Productivity-enhancing strategies and sustainable yet cost-effective building solutions are increasingly becoming the focus of the construction industry. One approach is gaining particular traction: modular construction using industrially prefabricated components. A prime example is the Wittum 1 daycare center in Reutlingen, a public-sector project delivered by MOD21. The timber modules were manufactured using two production lines from WEINMANN.

According to the German Prefabricated Building Association, modular room-based construction is becoming more common among prefab home manufacturers. Applications range from single-family homes to commercial buildings like schools and dormitories, as well as additions and vertical extensions to existing structures. Modular construction helps meet urgent market demands for faster and more affordable building. By leveraging repetition and scale, projects benefit from streamlined planning and execution, delivering cost-efficiency and speed. These benefits are especially apparent in larger housing and institutional buildings. Like other structures built using room modules, they allow for predictable construction progress, as they are manufactured in the factory under industrial production conditions with a high degree of prefabrication. For urban densification as well, modular construction ensures consistently high quality and especially short on-site assembly times. In addition, the elements and modules can be configured in numerous variations [1].

Projects for the public sector

MOD21, a young company founded in 2021 and specializing in modular and hybrid construction, is experiencing rapid growth. In 2024, the company doubled its incoming orders compared to the previous year and expects similar growth in 2025. “We're seeing strong demand for modular construction in urban areas like Munich and Stuttgart,” says Marin Zec, Sales Manager at MOD21. “Most inquiries come from the public sector: schools, daycare centers or military facilities. While there’s also interest from private investors, for example in hotels, the current economic climate makes those projects harder to implement.” Our primary client right now is the public sector.”

Setting a pioneering footprint

The city of Reutlingen commissioned MOD21 to build the Wittum 1 daycare center, their second modular childcare project in the region. The structure, a timber modular building, measures 35.5 m x 18.1 m and stands 7.5 m tall. “Construction lasted from January to June 2024,” explains Zec. “We prefabricated 38 modules in four weeks and installed them on-site in just five days. The finishing work took another three months.” Because the daycare center is located in Germany’s second-highest earthquake zone, both the foundation and structural system were designed to meet seismic safety standards. “Thanks to the sustainable timber construction and the use of regional materials, we achieved a 96% reduction in CO2e emissions compared to conventional construction—significantly lowering the building’s ecological footprint,” says Zec with satisfaction. For the off-site prefabrication of the modules, MOD21 used machines from WEINMANN Holzbausystemtechnik, based nearby in St. Johann.

“It was a complete success”

Today, Wittum 1 offers children a generous gross floor area of 810 m² across two levels. The center provides space for three groups, accommodating children both under and over the age of three. Facilities include: a kitchen and dining area, multiple group rooms tailored to each age group, a movement/activity room, accessible sanitary facilities, administrative and staff lounges “We delivered not only a high-quality, long-lasting building, but most importantly, the children benefit from a healthy indoor climate,” Zec explains. Lisa Sigloch, who oversees management and administration at Wittum 1, adds: “The building concept is a complete success. The layout is excellent— there’s plenty of space, it’s bright and functional. Everyone who visits gives us positive feedback.”

Producing elements on two lines

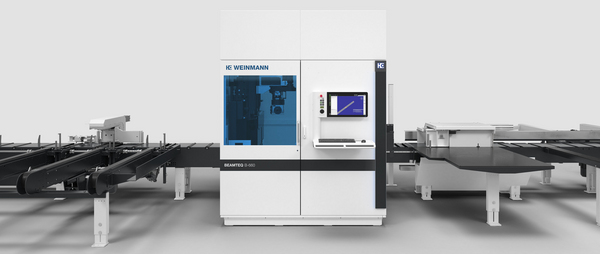

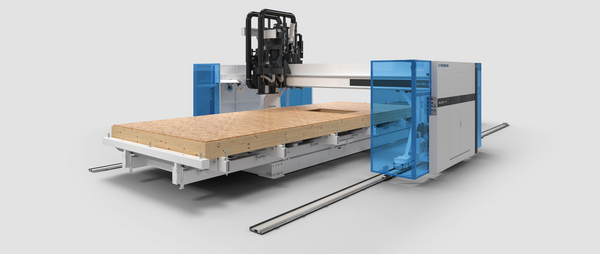

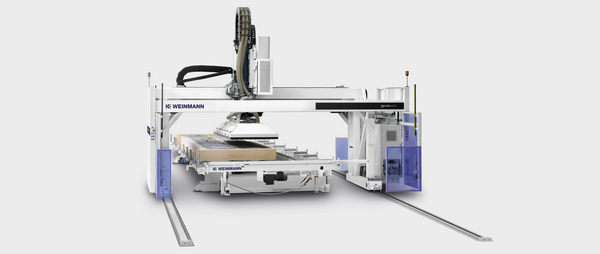

The modules were produced using WEINMANN technology near Toruń, Poland. Here, ERBUD—the parent company of MOD21—operates two production lines for manufacturing wall, floor, and ceiling elements. The wall production line begins with a carpentry machine including semi-automated material feeding, followed by a frame work station. Next, the process moves across three worktables equipped with a multifunction bridge, where tasks such as fire-rated interior sheathing are performed. Elements are flipped using butterfly tables. Insulation is applied fully automatically using a multifunction bridge from the WALLTEQ insu-Fill series, capable of processing both cellulose fiber and mineral wool. Two additional worktables, with a separate multifunction bridge, are used for exterior sheathing. The wall line concludes at a tilt table, which transfers the finished wall elements to an eight-lane wall slot. Some units then undergo final finishing, including window installation and exterior plastering. From there, the elements are transported by distribution trolleys and a crane to the next stage of expansion and assembly. The floor and ceiling production line includes: a processing table for building the framing, butterfly flipping tables, another worktable, a multifunction bridge that processes both the top and bottom surfaces of elements up to 4.2 meters wide. At the end of this line, a crane lifts the finished floor panels and moves them to the module line, where they are leveled and aligned to ensure perfect verticality during module assembly. Once the wall and ceiling elements are complete, they are assembled and moved from station to station on transport carts [2]. Based on these production processes, it’s clear that the WEINMANN system has been perfectly adapted to MOD21’s production workflow and on-site requirements. It offers high flexibility for future expansion and allows for the addition of new modules or components as needed. This flexibility was a key reason MOD21 chose WEINMANN. Zec explains: “WEINMANN convinced us not only with their flexible machine sizes and the ability to design a custom production line, but also with their overall concept, machine quality and adaptability to our specific processes. Another deciding factor was our existing relationship with the HOMAG Group, and the fact that short service routes within Poland are especially important for us.”

Built to meet demands

Projects like Wittum 1 demonstrate how modular construction offers a fast, cost-effective solution without compromising on quality. “On average, we’re up to 70% faster than traditional monolithic construction,” estimates Zec. By shifting more work into the factory, and by standardizing and optimizing construction workflows, MOD21 is able to: minimize typical on-site risk factors, improve process reliability, reduce the impact of supply chain disruptions. The fact that timber modular construction is a driver of productivity is clearly demonstrated by the WEINMANN production lines at MOD21. Digital planning tools not only optimize work preparation from design through material deployment, but also support automation and robotics, which significantly boost manufacturing efficiency and ensure seamless process integration. The production lines themselves operate with millimeter precision, are ready for use at any time and enable comprehensive quality assurance through integrated monitoring systems. “Our wall elements are produced on a 29-minute cycle,” reports Zec. “For floor and ceiling elements, the cycle is 59 minutes. Including element production, the entire room modules are completed within two days. Interior finishing takes about ten days, so the total cycle time for a finished module is twelve days— including installation, built-in cabinetry, kitchen, and sanitary fixtures.”

For the Wittum 1 project, all construction was carried out in compliance with DGUV regulations, which clearly define the requirements for daycare centers in Germany. Examples of safety features include finger-pinch protection on doors and safety glass installed up to a height of 2 meters. Glare-free lighting was installed in selected areas, and fall protection was fully ensured. Regarding acoustic performance, specific reverberation times were implemented to meet soundproofing requirements. One of the core benefits of modular timber construction lies in the material itself: the use of wood significantly reduces the 2e footprint of a building. “In the case of Reutlingen, this resulted in a CO2e reduction of 96%, and in a school project in Berlin-Straußberg, the savings were as high as 103%,” says the sales director. A key factor in achieving this is intentional planning: Materials are selected and assembled in such a way that they can be disassembled, separated and reused after the first lifecycle. The modular timber units themselves can also be repurposed—something that is not only possible, but already regularly practiced. “The lessons learned for us from the Wittum 1 project are significant. “One example is seismic safety. For this, we reinforced the connections between the modules and the foundation, and we added special anchoring systems between the modules themselves.”

The story continues

The importance of timber construction in Germany continues to grow. Today, more than one in five residential and non-residential buildings is constructed using timber and this share is rising, not least due to political support. A major milestone was the adoption of the new Model Timber Construction Guideline (M-HolzBauRL) in September 2024, which now needs to be integrated into the building codes of Germany’s federal states. For MOD21, the next project in the Reutlingen region is already underway—once again using prefabricated modules produced on WEINMANN lines in Toruń. The GWG Reutlingen, the city’s fully owned housing corporation, has commissioned a new child and family center. WEINMANN technology continues to enable ongoing innovation and rapid adaptation to evolving market demands, including new regulatory requirements. Its high production speed and optimized cycle times open up new possibilities for MOD21 in modular building manufacturing, allowing the company to implement innovative construction projects with even greater efficiency. This is especially relevant at a time when there is an acute shortage of housing.

Literature

[1] Bundesverband Deutscher Fertigbau: Neue Chancen durch modulares Bauen. [German Prefabricated Building

Association: New Opportunities Through Modular Construction.] Press Release, 12/02/2024

[2] Mohr, Joachim: Deutsch-polnisches Modul. [German-Polish Module.] In: Mikado (11)2023, p. 60–64

An article from the performance customer magazine 2025. Read more.

“WEINMANN convinced us not only with their flexible machine sizes and the ability to design a custom production line, but also with their overall concept, machine quality and adaptability to our specific processes. Another deciding factor was our existing relationship with the HOMAG Group, and

the fact that short service routes within Poland are especially important for us.”Marin Zec, Sales Manager at MOD21

MOD21

MOD21 is a company made up of engineers, architects and industry experts with 30 years of experience. The company sees sustainable development not as a trend, but as its social responsibility. For this reason, MOD21 is striving to make a positive change within the construction industry. The needs of the customer are the top priority for MOD21 when constructing new buildings. They use innovative technical solutions to meet individual expectations. The company was founded in the Rhineland in 1993, under the name GWI Bauunternehmen. Today, MOD21 operates nationwide. As part of the ERBUD Group, which employs almost 3000 people across Europe, the company benefits from shared synergies and works together with the other companies in the group to provide mutual support.

More information