Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Production Management Edgeband Management Set: The edgeband assistant

Production Management Edgeband Management Set: The edgeband assistant

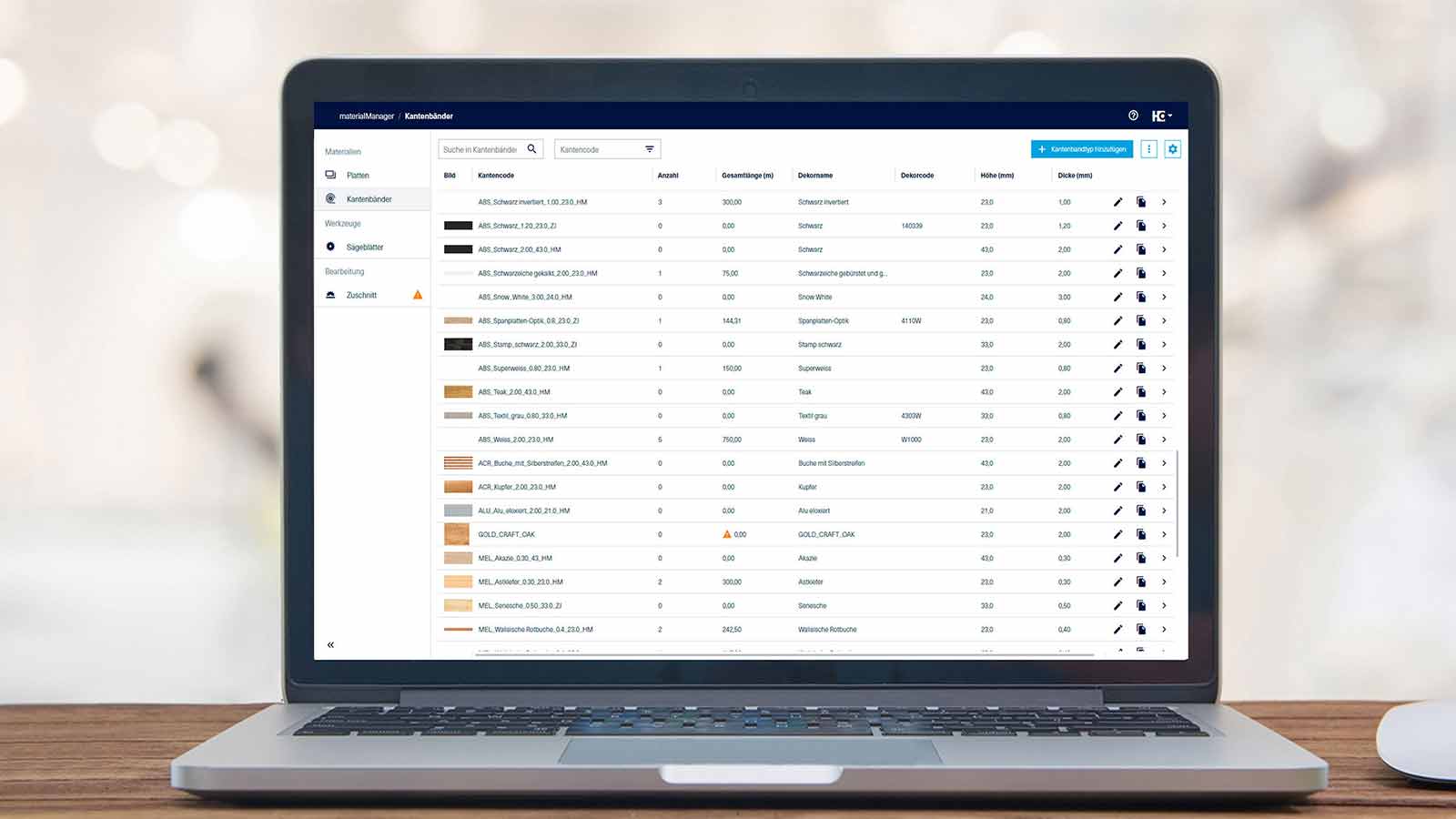

The edge material and all related information at a glance

With the edgeband assistant, you keep a complete overview of all information about your edge material and your material stock. You can find the right edgeband quickly and easily at any time, and the search for the material is over.

Highlights

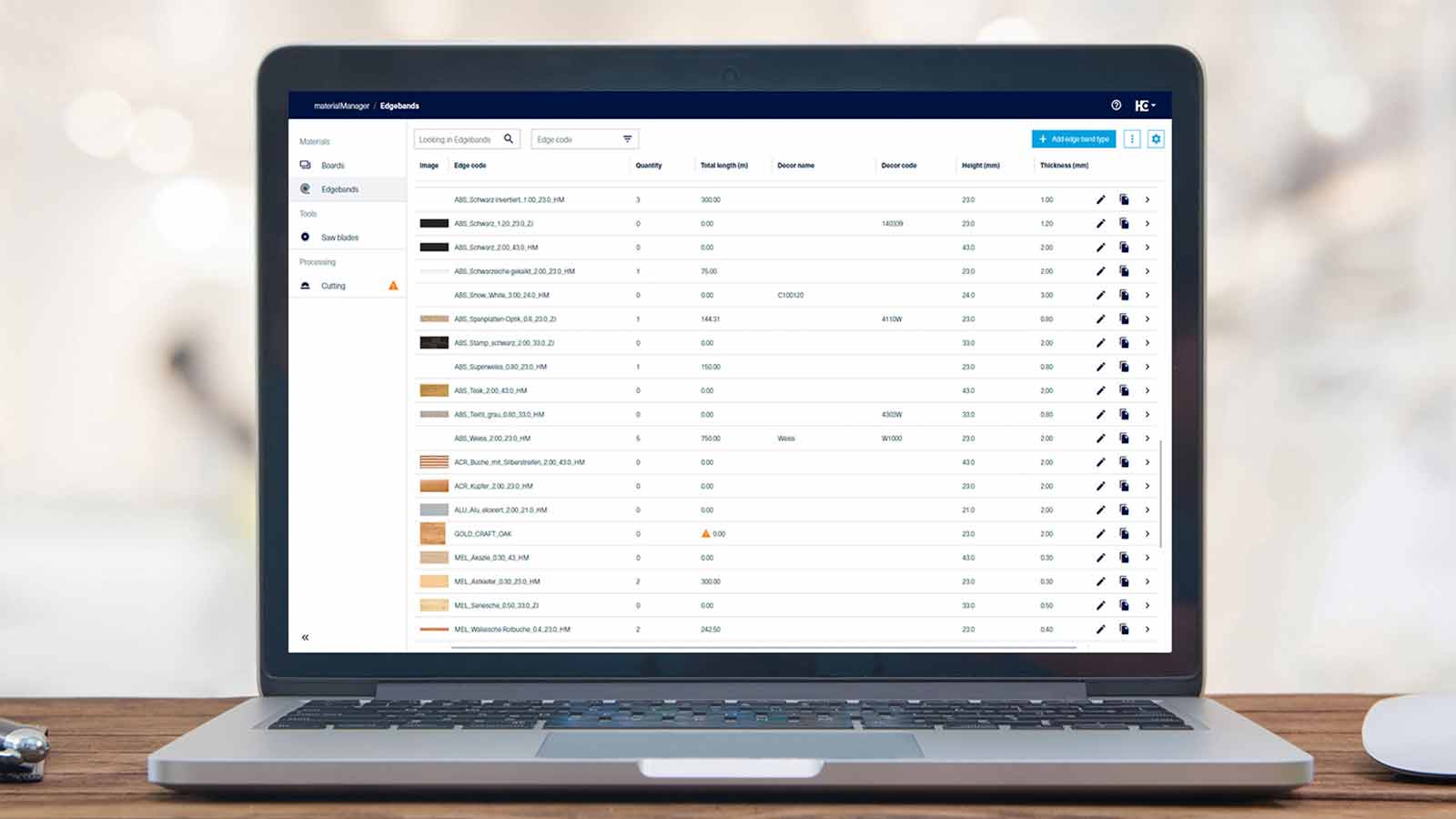

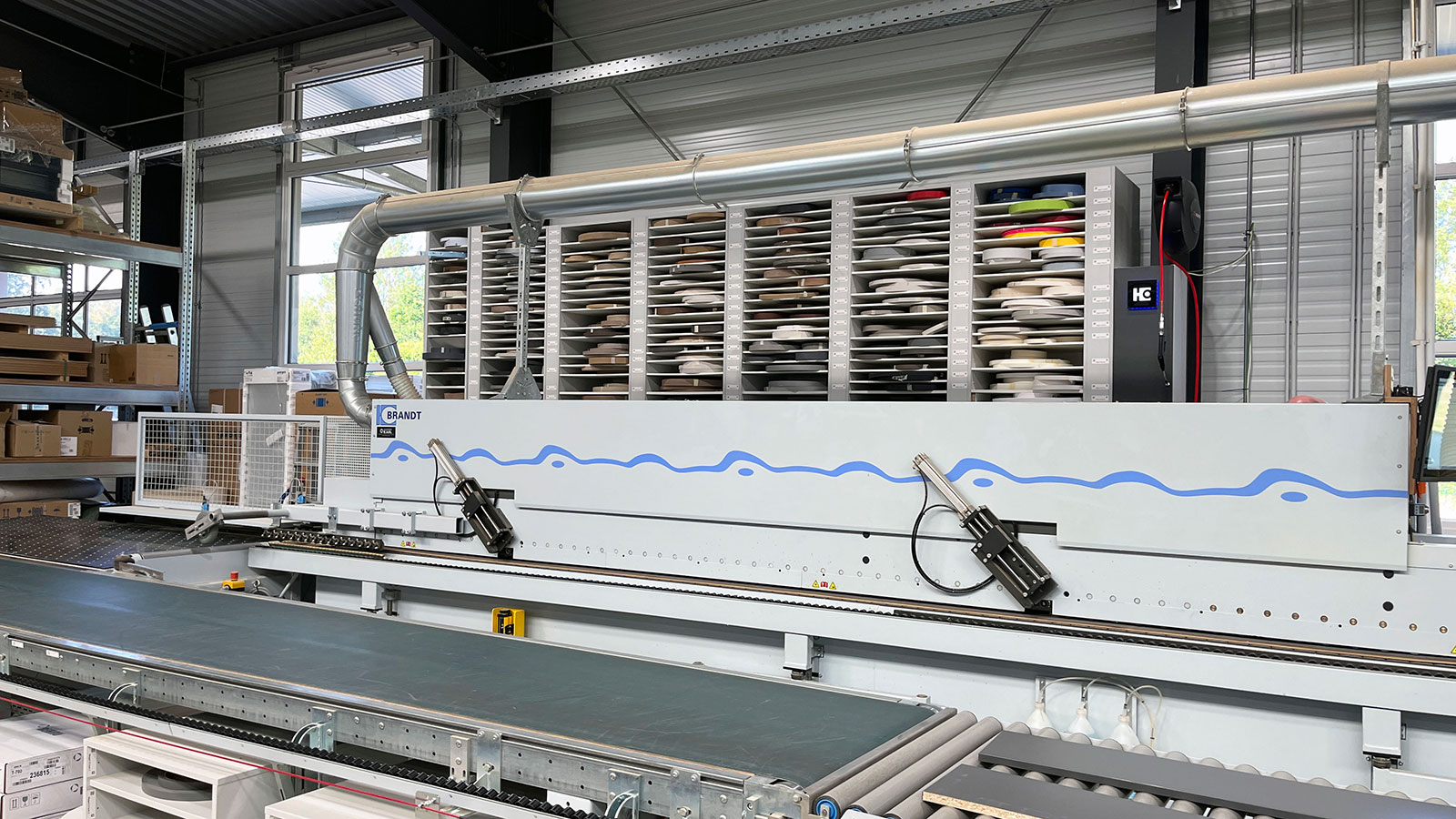

Complete overview: All edge information is available at a glance. The apps and the HOMAG edgeband rack offer a permanent overview of stock. The printer can also be used to create labels for the individual labeling of each edgeband coil.

Easy management: Clear management and unique identification of edges in the rack (incl. residual lengths). The system documents edges that are put into and taken out of storage, indicating the storage position.

Time saving: Reduced setup times thanks to faster edge changes and no longer having to search for edgebands.

Images

Features

-

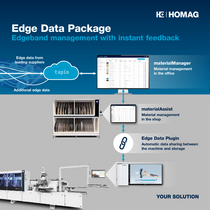

What does the Edgeband Management Set consist of?

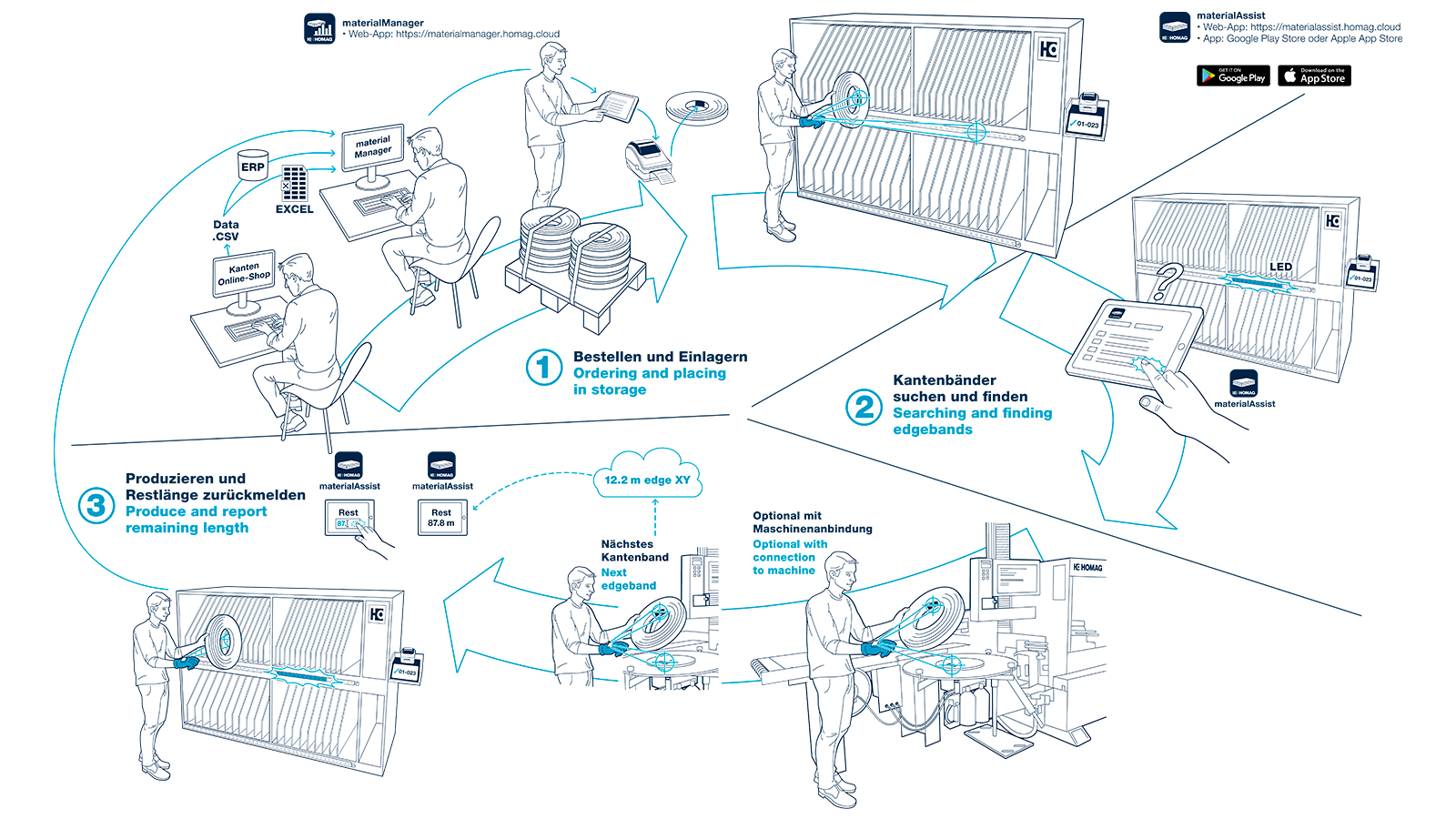

The following components are included in the scope of delivery:- Two apps: materialManager (central material management in the company), materialAssist Edge (edgeband management in the rack)

- Optional: LED strips for the materialRack Edge edgeband rack

- Label printer including two rolls of labels

- HOMAG CUBE (intelligent control box for connecting the rack and the printer to the Internet and the apps)

- Construction set for the materialRack Edge edgeband rack, available free to download

- Installation Guide #BuildYourSolution

-

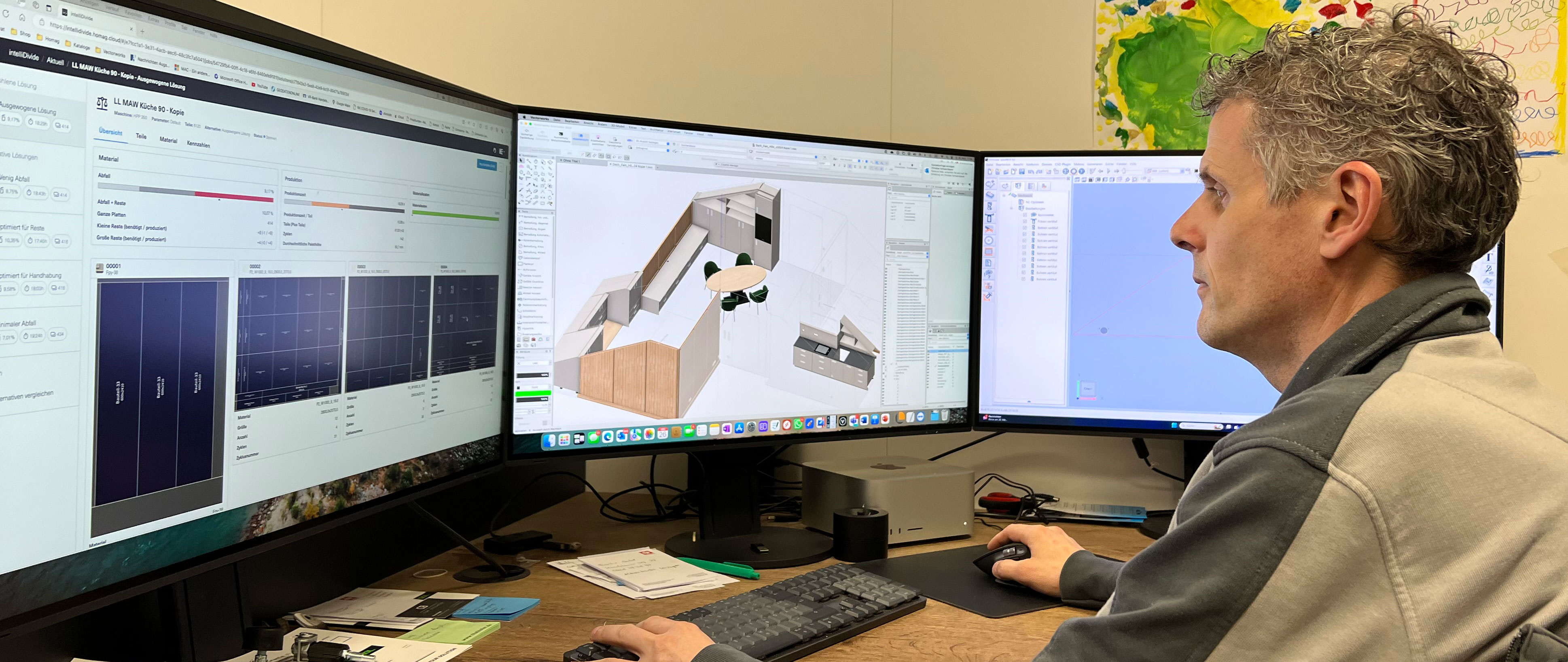

The workflow in the workshop:

- The first step is work preparation. First, create your edge material and edge data in the materialManager web app – or simply import it. The materialManager application allows you to manage all of the material for your organization in one central location. The app shows you the latest stock levels and the locations of each roll at any given time. In production, you store your edge rolls in the edge rack and store information for it in the materialAssist app on the tablet. You can now easily access all of the necessary information about each edgeband (properties, residual lengths). To aid edgeband identification, you can print the corresponding labels (containing ID, edge code and the dimensions of the edgeband) directly and just as easily.

- If a workpiece now requires edging, simply select the correct edgeband in the app or scan the corresponding code on the order slip. The storage location is immediately indicated by LEDs that light up on the edge rack, allowing you to find the right edge roll for the processing application quickly.

- After you have edged the part, you can update the residual length in the materialAssist app. The data is also updated in materialManager at the same time.

The result: Preparation of the edgebands is perfectly organized, you always have an overview of the residual lengths available and the edge banding machine can be set up more quickly.

Start now!

Technical Data

Is this product available in your country? Take a look at the availability here.

Further Solutions

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

The Edge Data Package in use

The Edge Data Package in use at the Lechner joinery

Brochures