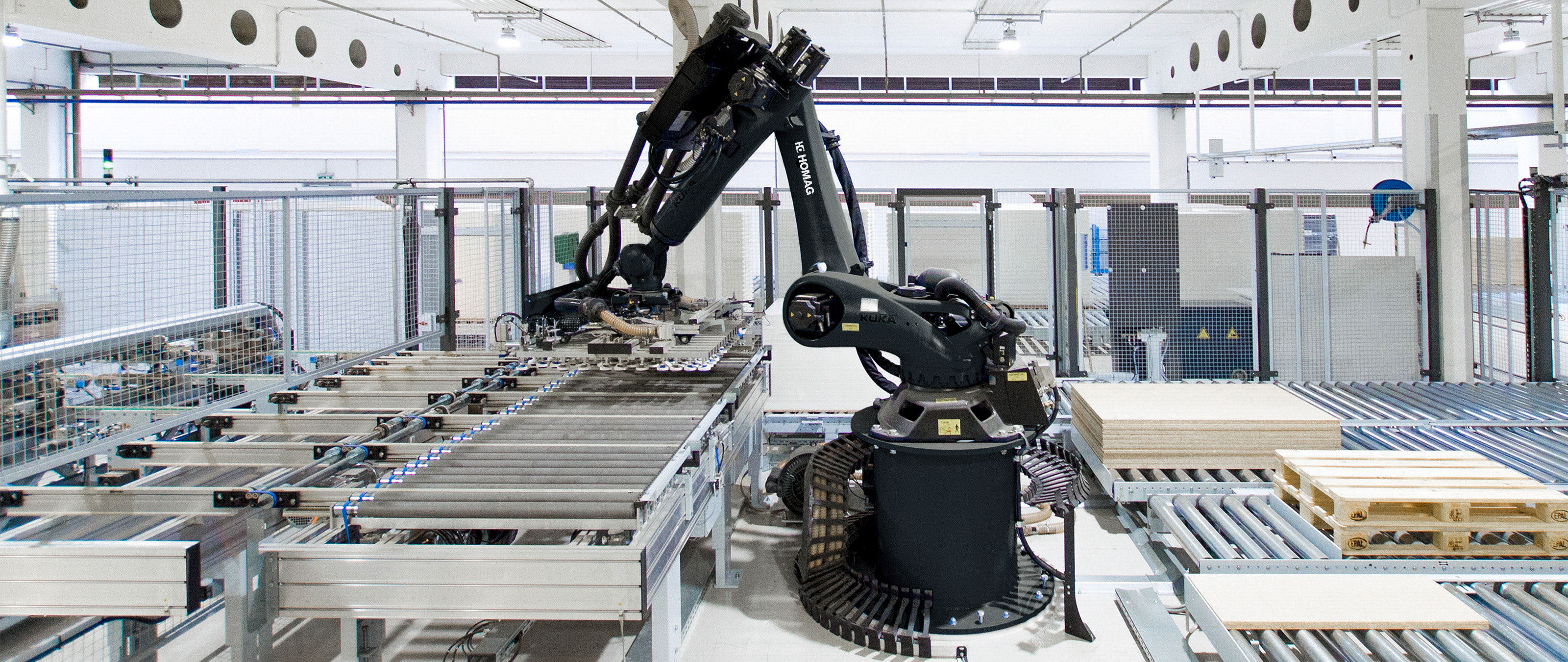

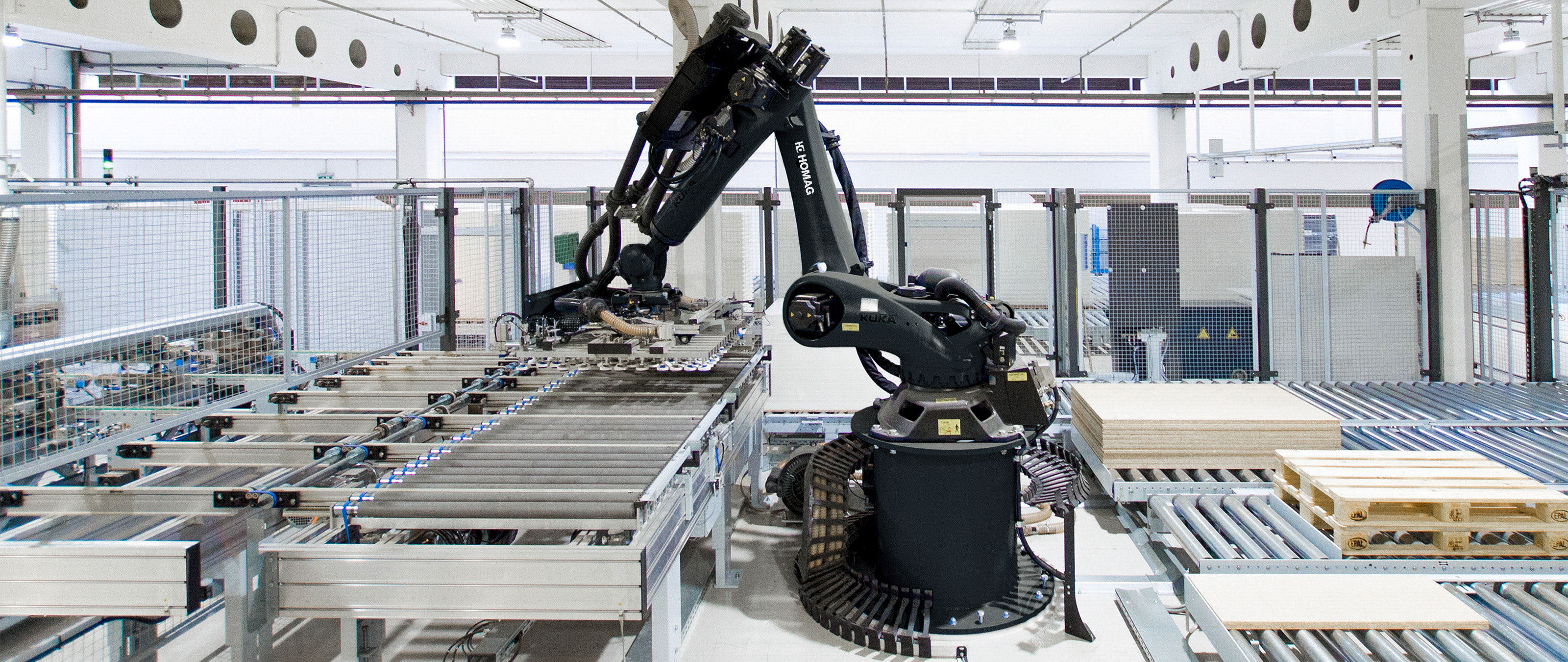

Robot Solutions for the Furniture Production

Increase productivity completely automatically with robot cells from HOMAG.

The robot as a real all-rounder

Regardless of whether it's handling in conjunction with sawing, laminating, processing edges, drilling, routing, assembling, packaging, or sorting and picking — robots are all-rounders in batch size 1 small series or series production. Innovative feed and stacking systems or pick-and-place applications ensure high performance with maximum repetition accuracy and extraordinary precision.

Robot systems for automation

Industrial robots can fully exercise their strength in areas including the automation of CNC processing cells, edge processing machines, buffer and picking systems, assembly systems, and packaging lines: regardless of whether that's the individual construction of the cell with different supply and discharge situations, part sorting, turning and alignment stations, parts checking, or part destacking.

The cell control system enables easy operation from series production to batch size 1 production.

One robot cell, many advantages for your production

- Maintenance-friendly

- High availability

- Greater efficiency

- Greater flexibility

- Better ergonomics

- Greater process reliability

- Less part damage

- Reproducibility

- Continuity

A selection of our robot solutions is available here.