Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

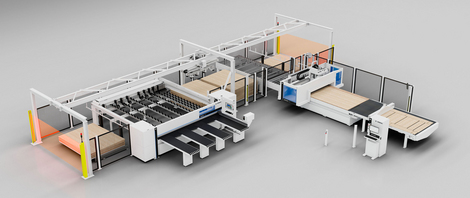

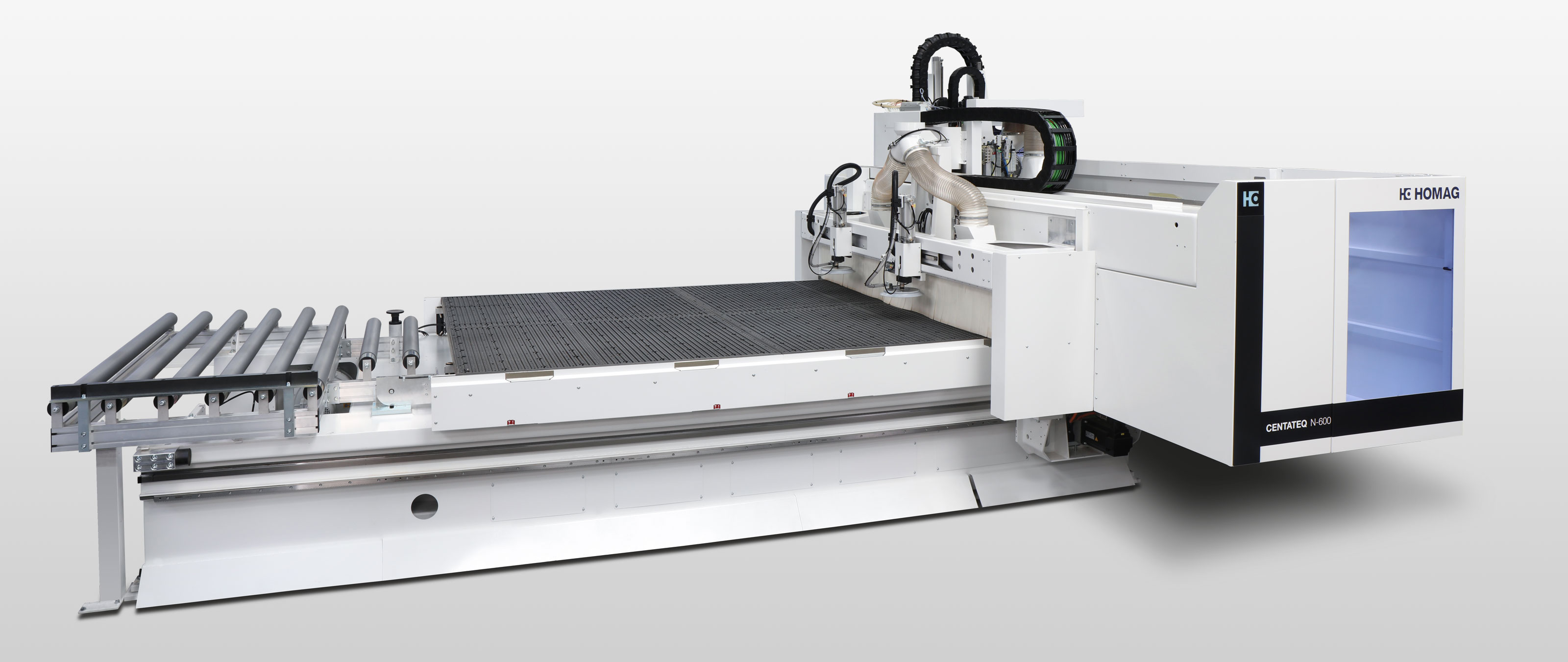

CNC Machining Centers CENTATEQ N-600

CNC Machining Centers CENTATEQ N-600

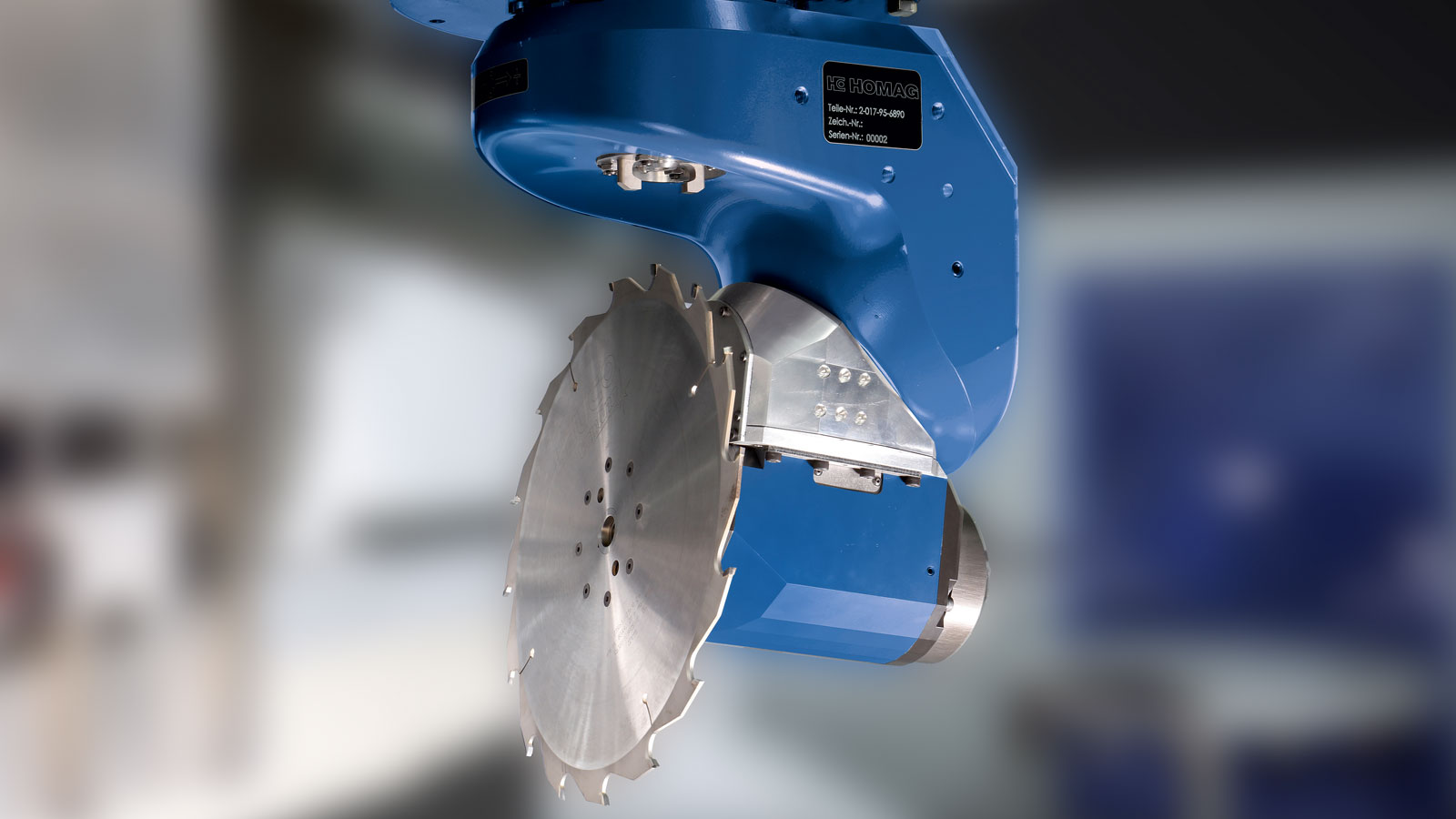

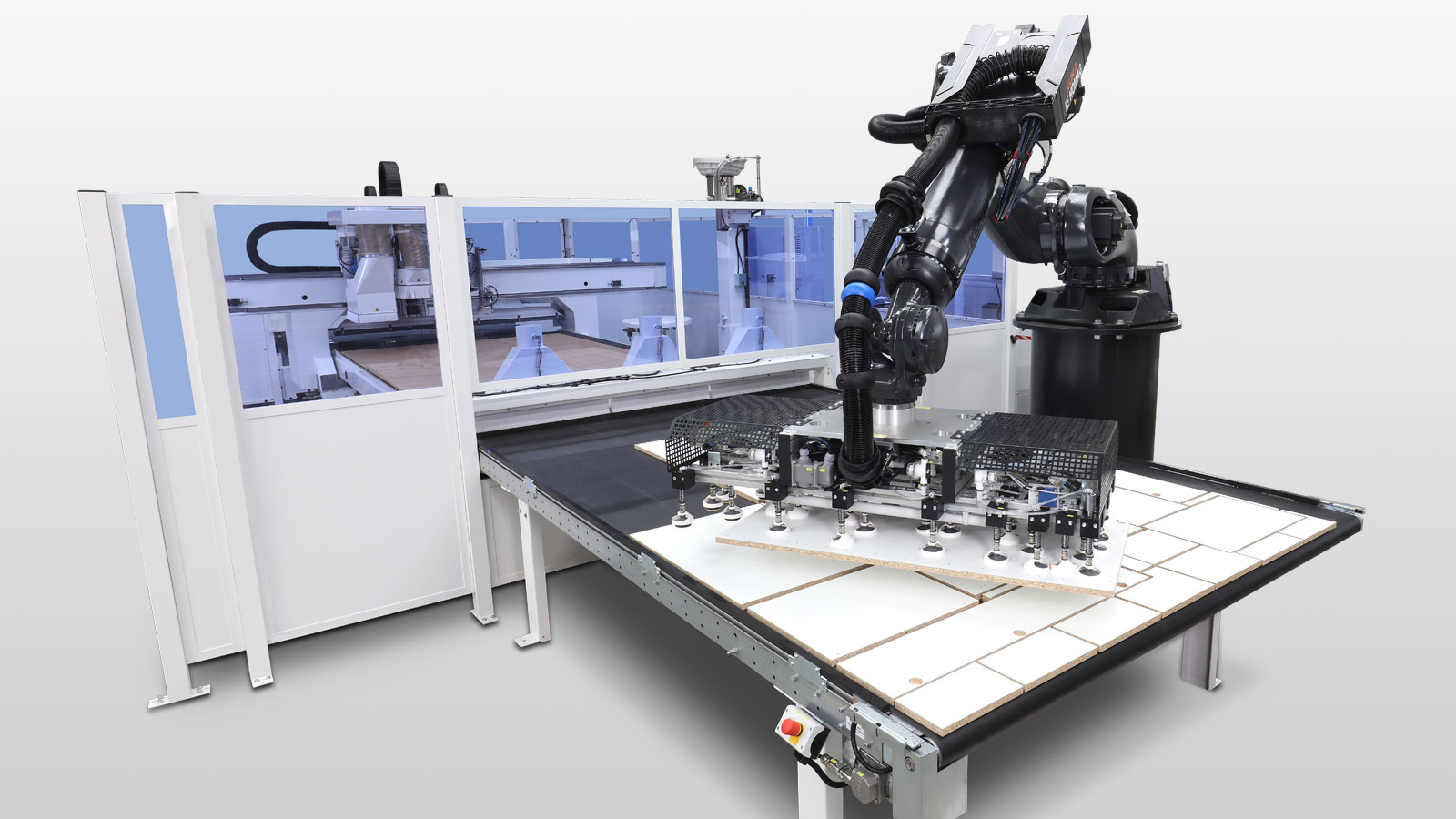

Nesting with 3-, 4- or 5-axis technology.

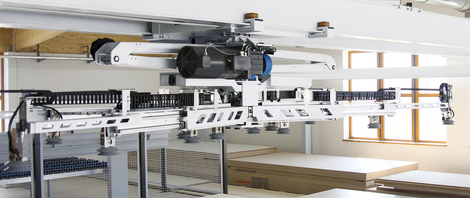

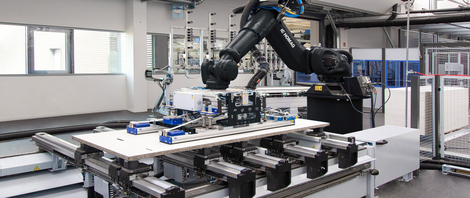

Our nesting machines enable cutting-optimized processing and dividing of plateshaped materials. We divide the typical nesting areas into four areas. The classic areas of nesting can be divided into carcass procressing, cutting and finishing of furniture fronts, processing for modular furniture production as well as “advanced materials” (e.g. Plexiglas, aluminum, Alucobond). Various possibilities for the automation of the material handling ensure a high time saving and more effective work.

Images

Features

-

2 synchronized digital servo-drives in X-direction guarantee highest processing quality

-

14-fold tool changer moving in X-direction

-

Vector speed X/Y 130 m/min

-

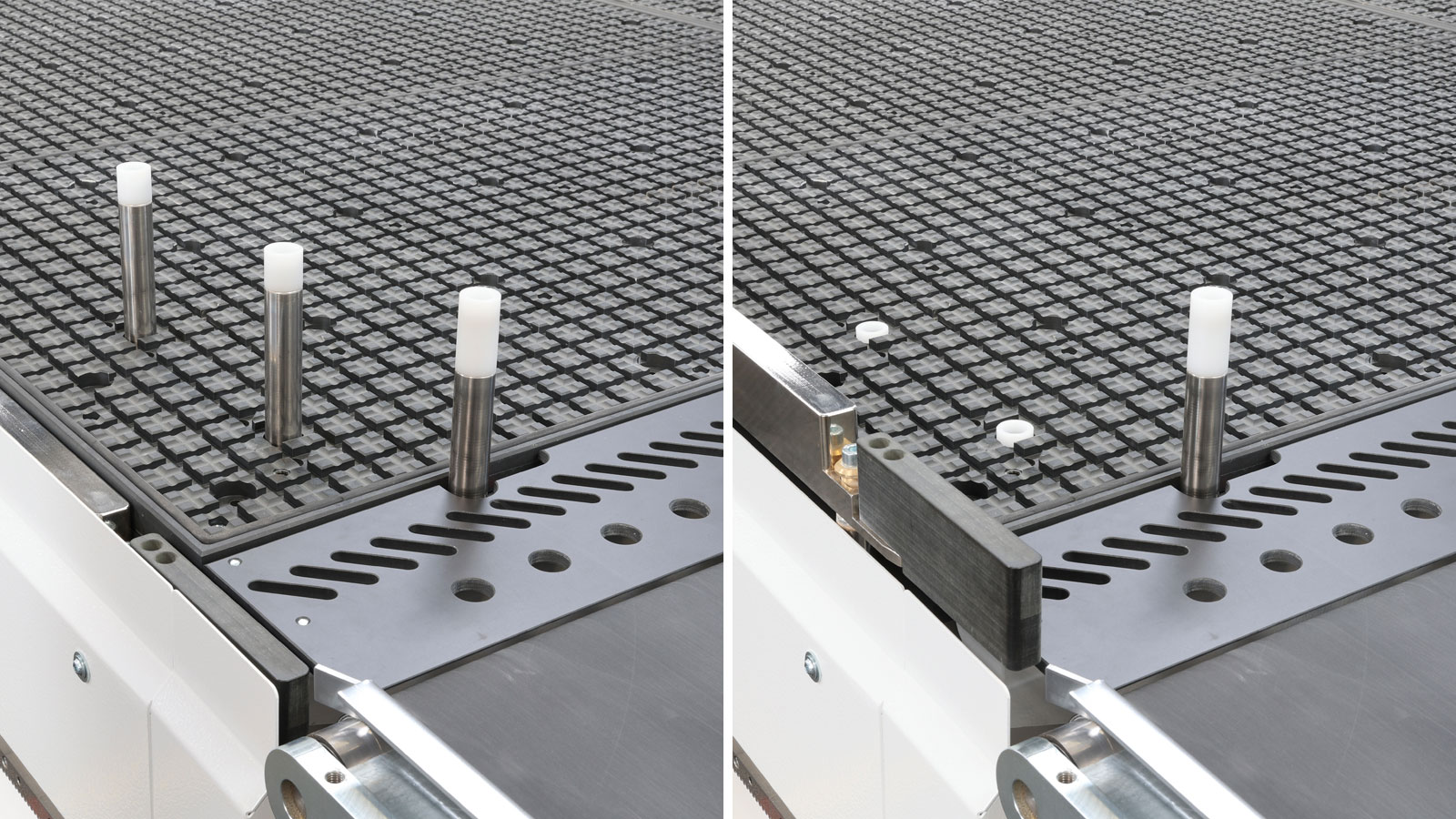

Efficient table field occupation by MATRIX Pro Plus

-

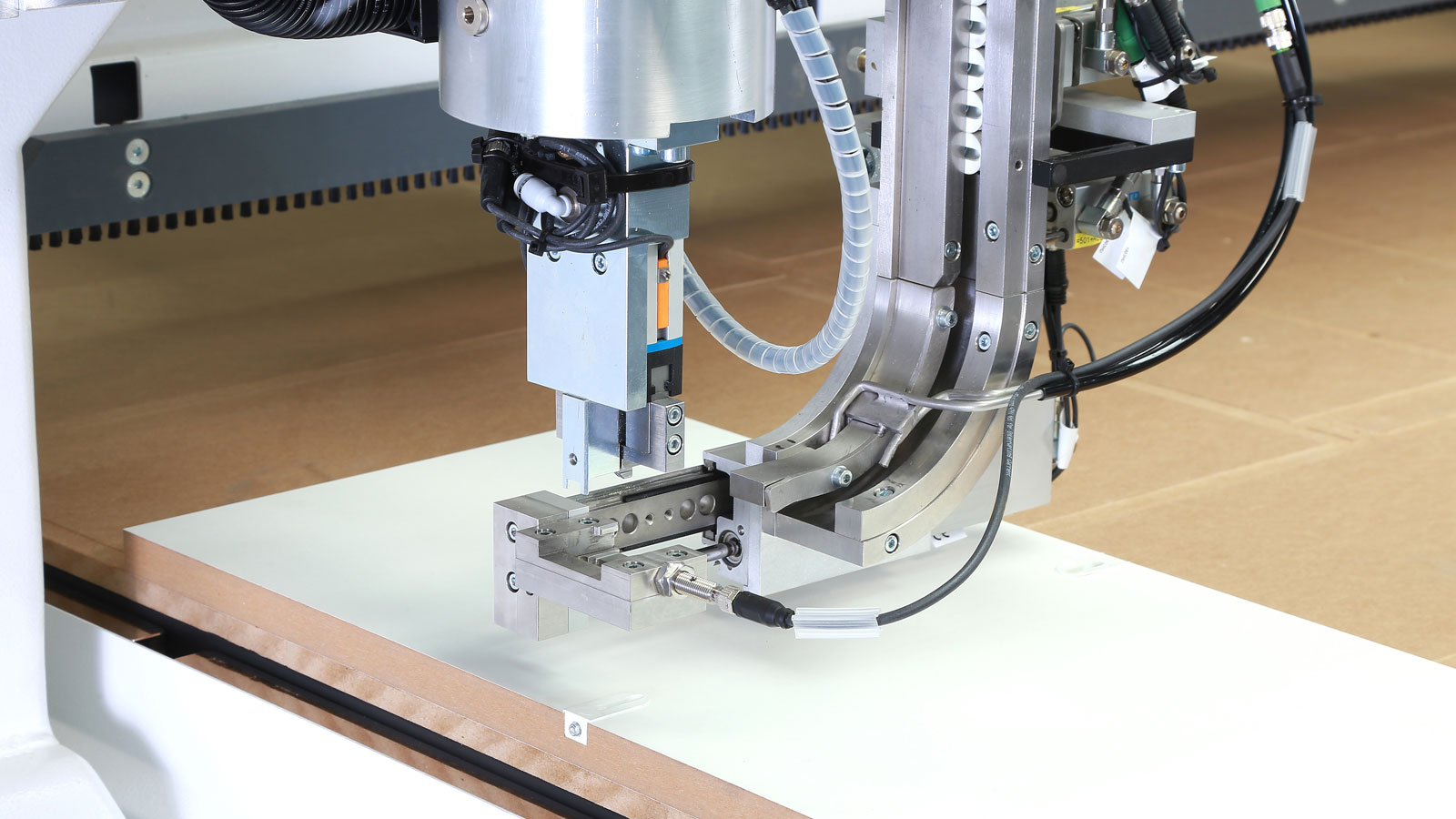

2 CNC-controlled Z-axes in combination with drilling block

-

The whole working field is reachable with all processing tools

-

intelliDivide Nesting – cutting optimization for CNC machines

-

Design furniture online and automatically receive all production data – with the cabinetCreator (Optional)

Technical Data

| CENTATEQ N-600 | 31/15/R 5 × 10 ft | 37/15/R 5 × 12 ft | 31/22/R 7 × 10 ft | 43/22/R 7 × 14 ft |

|---|---|---|---|---|

| Working field in X [mm] | 3.100 | 3.700 | 3.100 | 4.300 |

| Working field in Y [mm] | 1.550 | 1.550 | 2.250 | 2.250 |

| Working field in Z [mm] without automation | 210 | 210 | 210 | 210 |

| Working field in Z [mm] automatic push-off | 60 | 60 | 60 | 60 |

(Previous product name: CNC-Gantry Processing Center BHP 300)

Here's how your colleagues produce

Brochures