SmartWOP: The easy way to design furniture

Many customers want furniture design software that is easy to use but also offers maximum flexibility in design. With SmartWOP, HOMAG is offering a new software that meets exactly these requirements.

The software for innovative designs

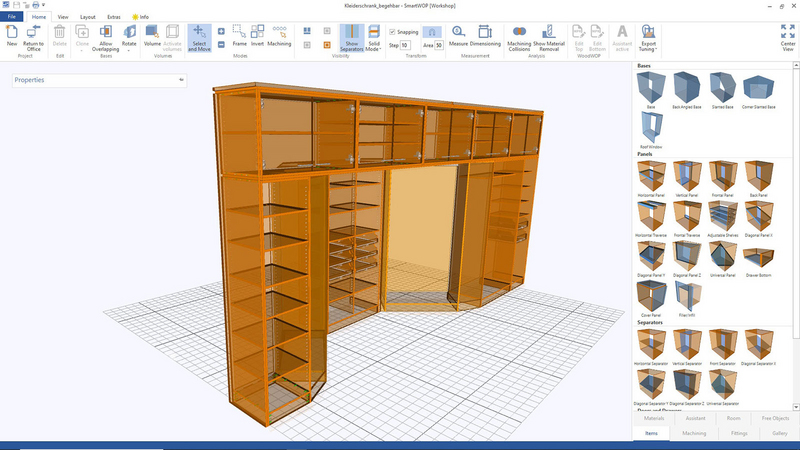

SmartWOP provides the user with a powerful CAD/CAM system that they can use to design custom furniture quickly and intuitively using drag and drop. The individual components of an item of furniture are simply dragged into a previously selected volume. In addition to the standard rectangular volume, special volumes such as a sloping ceiling or corner cabinets are also available. Furniture already designed can be stored in a separate library and can be accessed or changed at any time. The room planning function allows entire furnishings to be designed quickly and easily, including offices or kitchens, for example.

Intelligent operation and flexible design paths

The simple options for operation and design via drag and drop allow users to create custom-made furniture quickly and easily — without any CAD knowledge. The opening of doors and drawers can also be simulated, meaning potential collisions with neighboring components can be monitored and displayed. In addition, fixtures and connectors can be selected. The scope of delivery includes a large library with all common fixtures from the well-known manufacturers. Even your own woodWOP components can be added to the furniture without any problems.

Realistic representation of furniture

In addition to the design details, SmartWOP boasts particularly impressive functions for displaying the furniture. An integrated material library with a range of designs for panel and edge material enables the user to assign the corresponding material to each component very quickly. The freely rotatable 3D model therefore allows users to create a realistic representation of the furniture, even during planning stage.

The exploded view shows all the individual components of the planned object separately, meaning that it can be used as a tool to help design even complex pieces of furniture, for example.

Individual design of all furnishings

SmartWOP allows users to design not only individual pieces of furniture, but also entire furnishings. The room planning function allows users to design everything from individual cabinets up to entire living areas — depending on the requirements.

Powerful software duo: Innovative integration of woodWOP into SmartWOP

The integrated interaction between the two software solutions offers the special feature of selecting single parts of an individual item of furniture in SmartWOP and opening it directly in woodWOP. Processing steps can now be added and saved in woodWOP. All changes are transferred directly to SmartWOP and visualized there. The CNC programs are generated directly in SmartWOP and then contain all of the processing steps — those from SmartWOP and those from woodWOP. This is an absolutely unique feature that no other CAD/CAM system can offer in this form. This interaction opens up a huge range of possibilities in the design stage and, above all, in the subsequent CNC production.

Direct transfer of data from SmartWOP to the HOMAG apps and digital assistants

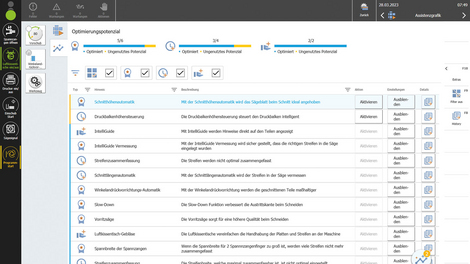

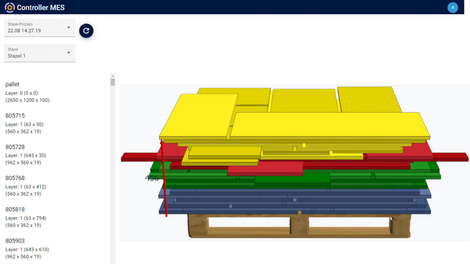

Production data such as CNC programs, parts lists for panel cutting, fixture lists or technical drawings are generated at the touch of a button. And don't forget, the data generated can then be passed directly to the HOMAG apps and the digital assistants, productionManager and intelliDivide.

As soon as a job has been transferred to productionManager, the parts lists and drawings can be accessed from anywhere. This means that all employees who work on the job right through to final assembly have access to all the job details — at all times. But productionManager does even more: The digital job folder clearly shows the progress of every single part or the entire job. The user can report single parts as "finished" for each process step (e.g. sawing, CNC, edge, assembly). HOMAG machines with a connection to tapio have the option of reporting production progress back to productionManager automatically.

With intelliDivide, the cutting patterns for the saw or the nesting patterns for the CNC machine are calculated automatically. intelliDivide's special feature is that it can calculate several alternative solutions simultaneously, e.g. optimized for minimum waste, minimum material costs or minimum production time. The user simply selects the result that is right for them.