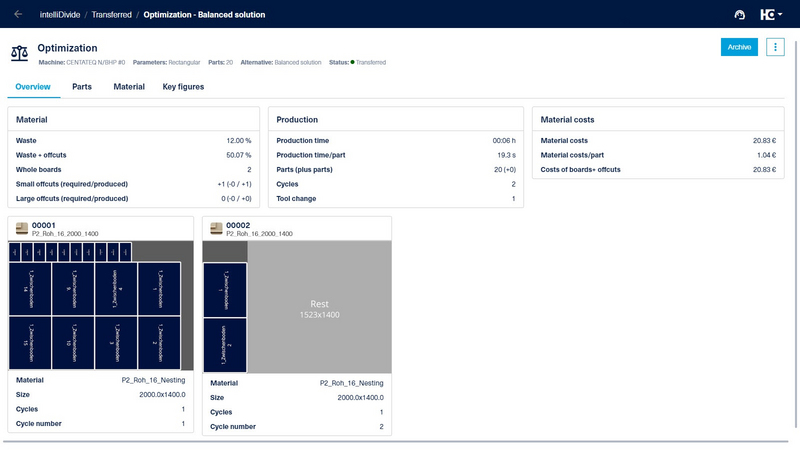

All-inclusive worry-free package for your nesting process

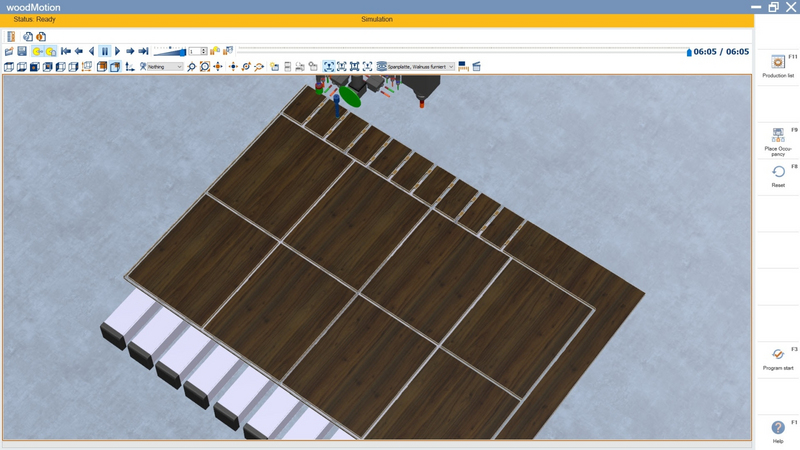

intelliDivide Nesting and woodWOP 8: Double software power offers an efficient nesting process

Users of woodWOP 8 and intelliDivide Nesting have access to a wide range of functions for accelerating the nesting production process.

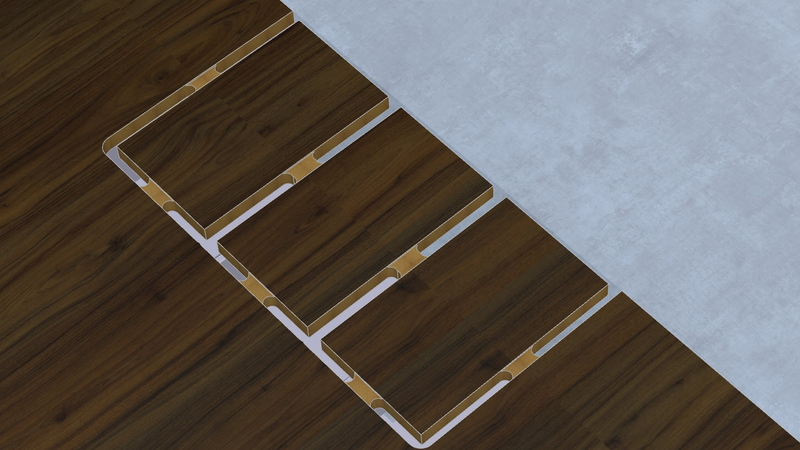

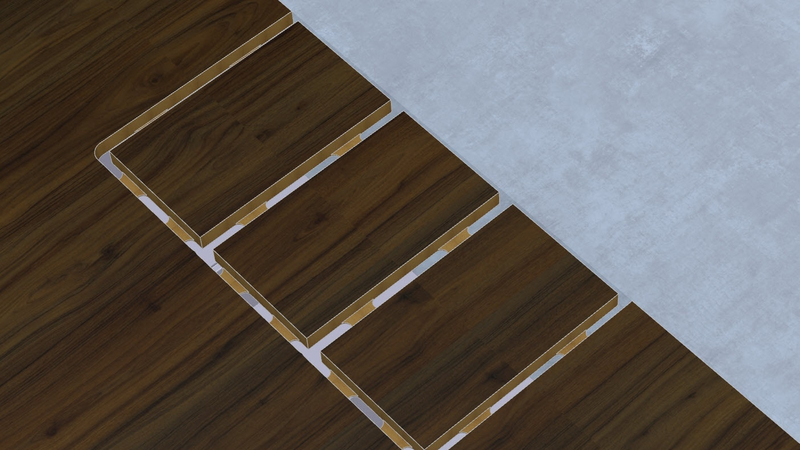

Positioning bars

You are probably familiar with the following problem: Small parts often slip during nesting because the small contact surface means that the vacuum cannot exert sufficient suction. In conjunction with woodWOP 8, intelliDivide Nesting now offers the option of connecting small parts with each other using support bars. The size and number of bars can be adjusted on an individual basis. After nesting, simply break the bars off or cut them off with a hand saw.

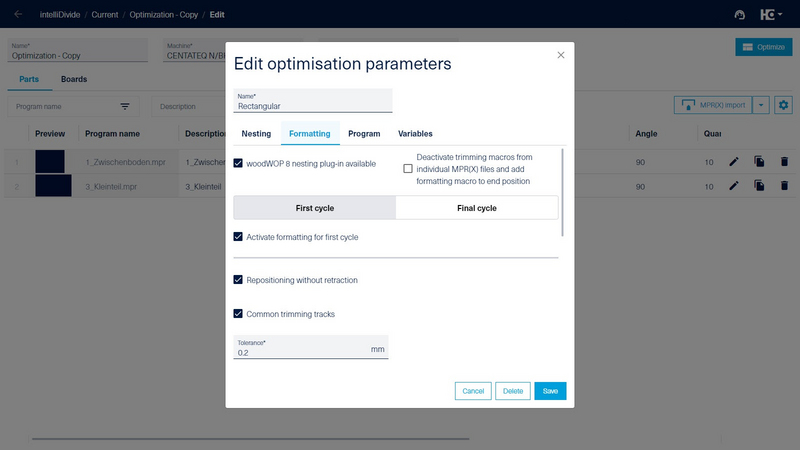

Stay down and common line

Do you want to minimize the processing time and make sure that the trimmer does not approach and withdraw from every single workpiece? Then simply use the option "Repositioning without retraction" or "Use common trimming tracks."

The "Repositioning without retraction" option, also known as the "stay down" procedure, optimizes the approach motions. The tool approaches only one point and remains at the specified trimming depth for the entire processing time. This shortens the processing time because the tool does not approach and withdraw from every single workpiece.

The option "Use common trimming tracks" (common line method) also ensures that the distance between parts corresponds exactly to the tool diameter. The tool then only moves through between two workpieces once and separates them from each other. This method therefore offers the option of reducing the processing time even further.

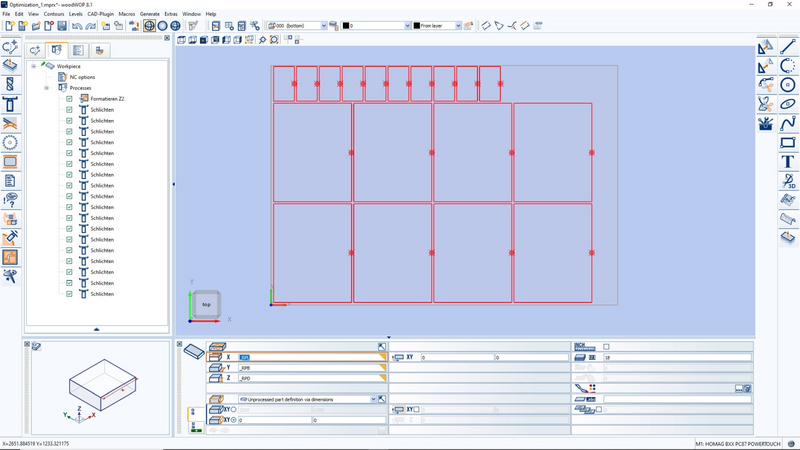

Trimming in steps

Another highlight is the option of setting several trimming feeds. For example, you can specify that small parts should only be pre-trimmed in the first cycle. In the second cycle, the trimming is then performed to the end depth.

NOTE:These functions are available only in conjunction with woodWOP 8 and the woodWOP nesting plug-in.