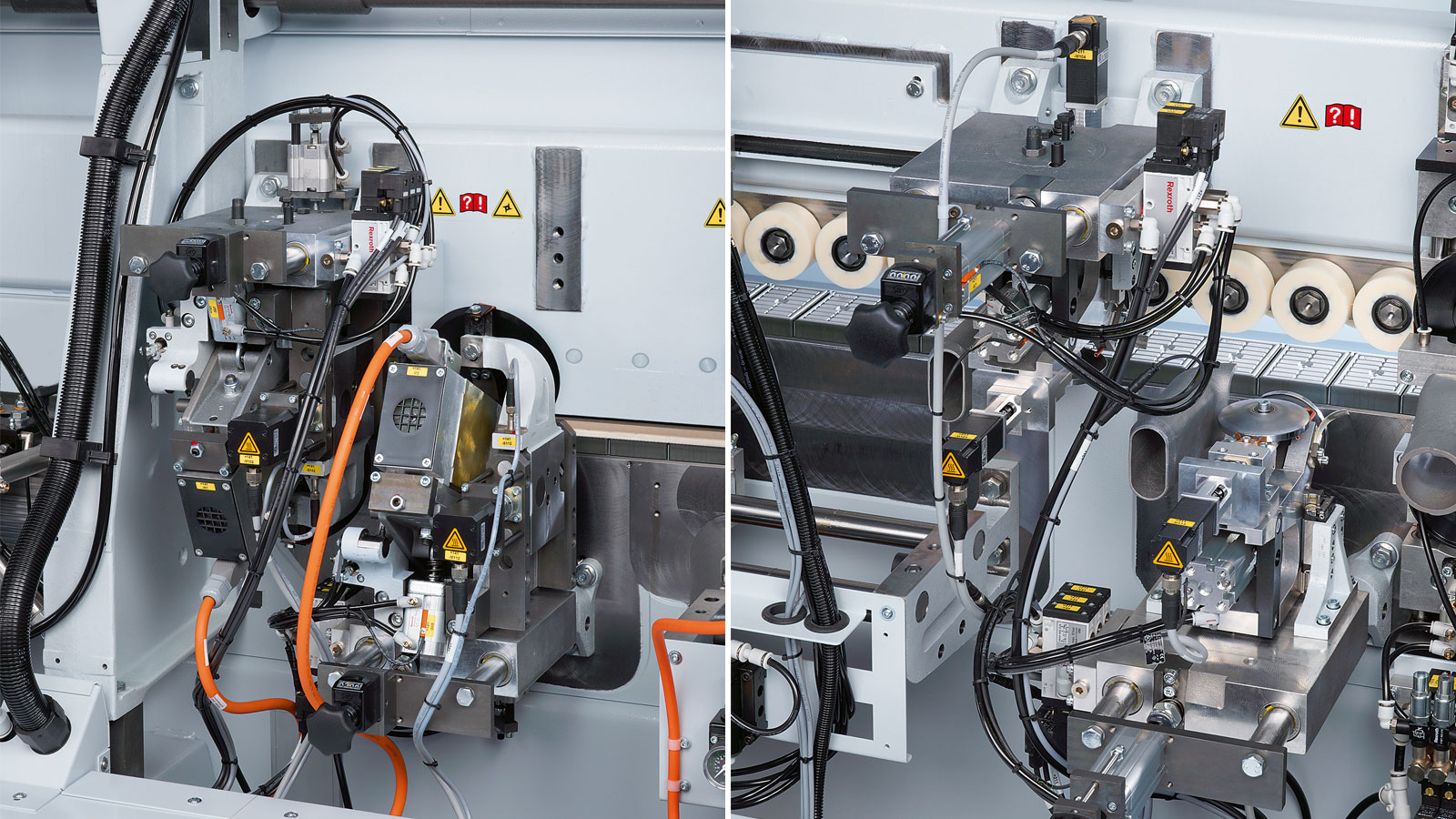

Universal melting unit: The glue can be changed quickly and easily using two special interchangeable containers for PUR cartridges or EVA granulate.

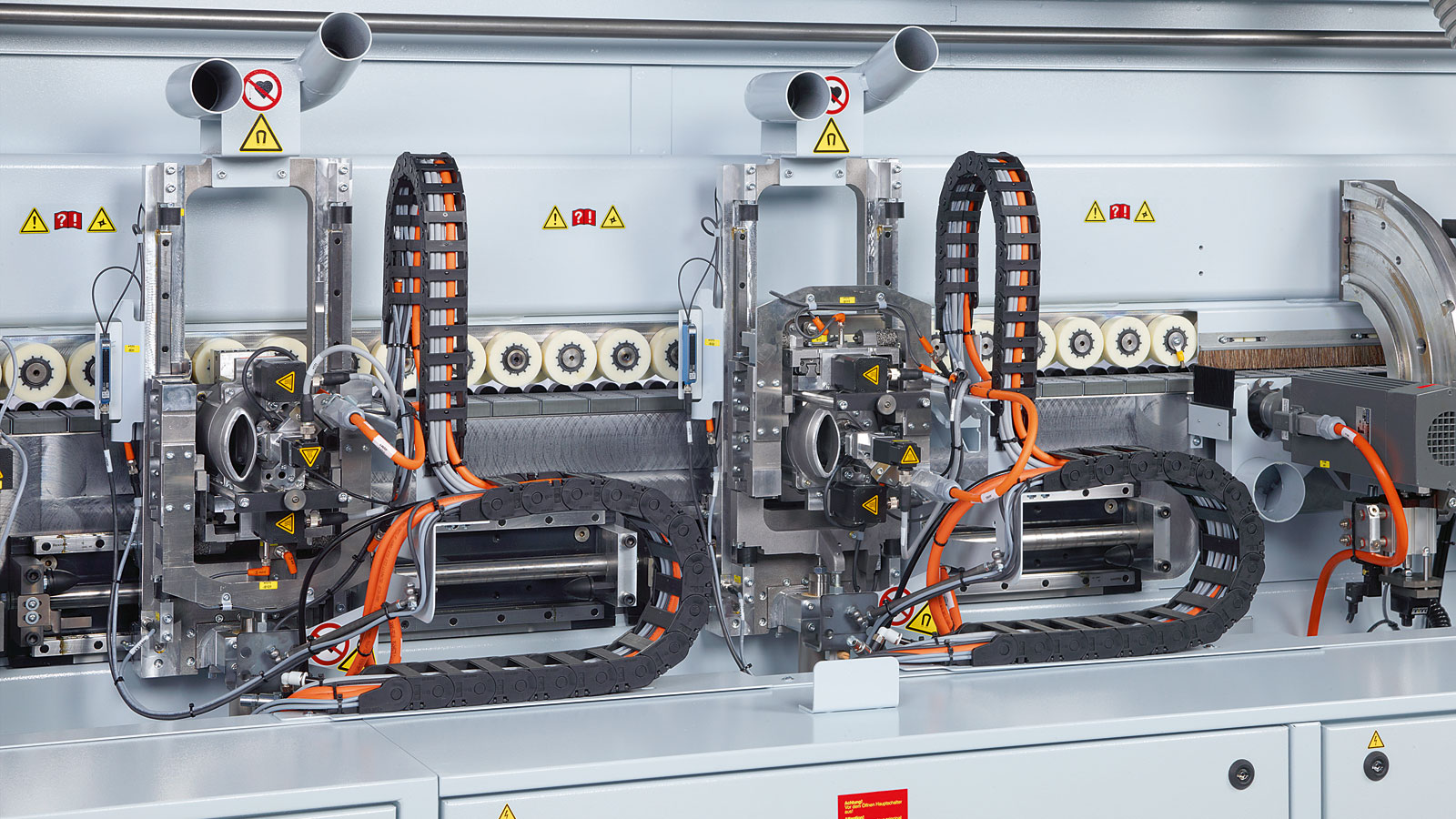

Top belt pressure as the basis for top quality, because the workpieces are optimally clamped for processing.

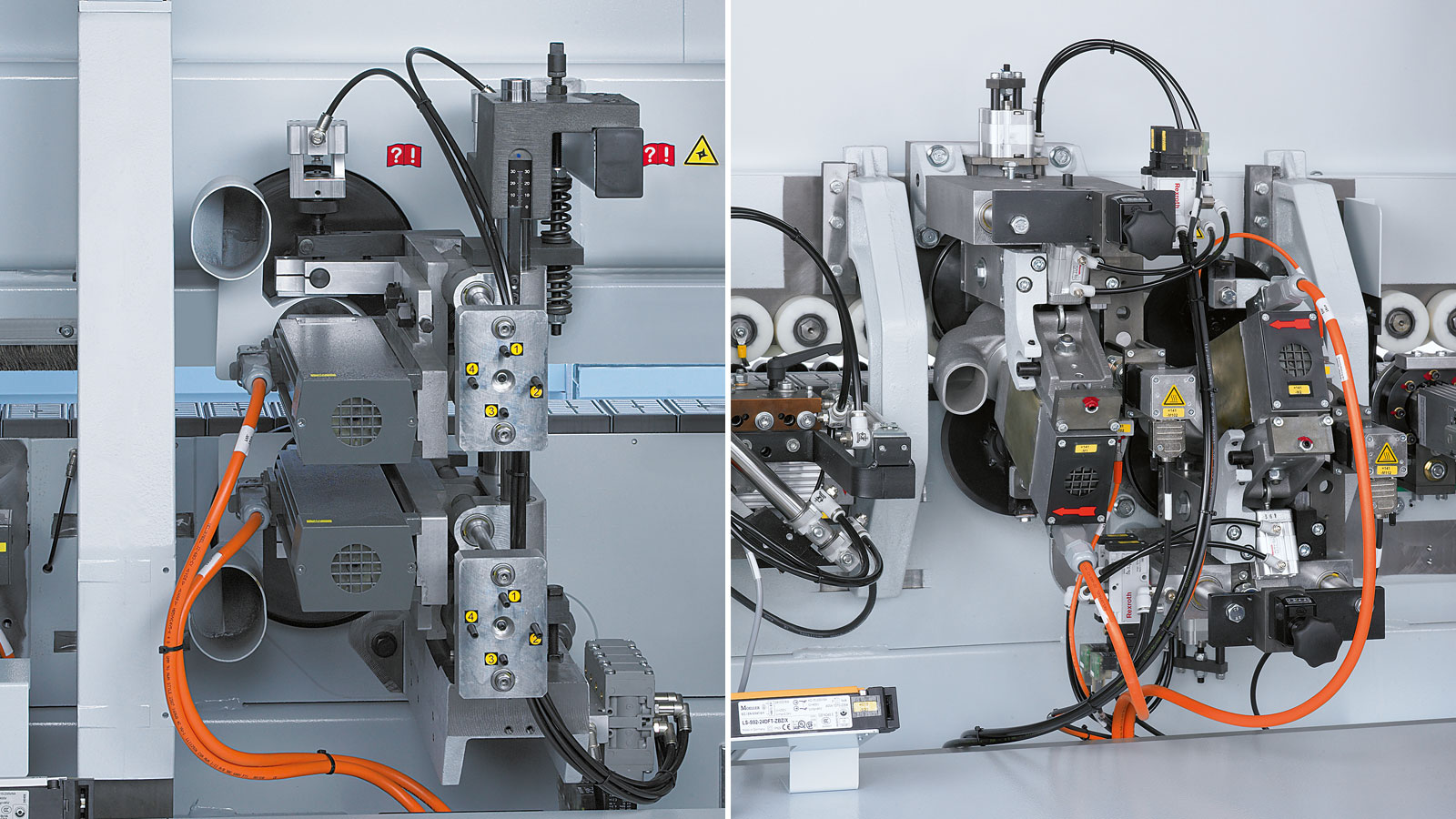

End-to-end multi-level technology in post-processing.

Images

Features

-

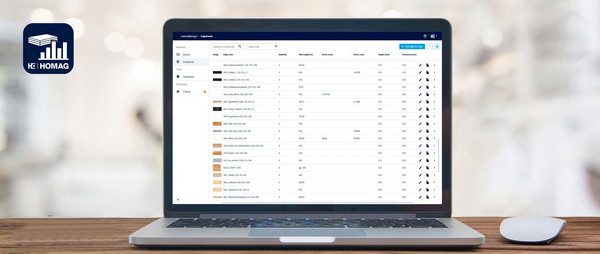

NEW: woodCommander 6 Software for quick selection of the processing programs and the edge material

-

Flexible glue application system for easy changing of the color and glue type (EVA, PU)

-

You can choose from 11 models and the freely configurable profiLine

-

Multifunctional profile trimming for corner rounding and flush trimming

-

Multi-stage technology for easy adjustment when changing materials

(As standard available at the edition-model) -

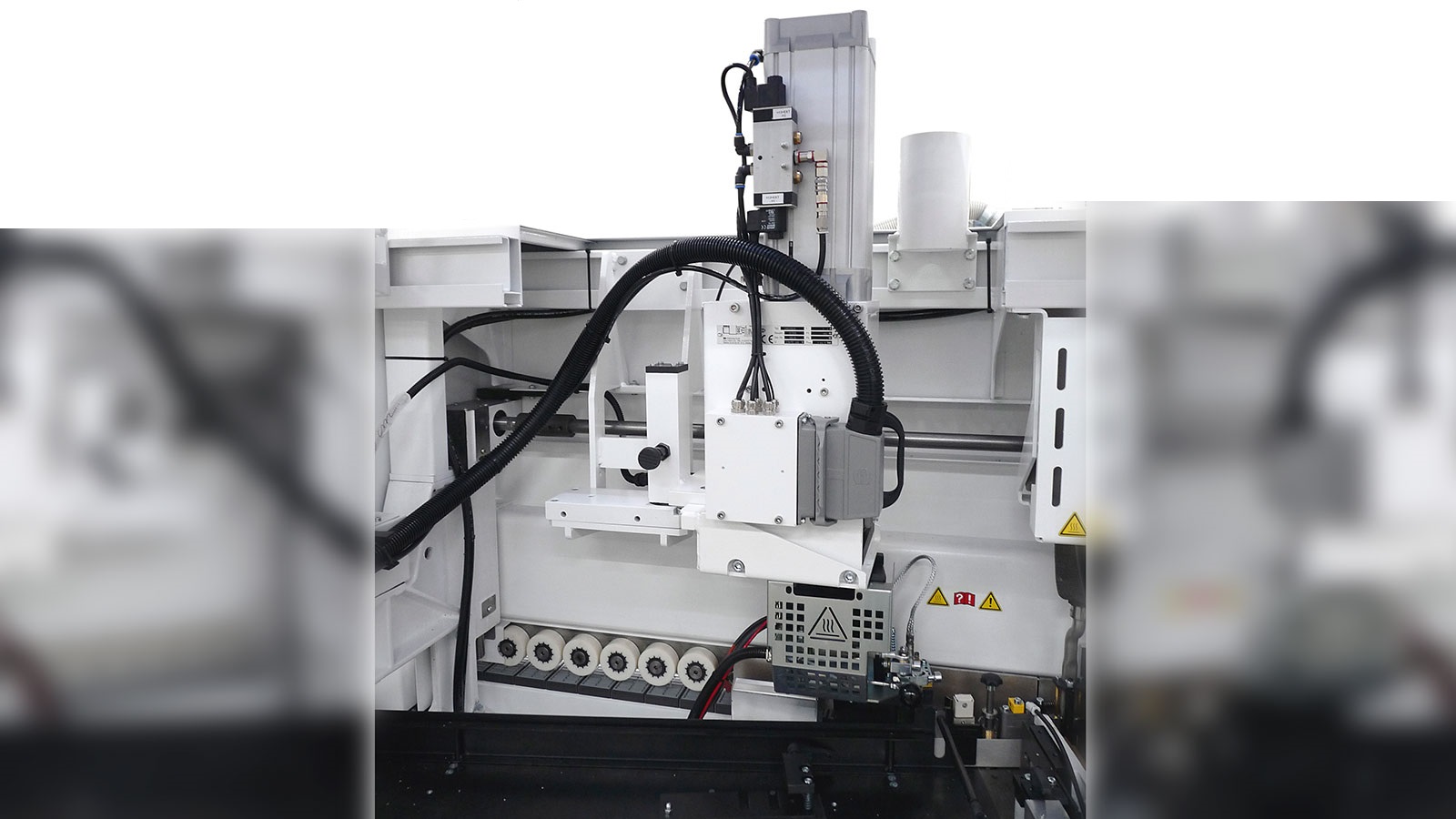

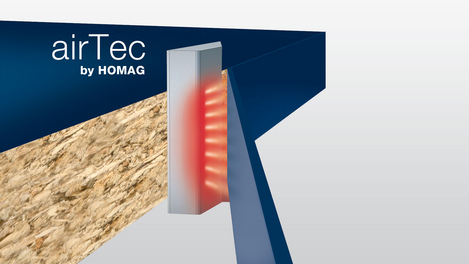

airTec unit for the perfect zero joint

-

Fully automated machine for excellent flexibility and easy adjustment

(As standard available at the Highflex-model)

Technical Data

| model 1650 FC | model 1660 FGC - 1670 FGC | |

|---|---|---|

| Machine length [mm] | 5,773 | 6,273 - 6,773 |

| Feed speed [m/min] | 8 - 20 | 8 - 20 |

| Workpiece width [mm]* in case of thickness 8 - 22 mm | 70 | 70 |

| Workpiece thickness [mm] | 8 - 60 | 8 - 60 |

| Edge thickness coils [mm] | 0.3 - 3 | 0.3 - 3 |

| Edge thickness strips / solid strips [mm] | 0.4 - 12 | 0.4 - 12 |

* depends on the workpiece thickness

| model 1650 E - 1660 E | model 1650 HF | model 1660 HF | |

|---|---|---|---|

| Machine length [mm] | 5,773 - 6,573 | 5,773 | 6,273 |

| Feed speed [m/min] | 8 - 20 | 8 - 20 | 8 - 20 |

| Workpiece width [mm]* in case of thickness 8 - 22 mm | 70 | 70 | 70 |

| Workpiece thickness [mm] | 8 - 60 | 8 - 60 | 8 - 60 |

| Edge thickness coils [mm] | 0.3 - 3 | 0.3 - 3 | 0.3 - 3 |

| Edge thickness strips / solid strips [mm] | 0.4 - 12 | 0.4 - 15** | 0.4 - 15 |

* depends on the workpiece thickness

** Assembly-dependent

(Previous product name: Edge banding machines Ambition 1600)

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

The EDGETEQ S-380 with the new LOOPTEQ O-400

The high degree of automation of the edge banding machine enables quick and easy removal or stacking of the finished parts and ensures smooth work processes.

Brochures

Product Comparison

Edge banding machine