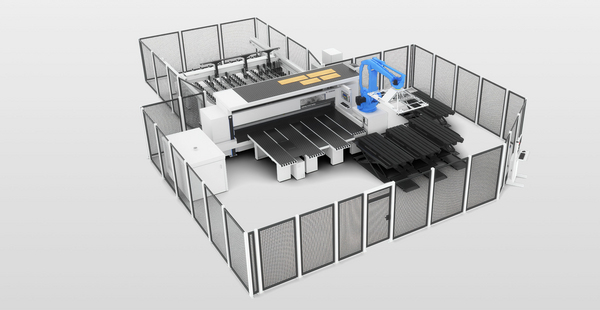

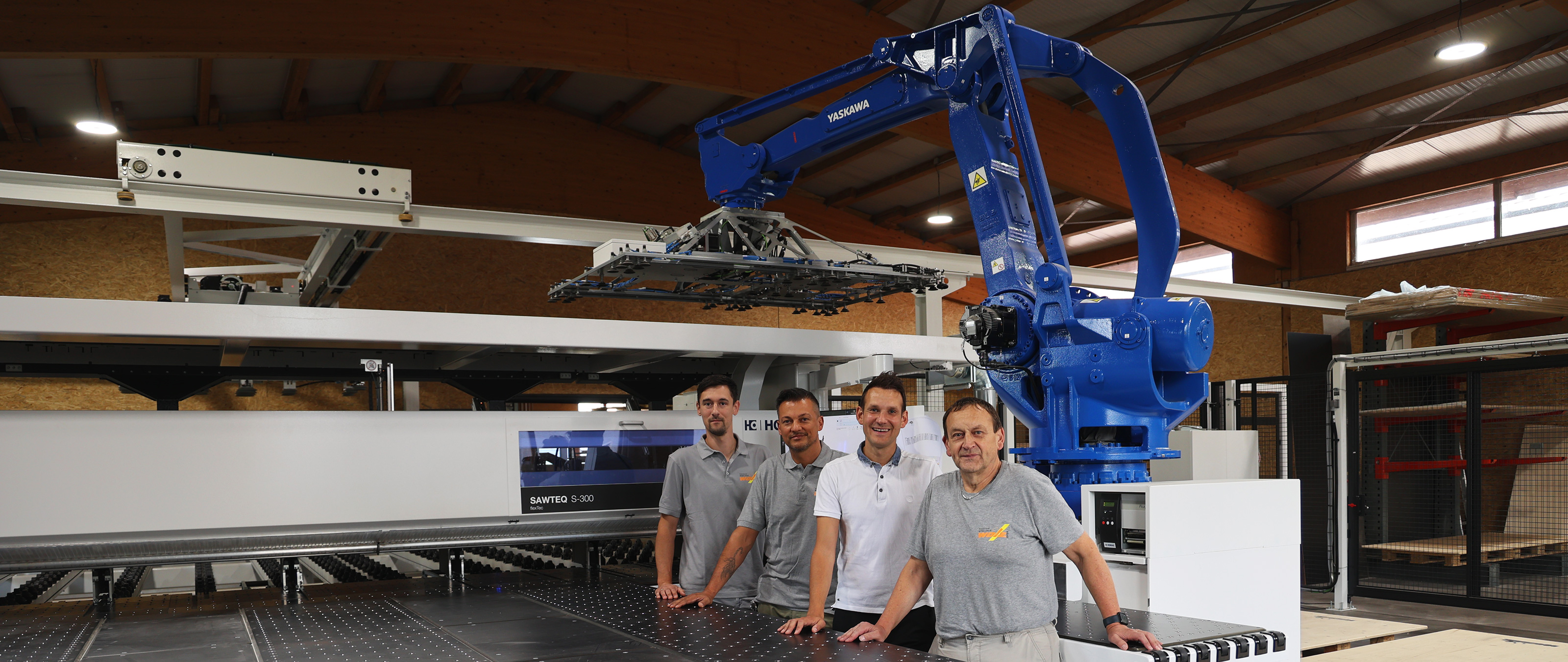

With 225 years in operation, spanning eight generations, the Schreinerei Wolz joinery is the definition of a traditional business. The family-run company near Crailsheim has been implementing tailored solutions for furniture and interior fittings since 1800. To achieve this, the company have a state-of-the-art machine pool at their disposal. A few months ago, the team led by Managing Director Stefan Wolz invested in a new robot saw with storage from Homag.

Depending on their route, those who visit Schreinerei Wolz in Kressberg-Waldtann often have to cross state lines to get there. This is because the company is located in the extreme northeast of Baden-Württemberg, on the border with Bavaria. Once you reach Waldtann, there's still a short distance left to go, because the company premises are located outside of town. "It is a real stroke of luck that our company founder chose this location," says Friedrich Wolz, who handed the joinery over to his son Stefan at the beginning of this year. “We have no space problems here and can expand if necessary.”

There are only a few companies that can look back on such a long history — and that have always remained in family hands. "We are celebrating 225 years of existence this year. My father is the seventh, I am the eighth generation," says Stefan Wolz, who grew up right next to the company. In 2014, he joined the family company “It was clear to me quite early on that I wanted to take on this task.”

Wolz is a typical furniture joinery with a lot of specialization. "We do everything from making a small cabinet for 'Jane Doe' to furnishing large luxury houses," says Stefan Wolz. Doors, windows and interior fittings complete the portfolio. In addition, the company has its own furniture store, which is directly linked to production. "With the commercial goods we have created a second pillar," says Stefan Wolz. His company sells around 200 kitchens a year and has specialist staff install them on-site at customers' premises. This broad portfolio has secured him competitiveness in difficult times.

Stefan Wolz first thought of buying a robot saw at the start of 2024: "When it came to our cutting capacity, we were at our limit. However, the saw proved to be a pinch point. And we thought about how we could bridge the gap." In fact, he did not want to make the investment until 2026 or 2027. "But we had very full order books — and a few more big orders have been added. This has accelerated the process." At Homag's technology days, he learned about the saw-storage-robot combination. “It convinced me to take this step immediately.”

The "Sawteq S-300 Flex Tec" with "Storeteq P-300" storage system has been in operation since February 2025. It replaces an old horizontal panel saw, which had no robots and no storage. The automation results in a significantly higher output. "In the past, we had a daily quota of 25 to 30 panels. That was simply too little for us. With the new robot saw, we can create upwards of 60 panels in a single shift," explains Christian Kern, Head of Work Preparation and Deputy Plant Manager. This allows the company to streamline work steps and to deploy employees more effectively elsewhere. “Now, not only are we operating eight-hour shifts, but we can also run cutting processes across two shifts or into the night. And the employee who previously only operated the cutting machine now also operates other machines.”

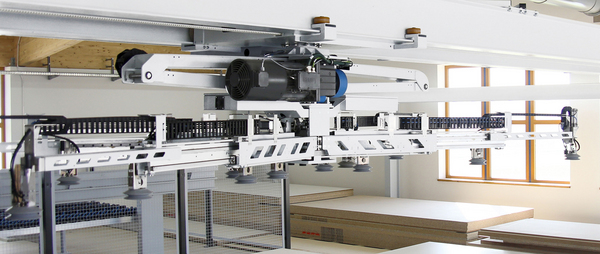

In addition to the robot connection, the employees are particularly pleased with the new storage system. "Previously, we had stored our panels in racks that were loaded with a forklift. This was extremely time-consuming. There was still a lifting table involved, but pre-sorting always needed to be done by hand," explains Christian Kern. In addition, direct access to the "Storeteq" storage system is increasing efficiency, as CAD/CAM is used a lot in the joinery. “You can immediately see how many panels are still available, what needs to be reordered, etc. In addition, the handling of offcuts is also a significant advantage.”

One challenge was integrating the robot saw with storage system into ongoing production. "During production, we emptied the old racks and had to make sure that we started training in a timely manner. And all this in a very tight time frame," Kern says. In addition, all processes had to fit together perfectly — from the power supply of the new machine to the suction device. Ultimately, everything worked smoothly. This was certainly also helped by the long-standing close partnership between Schreinerei Wolz and Homag. In addition to the new robot saw, the company also has two CNC processing centers (one from 2014, the other from 2018) and an edge banding machine with zero joint technology (from 2018) from Homag. In surface technology, a Bürkle painting system (from 2023) complements the modern machine pool.

The "Sawteq S-300 Flex Tec" is technically designed so that it can complete production over longer distances without any personnel. Alternatively, the saw can be operated manually as usual, making it very flexible to suit your requirements. This hybrid concept was one of the reasons for the investment at Schreinerei Wolz. "Sometimes we have special panels or sizes for which the robot is not suitable. We cut these manually," says Christian Kern. He estimates the proportion of manual cutting to be around 10 percent.

The lack of skilled workers often plays a role in investments such as this. That was not the case at Schreinerei Wolz, even though the company is just as affected as others by the difficult labor market. "We are lucky that there are still enough applications coming in. Some people are surprised when they see that so many young people work for us," says Stefan Wolz. There are currently six apprentices among the approximately 30 employees. An important factor is the good working atmosphere in the company. "You have to treat employees with respect and give them the freedom to develop," says Stefan Wolz.

This also applies to the change of generation in management. "Succession can only work if you let the youngsters do it," says Friedrich Wolz. "I often hear from others that it doesn't work there because the old generation can't let go." That was not the case with him. "I was able to set my own priorities right from the start. And I did," confirms Stefan Wolz.

Schreinerei Wolz has therefore successfully set the course for the future — both in terms of personnel and technology. This is reassuring for the company in its 225th year while it looks ahead and stays focused on the challenges to come.

“"Now, not only are we operating eight-hour shifts, but we can also run cutting processes across two shifts or into the night. And the employee who previously only operated the cutting machine now also operates other machines."”Stefan Wolz, Managing Director of Friedrich Wolz GmbH

Friedrich Wolz GmbH Schreinerei & Möbelhaus

Besuchen Sie die Friedrich Wolz GmbH Schreinerei & Möbelhaus hier

www.wolz-gmbh.de