Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

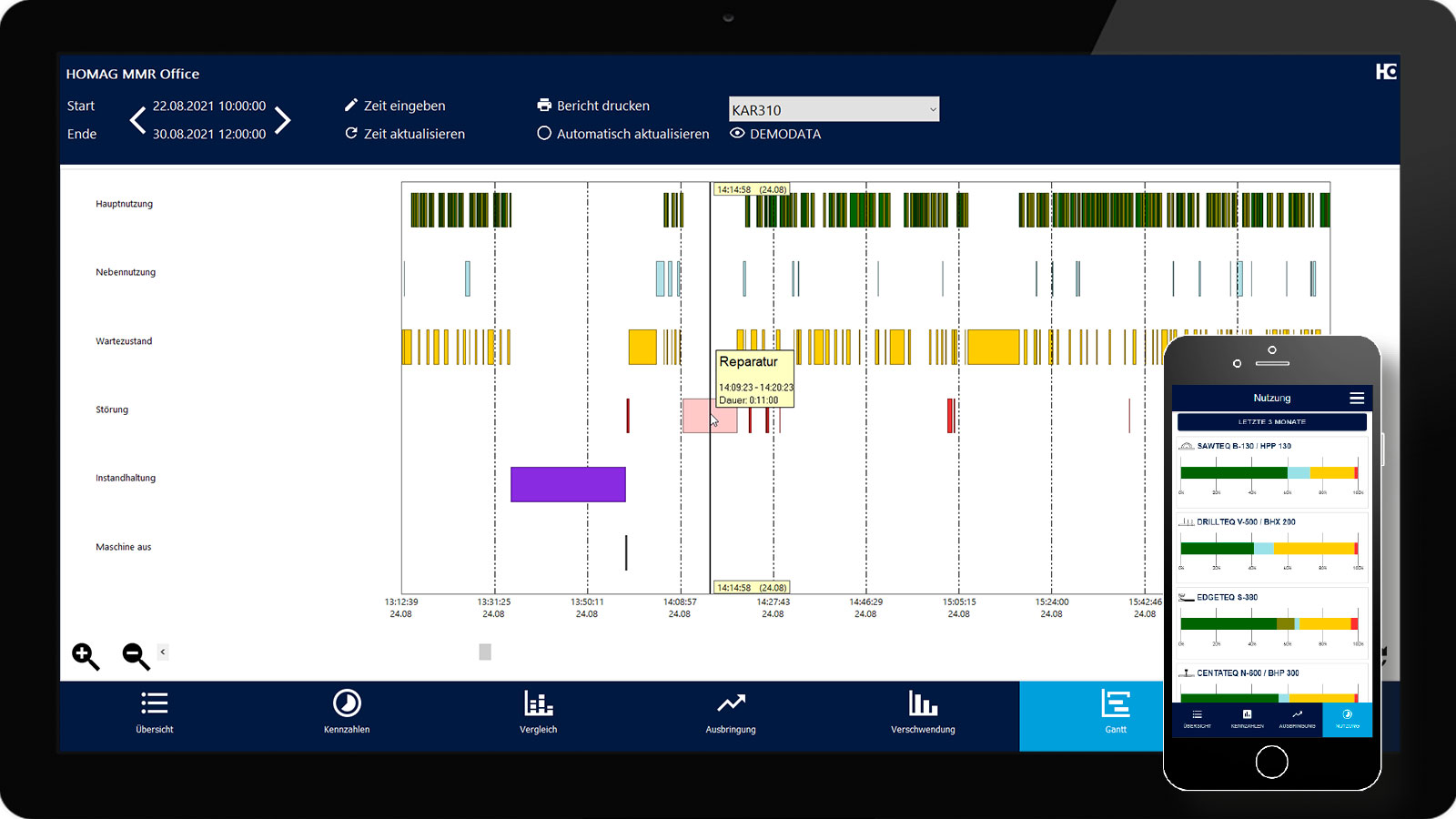

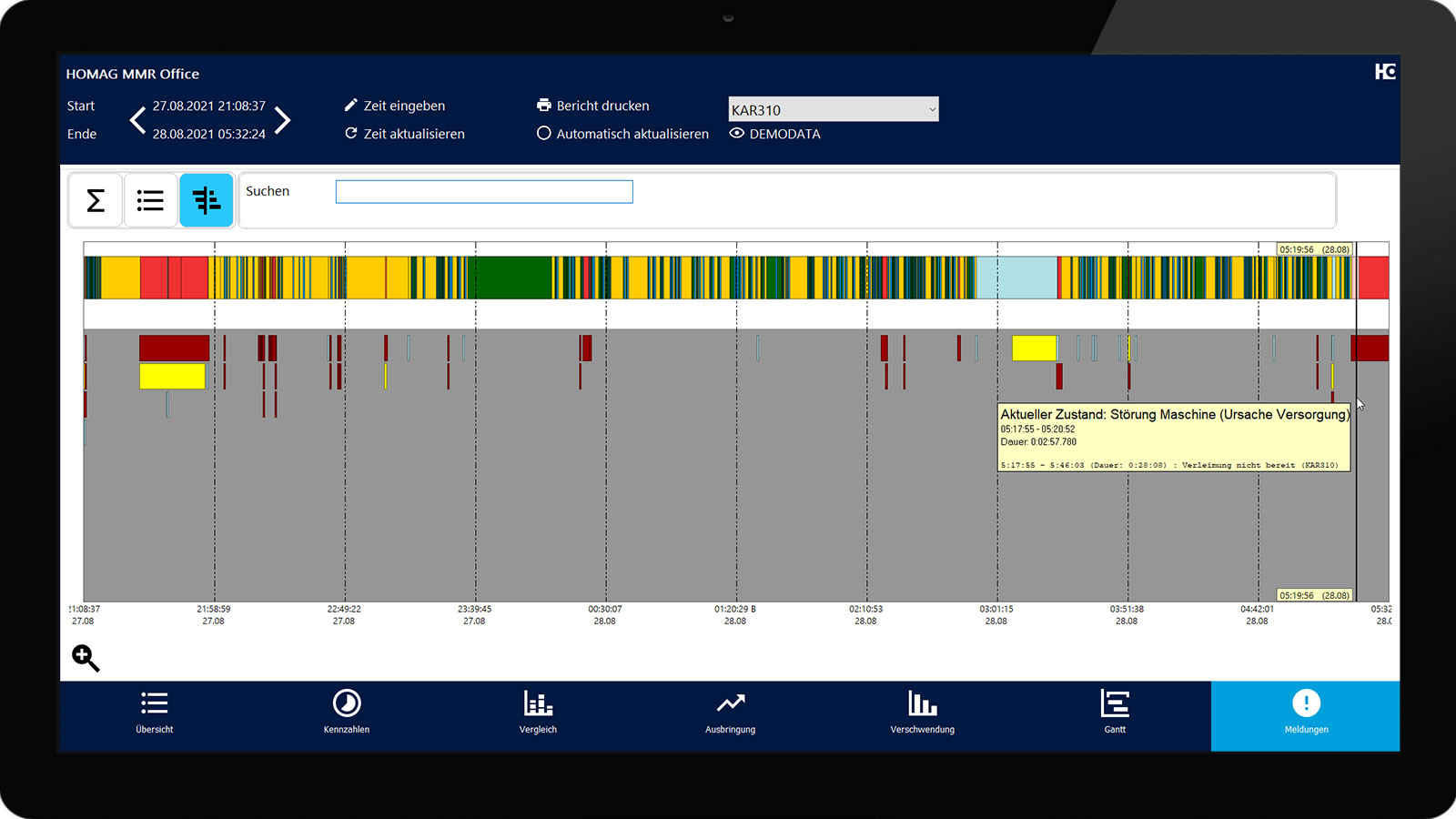

Production Management MMR Office

Production Management MMR Office

The software for analyzing your machine data

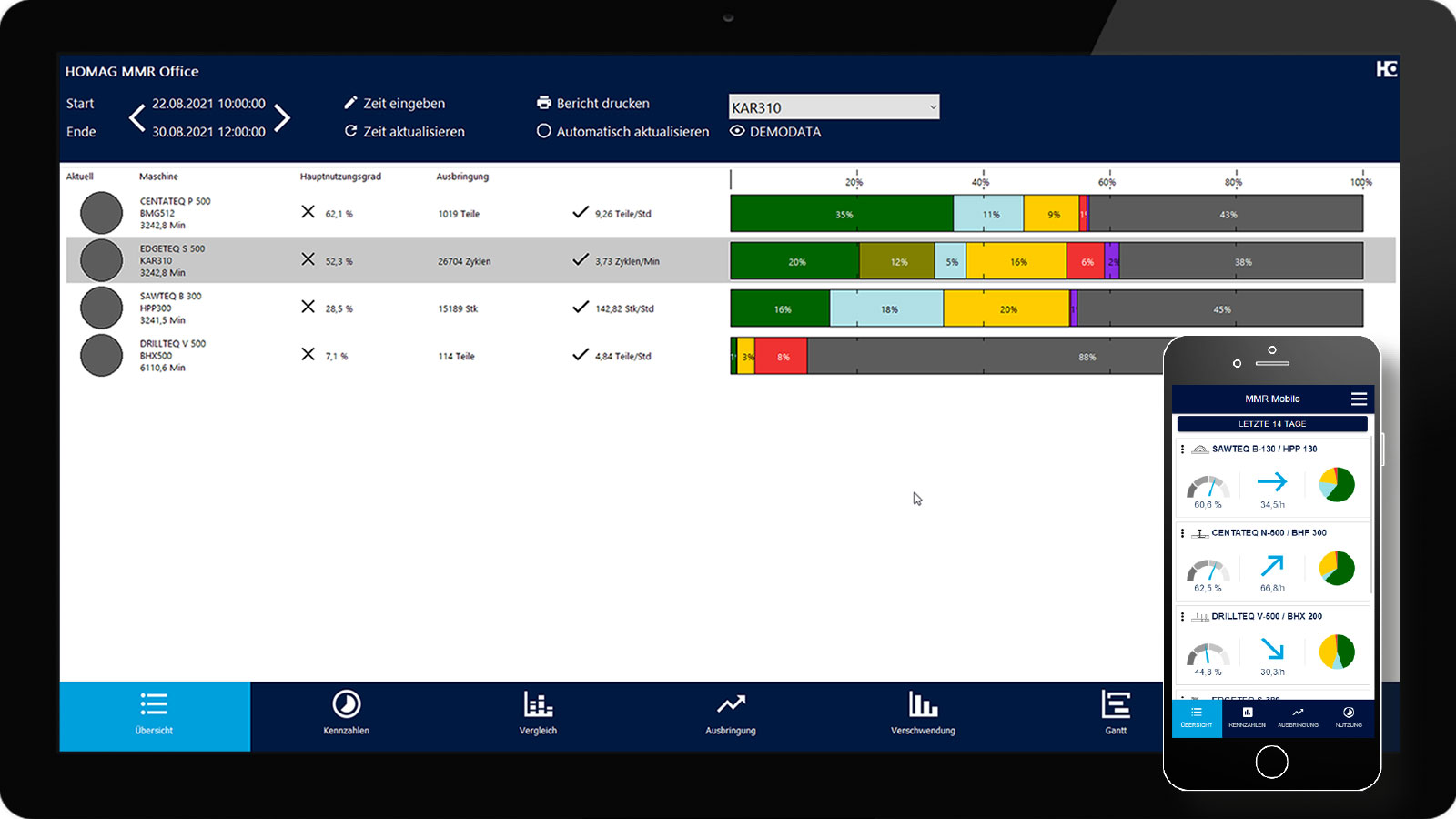

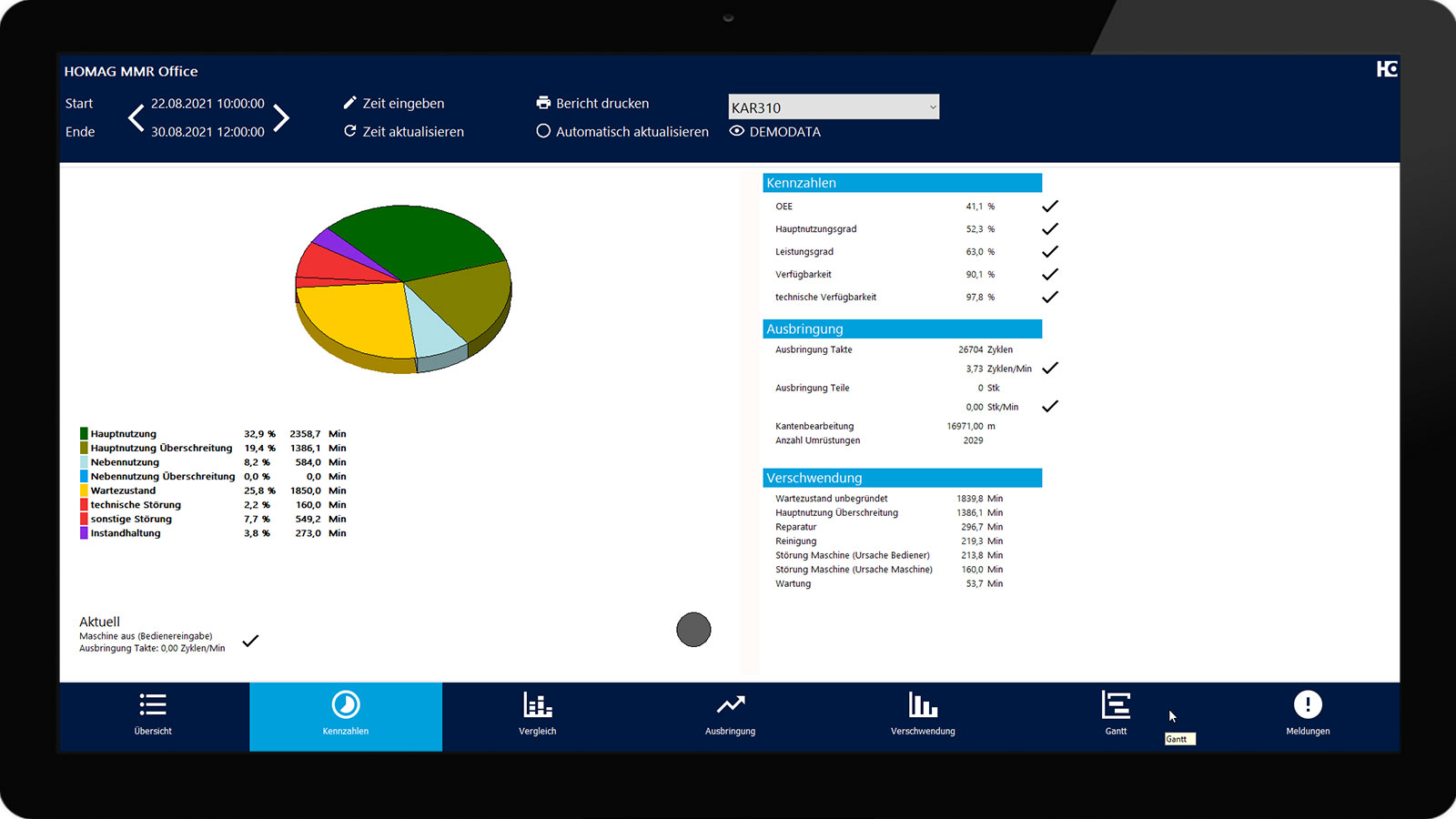

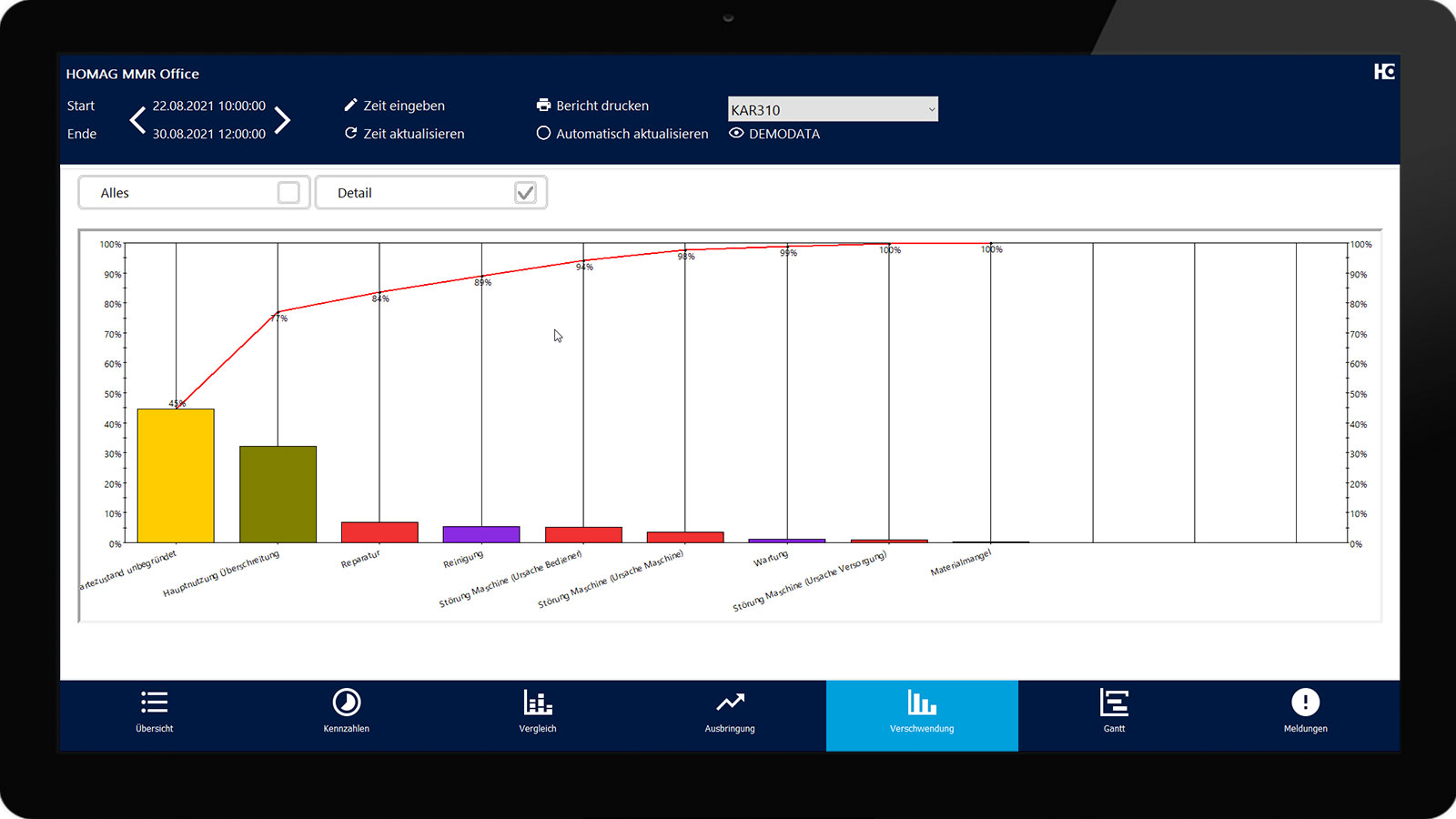

Anyone who invests in machine technology wants to unlock the full potential of their production environment. Are you making full use of your production capacity? On what machines is there potential to be more efficient? And what measures can you take to achieve this? To embed your machines in the production sequence in the optimum way, the performance and efficient operation of each individual machine is crucial. This is where MMR (Machine Monitoring & Reporting) in the form of an app and software provides an essential overview. Parts, cycles or changeover gaps and much more – you get real data, for easy analysis and real improvements. The best thing is that MMR also connections machines from other manufacturers as well as older machines.

Images

Features

-

The MMR Office (=Machine Monitoring & Reporting) software...

- ...can count parts, cycles, storage movements, cuts, panels and much more.

- ...knows the optimal cycle time for each part (for throughfeed machines).

- ...knows the necessary handling times in the machine process (e.g. for saws).

- ...can record automatic setup processes (e.g. for batch size 1).

- ...saves error messages with text.

-

Various expansion levels – MMR grows with you:

- MMR Mobile – all machines in your pocket: an overview of all machines, data is provided via the cloud, meaningful evaluations are available quickly, use is free of charge.

- MMR Office Lite – the lean solution for the office: detailed evaluations (going back up to 30 days), easy installation (access to the database on the machine), up to three machines can be connected.

- MMR Office – the expert evaluation tool for the office: detailed evaluations (going back up to two years), installation of a database on your server, connection of older machines and machines from other manufacturers, one, five or up to twenty machines can be connected.

Technical Data

Data interfaces

- OPC-UA and REST interfaces should be used to connect older machines and machines from other manufacturers.

Further Solutions

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Machine Monitoring & Reporting (MMR): The production tachometer of HOMAG

Software for analyzing your machine data.

Brochures