Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

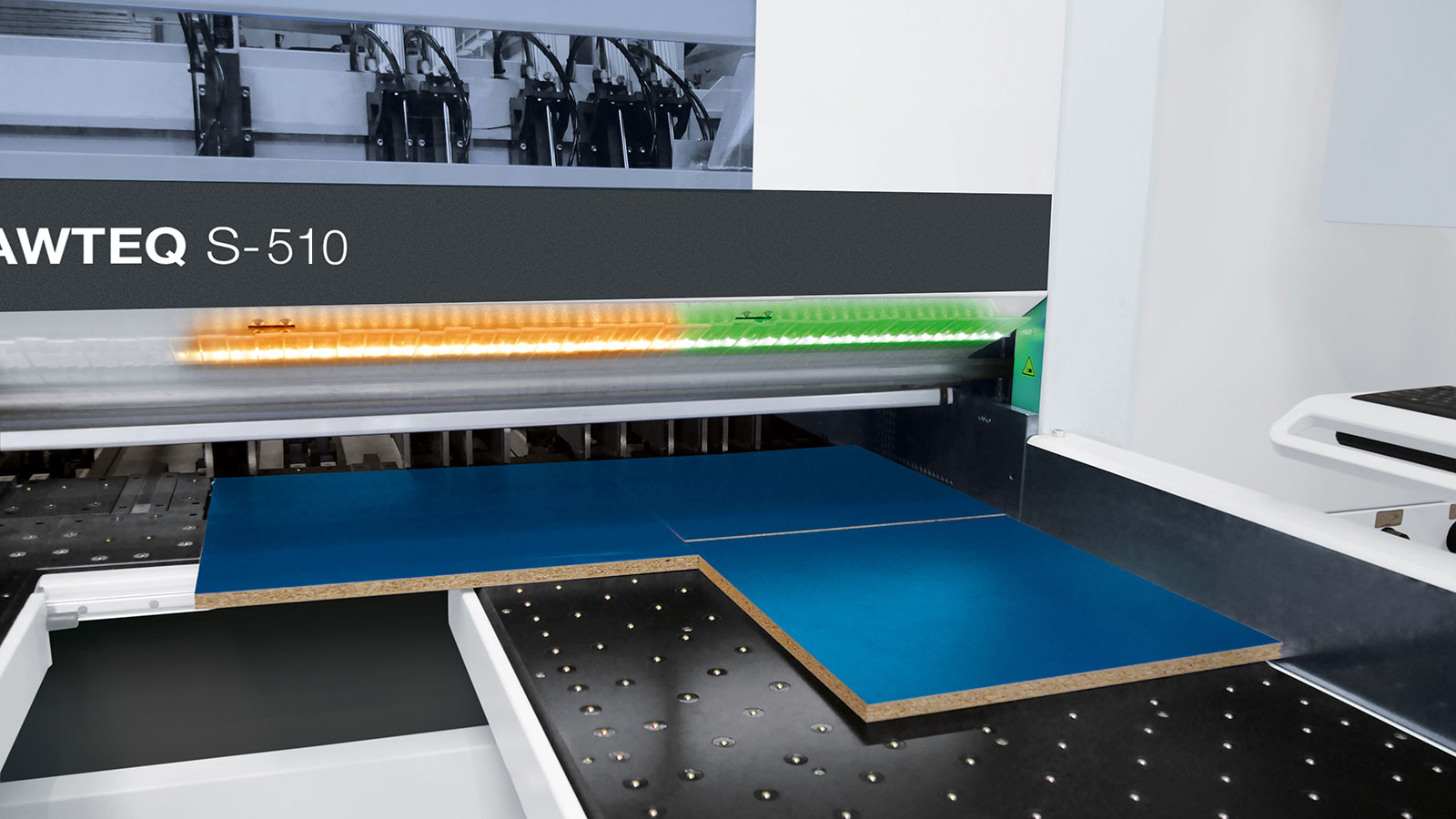

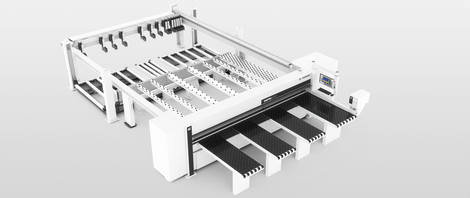

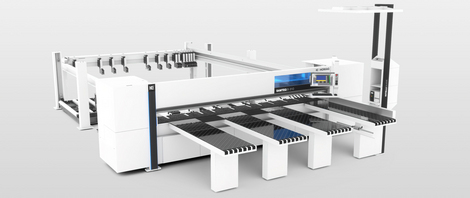

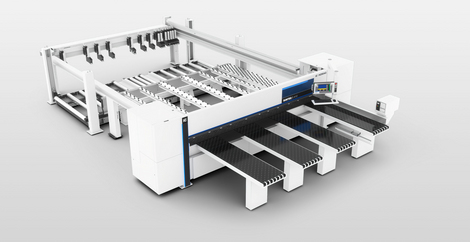

Panel dividing saws SAWTEQ S-510 with lifting table

Panel dividing saws SAWTEQ S-510 with lifting table

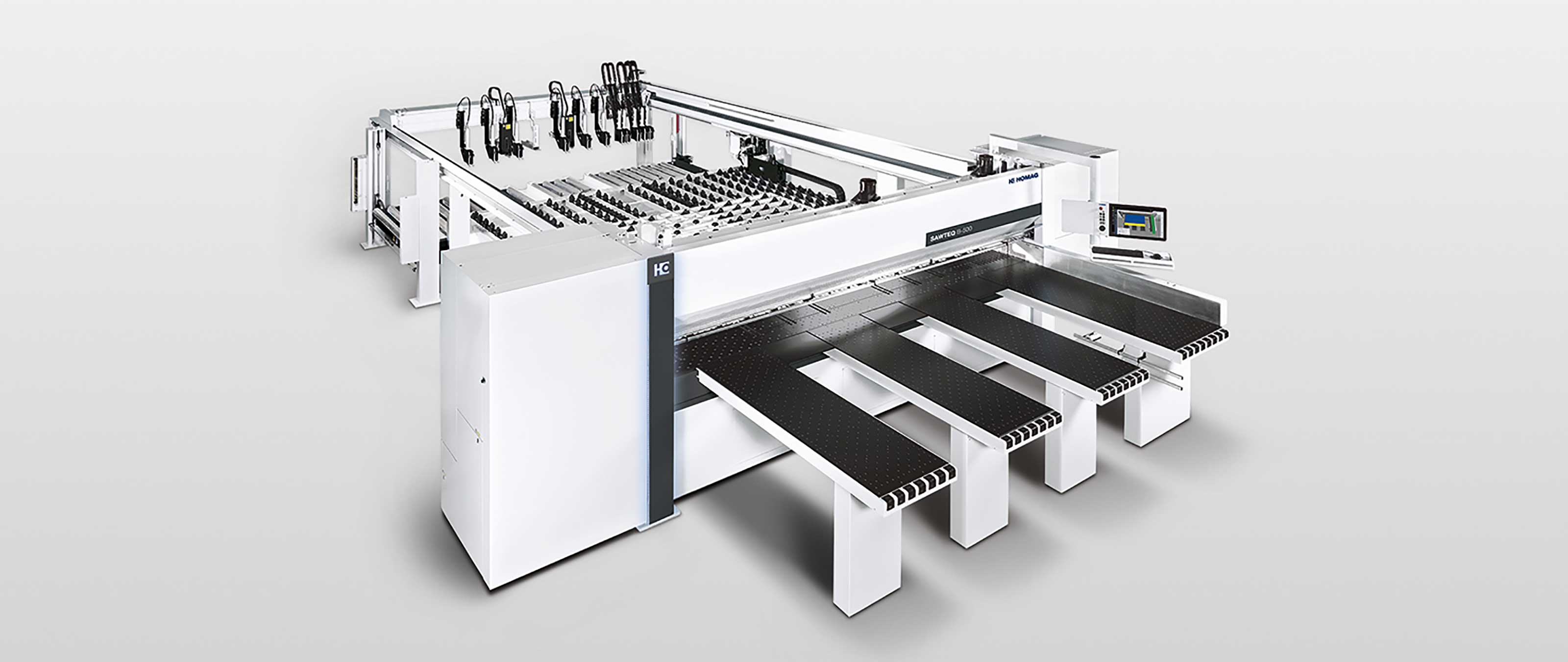

Stability ensures progress: A powerful package with automatic feed

The SAWTEQ S-510 is synonymous with uncompromising technology and enormous material throughput with maximum availability. This is ensured by the fact that the saws are very easy to service and maintain. Equipped with a lifting table for automatic feeding from the rear in addition to a large number of other technologies, the saw integrates seamlessly into highly efficient production processes and accelerates them even further. The carefully thought-out design makes the saw the ideal choice for demanding applications. Benefit from high performance, a long service life and customized configurations — and ensure optimal results for your business.

Highlights

Designed for high material throughput and even large-format book heights (cutting length up to 6500 mm)

Extremely torsion-resistant, low-vibration and stable saw body made of SORB TECH

Maximum dynamics and precision thanks to solid and durable saw carriage

Images

Features

-

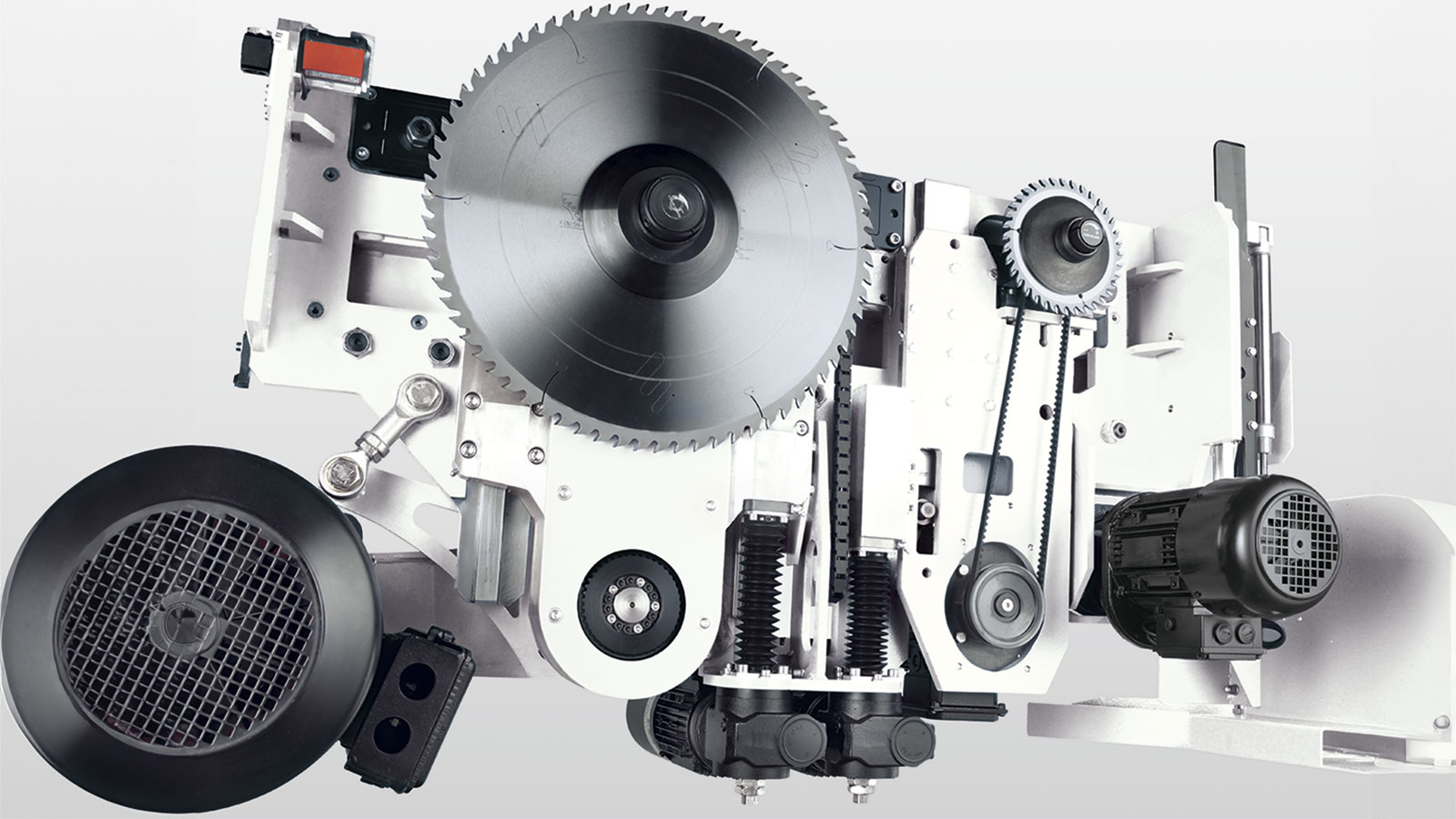

Solid construction and with high-end technology for demanding requirements

-

Innovative guide systems ensure durability and lasting precision

-

Compared to steel supports, the SORB TECH saw body enables up to:

- 10 times better vibration damping

- 20% higher sound absorption

- 30% longer tool life of saw blades -

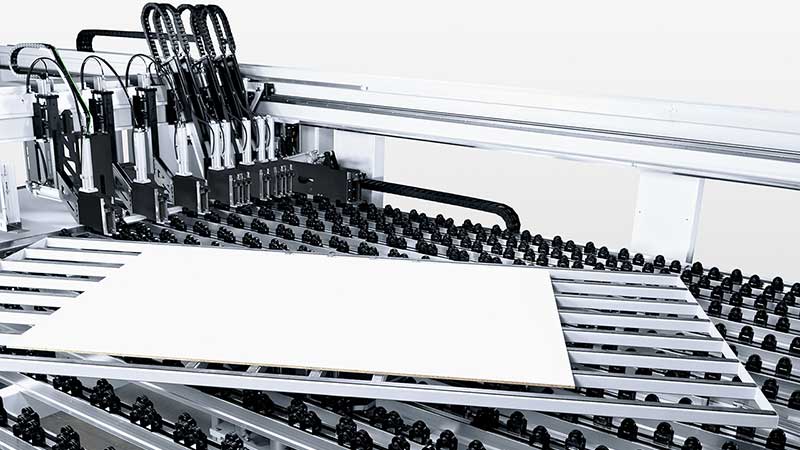

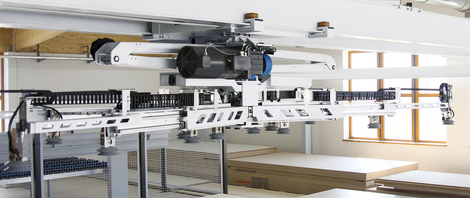

Ergonomic, fast and efficient feeding of books of panels via the lifting table

-

Energy-saving positioning of the main saw blade using a linear guide system with rocker arm

Technical Data

| Saw blade projection [mm] | 150 (170 as option) |

| Cutting length [mm] | 3,200 / 3,800 / 4,300 / 5,600 / 6,500 |

| Program fence speed [m/min] | up to 90 |

| Saw carriage speed [m/min] | up to 130 (150 as option) |

| Main saw motor [kW] | 50 Hz: 30 (47 as option) 60 Hz: 35 (54 as option) |

| Monitor | 24" full-HD multi-touch display |

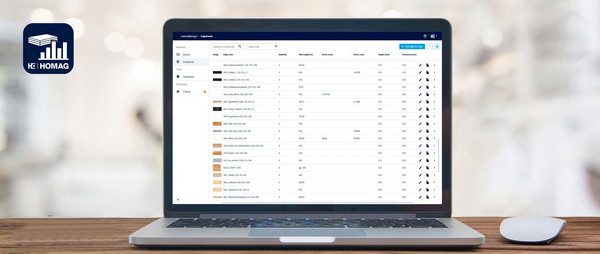

| Operating software | CADmatic 5 |

(Previous product name: Panel dividing saw SAWTEQ B-500 | HPL 500)

Software

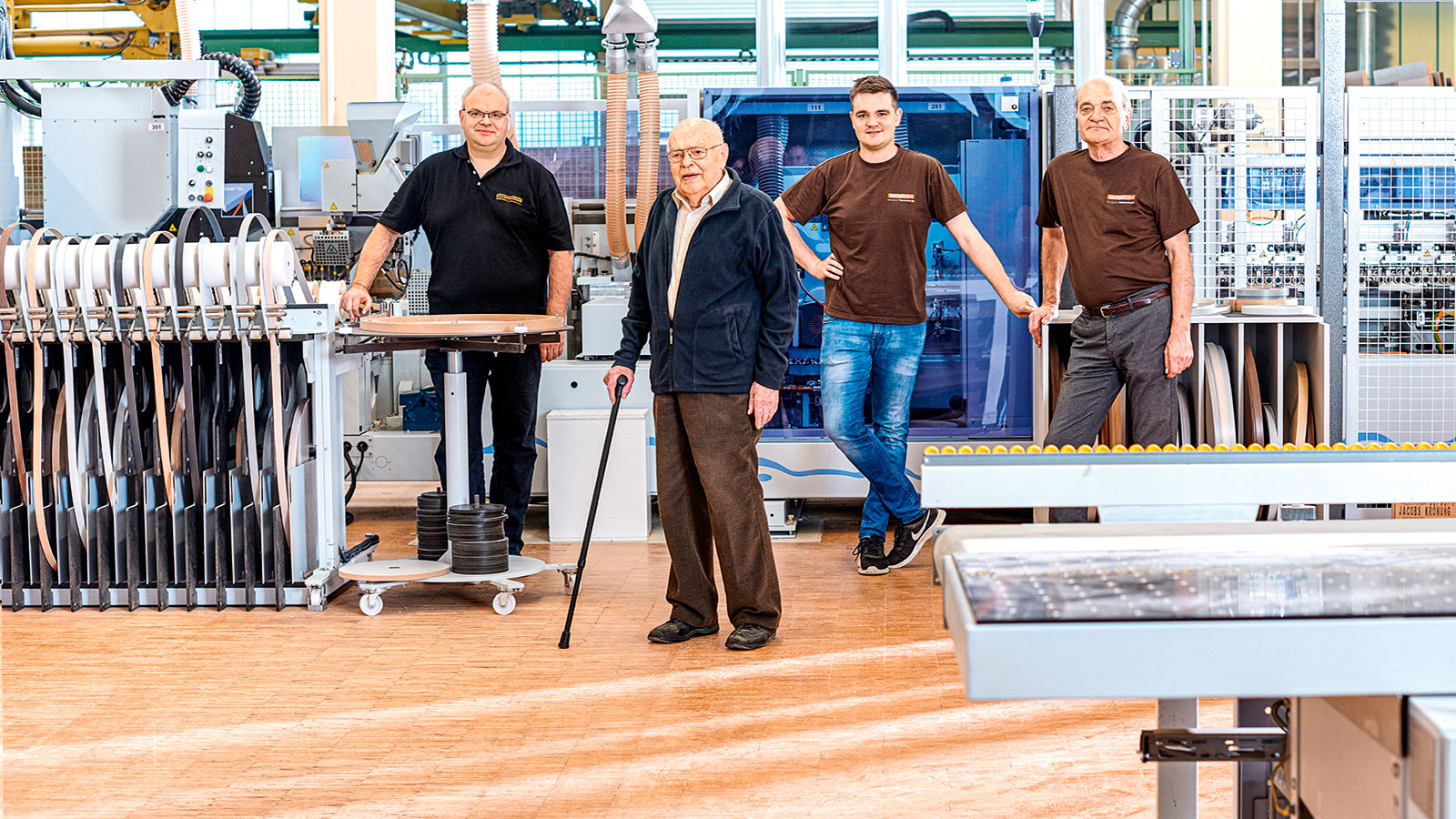

Here's how your colleagues produce

Brochures

Product Comparison

Lifting table saws for cutting