CNC Drilling and Dowel inserting Machines DRILLTEQ D-510

CNC Drilling and Dowel inserting Machines DRILLTEQ D-510

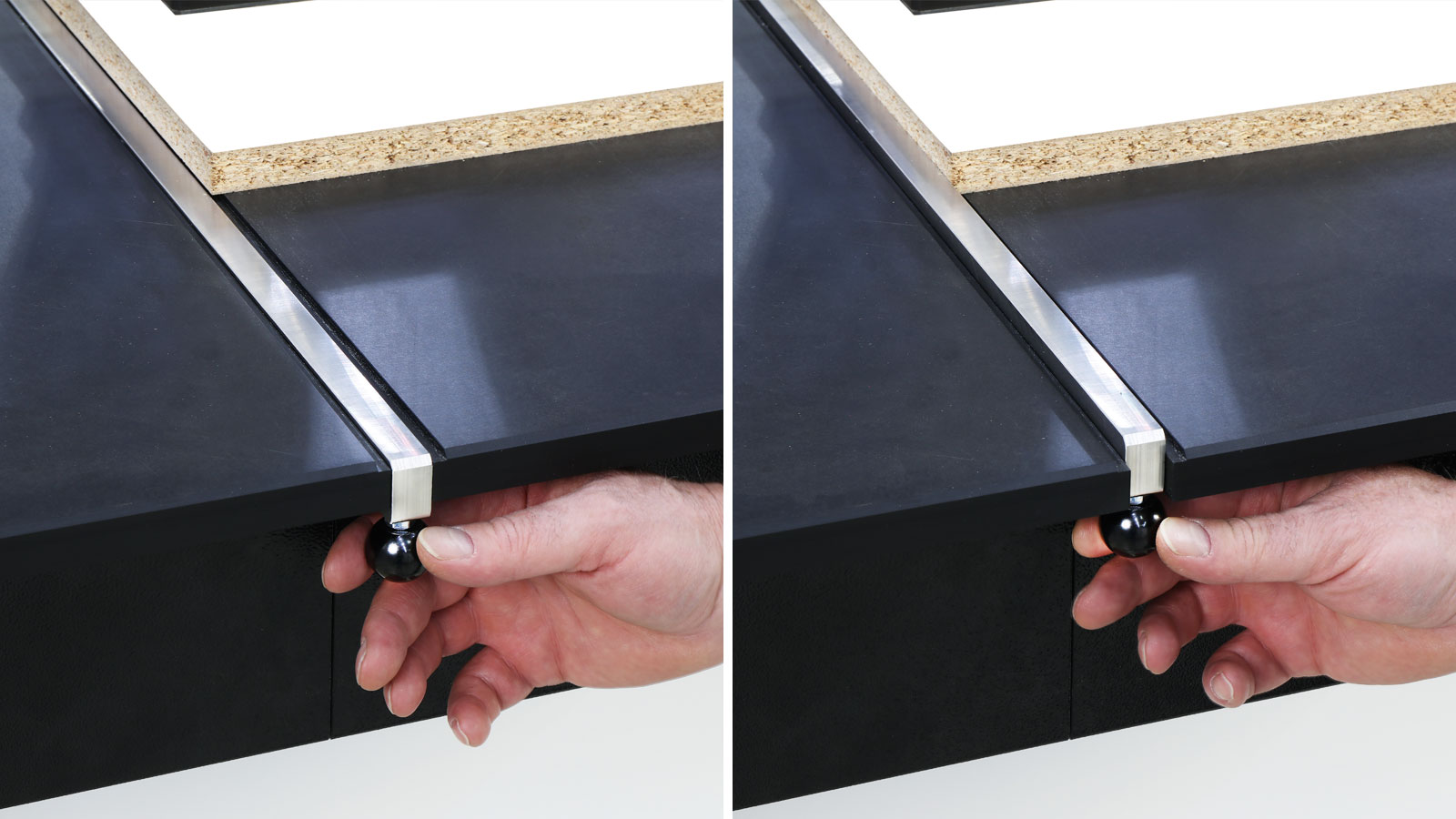

Complete processing in the edge area

Whether as individual machine or complementary product in connection with a CNC processing center – the DRILLTEQ D-510 allows complete and precise processing in the edge area by the clever combination of drilling, doweling and routing.

Highlights

Vertical drilling in the edge area - ideal for connecting fittings or pot hinge drilling.

Horizontal milling for back panels or furniture connectors, for example

Precise drill holes thanks to defined fences (X/Y direction) in the machine

Up to 8 adjustable clamping cylinders enable a safe and gentle clamping process.

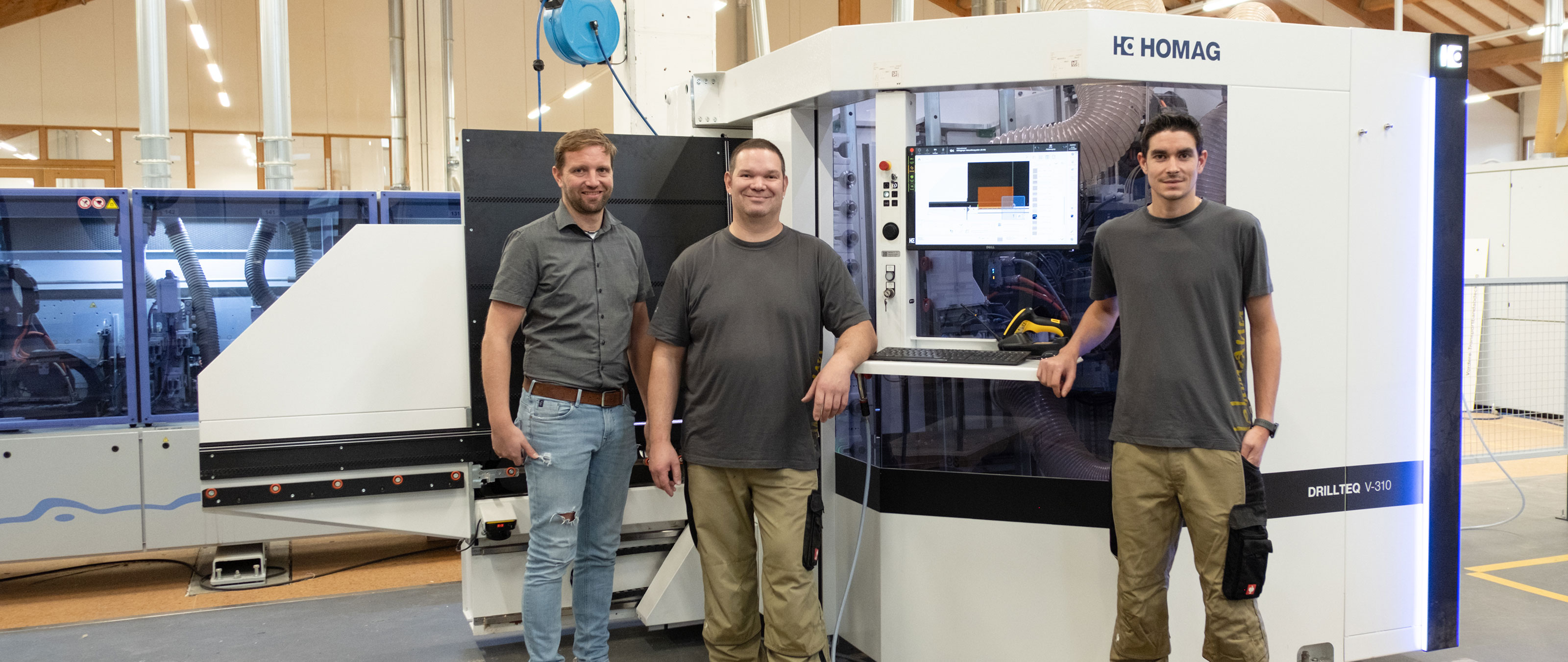

Images

Features

-

Flexible parts handling for up to 4 workpieces thanks to lowerable center fence and lowerable side fences

-

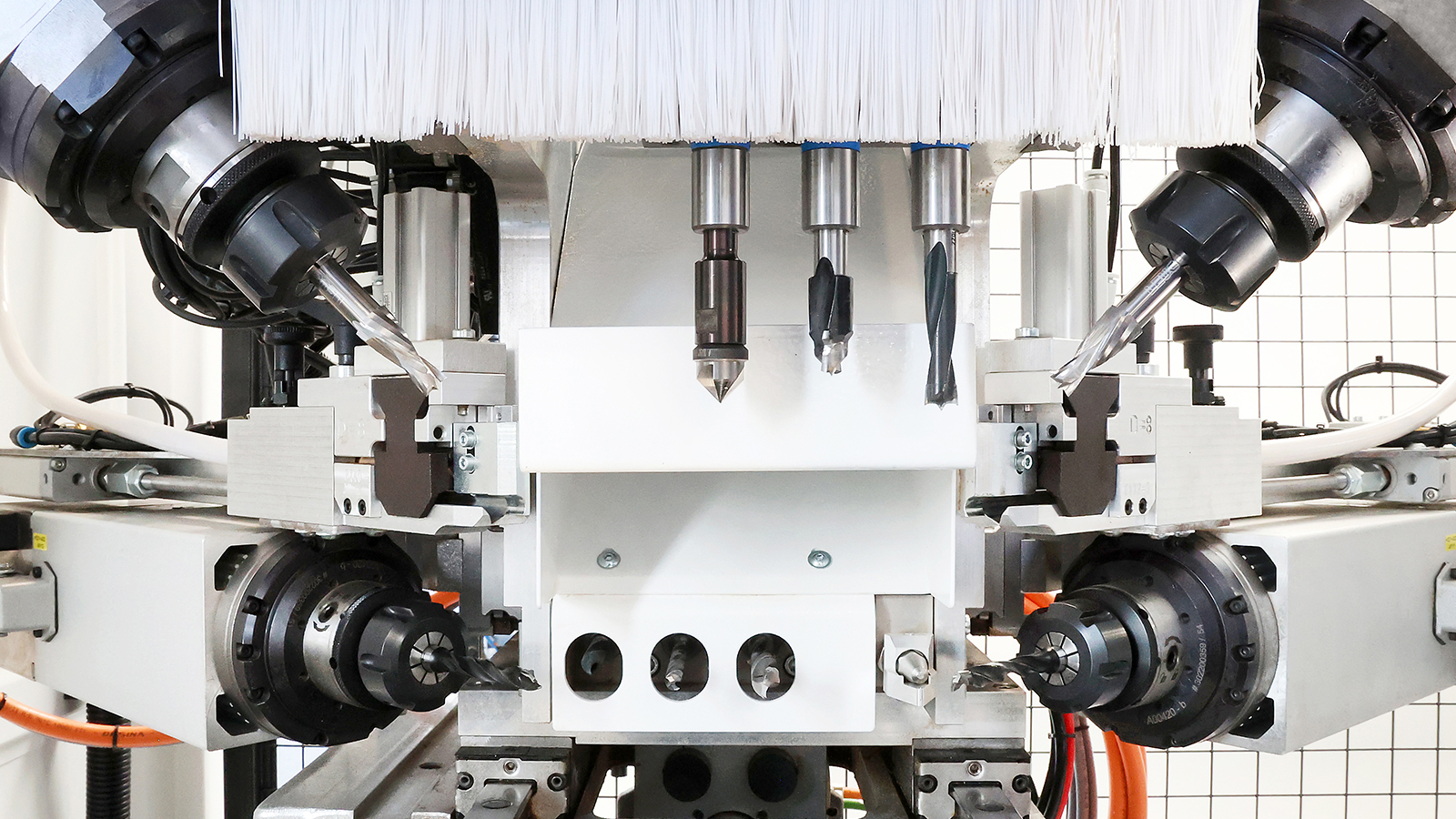

Horizontal drilling - up to 5 individually retrievable drilling spindles ensure precise processing

-

Vertical drilling - up to 5 individually retrievable drilling spindles in a 32 mm grid for different drilling diameters up to 35 mm

-

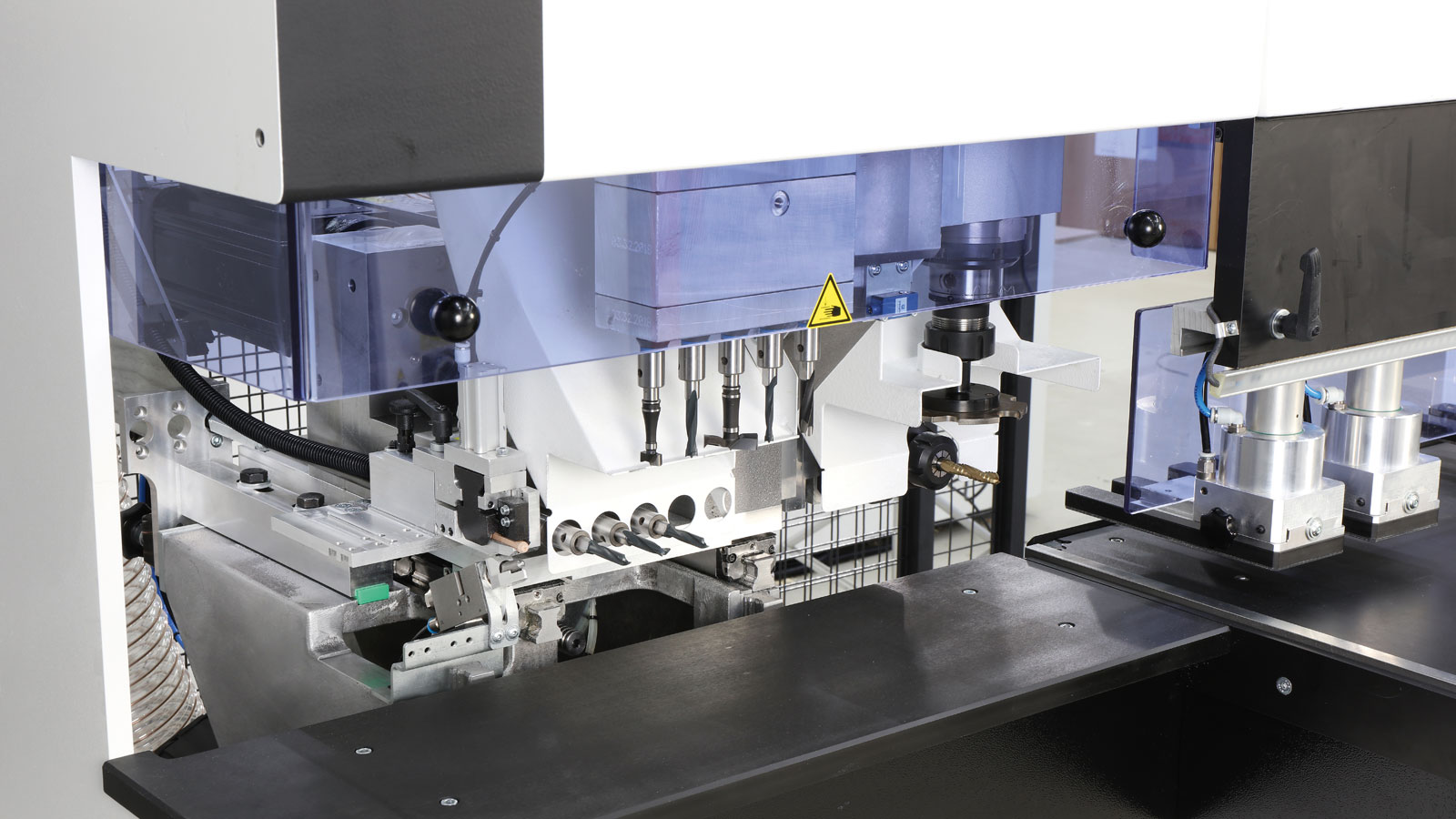

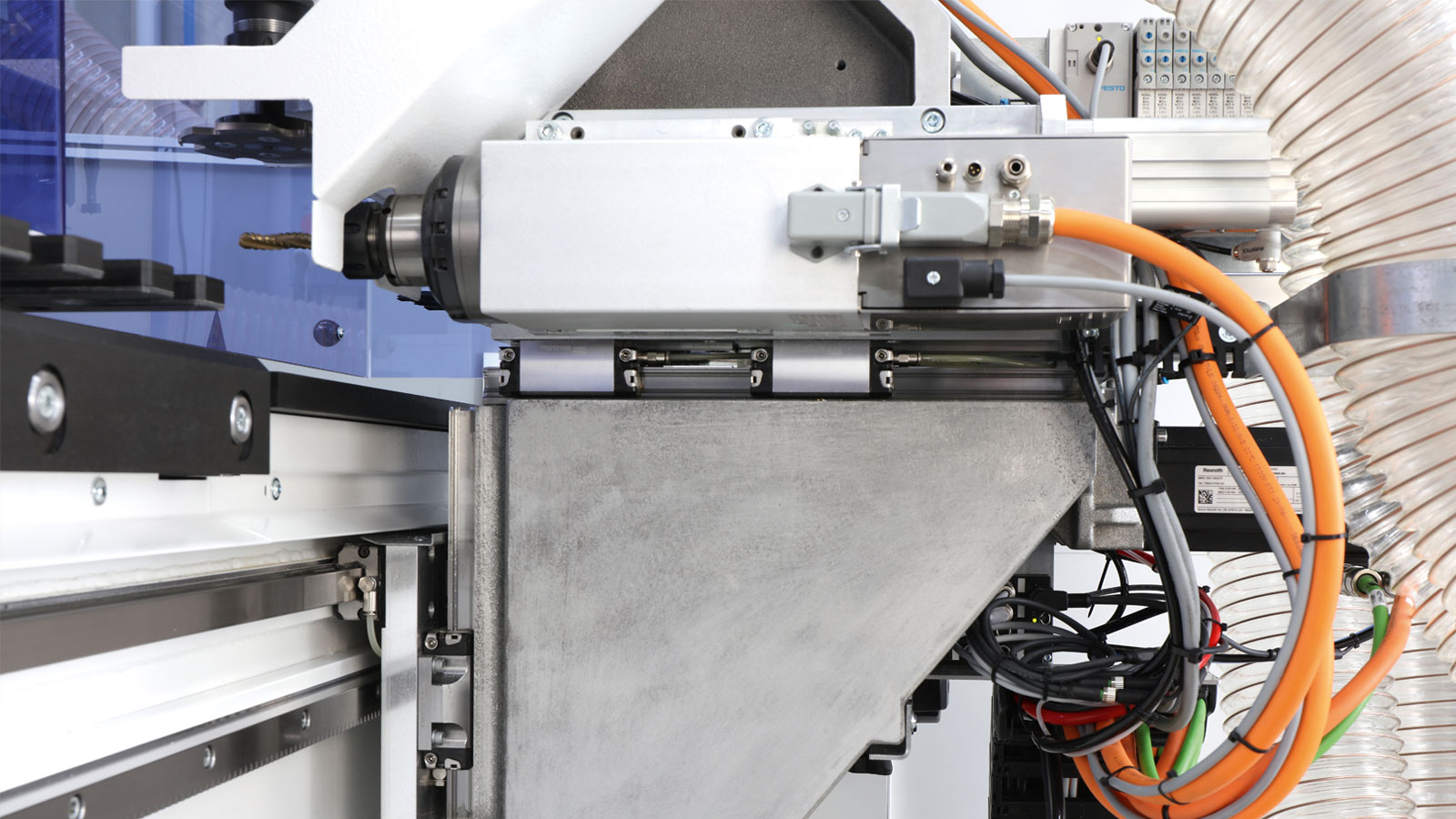

Horizontal milling - powerful, robust and proven milling spindle. A supply stroke of up to 80 mm enables milling at depth

(e.g. Tiomos H, Salice Air, lock case, etc.) -

Vertical routing - powerful, robust and proven routing spindle enables routing into the face of the workpiece (e.g. Clamex)

-

Automatic and safe dowel feeding by means of a vibration conveyor.

-

Dowel driving - glue nozzle with adjustable glue quantity and glue flow monitoring

-

Setting fittings - installation space for individual solutions for setting fittings and hinges (e.g. sockets, eccentrics, Cabineo etc.)

-

Improved ease of use and error prevention when positioning workpieces thanks to the intelliGuide Classic optical LED assistance system

-

Special configuration for 42° - 45° machining - horizontally in the end face, as well as vertically in the edge area. In addition to drilling holes, gluing and driving in dowels is also possible.

Technical Data

| DRILLTEQ D-510 | 1.250 | 2.500 |

|---|---|---|

| Workpiece length [mm] | 20 – 1.250 | 20 – 2.500 |

| Workpiece width [mm] | 20 – 800 | 20 – 800 |

| Workpiece thickness [mm] | 10 – 80 | 10 – 80 |

| Compressed air connection [inch] | R 1/2“ | R 1/2“ |

| Compressed air [bar] | min. 7 | min. 7 |

| Total connected voltage [kW] | approx. 11 | approx. 11 |

| Extraction connection [mm] | Ø 120 | Ø 120 |

| Total machine weight [kg] | approx. 1.600 | approx. 2.000 |

(Previous product name: CNC-Drilling and Dowel Inserting Machine ABD 210)

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

DRILLTEQ D-510 CNC-Drilling and Dowel Inserting Machine

Whether as individual machine or complementary product in connection with a CNC processing center – the DRILLTEQ D-510 allows complete and precise processing in the edge area by the clever combination of drilling, doweling and routing.

Brochures