"The Pilatus towers mythically over Lucerne — a place full of legendary stories," reads a Swiss advertisement for the mountain beside the village of Schwarzenberg. Within this small valley municipality lies the Vogel joinery. This company doesn't spin tales, but instead produces timeless wood-based products — using machines from HOMAG.

The Vogel joinery came from humble beginnings. Founded over 25 years ago, the family business has grown at a steady pace: more employees, more space, more orders. The team, which initially consisted of four people, is almost fifty strong today, and is headed by owner and managing director Markus Vogel and his wife. The idyllic, rugged landscape is reflected in the Schwarzenberg company's love of nature — and of wood as a material. Processing relies not only on the skills of its employees, but also on its machines and software. The main products are kitchens, doors and cabinets, along with furniture, interior fittings, windows, stairs, floors and more. The ultimate goal is quality and service. This brings in satisfied customers, mostly from the surrounding area of Lucerne. But the development has consequences: "We never planned to get so big," Vogel says.

Evolution marches on

Growth requires a rethink — both technically and spatially. In 2012, Vogel bought a larger property in the village. A workshop with increased automation was created at the new company headquarters in Kapellmatt — with the aim of keeping software and machines up-to-date at all times. But around ten years later, the company burst out of its seams once again. Relocation? Not an option. So the workshop and storage system had to be reorganized again. The solution was a high-performance panel saw, plus a storage system on a secondary level. To obtain this, the joinery needed a partner with an awareness of local conditions and the ability to provide modern technology and solve problems quickly — a partner that would be reliable both before and after the machine had been purchased. "Our customers rightly expect their order to be reliably implemented," the company's CEO acknowledges. "I also expect this from my partners: Direct communication, short distances, no detours."

No need to move mountains at the foot of Mount Pilatus

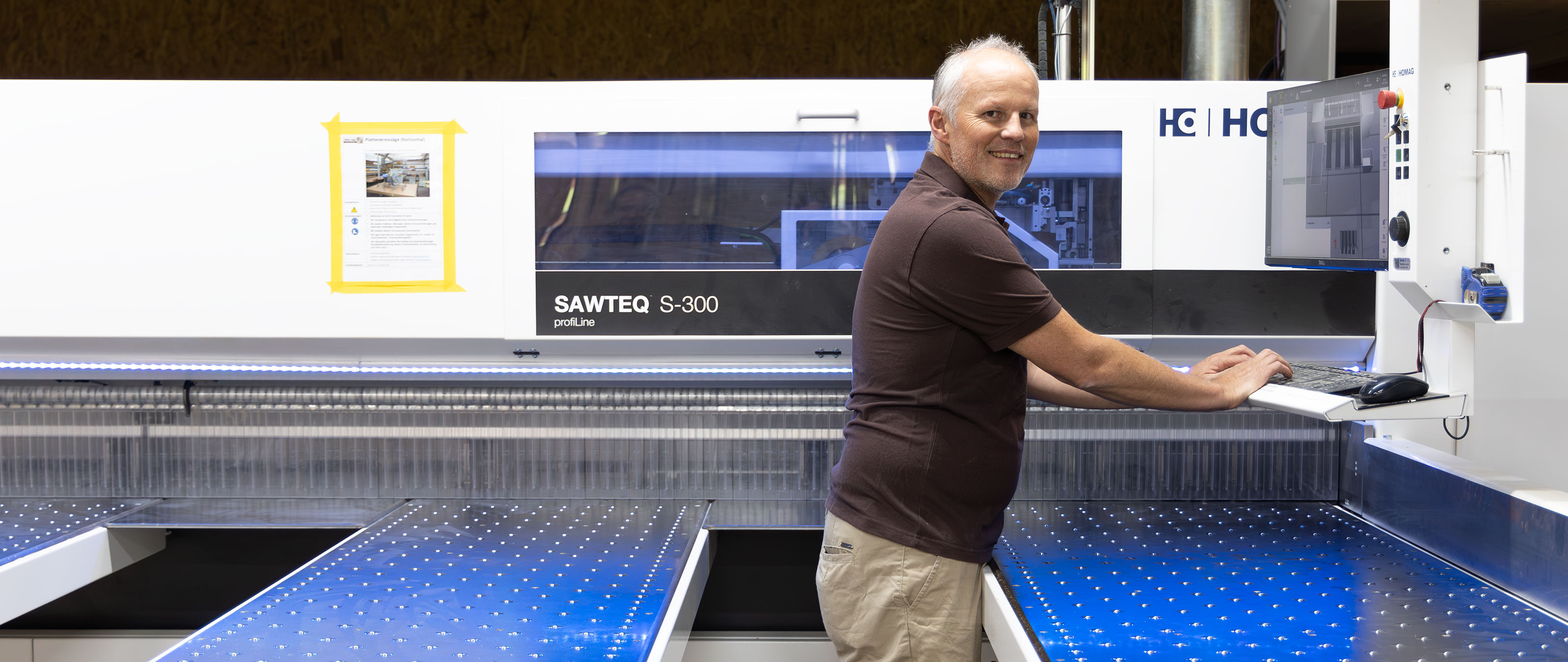

HOMAG makes the work a walk in the park. The distances are short and the communication is just as excellent as the machines and systems in Holzbronn. This works for the joinery at the foot of the mountain range. The two firms have been working together for a long time, and the Schwarzenberg joinery already has several HOMAG machines at its disposal. This proven quality is matched in terms of customer service. Vogel therefore knew who to contact about implementing these restructuring plans. In the end, there were a lot of factors to consider.

A switch-up in storage

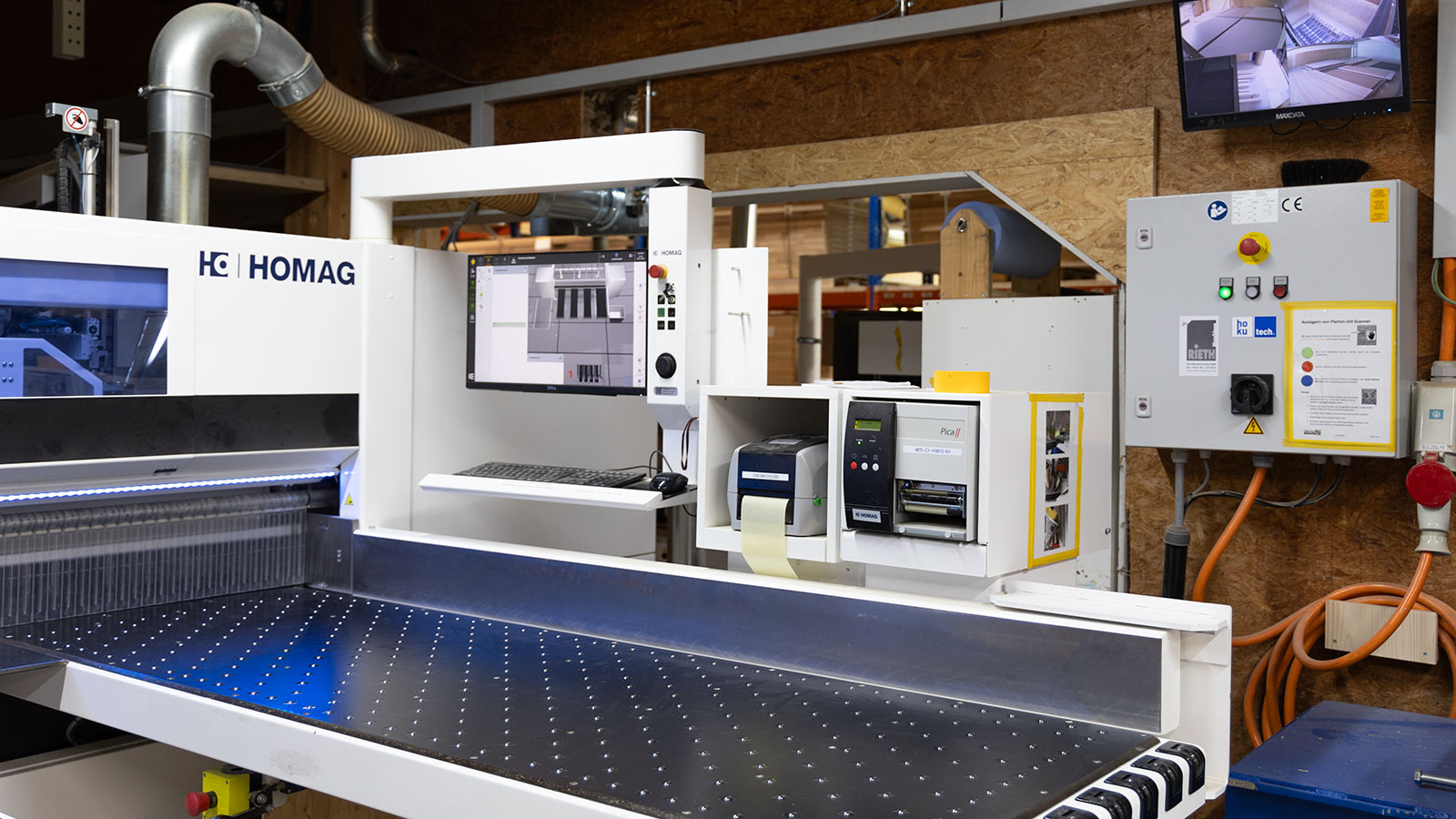

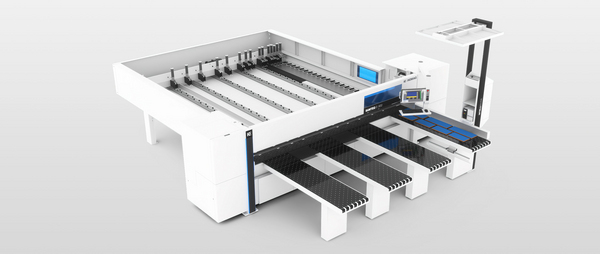

The SAWTEQ S-300 panel saw and the STORETEQ P-310 storage system were selected. However, because there was no space at the business location, the heart of production moved from the center to the sides — and the storage system underwent a switch-up. The saw was moved to the previous storage area, and the storage system was moved under the roof with diagonal ceilings. To protect employees, a movable fence was installed. HOMAG implemented this in its entirety, arguably creating the first storage system in Switzerland that is on a separate level to the workshop. "After a short period of familiarization, the cross rail ran quickly, safely and reliably," says Vogel.

Panel dividing: always the focus, never sidelined

Since then, waiting times have been almost non-existent at the Vogel joinery. This has been ensured by the intelligent storage system with 16 slots, two of which can be filled down to the lower level. Feeding and sorting are quick and carried out with care. "We always know what's in the storage system. After a week and a half, it all went perfectly." The recycling of residual panels has been a particular standout: "We produce new materials from the offcuts." Investment and restructuring have paid off time and time again. Production is quicker and the work is easier. Employees also feel that the atmosphere in the workshop has become quieter with the absence of forklifts speeding down the narrow corridors. "With the saw-storage combination, production runs more uniformly, more quietly and it's easier to focus. In spite of the fast order processing, things rarely get hectic." The panel dividing saw with ERP control system has been pushed to the sides. But this saw is not a wallflower. With features such as a scanner package, destacking module and pressure beam printer, it offers an affordable first step into fully automatic panel cutting. And it only needs one operator to run.

Versatile nesting and precise edges

The compact CENTATEQ N-500 CNC gantry processing center processes and cuts panels with minimal waste. Vogel uses the machine for the typical areas of application as well as nesting, to create furniture and cut and refine kitchen fronts. Its automated material handling saves time and makes work on the machine more effective. Two synchronized digital servo drives in the X direction ensure processing quality; the tool change system features several slots. The CENTATEQ with its standard equipment is also energy-efficient thanks to its high performance and low power consumption. Meanwhile, an EDGETEQ S-500 ProfiLine ensures precise glued edges. The selectable feed adapts to the productivity, which provides a suitable solution for companies such as Vogel with frequently changing performance requirements. "We save a lot of time with the return and use less plaster." Automation and expansion of the range of functions in this solid series are also individually available.

A proven partnership

Vogel values HOMAG's product range and the quality of the coordinated machines. In addition, it delivers on-site service in Switzerland. "The result is ideal and we have been fused together in this partnership," he says. "With HOMAG machines and systems, we are getting closer to our goal of achieving the speed of a factory with series production, while remaining a joinery business with genuine joiners." And if there is any doubt, a HOMAG specialist is always available with a practical solution for every problem. A second CNC has already been ordered.

“With the saw-storage combination, production runs more uniformly, more quietly and it's easier to focus. In spite of the fast order processing, things rarely get hectic.”Markus Vogel, owner and managing director of Schreinerei Vogel AG