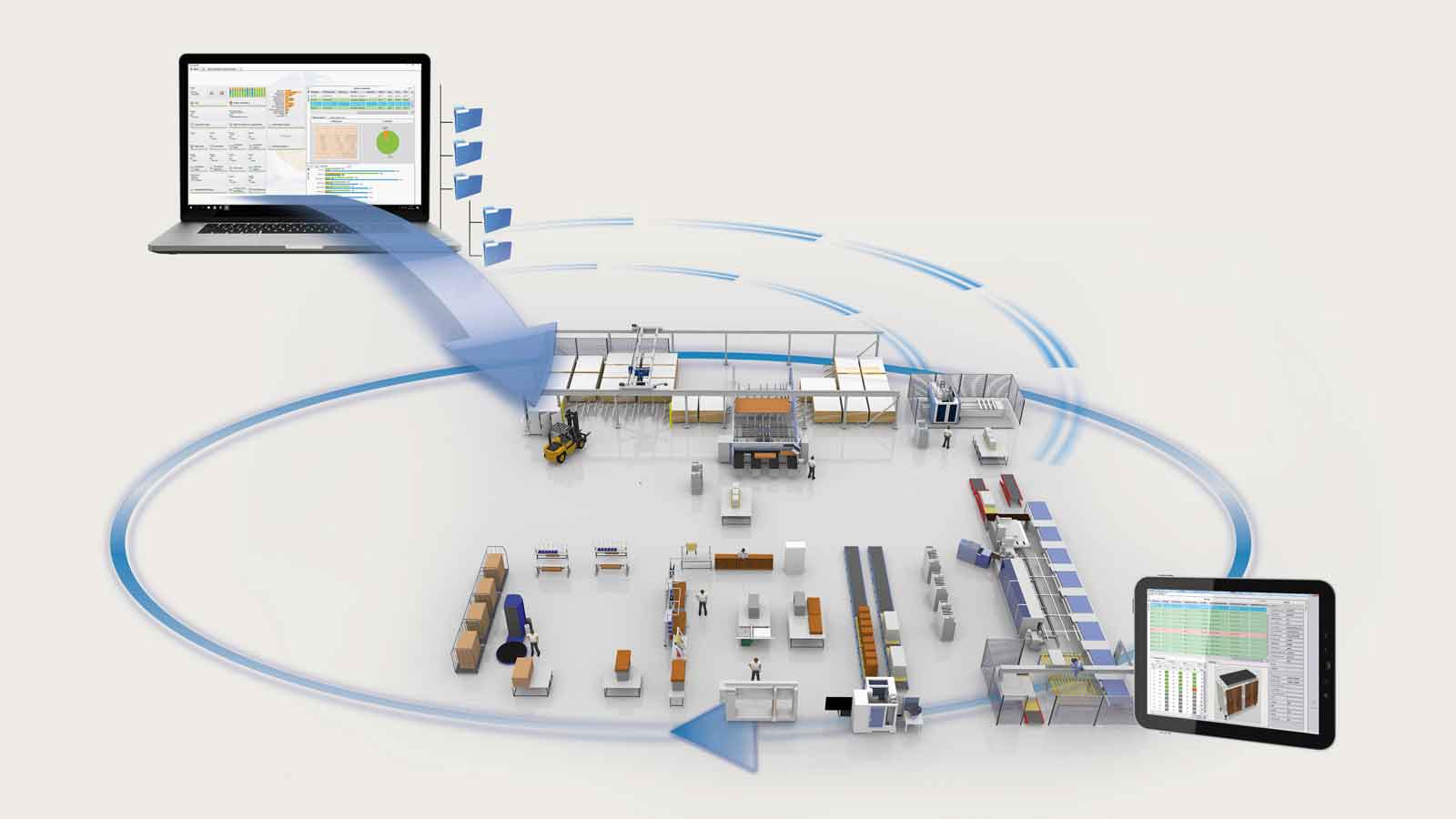

Digitalization and networking of furniture production or woodworking beyond company and national boundaries – this is the core of the “Industry 4.0 vision”.

The aim is for widely diverse units within the company to communicate with each other and even organize themselves. At the same time, machines operating today within a completely networked production set-up already “know” which component is currently needed, how it has to be processed and where storage bottlenecks exist.

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

The way you produce will change. See here how the furniture production of the future could look like!

The Factory of the Future

The aim of networked production is to produce customized furniture on an industrial scale – in the most efficient way and at a similar cost to that of mass production. With networked production, HOMAG offers an end-to-end flow of information. In addition, the intelligent workpiece plays a role, communicating to machines how it is to be processed. For this purpose, every workpiece is equipped with a digital identity that contains all specifications and production parameters.

The five fundamental elements of networked production:

- The digital component

- The intelligent machine

- Vertical networking

- Horizontal networking

- The intelligent workpiece

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Furniture production on the way to Industry 4.0

The Entry to Networked Production for Woodworking Shops

Stage 1:

Networking the office and production

First a suitable infrastructure has to be created in the company:

- To network all machines

- To move tasks from the workshop into the office —

- for example, CNC programming or central data storage

- To clearly assign workpieces to production data and processes using labels with barcodes

The benefits:

- Machine capacity is increased

- Other work processes are simplified by networking the office and the production area

- New programs or changes are available instantly on all machines

- Programs can be loaded onto machines automatically using labels with barcodes

- Labels simplify work steps such as assembly and picking

Stage 2:

Automated data generation – vertical networking

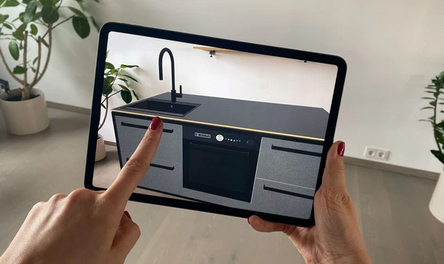

The focus is on optimizing IT processes during work preparation. "How do I create my manufacturing data from my customer's requirements?" This can be achieved using a CAD/CAM system such as HOMAG iX from HOMAG Consulting & Software.

The benefits:

- woodWOP "Project Manager" and "DXF-Import professional" tools reduce programming work

- woodCAD|CAM streamlines work preparation and reduces the number of manual work steps

- Production throughput times are shorter, since complete production information—cutting list, label, CNC programs, drawings—is available for all of the elements being manufac-tured. Errors and unnecessary queries are avoided

Stage 3:

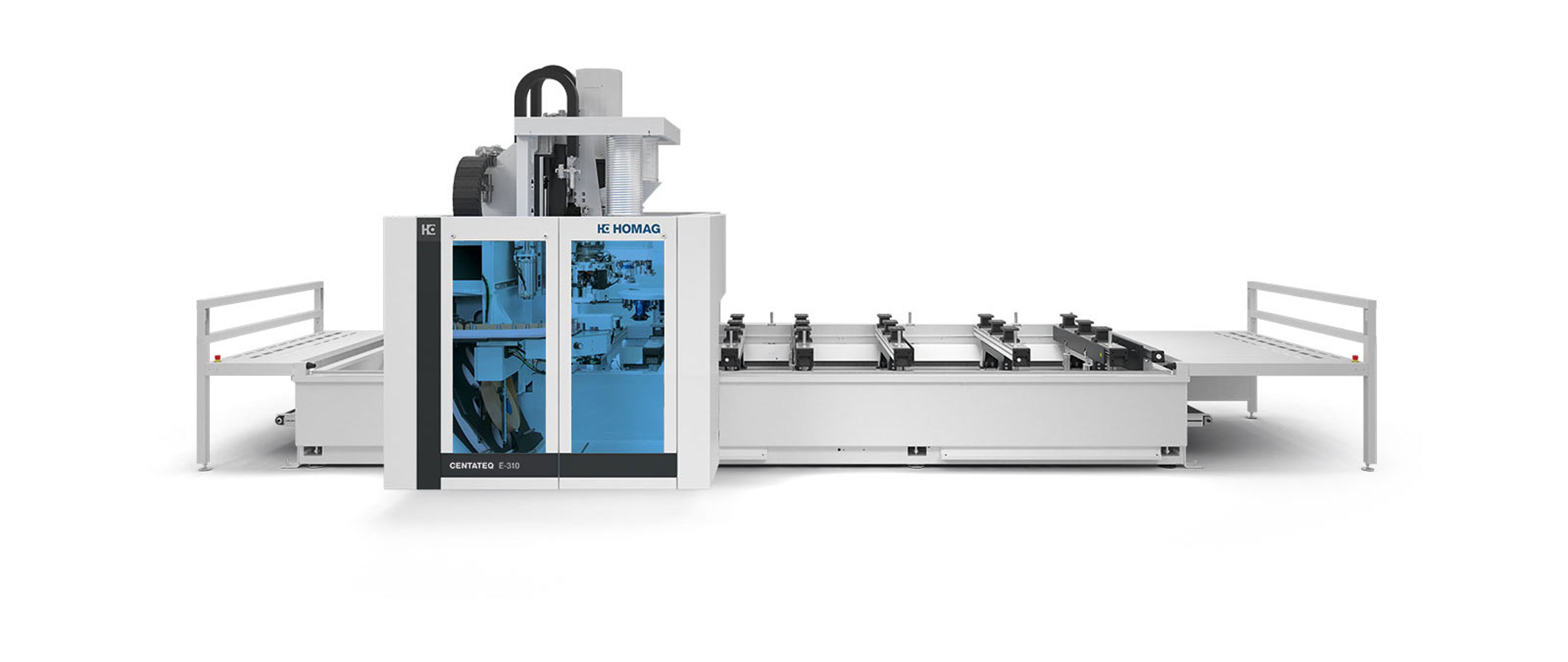

Optimization of production processes – horizontal networking

Over the coming years, production will be organized increasingly on a software-supported basis: From production and capacity planning through part and order tracking to the organization of finish processing, order picking and shipping. Here, we offer the manufacturing execution system ControllerMES, which is used particularly by medium-sized businesses.

The benefits:

- Transparent production

- Questions can be answered in real time

For example: "Are all of the components for order XY ready?"

"Do I have enough capacity to process the order?" - "Smart workpiece" — all of the relevant information can be retrieved at any time

- Every component is available at the right workstation at the right time.

- Organization of reworking and order picking is optimized

Read more about Networked Production and Industry 4.0 in furniture production

Brochure Your entry to a digital workshop. Providing solutions for any size.

( PDF , 5 MB)

Broschüre Ihr Einstieg in die digitale Werkstatt. Unsere Lösungen von klein bis groß.

( PDF , 5 MB)