Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

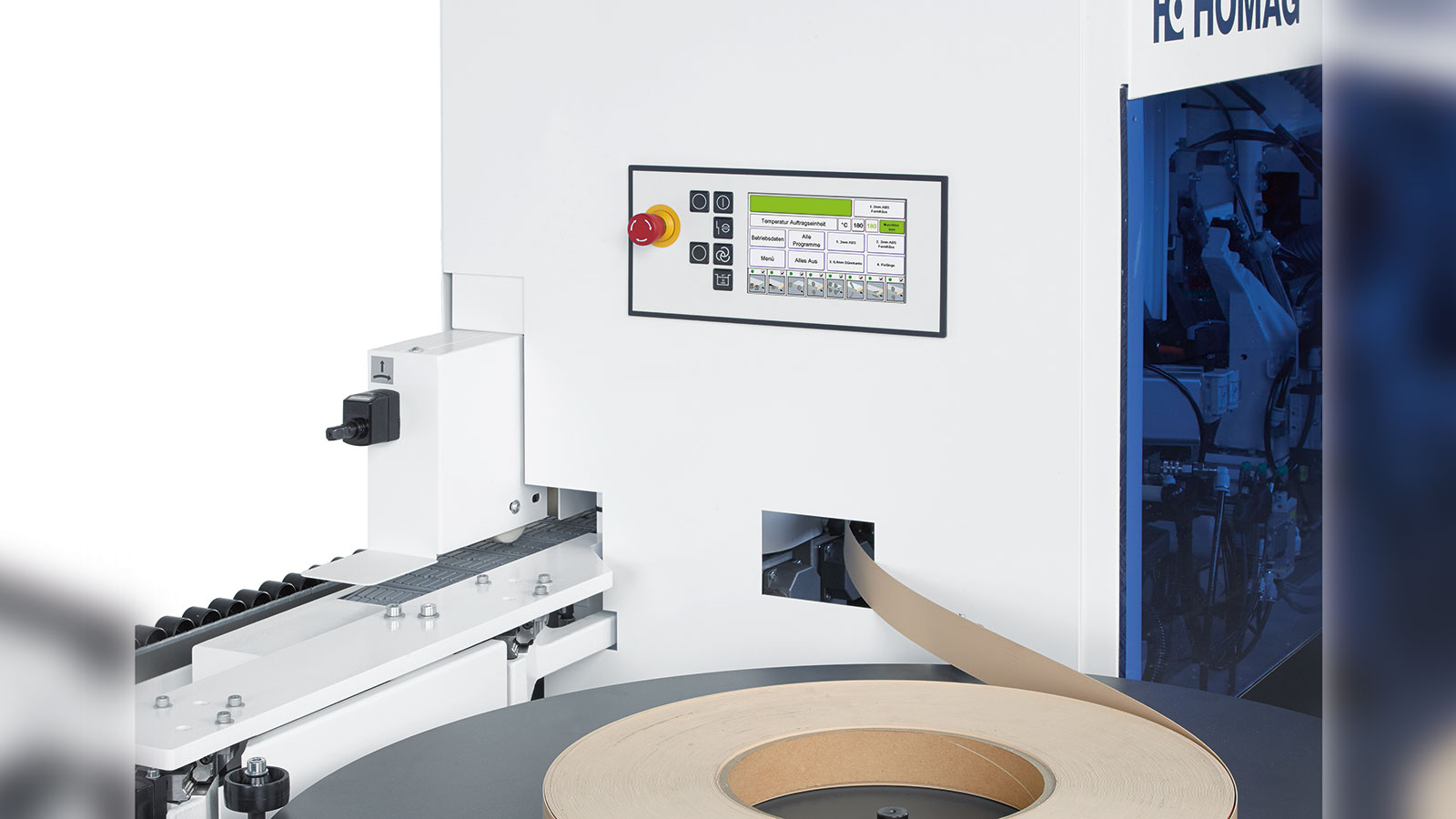

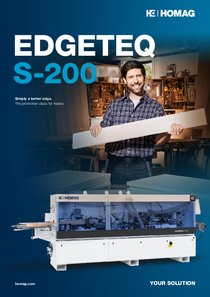

Edge Banding Machines EDGETEQ S-200

Edge Banding Machines EDGETEQ S-200

Simply a better edge.

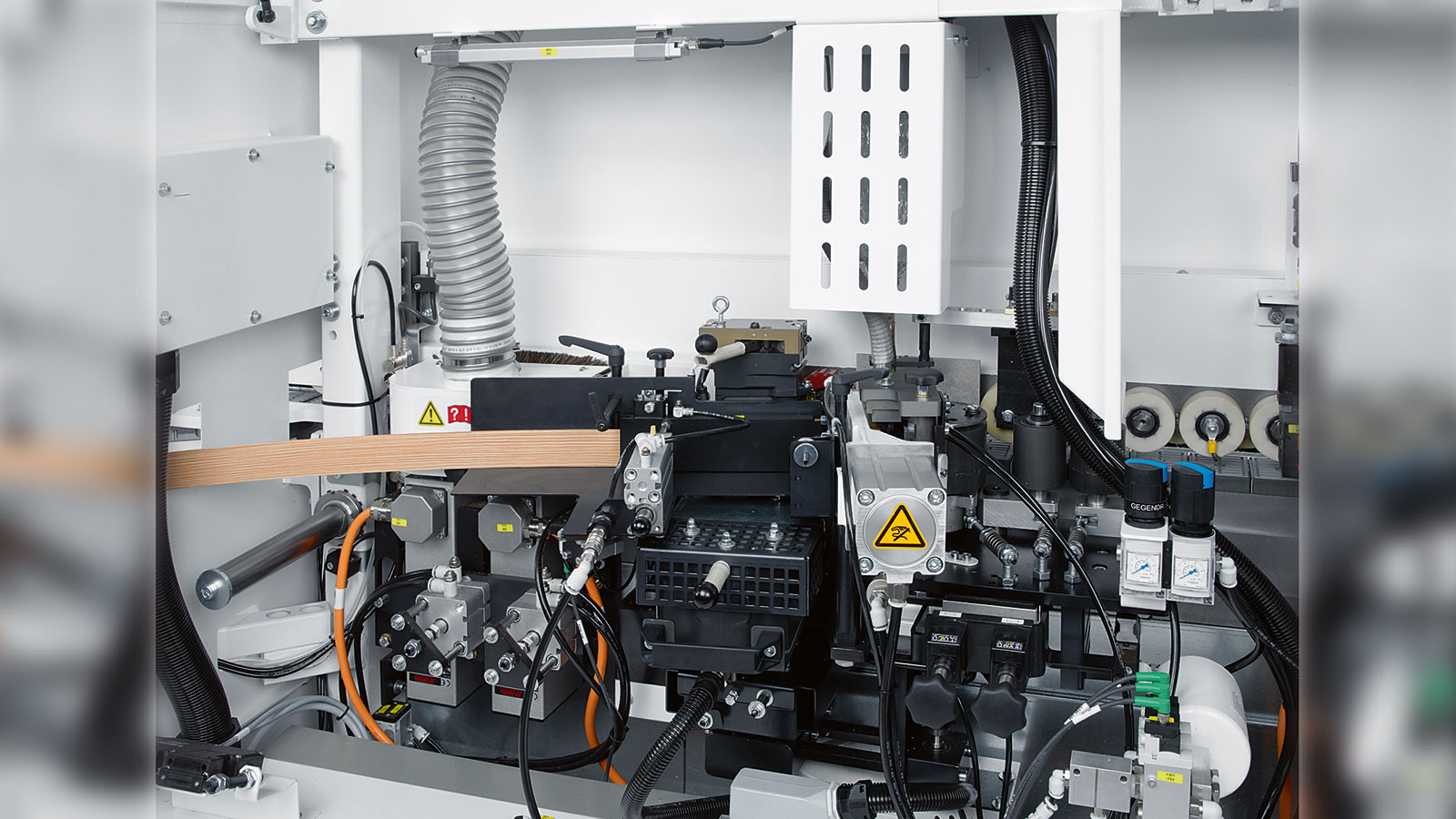

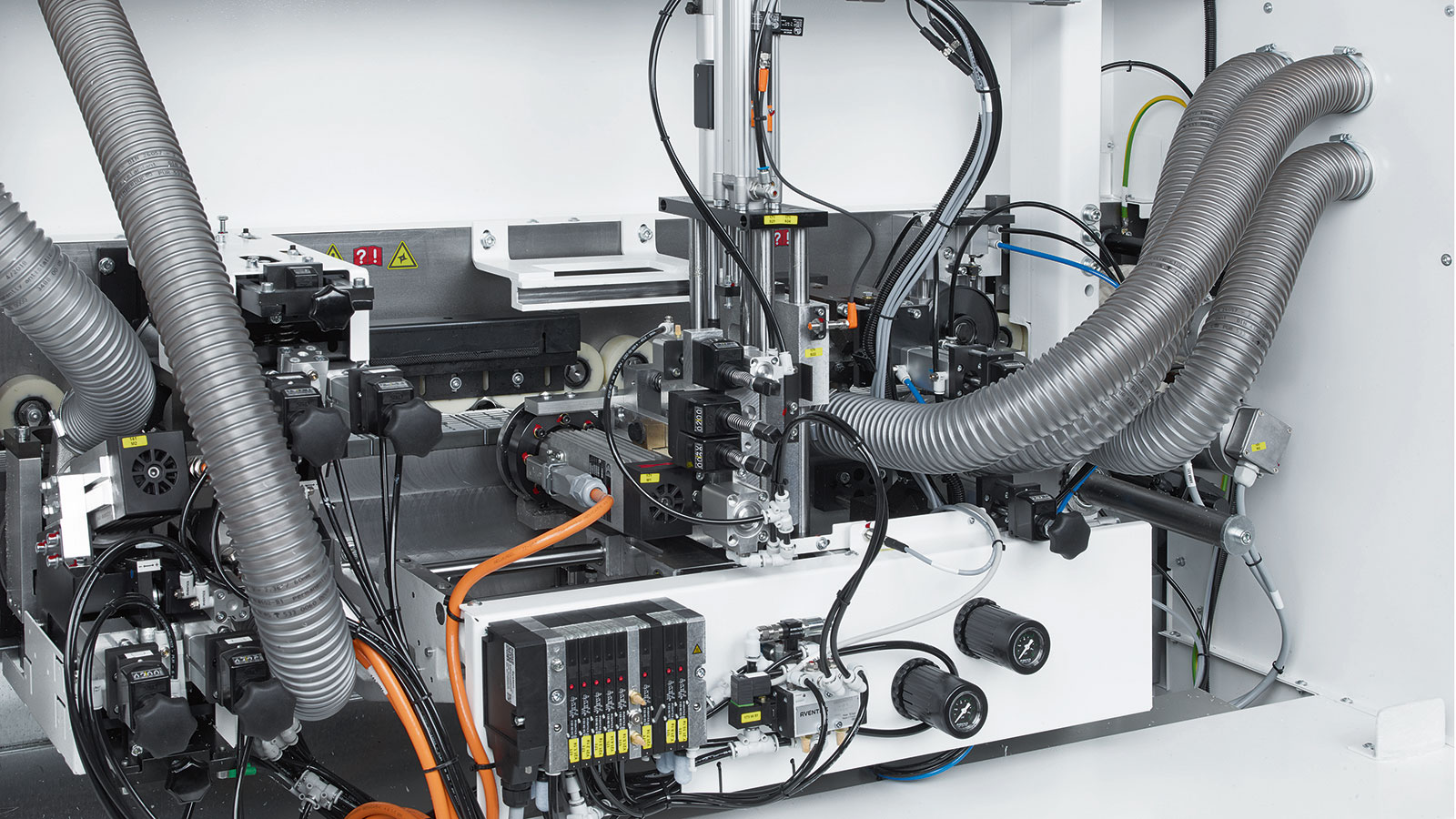

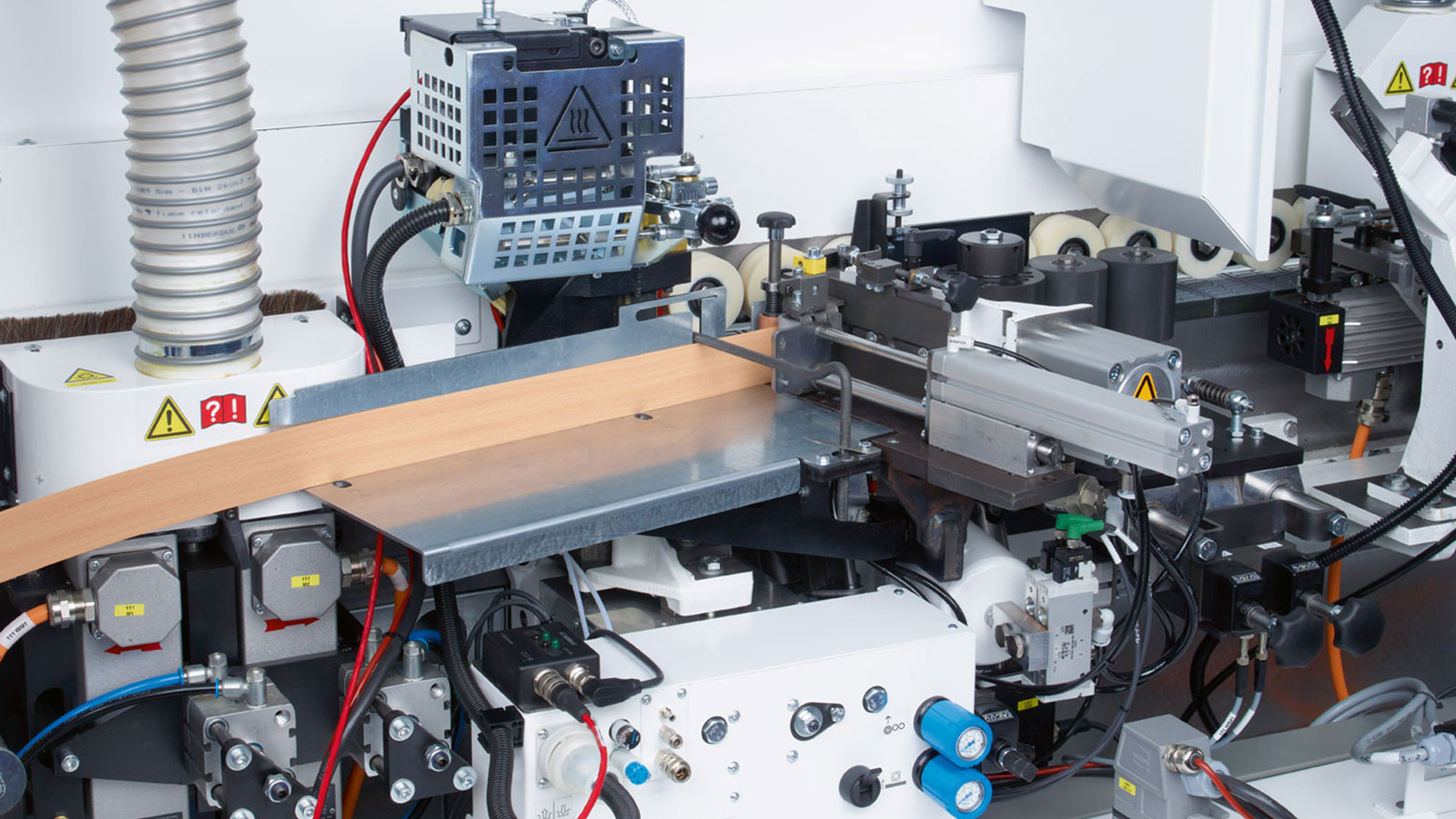

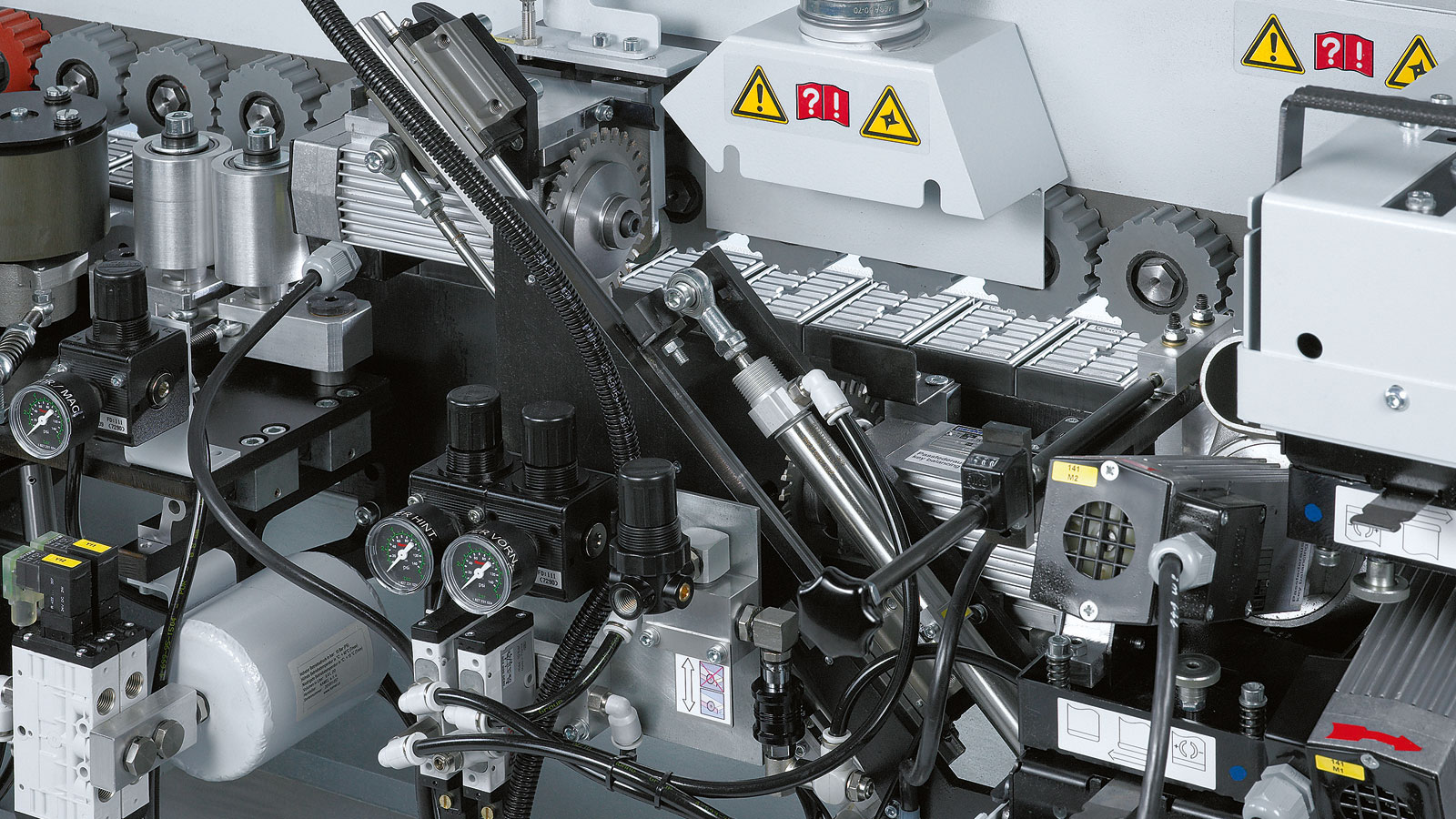

If you are new to mechanical edge processing, you have come to the right place. Fully process your workpieces with joining and profile trimming. All the machines are equipped with a precise gluing unit (i.a. for processing of PUR-glue). On request, we can equip two free spaces for post-processing in accordance with your requirements to provide you with optimum flexibility. Alongside the machine‘s extensive unit equipment, automation of the units is also a possibility. Thanks to their short and compact design, these machines are suitable for use even in the smallest of workshops.

Highlights

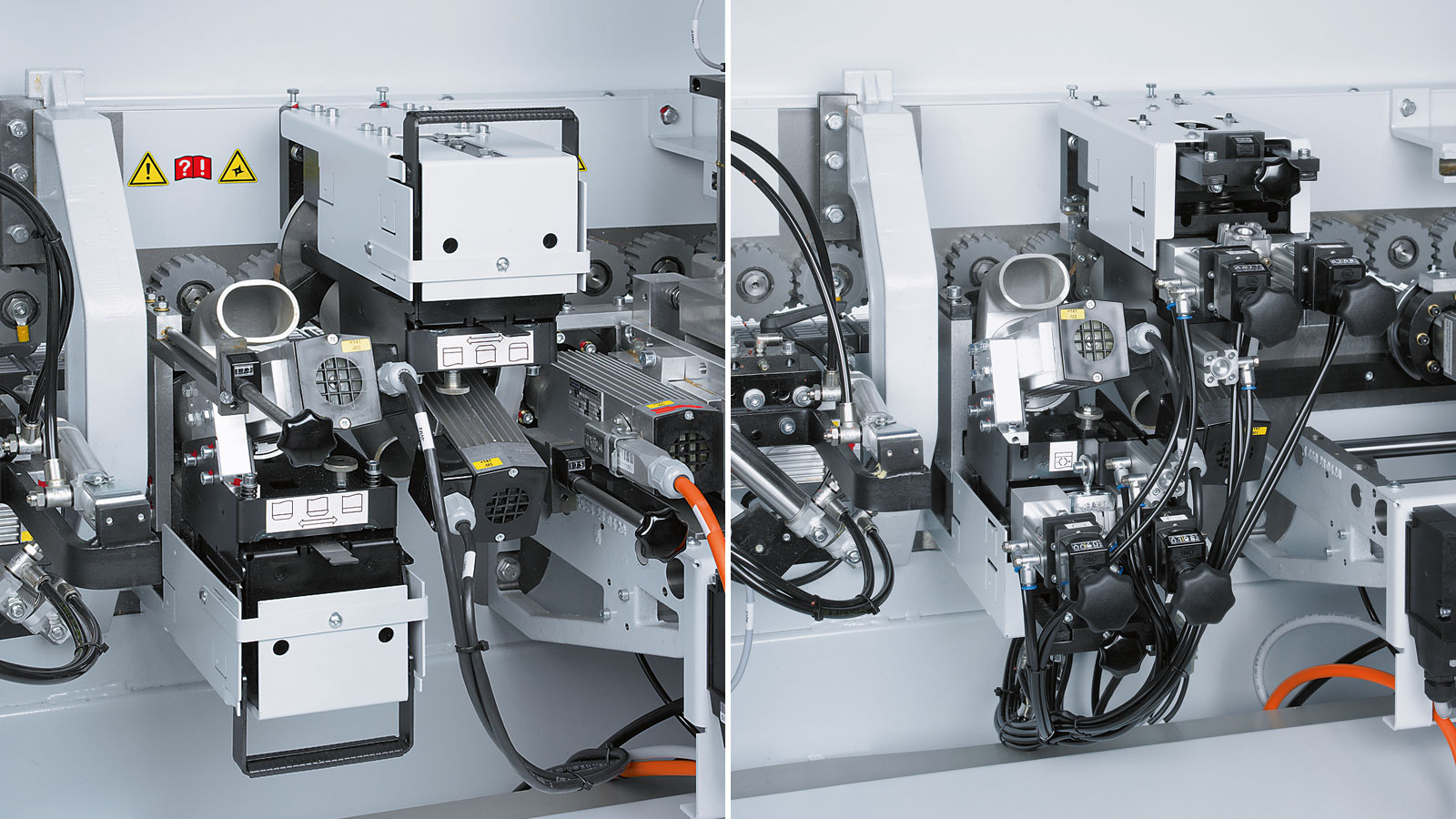

NEW: Industrial standard in the entry-level segment. Easy, fast and safe removal of the feed unit as well as an adjustable magazine height for different edge overlaps. The servo edge feed increases precision and durability.

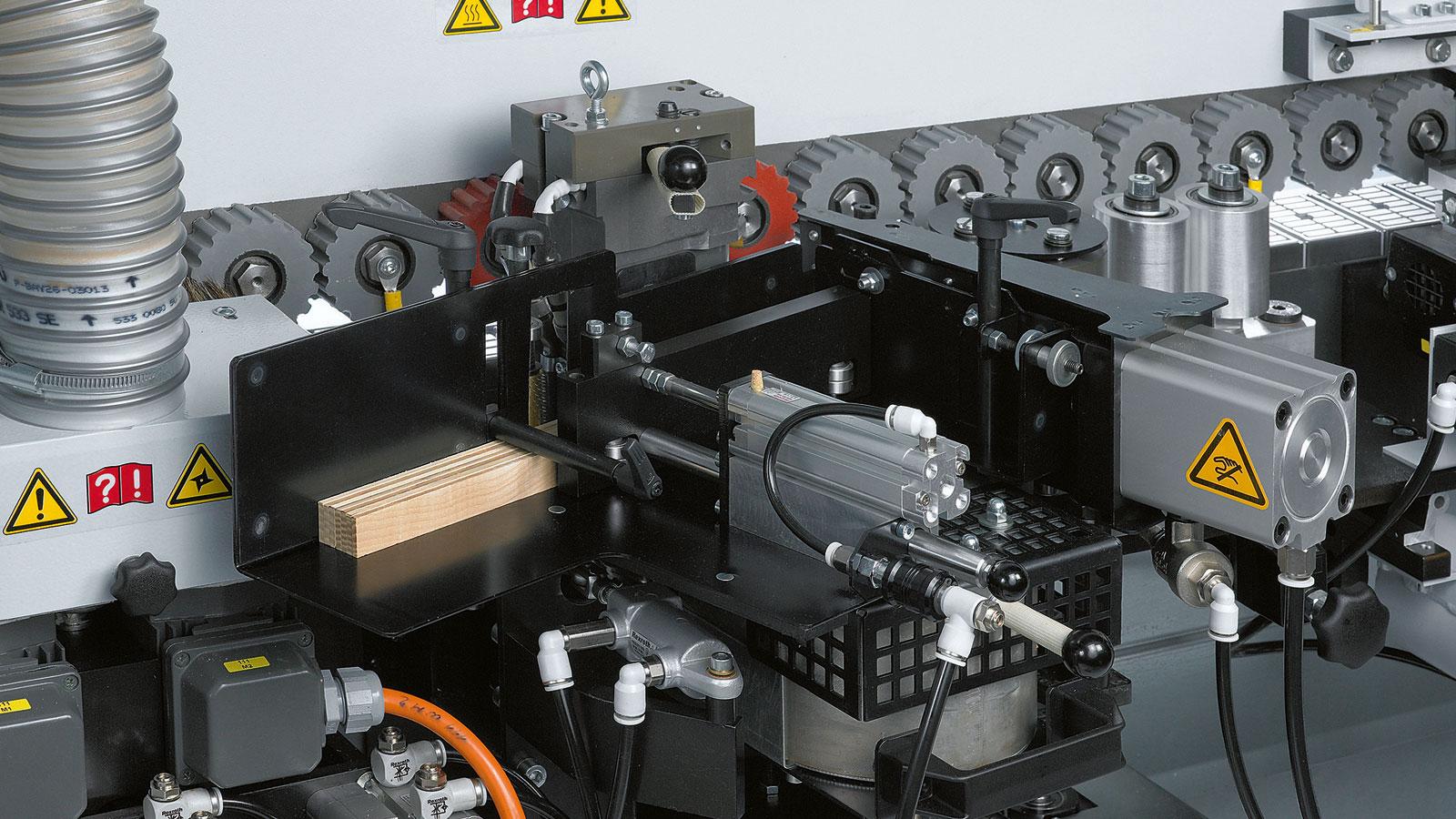

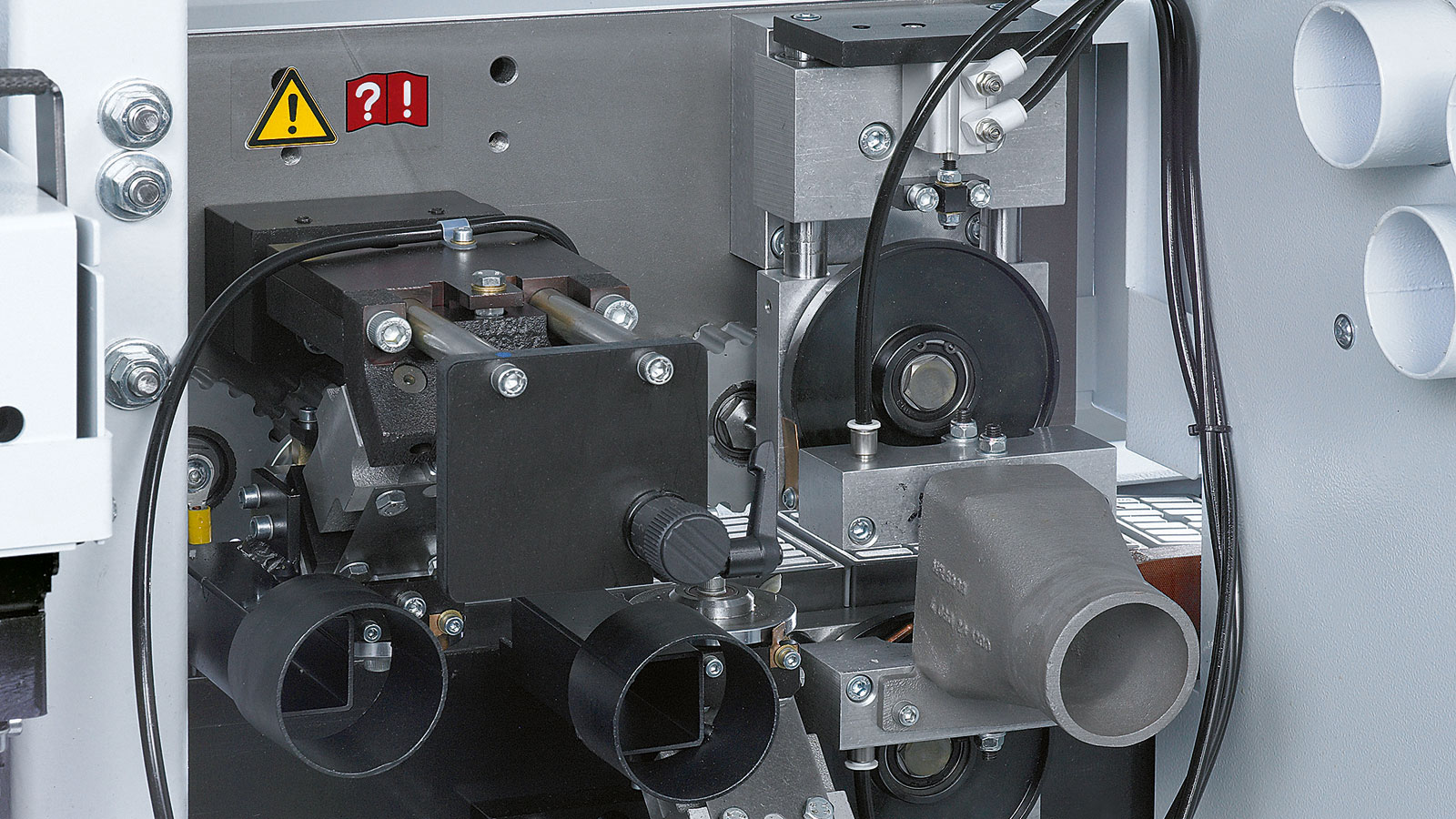

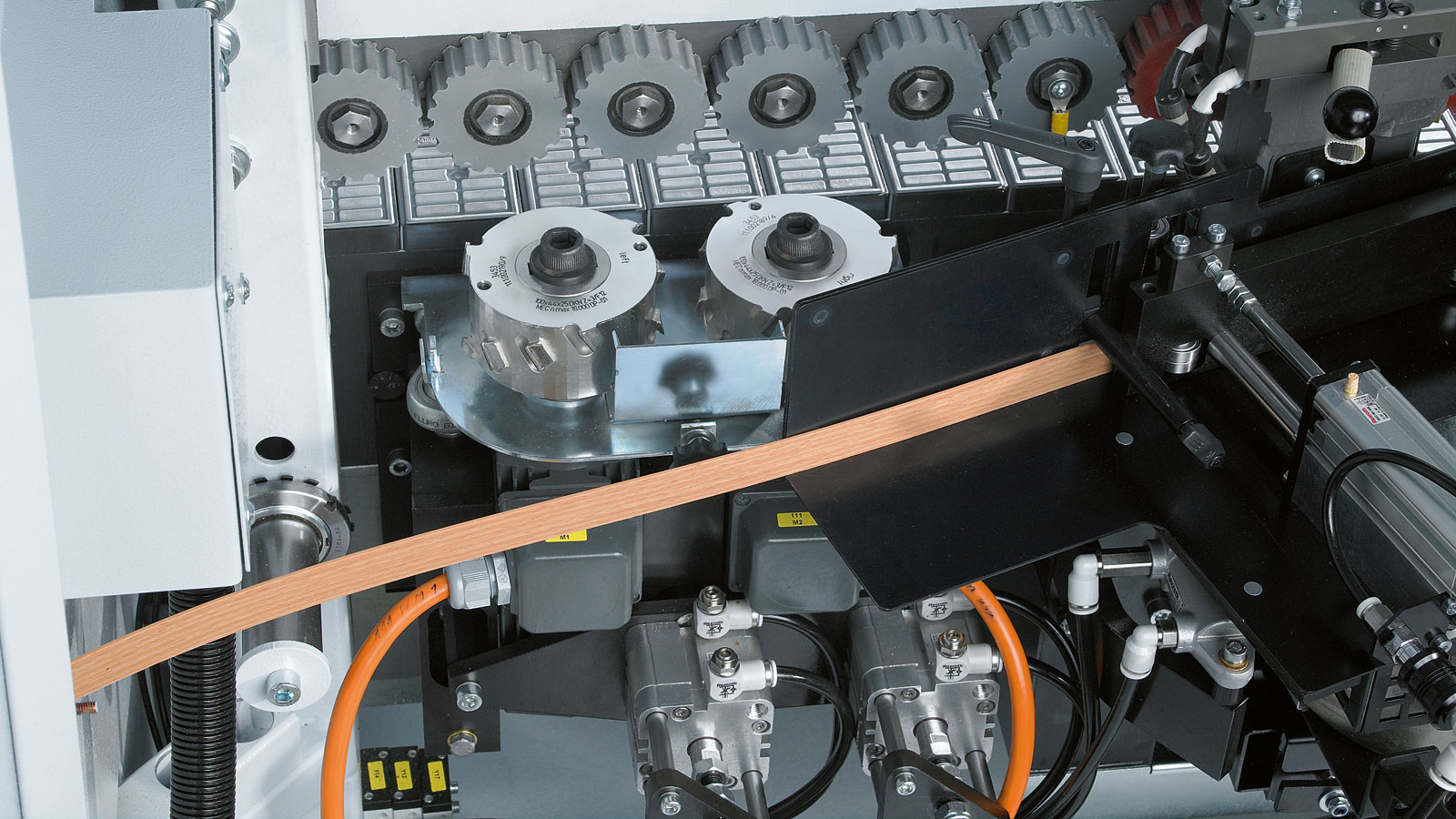

Joint trimming unit with perfect cut for optimum glue joint quality.

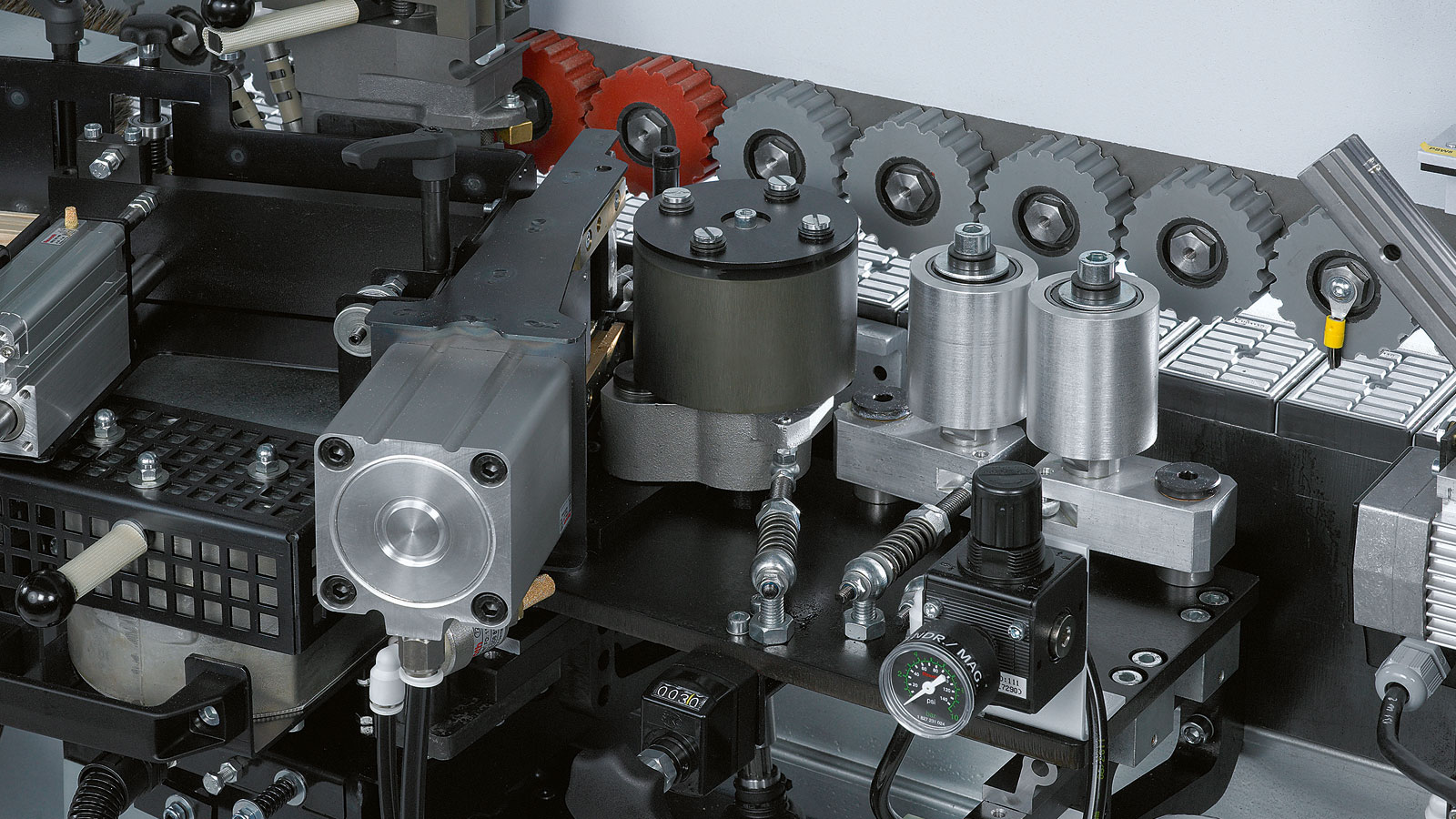

Two-motor snipping unit for optimum results.

Images

Features

-

Also available with joint trimming unit for a perfect cut and optimum glue joint quality

-

For banding edges of up to 3 mm and workpieces of up to 40 mm (60 mm - 1130 FC | 1130 AT)

-

Glue applied directly onto the workpiece to ensure constant application (i.a. for processing of PUR-glue).

-

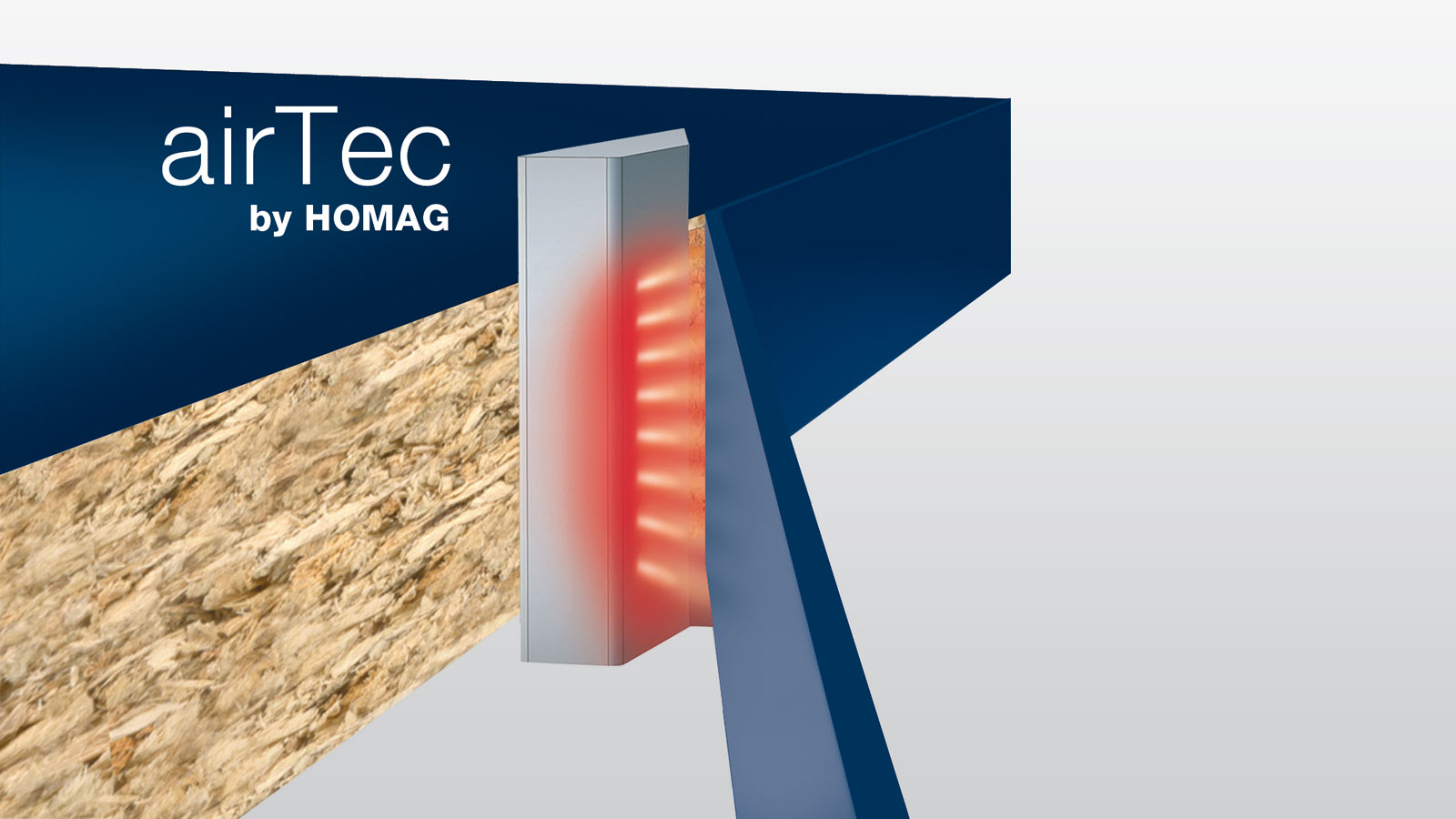

Zero joints - airTec unit for a perfect zero joint finish

-

Contour trimming unit for rounding corners

-

Freely configurable post-processing for a high level of flexibility

Start now!

Technical Data

Model 1100 / Model 1110 F | Model 1120 FC | Model 1130 FC | Model 1130 AT | |

|---|---|---|---|---|

| Machine length [mm] | 3.690 | 4.305 | 4.605 | 4.605 |

| Feed speed 8 [m/min] | 8 | 8 | 11 | 8 |

| Workpiece width [mm]* in case of thickness 8 - 22 |

|

|

|

|

| Workpiece thickness [mm] | 8 - 40 | 8 - 40 | 8 - 60 | 8 - 60 |

| Edge thickness coils [mm] | 0,3 - 3 | 0,3 - 3 | 0,3 - 3 | 0,3 - 3 |

| Edge thickness strips / solid strips [mm] | 0,3 - 3 | 0,3 - 3 | 0,3 - 3 | 0,3 - 3 |

* depends on the workpiece thickness

(Previous product name: Edge banding machines Ambition 1100: 8 m/min feed speed)

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Edge Banding Machine EDGETEQ S-200

The promotion class for trades. Achieve industrial quality even with our smallest EDGETEQ S-200 edge banding machine thanks to the new application unit with servo edge feed, flexible magazine height adjustment and vacuum suction cup-based strip separation - and increase process reliability and quality in your production.

Brochures

Product Comparison

Edge banding machine