Solution Engineering

HOMAG Solution Engineering offers innovative and customized solutions for the wood and furniture industry, tailored to your company’s needs. Our experienced team works closely with you to develop efficient processes and optimize your production. We accompany you from initial planning through concept development to implementation and commissioning to ensure your project’s success. Rely on our expertise for sustainable efficiency improvements in your manufacturing!

Your Production, Our Approach

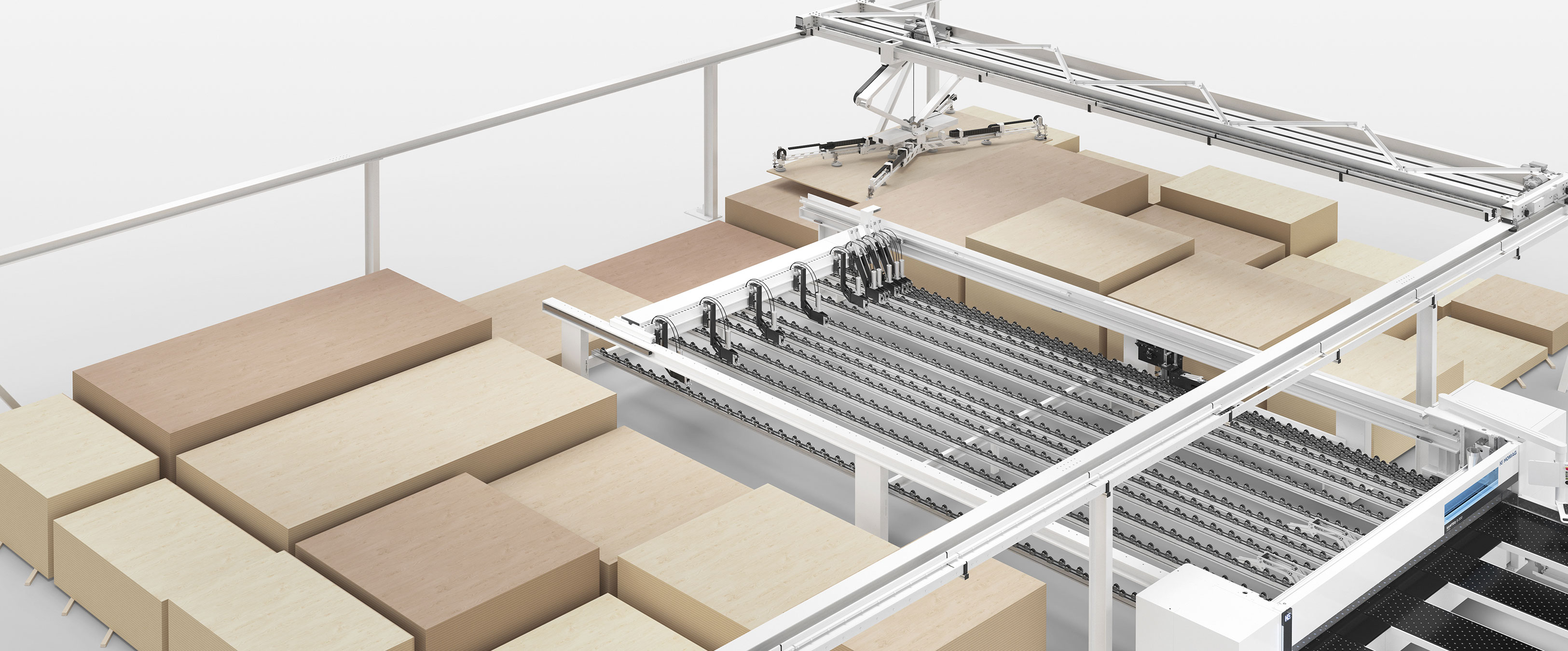

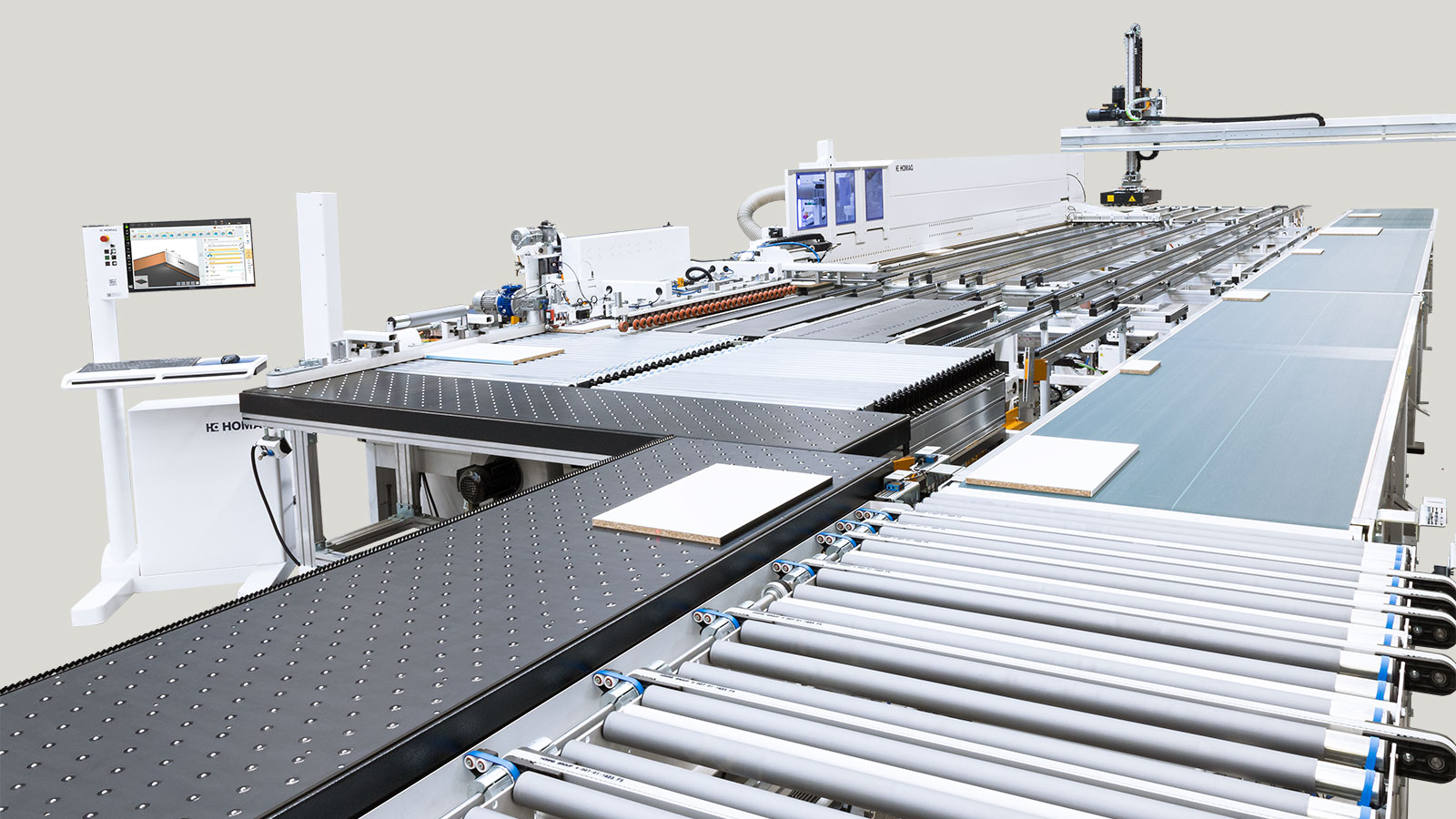

HOMAG – your reliable partner for customized system solutions in woodworking. Benefit from our long-standing expertise in wood, furniture, and timber house construction. Discover our wide range of technical possibilities for your optimal production. With comprehensive process understanding, we stand by your side as a competent partner. We offer holistic solutions for planning your individual requirements and needs, enabling us to realize sophisticated production systems.

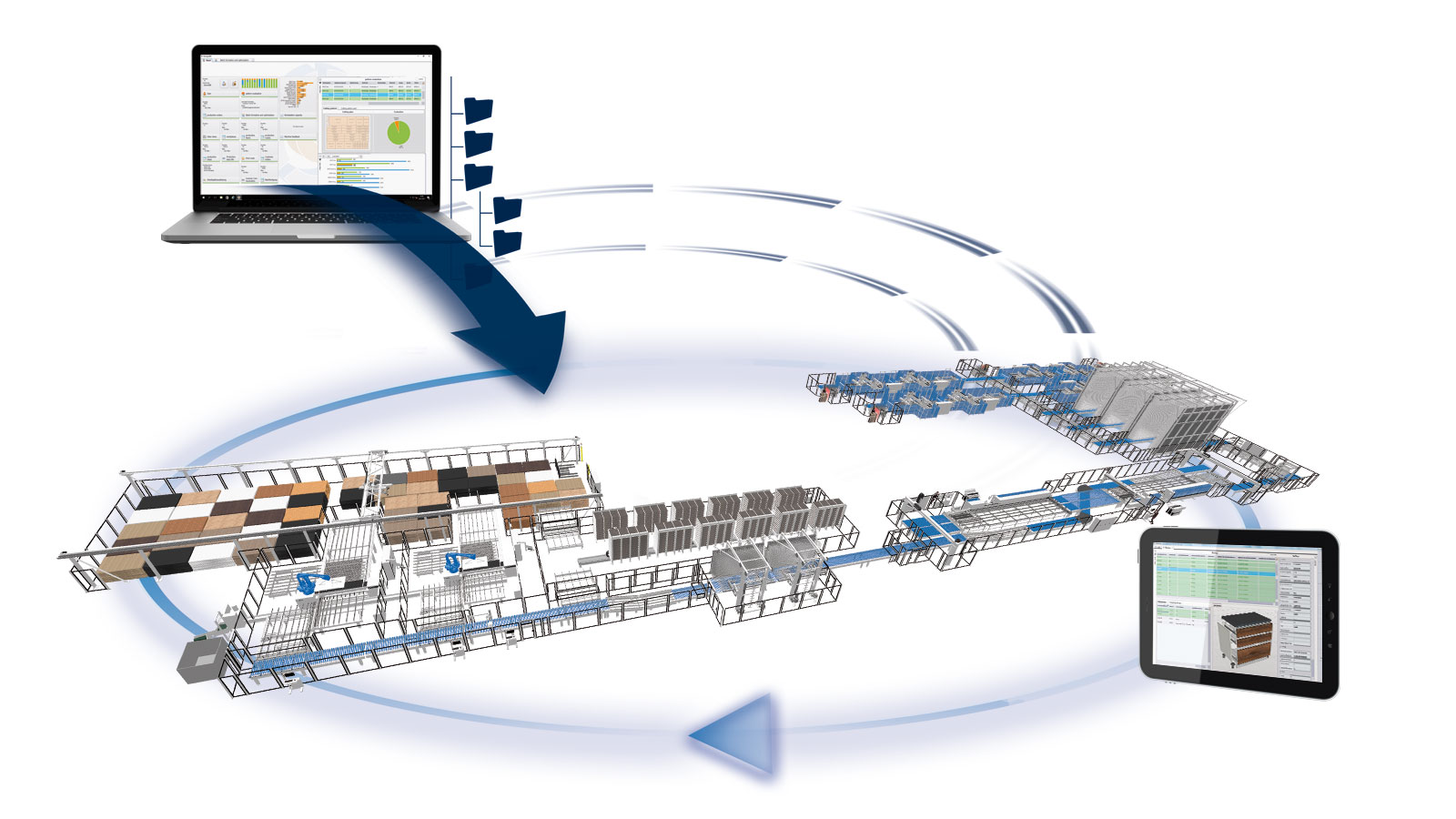

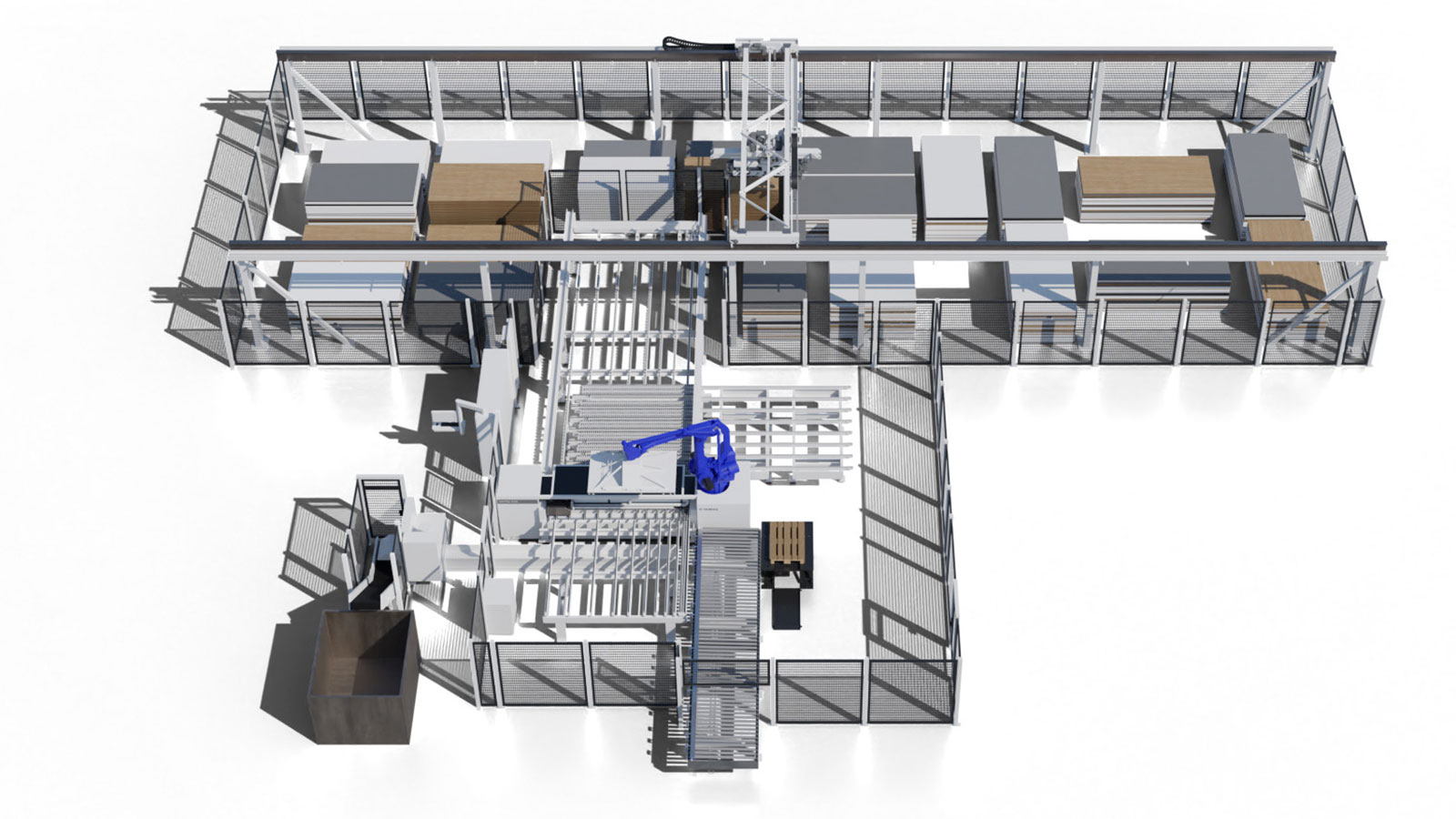

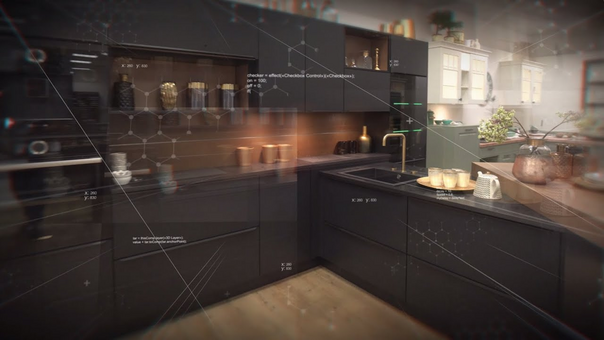

Virtual modeling of machines and production processes is essential when planning concepts – whether for small and medium-sized businesses or fully integrated industrial factories. We plan material flow controls, data interfaces, networks, and IoT connections from project start to acceptance. From planning to implementation, our transparent and structured project execution ensures reliable and timely results.

HOMAG Solution Engineering has years of experience with customized solutions and the realization of complete systems to high quality standards. Your project manager will be your personal contact from the initial discussion to successful project completion.

- Comprehensive production analysis: Evaluation and optimization of all manufacturing processes in terms of efficiency, quality, cost, and sustainability.

- Production aspects: Consideration of material procurement, warehousing, planning, production, quality control, and logistics.

- Collaborative planning: We develop your individual solution in close consultation with you and your planning team, considering your requirements and needs.

- Project team: We design your system by involving all relevant departments and are closely networked with our experts for all manufacturing steps and processes.

- Single point of contact: Continuous support from task definition through project planning to proposal presentation.

- Material flow: We ensure optimal material flow to plan an efficient and economical solution with you.

- Variants: In collaboration with our simulation team, we evaluate solution variants and consider early integration with your software environment and optimal system control.

- Support: We assist you from concept to commissioning.

- Training: We offer comprehensive training for your operating and maintenance personnel both at our facility and on-site.

- Support: We provide extensive support as needed for smooth operation and high availability.

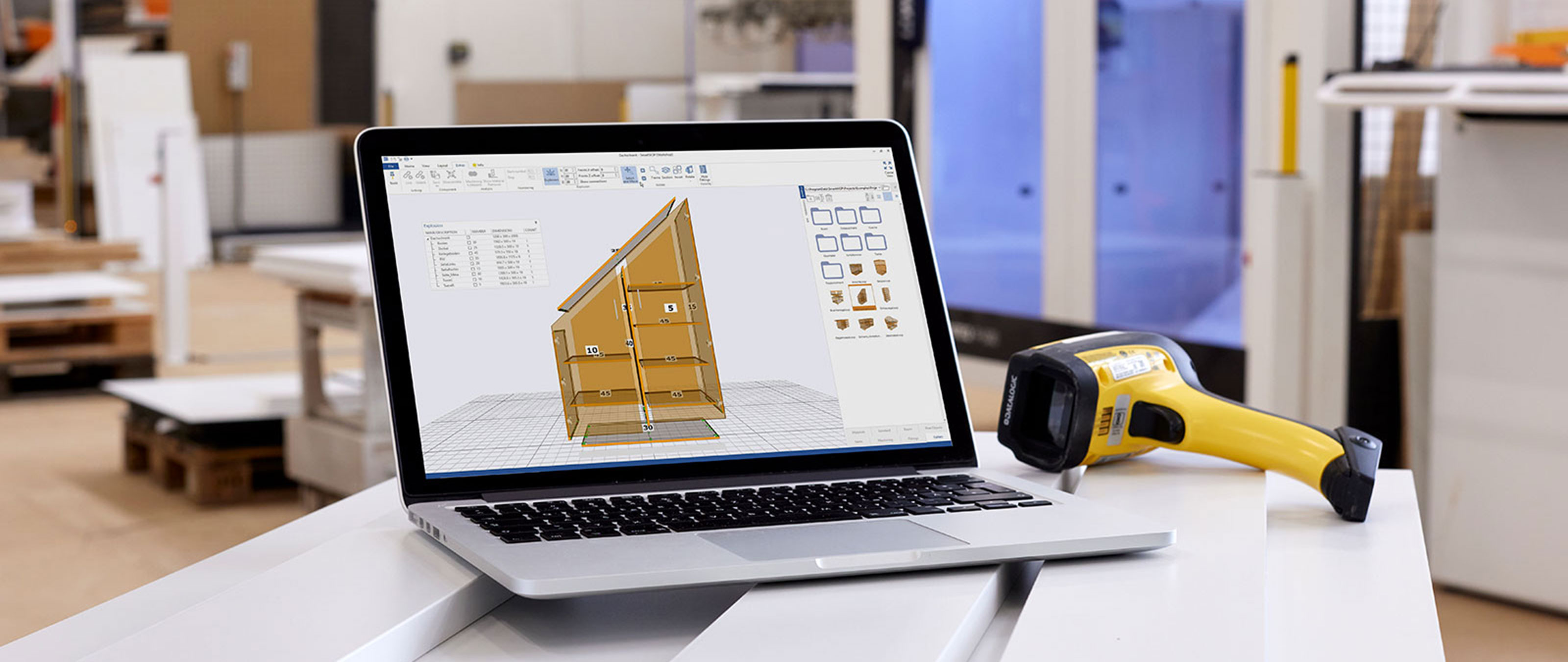

- Simulation tool: Our simulation software helps us design machines, cells, and buffers between processes and evaluate production philosophies. It ensures reliable performance planning using real data from your production.

- Investment and planning security: Simulation provides a comprehensive representation of concepts regarding manufacturing technology, material flow logic, and control to determine reliable performance metrics.

- Variant evaluation: Planning results are transparent and reproducible. Alternatives are objectively compared and evaluated. Variants can be flexibly created using simulation modules or different configurations.

- Your benefit: Virtual modeling of machines and production processes provides early confirmation of planned concepts or highlights areas needing further development.

We handle comprehensive planning of material flow controls, data interfaces, network architecture, MES and IoT connections, and barcode reading systems.

- System integration: Seamless integration of your system into your company’s system landscape.

- Fitting interfaces: Continuous planning and documentation of interfaces between involved systems ensure fast and secure system commissioning.

- Risk minimization: A consistently coordinated control and automation concept across all process steps ensures investment and planning security.

- Single point of contact: Continuous support for control-related requirements from planning to project acceptance.

- Everything from one source: We support you throughout the entire project – from order placement to successful commissioning, handover, and final acceptance on-site.

- Project organization: We coordinate all deliveries and project participants, both technically and in terms of scheduling.

- Milestones: Factory acceptance, deliveries, mechanical and electrical installation, cross-interface commissioning of machines, cells, and complete delivery scope, ramp-up, and final acceptance.

- Site management: Scheduling and technical coordination of all activities on-site, monitoring the project timeline, communication, and clarification with your project team and all suppliers.

- Single point of contact: Continuous organizational support from order placement to successful commissioning, handover, and final acceptance on-site.

Your Production, Our Processes.

Your Production, Our Performance Classes

Whether small or large projects, simple or complex tasks – we develop the right solution for your production while keeping performance requirements in focus.