Return Conveyors LOOPTEQ O-300

Return Conveyors LOOPTEQ O-300

For a wide spectrum in the material flow

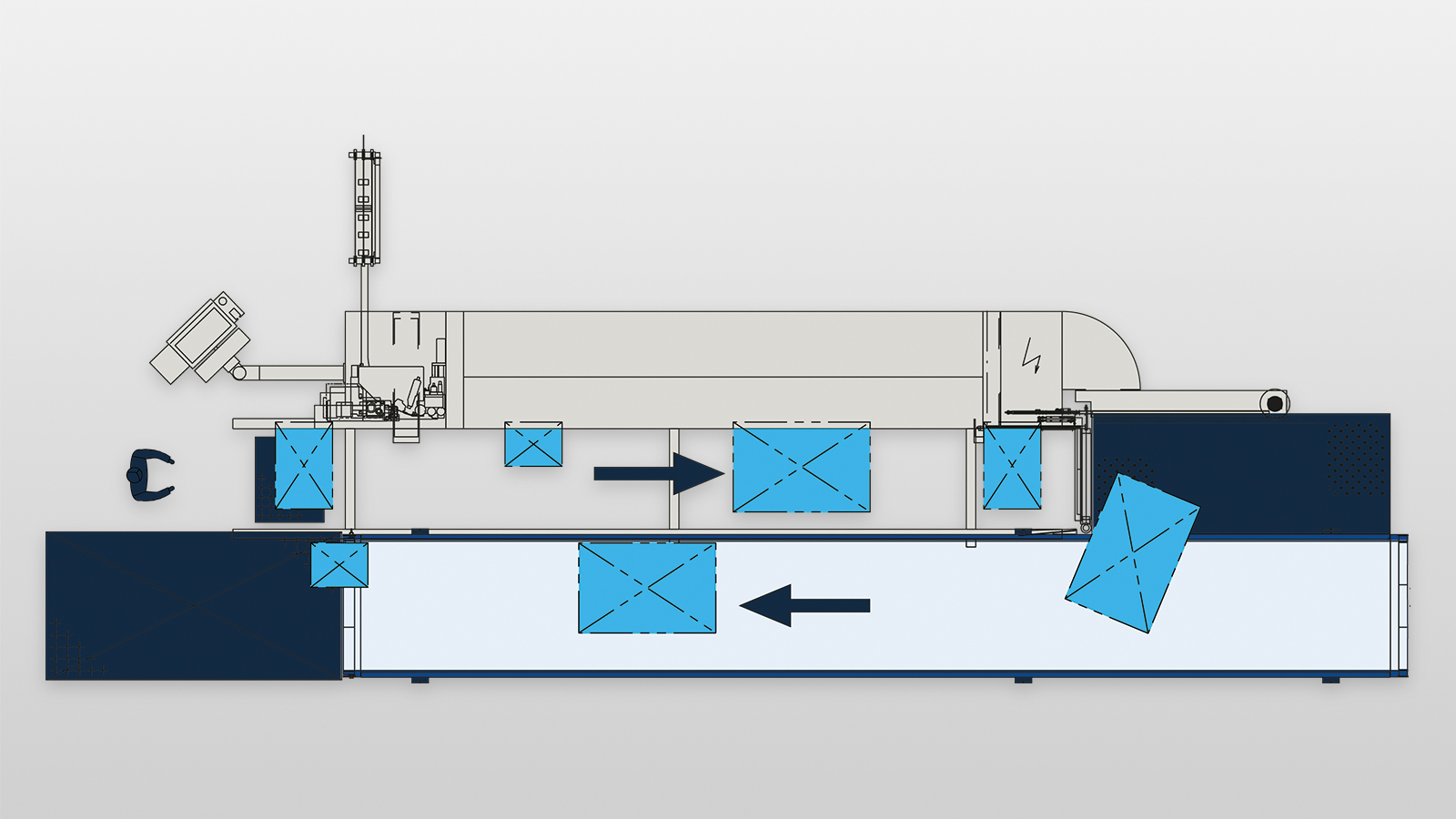

Whether handicraft or industrially oriented production. The LOOPTEQ O-300 transports the largest material variety and is indispensable for an economic workpiece return. It convinces by its high capacity and an especially gentle workpiece handling. The LOOPTEQ O-300 is best suited for customers with high material variety - from small and light up to large and heavy workpieces.

Benefits

- Fast amortization - pays off from 15 hours working time per week

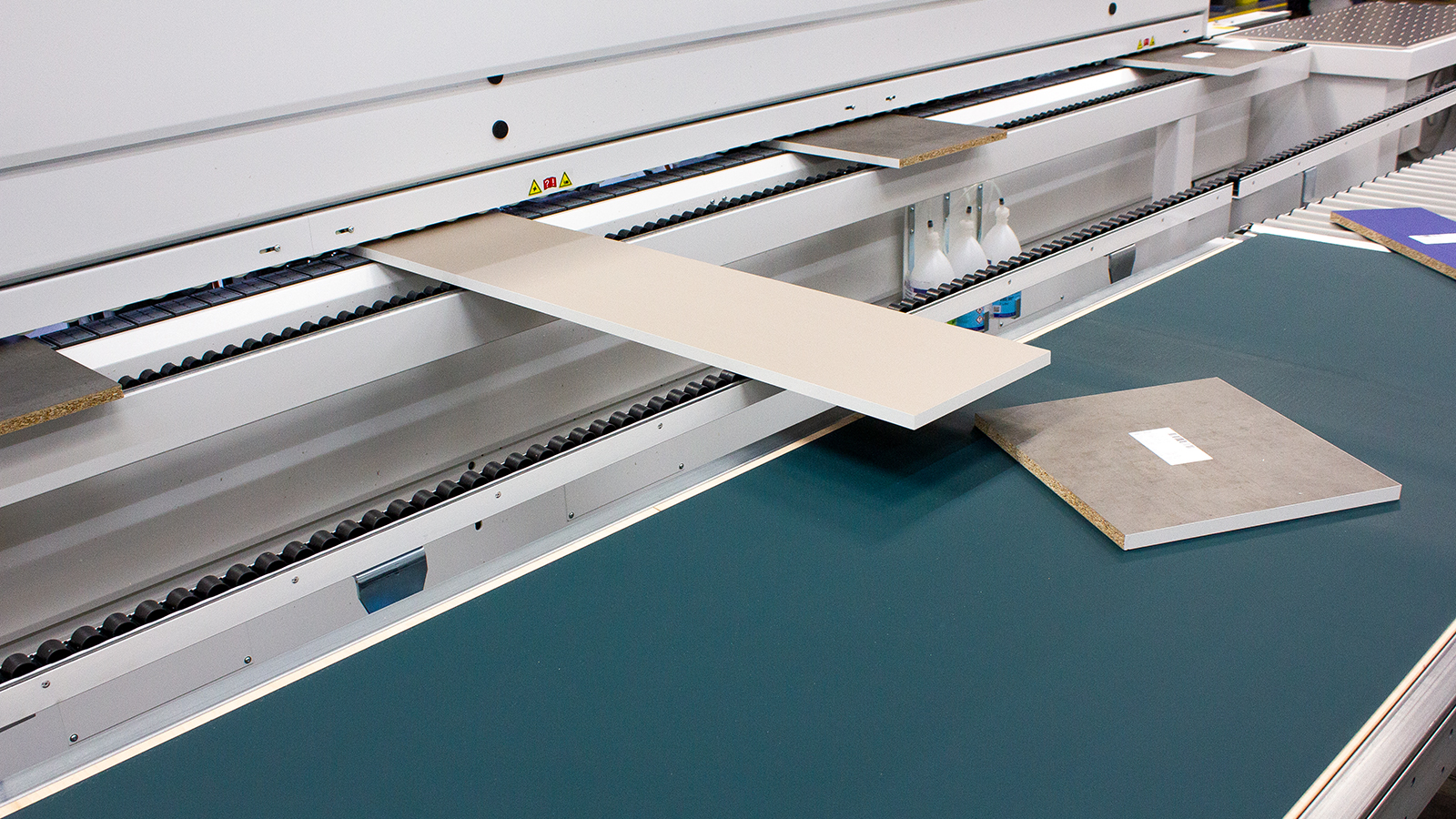

- Low quality costs - gentle workpiece handling with air cushion table

- No training necessary - assemble the LOOPTEQ O-300, connect it, and get started

- Flexible operator organization - thanks to economic one-man operation

- Ergonomic operation - operator will be released from heavy physical work

Images

Features

-

The LOOPTEQ O-300 perfectly harmonizes in size, capacity, and speed with HOMAG Group's unilateral edge banding machines

-

Optimum part handling thanks to an air-cushion table without ball valves

-

High capacity also in case of small workpiece gaps

-

Simple belt cleaning equipment is already included in the standard

Technical Data

| LOOPTEQ O-300/20 | LOOPTEQ O-300/25 | |

|---|---|---|

| Workpiece length [mm] | 300 - 2,500 | 240 - 2,700 |

| Workpiece width [mm] | 60 - 800 | 60 - 1,000 |

| 4-sided processing* min. workpiece length [mm] | 300 x 80 | 240 x 80 |

| 4-sided processing* max. workpiece length [mm] | 2,000 x 800 | 2,500 x 1,000 |

| Workpiece thickness [mm] | 8 - 60 | 8 - 80 |

| Workpiece weight max. [kg] | 50 | 50 |

| Mass per unit area max. [kg/m²] | 20 | 20 |

| Working height [mm] | 835 - 950 | 835 - 950 |

| Feed Speed [m/min] | 8 - 30 | 8 - 30 |

*Larger workpieces can be returned or even fed out at 4-sided processing with manual support during crosswise offset and turning.

(Previous product name: Return conveyor BOOMERANG® TFU 140)

Software

Here's how your colleagues produce

Brochures