This is evident not only in the increasing number of projects, but also in the advancement of technical capabilities, closely tied to a broader process of industrialization within the sector. Political developments at the European Union level are creating better conditions for timber construction, even in countries like Spain, where it has traditionally played a minor role. In fact, over the past ten years, Spain has shown signs of a turning point, with steady, if gradual, momentum building.

New opportunities for timber construction in rural areas

Spain is characterized by strong contrasts between north and south, and between urban and rural regions, which generate varying trends for the timber construction sector. In many rural areas, construction knowledge has traditionally been passed down from father to son. However, following the severe construction crisis of 2008 and a lack of young talent, many of the traditional building companies that once provided a wide range of high-quality turnkey homes have disappeared from the market. Today, individuals looking to build a home in these regions struggle to find reliable construction firms. What remains is a large number of autonomous, informal contractors, but few professional building companies. This challenge is compounded by sharply rising prices, driven by the fact that the few remaining firms only take on projects they consider financially attractive. As a result, a market gap is opening for young timber construction companies, especially those able to offer clients fixed pricing and tight scheduling—providing a higher level of investment security than conventional providers.

Steady growth in a strong construction market

Overall, the structural shifts of recent years have led to timber construction in Spain doubling its market share—from around 1% in 2019 to 2–2.5% at present. Compared to figures from German-speaking countries, this may seem modest, but the trend is clearly upward, with momentum continuing to build. One of the companies that HOMAG Senior Sales Manager Thorsten Franz Linke sees as having a promising future is timber construction firm Madergia, based in Ansoáin near Pamplona. Founded in 2005 by a group of engineers, the company is located in Navarra, northern Spain. With 32 employees, an annual turnover of €10.5 million and up to 70 timber construction projects per year, Madergia is now considered one of the major players in the Spanish market. Managing Director Alberto de Miguel Lozano looks back on a successful company history—marked first by steady, moderate growth, and since 2022 by a period of rapid expansion. From the beginning, the company has focused on single-family homes and engineered timber structures, particularly long-span roofs for sports halls, commercial buildings, and public facilities. Over the years, the company has expanded its portfolio to include multi-story residential buildings, commercial properties and facilities in the health and education sectors, which now account for around 70% of total revenue. Its delivery area spans all of Spain, including the islands.

Supplier to major construction firms

The contracts typically come from construction companies, to which the firm supplies industrially prefabricated timber components as a subcontractor. In doing so, the company flexibly employs timber frame constructions, CLT structures, or hybrid building methods, depending on project requirements. It also demonstrates a high degree of flexibility in the execution of timber frame elements. The timber components are always delivered as closed elements, although Alberto de Miguel Lozano does not see a trend toward fully turnkey timber buildings for the company at this time. The general contractors are commissioned by private developers, investors, companies, and municipalities. Key contacts include property managers, project developers and architects, all of whom are also target groups for Madergia. Alberto de Miguel Lozano: “What matters most to us is that each of them knows and uses our solutions—even though, in practice, we mainly work for the contractor.” Thanks to this strong network, Madergia is increasingly involved in early planning discussions with the end customer. “That leads to more efficient solutions, because it allows us to work directly with planners to develop the best possible timber construction concepts,” explains the Managing Director. Customers also value the company’s reliability, consistent quality, fixed pricing, strong service and adherence to deadlines. A high percentage of new clients come through word of mouth.

Restructuring for the future

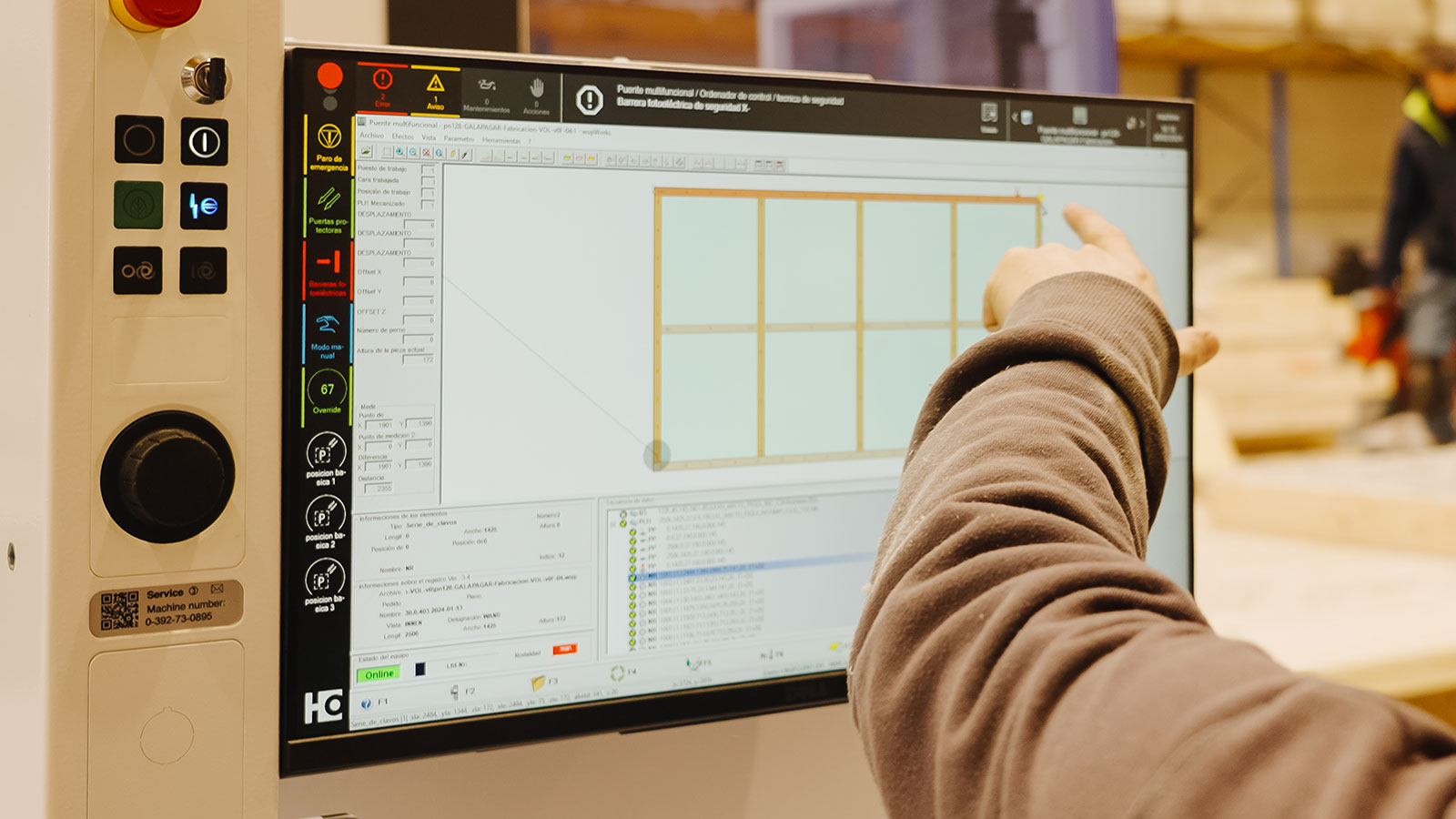

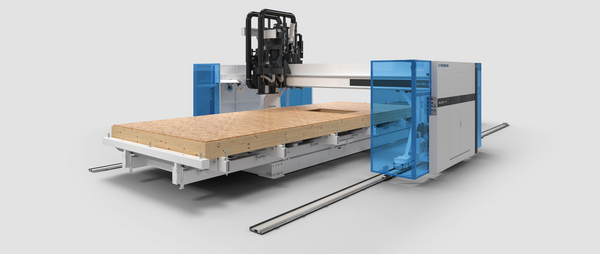

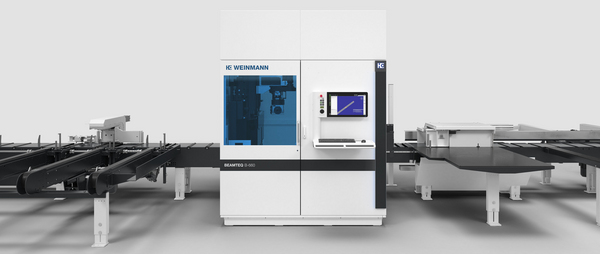

With growing momentum in the timber sector, driven by the climate debate, EU directives, and a broader shift toward industrialized construction, the company anticipated strong growth in the years ahead. In 2022, it decided to modernize production, having already integrated a WALLTEQ M-380 multifunction bridge as an initial step. “Right now, trends in Europe are moving from north to south,” explains Alberto de Miguel Lozano. “So we just have to look north to understand what’s coming to Spain next.” That’s why, in 2022, we initiated a restructuring process to get ahead of the wave we were certain was coming. The goal of the investment was to increase production capacity, boost precision, and achieve a consistently high level of industrial component quality. Rather than entering new markets, the company focused on gaining speed and efficiency in its current segments—reducing cycle times, improving production planning, and shortening on-site installation time through higher prefabrication levels. Ergonomics was also a key priority for Alberto de Miguel Lozano—not due to labor market pressures, but out of a commitment to improving workplace conditions. Recruiting new employees is relatively easy for Madergia, as the company is considered highly attractive, especially among younger workers. In 2022, company management entered into initial exploratory discussions with Thorsten Franz Linke, the responsible Senior Sales Manager at HOMAG. These talks were not just about aligning the new WEINMANN production line as precisely as possible with current construction methods, but also with anticipated developments within the company.

Successful growth in two phases

At Madergia, an additional challenge was to divide the planning and implementation of the new production line into two phases. Initially, the first machines were to be installed at the company's former site, where space was limited. Twelve months later, the plan was to relocate to a new facility with larger halls and complete the installation of the full line. “WEINMANN designed our system in such a way that efficient operation was possible at both locations,” recalls Alberto de Miguel Lozano today. The managing director also highlights as a positive that they were able to combine a custom-built timber worktable, tailored in-house to the company's specific needs, with the new line. Another key benefit was the valuable support provided in optimizing shopfloor processes, including a crucial recommendation on how to seamlessly integrate the company’s existing blow-in insulation plate into the production flow. Madergia also received support in fine-tuning specific details—for example, in adapting from nailed to stapled joints, and in translating Cadwork drawings into machine-readable formats. The latter task was handled effectively, thanks to the company’s experienced work preparation team. From the perspective of company management, the collaboration during this phase was both smooth and efficient. As a result, in addition to the multifunction bridge already in use, the company placed orders for a carpentry machine, an assembly table and two vacuum lifters as the next step in its automation strategy. Further equipment orders are planned following the move to the new facility. The startup phase of the new technology in early 2024 confirmed the positive impression gained during the earlier discussions. Thanks to pre-start training and on-site support from WEINMANN employees during the first week of production, the company experienced a smooth production transition, without any downtime or interruptions. Issues, such as challenges with cutting thick timber panels, were resolved quickly. “After a short time, the new cycle times were already outperforming our previous results,” recalls Alberto de Miguel Lozano. “This allowed us to begin offering our customers shorter delivery times, which significantly strengthened our market position.” The same applies to cost savings in production, which are passed on to customers, and to the increase in the level of prefabrication made possible by the new technology—reducing labor on the construction site. In summary, this investment marks a clear step toward industrialization, making the company noticeably more attractive to its clients.

An optimistic outlook for the future

The company is now actively leveraging the new technology in its marketing and, following a successful 2024 “during which we learned a great deal about handling the new systems during ongoing operations,” it feels ready to take the next steps. “Thanks to the new technology, we’ve achieved a level of precision that gives us the confidence to build even taller structures in multi-story construction,” explains the managing director. “That’s why I believe we’ll continue to grow just as rapidly in the coming years.” This is especially likely because the company now has brand-new processing capabilities at its disposal in the new facility, which spans approximately 10,000 m2—enabling the development of even higher-value products for the market. “With WEINMANN, we’ve found the right partner to continue strengthening our market position by delivering excellent work at a competitive price.”

An article from the performance customer magazine 2025. Read more.

“Today, we’re able to deliver better quality in less time and at more competitive prices, which has

clearly strengthened our position with customers.”Alberto de Miguel Lozano, Managing Director of Madergia

Madergia

Madergia is a company that specializes in industrial construction and designs, manufactures, supplies and assembles timber construction systems. Founded in 2005 by a group of engineers, the company is located in Navarra, northern Spain. With 32 employees, an annual turnover of €10.5 million and up to 70 timber construction projects per year, Madergia is now considered one of the major players in the Spanish market. The company has already completed over 1000 projects and operates two production centers in Oricáin and Aoiz.

More information about the company