As in Japan, timber construction has a long-standing tradition in South Korea. The classic residential building is the “Hanok”—a wooden house featuring underfloor heating and climate-regulating clay walls, offering a high level of comfort. Even today, Hanoks are still built in traditional woodworking shops, and master carpenters rank among the highest-paid tradespeople in the country. Their skill is widely recognized, and the fact that the South Korean contestant was crowned world champion carpenter at Holz 2022 in Basel is no coincidence. Unlike Japan, where major automotive manufacturers operate large-scale timber housing factories, timber construction in South Korea remains a niche market. Most of the population lives in metropolitan areas, where buildings are typically made of reinforced concrete. However, niches for timber construction are emerging on the outskirts of cities and in rural areas, where demand is growing steadily for healthy and sustainable building solutions. This has led to continuous growth in the timber construction sector over the past few years, not just in residential buildings, but increasingly in high-end commercial properties as well. One sign of the growing prestige of timber construction in the country is that Blumer Lehmann AG was awarded the contract in the early 2020s to build an exclusive golf clubhouse with a free-form roof in Pocheon.

Modern modular houses

One of the rising players in South Korea’s timber construction sector is Space Factory, based in Gyeonggi Province. Founded in 2004 under the name Hangulhousing, the company began building timber-frame residential homes. Today, its focus lies in modular, two- and three-story homes, located primarily in desirable suburban areas and rural regions. In this segment, Space Factory is the national market leader, with a delivery area that covers the whole of South Korea. Until the end of the decade, the company primarily relied on on-site stick framing, following the American model. This approach led to issues with build quality and high construction costs. “To address these challenges, we decided to invest in manual prefabrication methods from the U.S.,” recalls CEO Park Jung-jin. “The goal was to improve the quality assurance of our homes. When carpenters work on-site, the final result often depends heavily on their condition that day. That requires constant, thorough quality control—and even then, you can't achieve the same build quality as with factory prefabrication.” The weather conditions in South Korea were another strong argument in favor of prefabrication: “We have very wet summers and cold winters, which cause construction delays of four to five months each year when building on-site,” explains the CEO. Finally, cost efficiency played a decisive role: “Our aim was also to reduce costs through prefabrication. On a construction site, that’s virtually impossible. In a controlled factory environment, however, there are countless opportunities to integrate cost-saving strategies directly into the production process.”

1000 houses per year

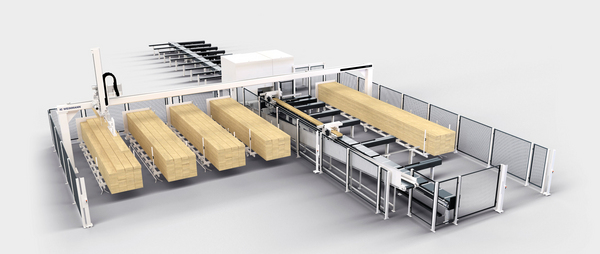

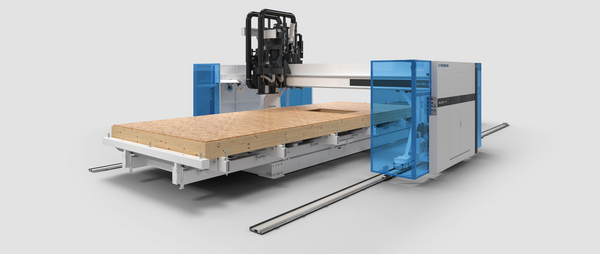

The company’s investment in a manual production line marked its transition to the prefabrication of complete modules. At that time, single-sided sheathed elements were produced, assembled into modules, and then closed after the installation of plumbing, heating units and electrical systems. However, due to the manual processes involved and the limited space in the production hall, the company soon reached its capacity limits. Recognizing the need for further automation, CEO Park Jung-jin recalls: "That was reason enough for me to travel to LIGNA in Hanover in 2019, where we met several companies from Italy, the UK, Sweden and Germany that offered relevant production lines. Eventually, we got in touch with the company that offered us the most comprehensive and professional solution: WEINMANN.” At the time, the company was producing 150–200 houses per year, but already had its sights set on scaling up to 1000 units annually. Another key driver was the need to raise quality standards. While South Korea had long followed American timber construction standards—with about 90% of its timber sourced from the U.S.—new regulations regarding insulation performance were pushing local manufacturers to revise their wall constructions. According to CEO Park Jung-jin, WEINMAN was the right partner to meet both challenges: “WEINMAN machines are not only significantly faster and more precise than manual equipment—they allow us to build high-quality structures at scale. Even more importantly, their flexibility in terms of component configuration enables us to fully meet Korean insulation standards.” As a subsidiary of the HOMAG Group AG, WEINMANN also offers what CEO Park Jung-jin sees as a major advantage: “They have a global presence, including a local branch in South Korea. That means we benefit from professional after-sales service, including training, maintenance and fast support when needed. This local presence was a decisive factor in our decision to choose WEINMAN.”

Smooth transition

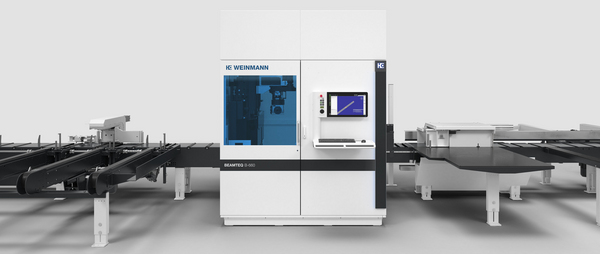

The initial contact, a visit to Weber-Haus, was followed by a longer dialog with intermittent pauses, during which a clear picture gradually emerged: a well-equipped production line featuring an automated frame work station, a total of 16 processing tables, five multifunction bridges, several cutting centers, and two lines for module assembly. The reason for the extended development phase, which continued until 2022, was the client’s search for a suitable site. This phase came to an end in October 2022 with the groundbreaking for a hall measuring 200 meters in length and 90 meters in width. From early 2024, the hall was gradually equipped with the ordered workstations. By September, the company officially began production at its new location. After on-site staff training by the WEINMANN Academy, the launch was supported for five weeks by a dedicated trainer, who not only continued training during live operations but also offered valuable insights into how minor product adjustments could make the new production setup even more efficient. As a result, the transition from the old to the new factory was smooth and seamless. Today, Space Factory is operating at a cycle time of 20 minutes per (multi-)element, already coming very close to the targeted 15-minute cycle—and bringing the goal of producing 1000 houses per year well within reach.

Next step in sight

As a result of its modernization efforts, Space Factory achieved a quantum leap from traditional stick framing to modern modular construction in less than five years. Alongside improvements in cost structure, the company’s market share also grew significantly. Park Jung-jin: “Affordable housing is the key to success in our market.” At the same time, the CEO of Space Factory is already eyeing the next stage of growth for the company: “We’ve now reached an important milestone in our development, but this is by no means the final destination I have in mind for Space Factory. Unlike in Germany, there are still no timber buildings in South Korea taller than four stories. In collaboration with WEINMANN, we’re planning to expand the market for modular timber housing so that we can build taller structures in the future.” Park Jung-jin strongly encourages others in the industry to follow this path: “Around the world, it’s becoming increasingly difficult to find skilled labor and the cost of labor keeps rising. Prefabrication, mechanization and automation offer a way out of this dilemma. By reducing reliance on manual labor, companies can achieve significant cost savings, turning automation itself into a competitive advantage.” “If I had one piece of advice for other timber construction companies, it would be this: reduce your dependence on labor through automation, even if it means higher upfront costs. In the long run, it pays off.”

An article from the performance customer magazine 2025. Read more

“Eventually, we got in touch with the company that offered us the most comprehensive and professional solution: WEINMANN.”Park Jung-jin, CEO Space Factory

Space Factory

Founded in 2004, Space Factory focuses on modular two- and three-story homes, located primarily in desirable suburban areas and rural regions. In this segment, Space Factory is the national market leader, with a delivery area that covers the whole of South Korea.

More information about the company