Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

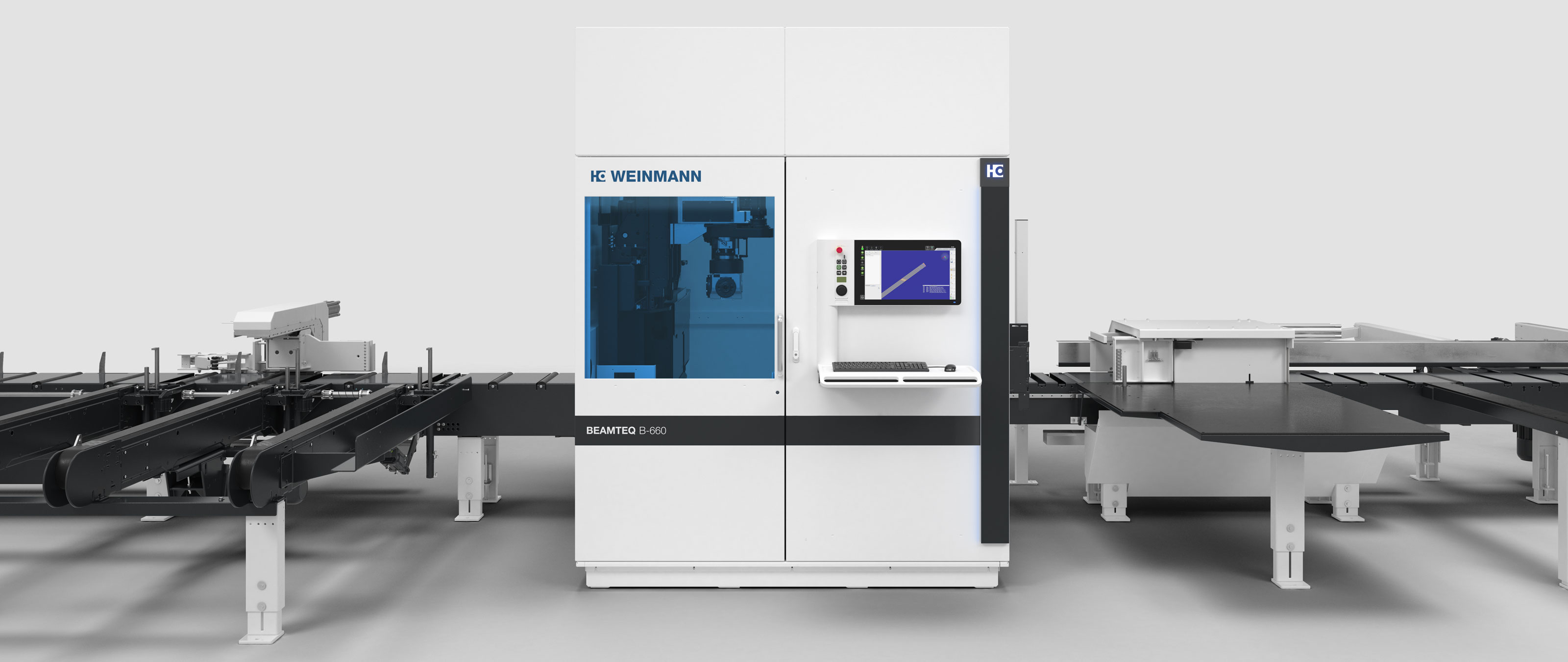

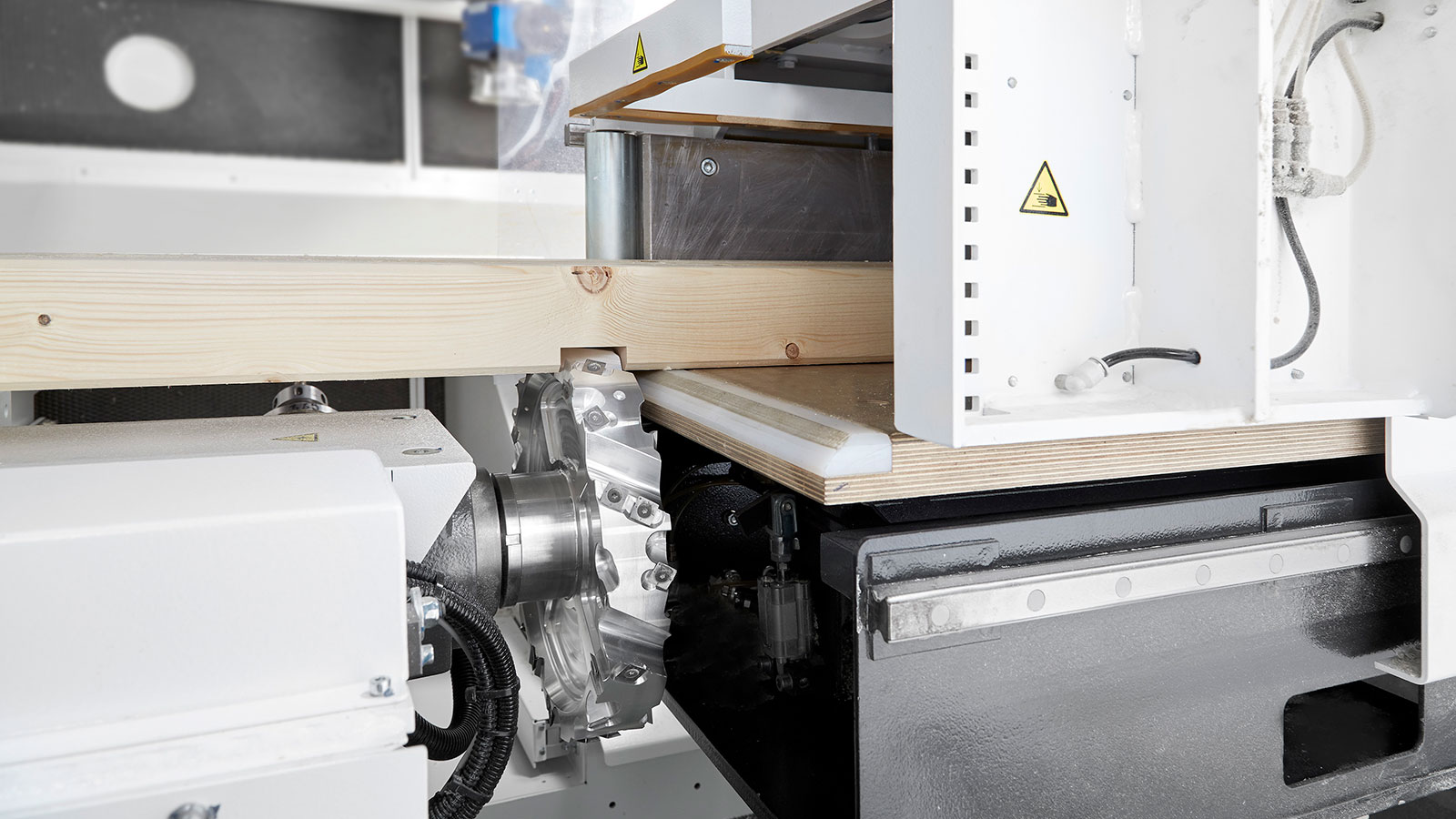

WEINMANN Carpentry Machines BEAMTEQ B-660

WEINMANN Carpentry Machines BEAMTEQ B-660

All six sides of a component in a single run

Benefitting from an underfloor unit, the BEAMTEQ B-660 from WEINMANN enables fully automated processing of all six sides of a component. Quickly and easily manufacture blocking grooves on rafters and dovetail connections on both sides of ridge beams.

Highlights

The underfloor unit enables fully automated processing of all six sides in a single throughfeed.

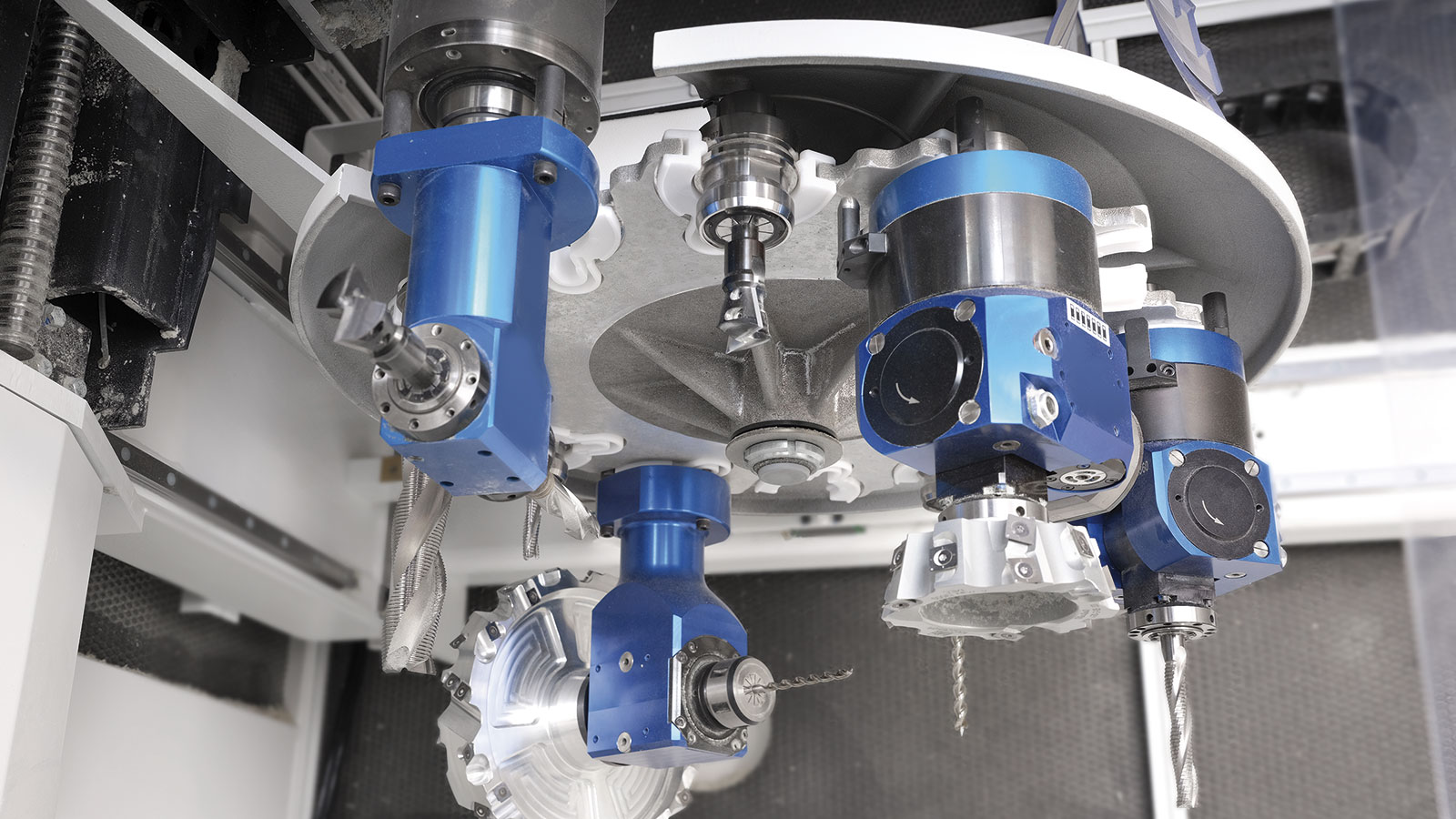

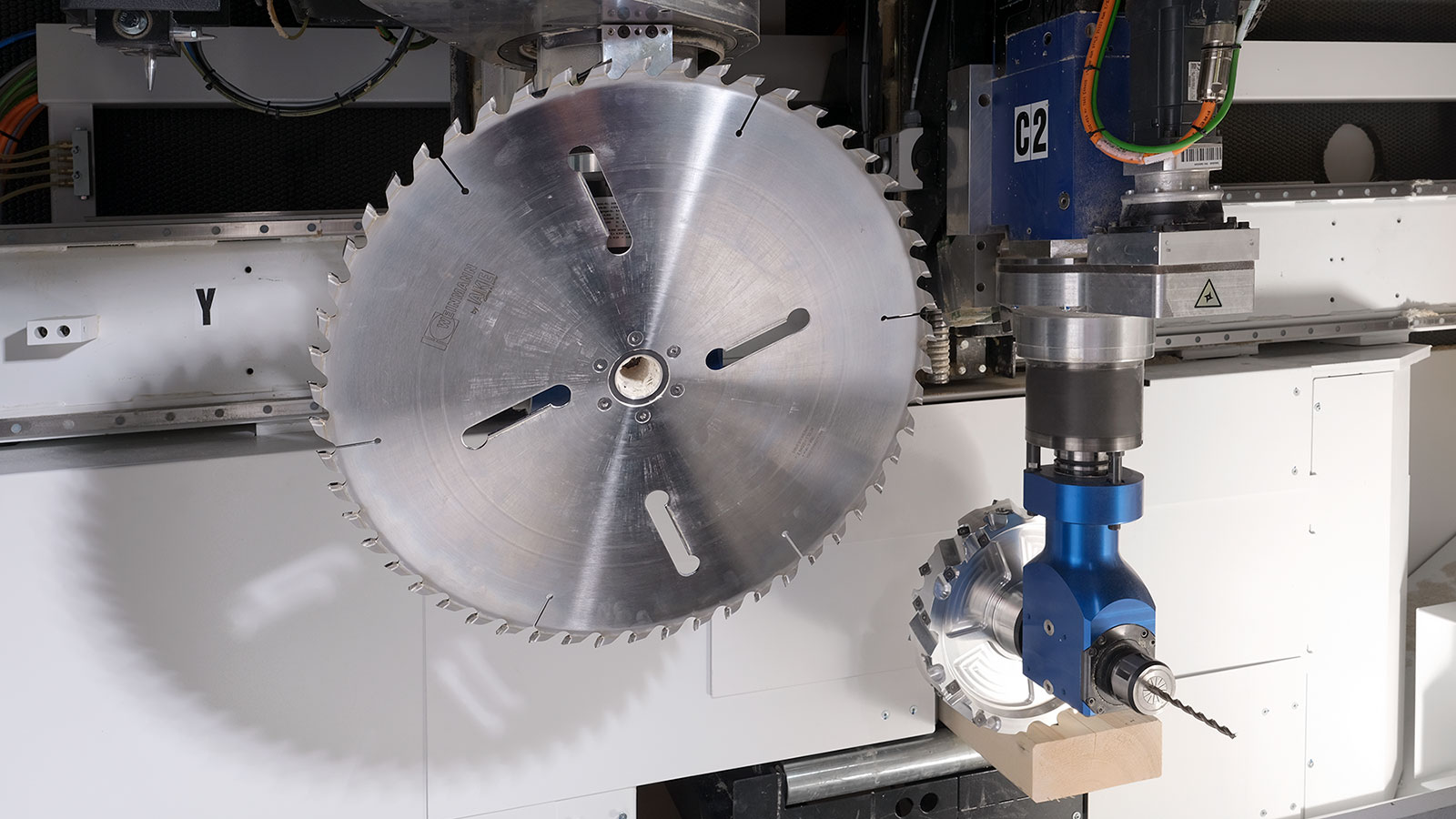

High level of flexibility thanks to the sawing unit and additional tool spindle including the automated tool changer for up to 12 tools. A FLEX5 processing unit and tool angle unit provide the option for complex processing, e.g. horizontal processing or miter cut processing.

Side milling cutter and trimmer or dovetail trimmer installed on the underfloor unit.

Images

Features

-

The underfloor unit: Features a 6.6-kW side milling cutter plus a 7.5-kW drive unit for a finger trimmer, dovetail trimmer or drill

-

12-slot tool changer and second integrated main spindles

-

5-axis technology for trimming, sawing and drilling

-

Reduced noise and dust emissions thanks to the fully enclosed machine housing

-

FLEX5 sawing unit: A rotation angle of 0–360° in conjunction with a swivel angle of 0–90° allow you to process angled cuts, notches, rafter assembly cuts and rip cuts

-

High level of processing accuracy thanks to the NC gripper system combined with vertical and horizontal clamps

Technical Data

| Min. cross-section [mm] | min. 20 x 50 max. 200 x 455 |

| Unprocessed timber length [mm] | min. 1,500 |

| Unprocessed timber length with intervention [m] | max. 16.5 |

All technical data are without engagement!

(Previous product name: Carpentry Machine WBZ 160 powerSIX)

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Master joiner: The latest generation of the BEAMTEQ B-660 at Nehr Holzbau

Nehr is delighted with its new BEAMTEQ B-660: It has a small footprint, works more precisely and faster thanks to the latest control technology and scores points with its improved chip extraction and much more.

Brochures