Sharing Passion. HOMAG at LIGNA 2023

It's that time again: HOMAG will be validating that it shares the same passions as you, under the theme "Sharing Passion" at LIGNA — the world's leading trade fair for the woodworking industry, which will take place from May 15 to 19 this year. You can look forward to a lively exhibition experience where HOMAG will showcase the right solutions to meet your requirements and provide you with a multitude of new ideas. The innovation ranges from individual machines, integrated cell concepts and robotics up to complete system solutions that suit all applications, production levels, and performance classes. HOMAG will also present solutions from WEINMANN, Kallesoe and System TM, and key HOMAG partners tapio, BENZ Tooling and SCHULER Consulting will also be present.

Solutions for CNC processing

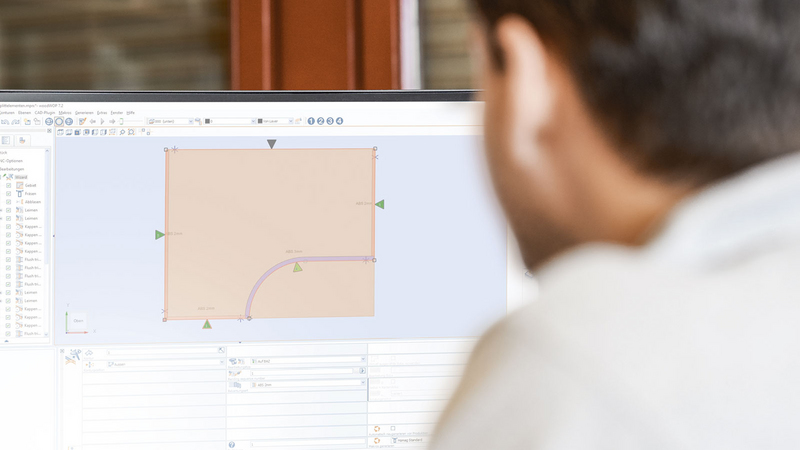

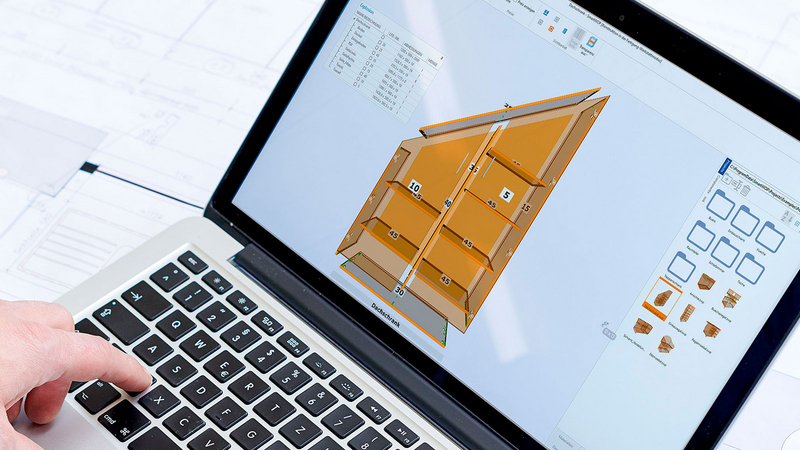

woodWOP update to version 8.1

The latest version of the woodWOP programming software is packed with new features and enhancements that make using this powerful software even easier and productive than before. For example, the pocket processing programming has been completely revised as an enhancement. Users can now define the approach mode, the reference point, and the shape, significantly increasing flexibility during programming. The nesting plug-in allows users to manually position and nest individual woodWOP programs on an unprocessed panel directly in woodWOP. The nesting plug-in then automatically generates the milling path for separating the workpieces. When it comes to simulation and calculating the processing time, users can look forward to woodMotion 8, which has an impressively improved visualization. For customers who want to know processing time, woodTime is now available. In addition, the new CNC test suite enables large quantities of woodWOP programs to be checked quickly during work preparation. As well as determining the processing time, the executability of the programs is also checked. This means that users know in advance how long a job needs on the CNC, thereby preventing unplanned waiting times and optimizing production and scheduling.

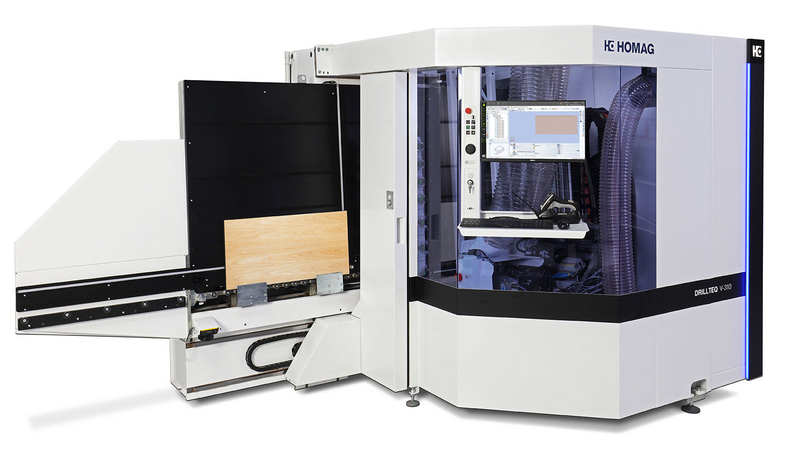

DRILLTEQ V-310 — Now with robotic support

Automation and processing with a reduced availability of qualified personnel is becoming increasingly important in woodworking shops. The innovative DRILLTEQ V-310 vertical CNC processing center, nicknamed "The Raumwunder"—which was unveiled at last year's Holz-Handwerk trade fair—will now be able to benefit from robotic support in the future. The reliable supply of workpieces by the robotic system makes the DRILLTEQ V-310 a high-performance machining center and therefore an optimal production tool in woodworking shops. The benefits of introducing a robotic system are obvious, since the robot does not require breaks, can work in the workshop around the clock and can ensure a consistently high-level of quality. The possibility of using this tool in the future will allow small and medium-sized companies to save time and reduce the workload for employees. The resulting flexible organization of personnel enables the workforce to be used for other value-adding activities and production processes. This creates added value for the system in terms of quality, availability, and performance. Of course, there is still the option of loading the DRILLTEQ V-310 manually for individual workpieces.

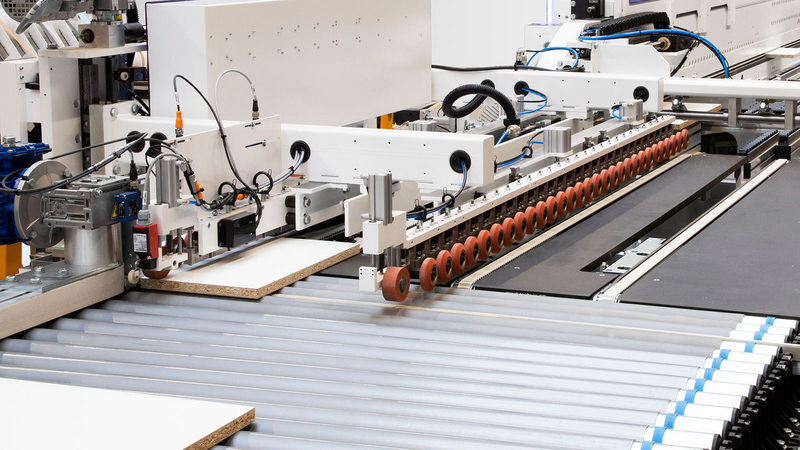

Innovative edge banding machines from HOMAG

News from the EDGE machine pool

The WZ14 workpiece feeding system—which was previously only available for high-production models of edge banders from HOMAG—is now also available for edge banding machines in the EDGETEQ S-500 series. Thanks to the extended push catches of the WZ14, workpieces are guided safely under the top roll pressure unit. The moving gantry ensures precise parallel cuts — a prerequisite for achieving correct angles. This means that even rough-edged workpieces can be processed perfectly. Another perfect supplement to the EDGETEQ S-500 is the LOOPTEQ O-600 gantry return conveyor system. Intelligent automation forms the basis for a high-performance, interlinked material flow. The defined part rotation when moving the workpieces results in a process-oriented return for incomplete parts, and all finished workpieces can be ejected or stacked by this system.With the EDGETEQ S-500 narrow parts machine, users can now also precisely process very narrow workpieces, down to 40 mm (1.57 inches).

At our LIGNA experience, the highly flexible EDGETEQ S-380 edge bander is equipped with the LOOPTEQ O-300 return conveyor. The workpiece return transports a wide variety of parts and increases overall efficiency through high performance and gentle workpiece handling. It is ideally suited for users with a wide variety of parts — from small and light to large and heavy workpieces. A new air cushion table concept, including sliding carriages, will also be presented (also for the EDGETEQ S-500). The ergonomic machine infeed ensures a safe and right-angled workpiece feed. For processing edge overhangs and copying corners, the MF50 multifunction trimming unit features a stepping motor for automatically adjusting to different edge thicknesses.

Software for wide variety in the parts flow

The new woodCommander5 software version also enables internal and external data exchange. The software is designed to select processing programs and edge material and enables the reliable and fast recording of production parameters as well as the workpiece-oriented creation of machine programs. Thanks to the intelligent grouping of levels of information, fewer clicks are required to produce the desired results. The real 3D workpiece simulation displays the dimensions directly on the 3D workpiece and the automatic checking of impermissible parameter combinations ensure a high level of operating safety, which is reflected in time and cost savings.

With the edge data plug-in software module, woodCommander5 creates a direct connection between the machine control unit and the edge band assistant. The app provides a comprehensive overview of all information about edge band material, including material stock. Data such as edge thickness, edge height and available length of the selected edge roll are transferred directly to the machine using the edge data plug-in from the edge band assistant app. This saves the operator from having to input data manually on the machine. Thanks to the plug-in, the edge banding machine also reports the remaining length of the edge roll back to the app. This means that the edge band stock is always up to date for the machine operator as well as for colleagues in work preparation and purchasing. The precise recording of material data enables optimal use of the edge bands and effectively increases the sustainability of production.

At LIGNA, HOMAG will be demonstrating the automatic recording of edge band data between the machine and the edge band assistant live.

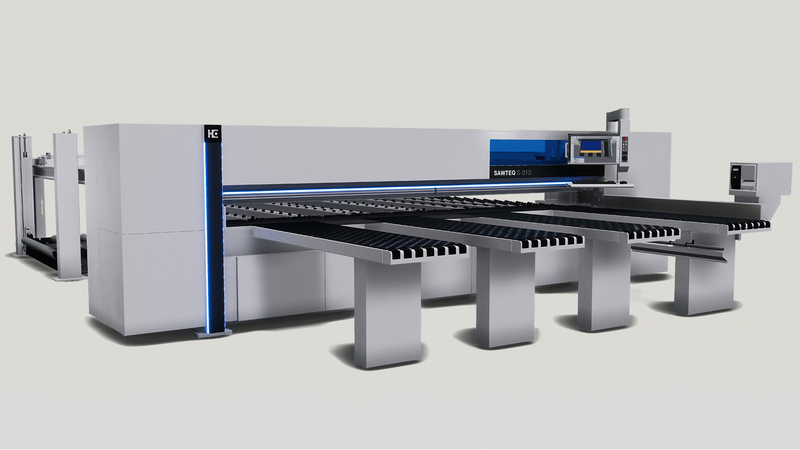

World premiere of the new SAWTEQ B-300 and B-400 panel dividing saws

Redefining flexibility and performance

HOMAG will be presenting the all-new SAWTEQ B-300 and B-400 series panel dividing saws for the first time, both of which have been updated with significant and innovative new features. The cutting solution combines performance, speed and reliable technology with increased intelligence and digital, self-learning functions. This is reflected, among other things, in an increased performance level because of an improved sawing process and optimization with reduced energy consumption. Machine operation has also been rethought. Thanks to improved working positions, the way the operator works with the saw control system is now even more flexible and ergonomic. The intelliGuide Classic operator assistance system— which is now included as standard—supplements these optimizations and guides the operator through the cutting process safely and intuitively using LED signals. In addition, a new feature within the saw control system monitors optimal machine use and provides continuous support through appropriate information — another step toward intelligent machine control. The focus is also still on cutting quality. As well as materialManager Advanced, which automatically specifies optimal saw parameters, the machine is also equipped with a new function that uses sensors to detect the dimensional accuracy of the workpieces and transparently reports this back to the operator. This increases process reliability and provides more transparency in cutting.

A new panel storage platform combines the strengths of automation with intelligent logistics

At LIGNA, HOMAG will be presenting the new, completely revised range of STORETEQ panel storage technology for the first time. The range meets the requirements of both small woodworking shops as well as large industrial furniture manufacturers. Rapid changes in market conditions that require flexible, efficient, and sustainable adjustment were the clear focus of development. The portfolio will be enhanced through the introduction of a feeding solution for the entry-level segment as well as, for the first time ever, second-level and dual-level storage systems. Processes are significantly improved as a result of increased reliability, availability and standardized data integration and processing — this is achieved by the consistent use of the powerful, leading woodStore storage system software. The second-level and dual-level STORETEQ storage systems also offer optimal utilization of available resources and address the issue of space limitations that exists in many countries.

The new HOMAG feeding solution for SAWTEQ B-200 series panel saws has been specially optimized and will be unveiled live at LIGNA. This means that fully automatic panel feeding is also possible with the entry-level series. The continuous process flow not only means higher productivity, but also a more ergonomic working method. It also helps to avoid material damage during material transport.

Step into the future in an innovative and digital way

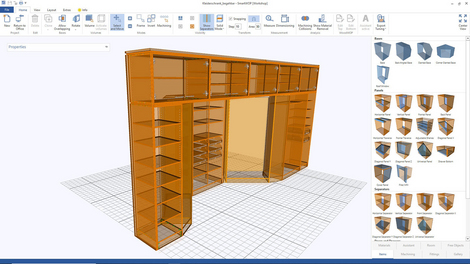

SmartWOP: The easy way to design furniture

Many customers want furniture design software that is very easy to use, with maximum flexibility in the design process. With SmartWOP, HOMAG offers a new software solution that meets exactly these requirements and makes the typically extensive creation of master data obsolete.

With SmartWOP, all users, including those without any prior CAD knowledge, have a powerful CAD/CAM system at their fingertips, which they can use to design furniture intuitively in the shortest possible time using drag-and-drop. The furniture simulations created can then be saved in the library and called up or modified at any time. The production data generated, such as CNC programs and parts lists for cutting, can then be transferred directly to the HOMAG apps and digital assistants.

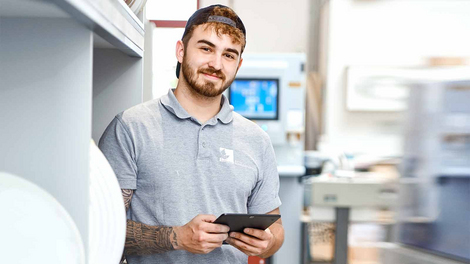

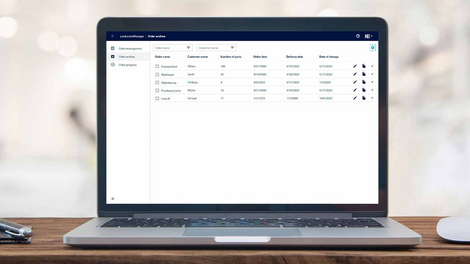

productionManager: Endless paperwork is a thing of the past. Today it's all about the digital job folder.

No more endless paperwork. The order books of many woodworking shops are full. This makes it even more challenging to keep track of everything and to keep the job data up to date for all employees. HOMAG's solution to this jungle of information is productionManager, the digital job folder.

It gives every employee access to all information about every job in real time. The current job progress of the individual components is also displayed directly. This ensures end-to-end transparency throughout the entire operation. This web-based app can be used via a laptop or tablet. The advantage of this free web-based software is that no cumbersome installation or download is required--the software is always up to date and provides complete transparency about jobs at all times.

Create added value easily

HOMAG is focusing on service

For HOMAG, sharing passion means developing and offering individually tailored solutions with passion. From pure technology, to software, through to service and support. This is exactly what HOMAG LifeCycleService stands for. HOMAG has recently revised the price/performance offers so that the solutions offered are now better tailored to the size of the company. From 24-hour spare parts deliveries to discount campaigns in the HOMAG eShop, through to 100 easy-to-access digital training courses in the HOMAG Academy, the passion for supporting your business is clear. All visitors on site at LIGNA can see this for themselves.

WEINMANN is your partner for timber construction: The A to Z for your timber framing needs

Highly efficient production with robots and multifunction bridges

The requirements in timber construction are very diverse, since customer demands are highly customized and individual. A wide variety of wall structures, materials and element sizes are the norm. When manufacturing wall, roof, and ceiling elements, it is therefore even more important to work with machine technology that can be used flexibly.

At LIGNA, WEINMANN will be presenting a highly automated and collaborative production cell. The FEEDBOT W-500 robot automatically places panels on the framework. In conjunction with the new WALLTEQ M-300 multifunction bridge, this creates a flexible and autonomous production cell. This cell secures and processes the element independently and is characterized by a high degree of flexibility for processing different materials. It achieves a high level of performance thanks to automatically interchangeable fastening units.

Creating value through services

With its services, the WEINMANN Academy meets the increasing demands placed on timber construction companies regarding more complex work preparation and the further development of their own business model. In addition to the offers for training, production support and increasing the efficiency of the company, further services are offered continuously for timber construction companies in conjunction with SCHULER Consulting. Here, the WEINMANN Academy aims to offer increased support for the qualification of specialists in timber construction and act as a provider of overall solutions. As a competent partner, WEINMANN is there for its customers in all matters relating to timber construction, from A to Z.

Tailor-made system solutions for solid wood processing

45 years of expertise in wood processing

System TM—which has been part of the HOMAG Group since 2020—will also be represented at LIGNA. The core competence of System TM lies in the optimization of solid wood using automated processing systems. As a supplier of complete solutions, the company offers a wide range from the planning, development, and installation of production lines, to further training of employees, to service and maintenance. With more than 300 installations worldwide, System TM is an expert in individual solutions for highly integrated and fully optimized systems.

Optimization of personnel and wood resources

Wood is a sustainable and carbon-neutral resource that must be treated with care. The machines from System TM make it possible to get the most out of raw wood material and to produce high-quality products with minimal waste. A high degree of automation and self-regulation also ensures that personnel resources are optimized. In conjunction with Kallesoe—the worldwide specialist for high-frequency presses, and a member of the HOMAG Group since 2021—complete solutions for the production of glued timber, glued laminated timber and glue-laminated wood are also offered.

Digital tools and solutions for the wood industry

Remote maintenance and digital machine service with ServiceBoard

If a machine is at a standstill, production is stopped, and the corresponding service partner must be contacted. With ServiceBoard, tapio offers the optimal solution for all service cases. If there is an error on the machine or if it is at a standstill, a service ticket can be created digitally via ServiceBoard, and the machine operator can describe the error in detail and add photos. The ticket is then automatically forwarded to the correct service partner.

Previously, ServiceBoard could only be used via the tapio app. In the future, ServiceBoard will also be available as a web app and will be able to be used without prior download.

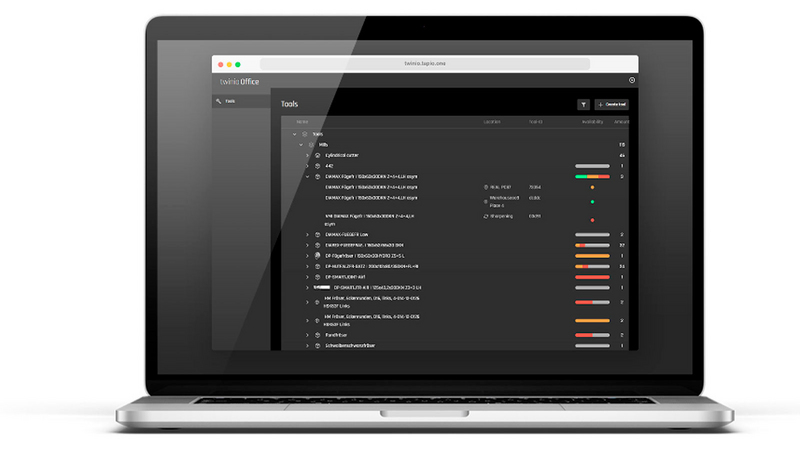

Digital tool management with twinio

With twinio, you can now manage your tools—such as saw blades, trimmers, and CNC tools—digitally and on the go via the web app in your browser, all from the comfort of your desk. Simply scan the tool to detect and manage it. You can also create your own tools, as well as easily change defined parameters, such as the tool running meters. Tool-related actions can be performed quickly, and users can see where the tools are located immediately.

Full transparency of the value stream and intralogistics

Digital value stream optimization from SCHULER Consulting

Increasing the efficiency of the entire production process is a daily challenge for manufacturing companies. Consistent recording of production data is often not possible in a mixed machine pool. Influential factors such as process times and transport routes remain unknown. The digital value stream optimization from SCHULER Consulting makes flows of materials and goods visible via a tracking system and records machine data by using external sensors, independent of the machine brand and age. All production data, including data from existing systems (e.g. ERP, MDE, MES) is incorporated into a digital value stream dashboard. This data forms the basis for the targeted and continuous production optimization.

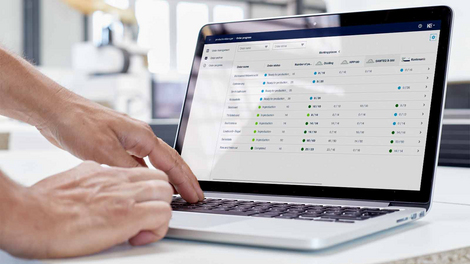

Full control over production: Innovations in the ControllerMES production control system

The ControllerMES production control system from HOMAG provides a flexible package for optimal production planning, control and monitoring of production processes and ensures intelligent networking of all information flows in production.

An efficient new feature of ControllerMES is the automatic batch formation. Based on defined rules, the software now enables the optimal, automatically controlled formation of cutting batches. These are determined individually, considering upstream and downstream production processes. Manual corrections are possible at any time. This not only saves time and material, but also optimizes production processes. With the new automatic stack formation, components can be optimally arranged on a stack. As well as considering the layer offset within a stack, its reversibility is also checked. A further innovation can be seen in the configurable HTML5 dashboard, which can be created individually using production KPIs. The modular structure makes it easier to configure the dashboard.

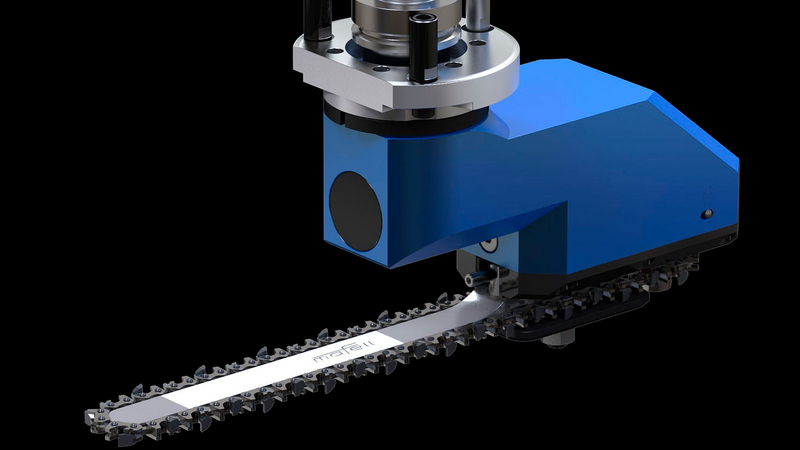

Trimming chain units for deep pockets

Now enable completely new processing steps

Maximum accuracy — BENZ Tooling presents its new trimming chain unit for slitting and inserting very deep and flat pockets. The tool does not require any additional chain lubrication, ensures automated chain tension throughout the entire production process, and optimizes the efficiency of the overall processes. Since completion takes place directly on the CNC machine, post-processing is no longer necessary.

With BENZ i.tag—the digital type plate—product data can be called up on a smartphone anytime, anywhere. Thanks to its fast and easy handling, no special software is required because the information is managed securely on an NFC tag. A contact function via online form, email or telephone enables direct contact with BENZ Service. By saving on paper, BENZ i.tag supports the digitalization of processes and facilitates the sustainable handling of technical data and documents.

Nesting — Efficient cleaning thanks to an optimized blowing nozzle unit

Increased flexibility thanks to a modular design from BENZ

The new trimming unit with blowing nozzles enables more efficient cleaning of processing surfaces and reduces production costs by regulating the compressed air on the unit itself. The modular design enables flexible use by combining collet chucks and hydro-expansion chucks. This means that a wide range of cutting tools can be used and a high level of concentricity can be achieved. A 40% reduction in the design and optimized bearings ensure smooth and vibration-free operation. The tool can be optionally equipped with minimum quantity lubrication or several blowing nozzles. High-quality ceramic bearings ensure maximum usage duration and service life of the blowing nozzle unit.

All nesting units are equipped with the BENZ i.tag digital type plate.

Count on HOMAG for the right solutions

Sustainability and innovation

HOMAG is also focusing on and sharing passion for sustainability and the prevalent issue of preserving resources. In addition to setting corporate objectives, for example saving energy resources such as gas and heating oil, HOMAG is also identifying potential energy and resource savings on machines, such as saving electricity, dust extraction energy and using material optimally to reduce waste. The HOMAG trade fair stand at LIGNA is also equipped with sustainable materials and elements with a focus on preserving resources. At the HOMAG Innovation Center, all LIGNA visitors will also receive comprehensive answers to questions about more sustainable, more resource-efficient production and innovative processing methods.