Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Production Management Sorting Production Set: The sorting assistant

Production Management Sorting Production Set: The sorting assistant

Every part has its place – with our assistant for the sorting of furniture components

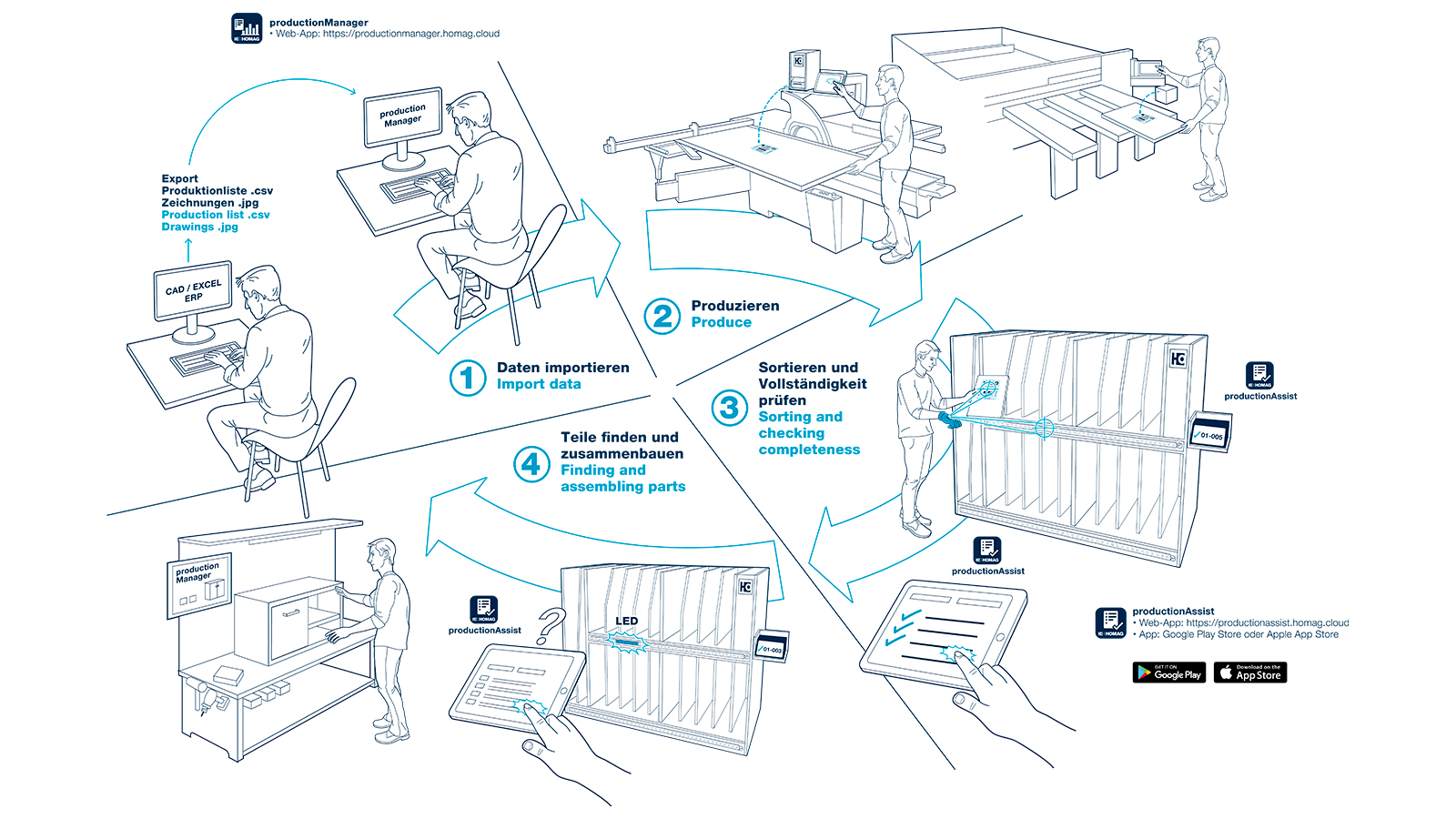

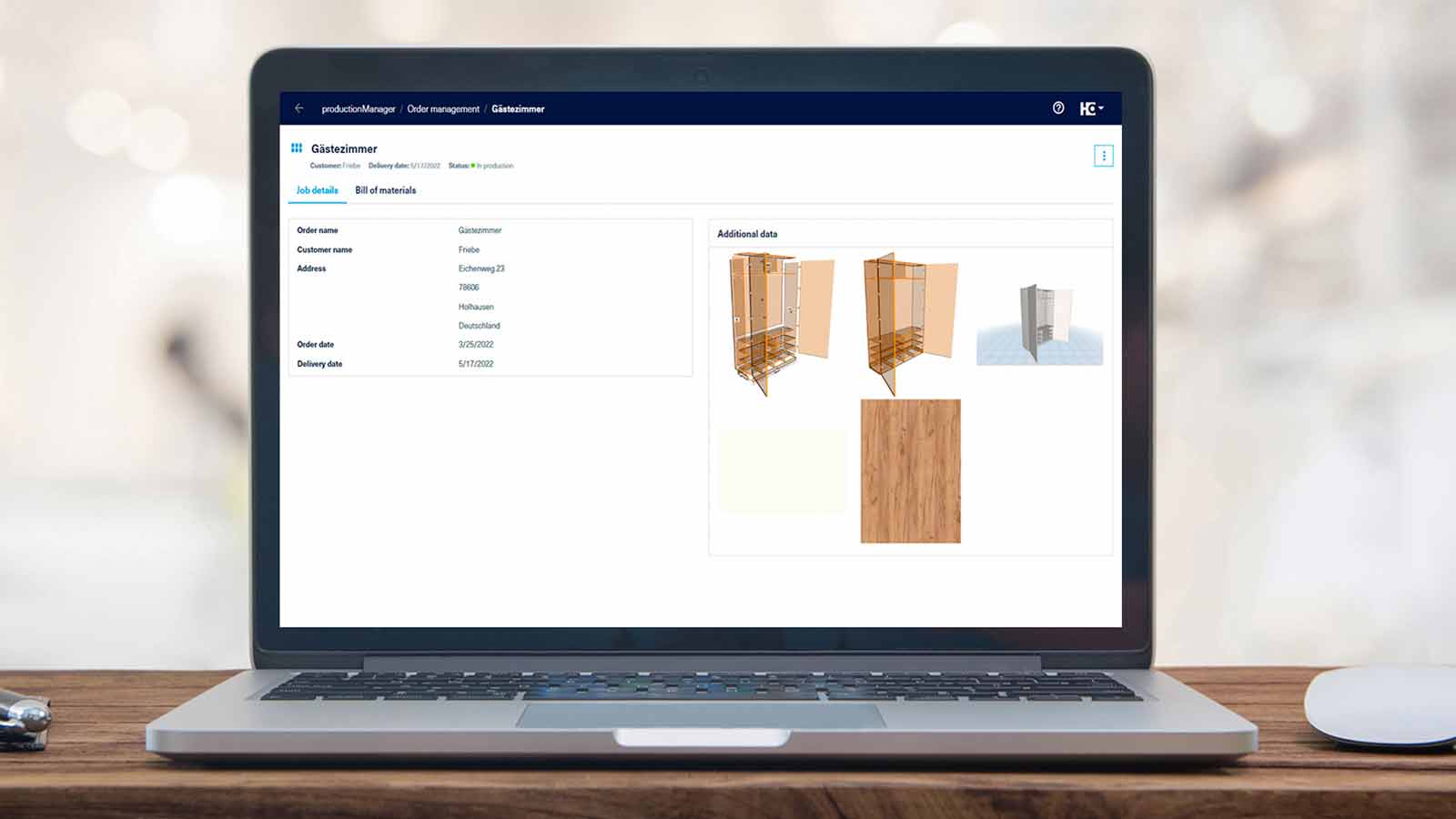

Our sorting assistant supports you with the sorting of components in the workshop. In this way, you always have an overview of the furniture parts for which processing has already been finished and which are complete for assembly, packaging or further processing. The productionManager (part of the sorting assistant) provides you with all the information about your job at all times. You can view the status of your parts in the job progress – and in real time! This allows you to create consistent and transparent workflows for your entire business.

Highlights

Transparent: Overview of the completeness of the furniture or components to be sorted. You can sort your parts cabinet by cabinet and prepare them for the assembly area.

Saves time and secures workflows: No waiting times due to missing parts – all parts for assembly are complete. The productionManager, the digital job folder, also provides all information (including drawings).

Intelligent way of working: The productionAssist Sorting app notes the storage positions used in the intelligent sorting shelf and suggests the appropriate storage position for your components.

Images

Features

-

What does the Sorting Production Set consist of?

The following components are included in the scope of delivery:- Two apps: productionManager (digital job folder) & productionAssist Sorting (production assistant for sorting)

- Freely configurable LED strips for the sorting rack

- HOMAG CUBE (intelligent control box for connecting the printer to the Internet and the apps)

- Construction plans for free download

- Installation Guide #BuildYourSolution

-

The workflow in the workshop:

- During work preparation, an order is first created, imported or transferred from the upstream system into the digital job folder, productionManager. If the order is approved, processing starts.

- During the production of your components and furniture, you always have an overview of the status of your orders.

Sorting after cutting

- Each component is given its own label during cutting to aid identification.

- To begin sorting after cutting and thus optimally prepare the components for edging, scan the label on the workpiece and the productionAssist Sorting app will suggest a storage position depending on the edges to be glued to the respective component. Parts can also be assigned manually by clicking in the app.

- Once all parts of an order have been sawn and sorted in full, the app provides feedback, which means that you can edge similar parts together. The missing parts can be displayed at any time.

Sorting before the assembly area

- Before the assembly area, sort all finished parts systematically (by order item/item or all parts of an order) in the shelf. To enable this, when you scan the label on the workpiece, the productionAssist Sorting app suggests a shelf compartment for storage. The part can be assigned manually in the app or by scanning the compartment barcode, e.g. using a scanner glove.

- If all parts of a piece of furniture are complete, the app will send feedback to say that the order is complete. The missing parts for each order can be displayed at any time.

- As soon as the parts are to be removed from the shelf, the app and the LEDs on the shelf indicate where the corresponding parts are located.

Start now!

Technical Data

Is this product available in your country? Take a look at the availability here.

Further Solutions

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Digitalized processes in furniture production

Finding the path to a digital future — with a customized production concept using the HOMAG app and software solutions

Brochures