Based in Hatfield, XCUTS is pushing the boundaries of what fast service means in the panel processing industry. Offering cutting, edging, CNC milling, spray painting, and high-quality board supply, the company has fine-tuned its manufacturing to a precise degree, delivering remarkable turnaround times of just 24–48 hours. For bespoke carpenters, interior designers, builders, and DIYers, that speed makes all the difference.

In the early days of the business, however, these lead times were merely an ambition. To make it a reality, XCUTS would need machinery of the highest calibre. The answer was HOMAG.

A vision for speed and scale

“From the start, our vision was to offer extreme speed without compromising on quality,” explains Amir Navazani, Managing Director at XCUTS. “We take a lot of pride not just in our work, but also in our facility, so we wanted machinery that would look the part as well as play the part. Truthfully, we would only be satisfied with the best machinery that money could buy.”

Choosing the right partner

XCUTS left no stone unturned in its research. “We went to Germany and Italy, meeting with multiple suppliers and testing machines. I’d known about HOMAG for several years, and suspected that would be where we’d end up, but I wanted to be sure we’d explored all possible avenues.”

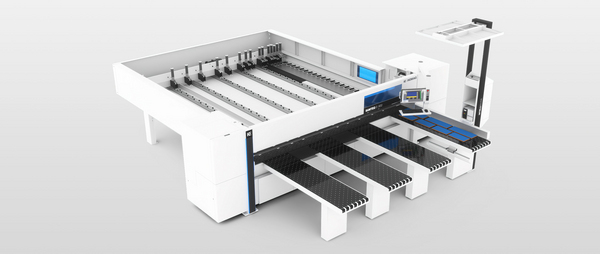

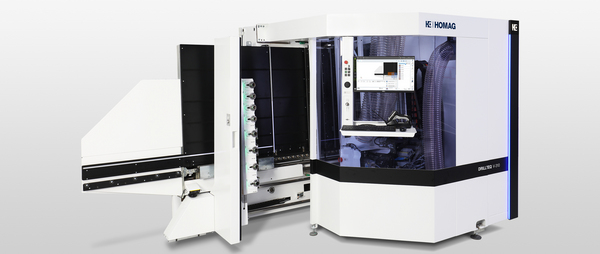

HOMAG indeed emerged as a front-runner. “We had several great meetings with them in which we explained our business, our plan, our goals, everything. They took it all on board and suggested a suite of machinery that ticked every box.” This suite consisted of two SAWTEQ S-300 beam saws, a DRILLTEQ V-310 vertical CNC, and an EDGETEQ S-300 edge bander supported by the XES 200 glue pot pre-heating station.

Then came the time to see the machines in action. “We visited HOMAG at Castle Donington where they let us test and work with the machines. What we saw really impressed us, but still we wanted to be absolutely certain that they were the right choice, so we actually asked HOMAG if we could visit a customer of theirs who had recently purchased these same machines.

“They said yes, no problem, and drove us out to their customer. Speaking directly with the operators and owners gave us complete confidence. We knew we were choosing the right machines and the right partner.”

Seamless installation and training

“The installation was really straightforward,” reflects Amir. “We had some complications on our end which meant we had to change some of the installation dates around, but this was no trouble for HOMAG. They were flexible, accommodating, and highly efficient. We were up and running in no time.”

Training, too, was comprehensive. “This was new technology for us, so it was important that we were brought thoroughly up to speed. HOMAG’s team took the time to ensure we fully understood everything, and after the initial training, they were always happy to answer any further questions we had.”

Exceeding expectations

Today, HOMAG machinery is the beating heart of XCUTS’ operation. “Before investing, we couldn’t possibly have reached our targets. Now, thanks to HOMAG, our vision of an ultra-fast service model has become a reality,” Amir explains.

“The speed of these machines is incredible, as is the capacity and the accuracy. Our expectations were very high, yet they have been exceeded. Seeing the saws and edge banders do what they do on a daily basis is a joy. We are extremely happy with the output and the results.

“As a bonus, the machines look fantastic. This is important to us because, as mentioned, we take a lot pride in our facility. When customers come to visit us, we want to them to be impressed. That’s certainly the case now with HOMAG’s kit on full display."

Service that matches the machines

For Amir, HOMAG’s support is just as critical as the technology itself. “With machines of this nature, you will always encounter issues. What matters is how the supplier responds. Downtime is so costly in this industry, particularly when rapid lead time is a major selling point. We simply can’t afford to wait days for machine maintenance – luckily for us, HOMAG understand this completely.

“They are extremely fast at responding and resolving any hiccups, no matter how minor. A lot of the time they can do this over the phone, but if it requires a site visit, that’s no problem for them either. That reliable service is priceless.”

Looking ahead

With demand continuing to grow, XCUTS is already planning further investments with HOMAG. “We’ve had some great meetings about the next phase,” Amir confirms. “There’s no question of going anywhere else. The speed, the capacity, the quality, it’s all simply outstanding. HOMAG has helped us achieve our vision, and we’re excited about where this partnership will take us.”

For more information or a demonstration of HOMAG’s machinery and software, please contact HOMAG UK on 01332 856500, option 4 for the sales department. Or email info-uk@homag.com.

“The speed of these machines is incredible, as is the capacity and the accuracy. Our expectations were very high, yet they have been exceeded. Seeing the saws and edge banders do what they do on a daily basis is a joy. We are extremely happy with the output and the results.”Amir Navazani, Managing Director at XCUTS

XCUTS Ltd

XCUTS offers a wide range of services and products to meet the needs of bespoke carpenters, interior designers, general builders, and DIYers.

xcuts.co.uk