Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

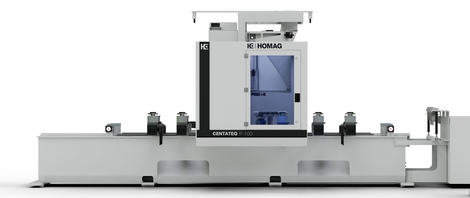

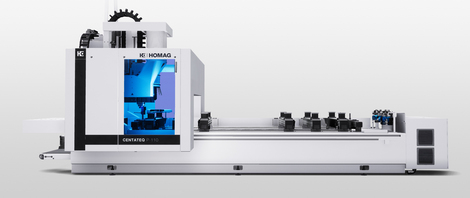

CNC Machining Centers CENTATEQ P-510|610 + E-510

CNC Machining Centers CENTATEQ P-510|610 + E-510

Maximum performance and possibilities - a complete system.

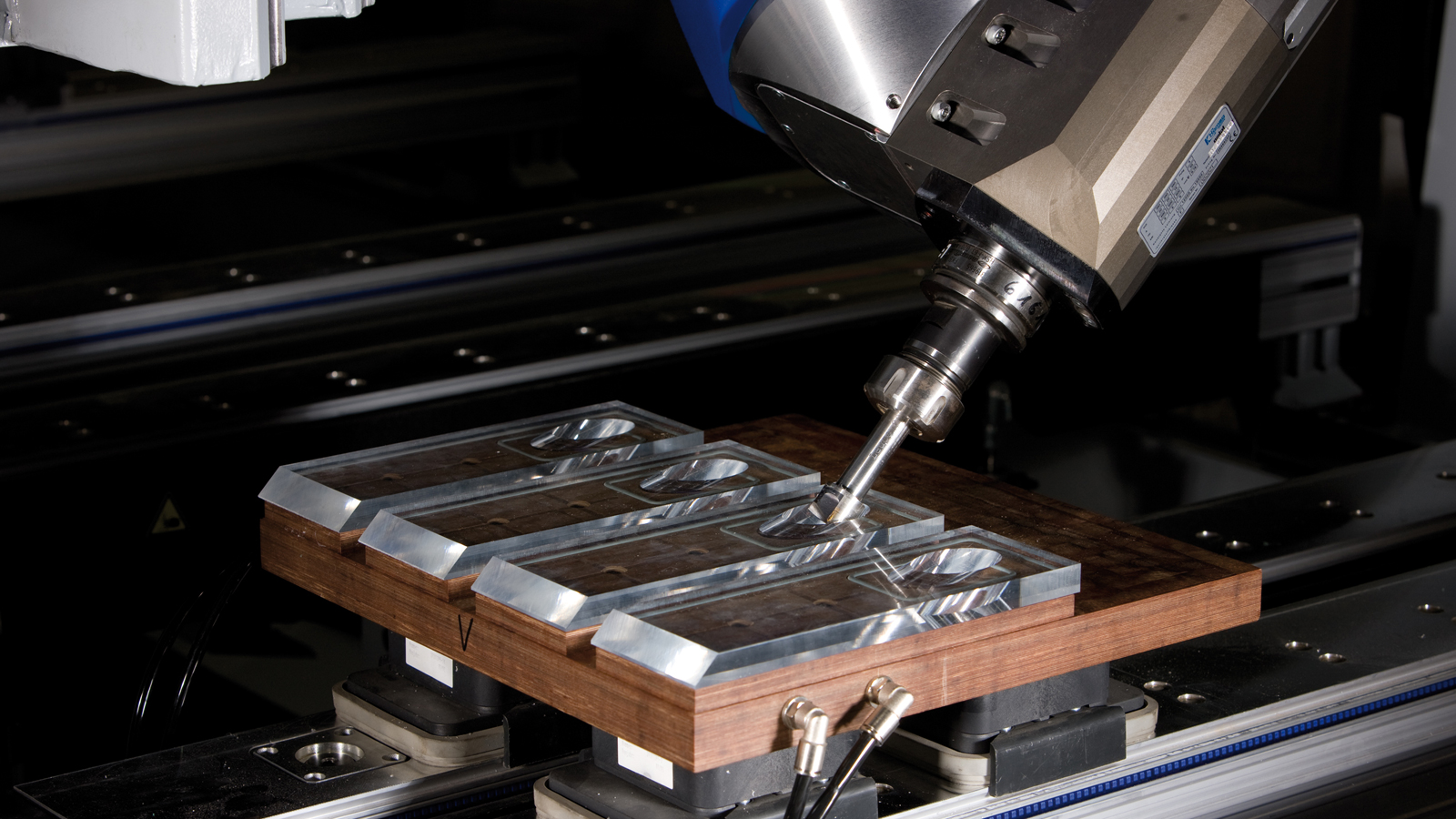

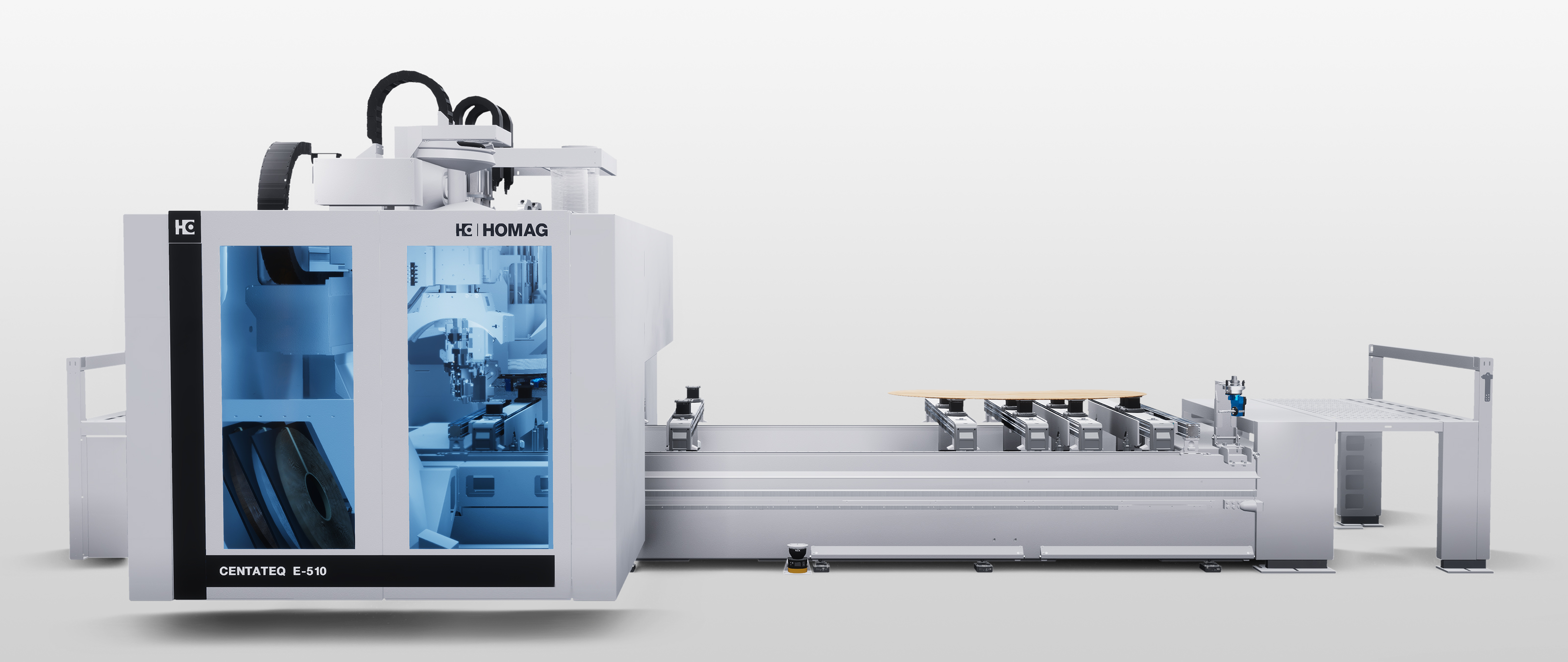

Your choice when it comes to CNC processing for demanding production requirements Stairs, furniture, windows, doors, interior fittings - with machines from our CENTATEQ P-510|610 + E-510 series, you are ideally equipped for all your tasks. Each of these CNC machines forms a complete system that is your basis for maximum performance and possibilities for meeting your customers' requirements.

Highlights

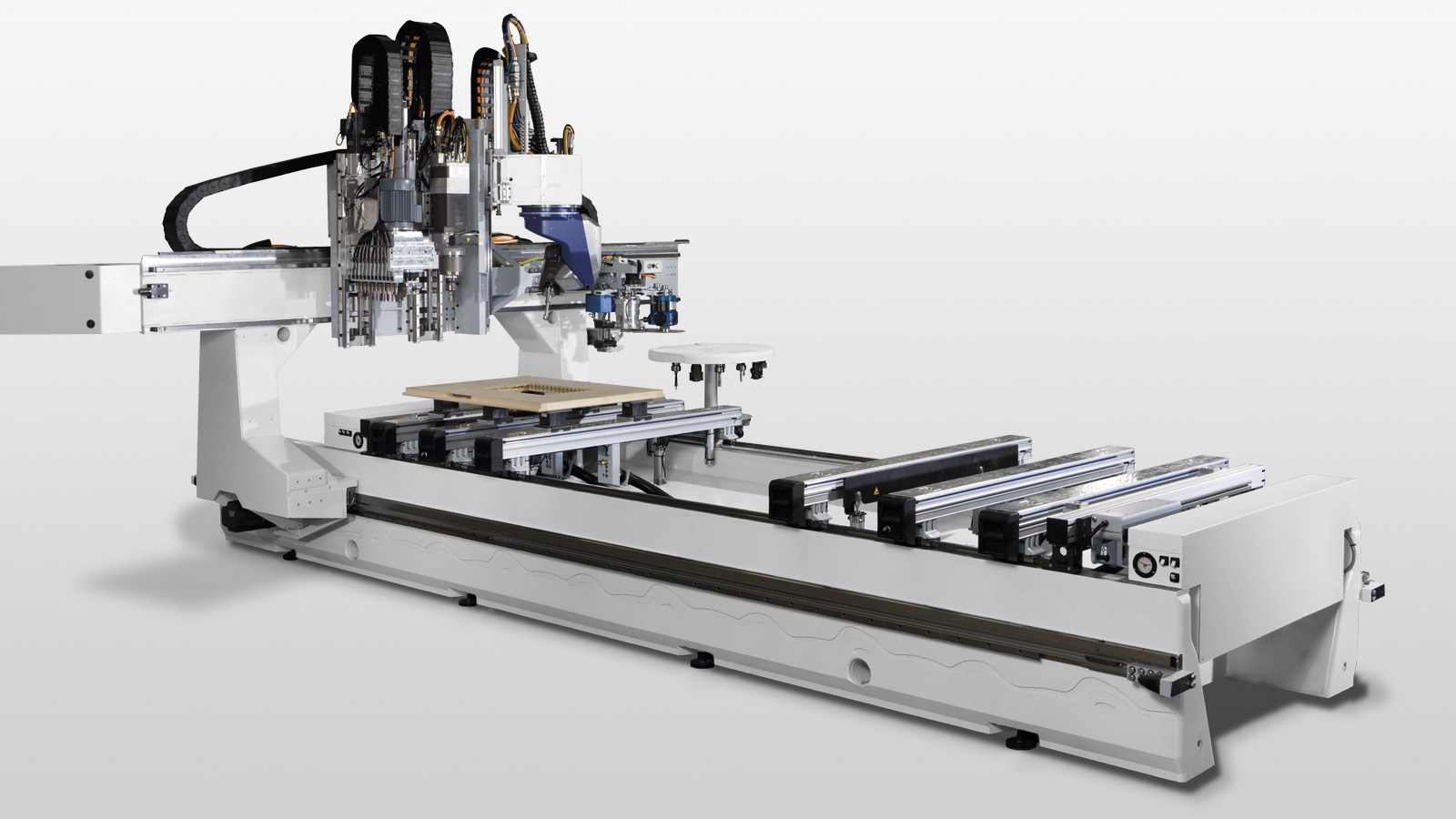

Scalable performance thanks to individual equipping of the moving gantry with milling spindles, drilling gears and tool changers. Moving gantry with drive on both sides for machining depths of over 3,000 mm. Machine frame made of SORB TECH mineral composite material

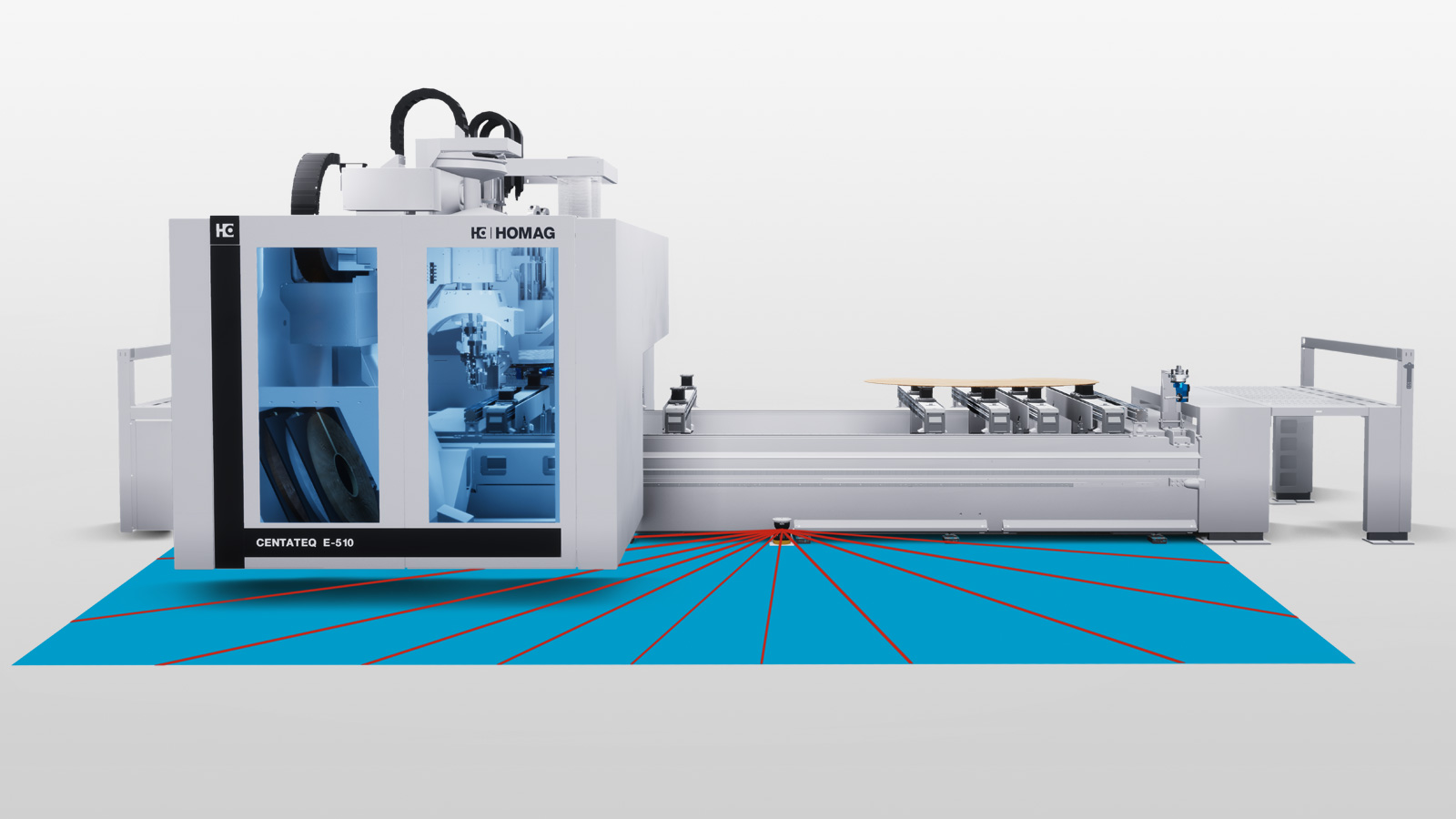

safeScan - area scanner for non-contact safeguarding of positioning on the automatic table and feed reduction in conjunction with the Speed-Pack. No fixed installations in front of the machine save valuable space.

Bevel edge banding - different design styles and constructive solutions can be realized efficiently and economically

Images

Features

-

Maximum visibility: The large window provides an optimum view of the machine during processing.

-

Perfect edge banding: powerEdge Pro unit technology for perfect shaped edge banding - optionally also with glueless zero joint or with swivel-mounted unit for bevel edge banding

-

Always in the right position: Effective extraction with low connected load thanks to optimized chip collection and removal. The hood can be adjusted in stages or optionally by motor and automatically adapts to the workpiece thickness.

-

HOMAG drilling technology: High-speed drilling technology, clamping of the spindle and quick-change system for tools. Precise drilling, fast cycles, maintenance-free and durable design. Additional optional attachment units extend the machine's range of applications.

-

Spindle sensor: Milling spindles with hybrid bearings offer a long service life. An additional vibration sensor detects tool imbalances and protects the spindle from overloading, e.g. due to excessive feed rates.

-

Pneumatic interface: Interface with triple support on all C-axes and optionally on the DRIVE5 5-axis heads enables the use of traced units, e.g. for precise rounding at the top and bottom, regardless of thickness tolerances.

-

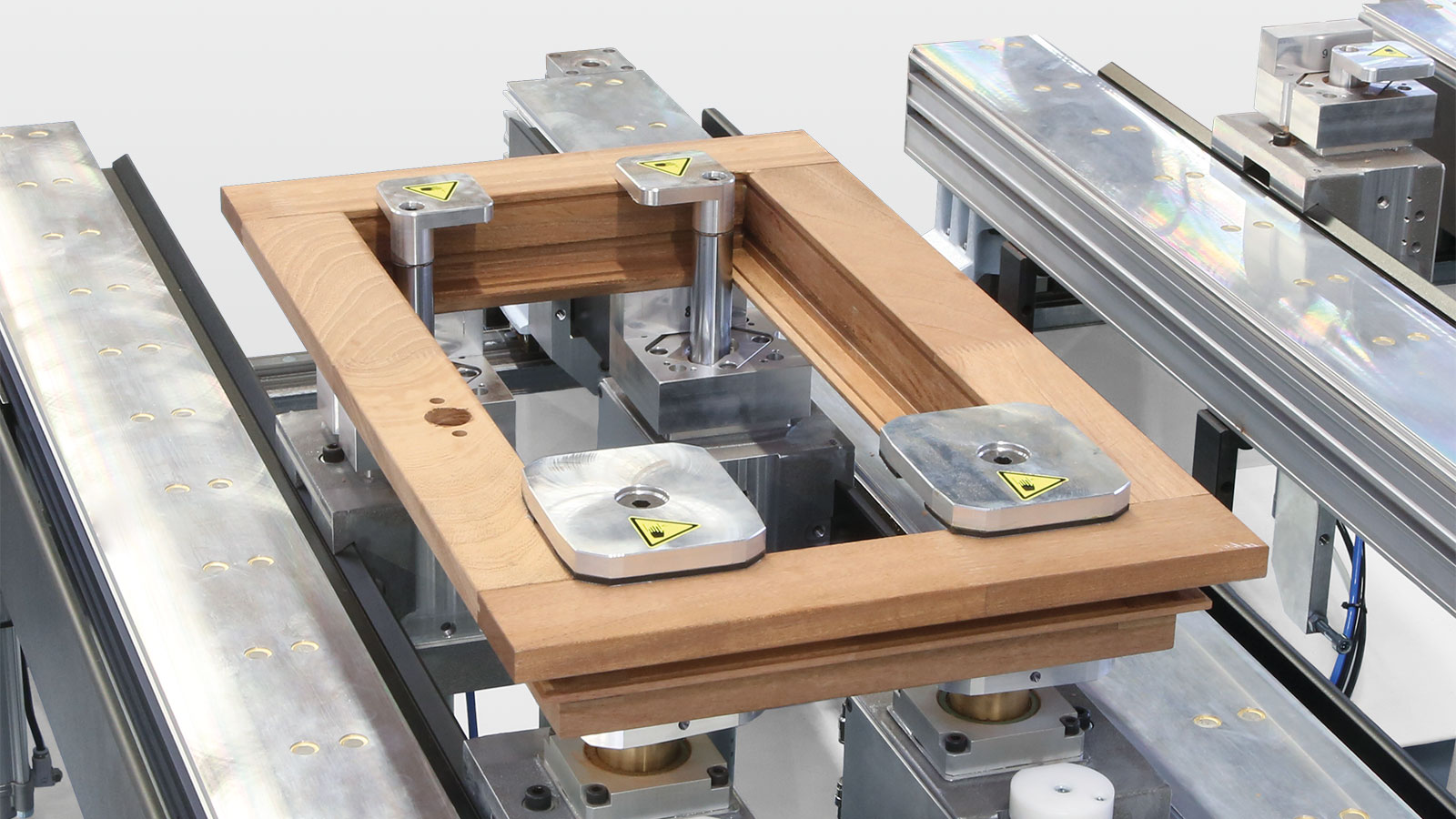

The right table for every application: aluminum grid table, console table with optional LED set-up aid or automatically positioning A-table with an extensive modular system of clamping elements. This is what safe, flexible and convenient clamping looks like.

Technical Data

| Workpiece length X [mm] | /33 | /40 | /60 | /74 |

|---|---|---|---|---|

| Individual processing (all units) | 3,300 | 4,000 | 6,000 | 7,400 |

| Pendelbearbeitung* (all units) | 1,025 | 1,375 | 2,375 | 3,075 |

| Workpiece width Y [mm] | /xx/15 | /xx/19 | /xx/22 | /xx/32 |

|---|---|---|---|---|

| All units in main spindle (front stop) | 1,325 | 1,675 | 2,025 | 3,025 |

| With tool diameter 25 mm (rear stop) | 1,325 | 1,675 | 2,025 | 3,025 |

| Gluing (rear stop) | 1,550 | 1,900 | 2,250 | -- |

| Workpiece thickness Z [mm] | 510 | 610 |

|---|---|---|

| With tool length 230 mm | 300 | 500 |

Some workpiece parameters may depend on the tools used. Please see the relevant brochure for further technical data.

*Dimension with central division. Pendulum field size adjusted dynamically to component size.

(Previous product name: BMG 510|610 processing centers)

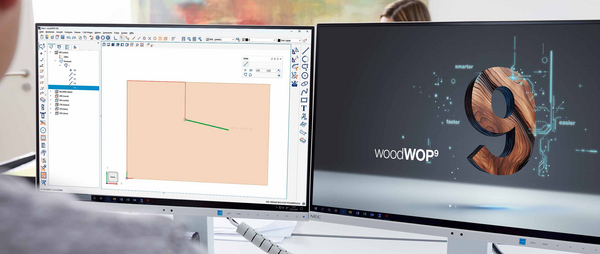

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

HOMAG CENTATEQ P-510 | Window production with 3-stage clamps

The CENTATEQ P-510 is the right choice for demanding production requirements such as stairs, furniture, windows, doors and interior fittings.

Brochures

Product Comparison

CENTATEQ CNC- processing centers