Panel Dividing: new machines and software solutions provide even greater flexibility and efficiency

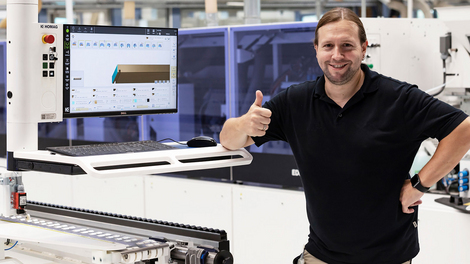

It's that time again: from July 12 to 15, HOMAG will be presenting new machines and software solutions in the field of panel dividing technology at HOLZ-HANDWERK 2022 in Nuremberg.

NEW: The SAWTEQ B-130 entry-level saw provides even more flexibility and material throughput.

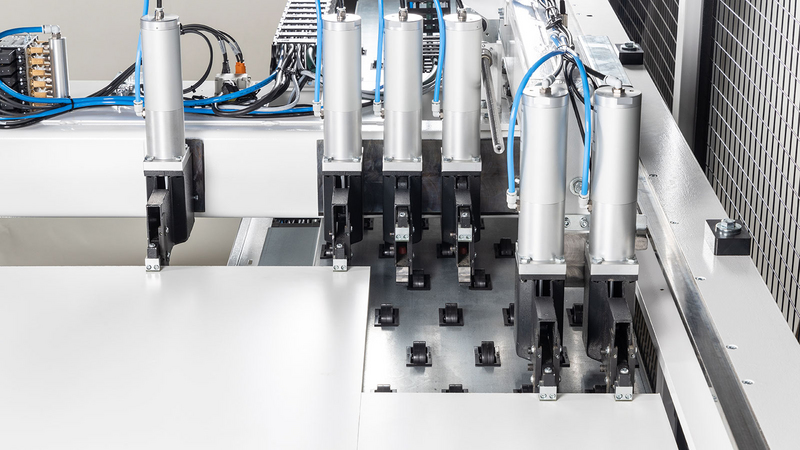

The smallest SAWTEQ B-130 panel dividing saw will be equipped with a further, optional clamp for the first time at HOLZ-HANDWERK 2022 in Nuremberg. This clamp will allow even more cutting patterns to be processed using the proven Power Concept Classic technology. This increases the output significantly and allows production peaks to be managed without problems.

Good to know: The optional clamp is also available for the SAWTEQ B-200 series.

Power Concept Classic

- Simultaneous dividing of two strips with different cross cut divisions on the SAWTEQ B-130 and B-200

- Drive unit independent of program fence

- Ideal in combination with intelliGuide Classic

- Can easily be retrofitted for machines at any time from July 2021

The benefits at a glance:

- Up to 30% more output, depending on the cutting pattern

- Lower costs per cut

- Significantly improved material flow

- High material throughput and easy management of peaks in production

- Intelligent strip sorting at the saw for maximum utilization factor

NEW: SAWTEQ B-300 flexTec/B-400 flexTec with improved performance — now with up to 1000 parts per shift.

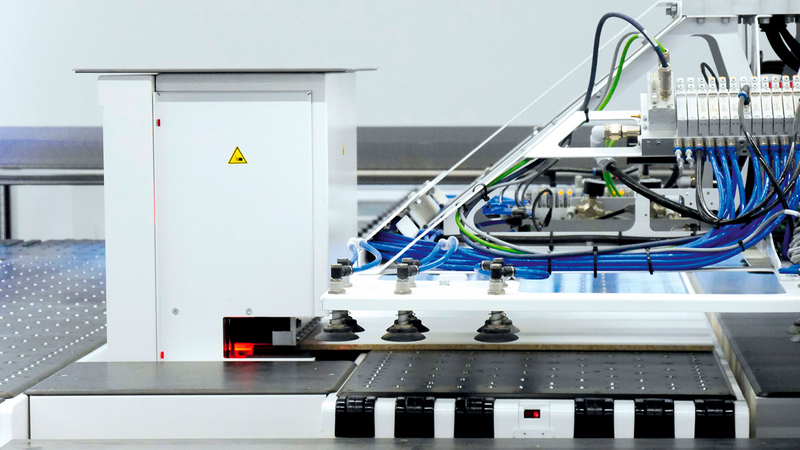

With the SAWTEQ B-300 flexTec and SAWTEQ B-400 flexTec series, HOMAG is focusing on increased performance and efficiency. In addition, the new models allow more flexibility and ensure an even higher level of quality.

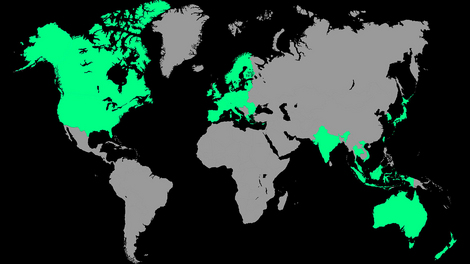

The SAWTEQ B-300 flexTec and SAWTEQ B-400 flexTec robot saws enjoys popularity worldwide thanks to their flexible use. The saws are technically designed in such a way that they can handle batch size 1 production over long periods without any personnel. In addition, they can be operated manually as usual, making them very flexible to your requirements.

With this new level of performance, HOMAG is setting new standards in both robot performance and operating freedom. The new level of performance is achieved through continuous further development of processes, software and technology. The innovations are aimed in particular at increased use of the passive buffer and efficient use of the robot.

Depending on the range of parts and the existing production processes, up to 1000 parts can be produced per shift, which corresponds to a significant increase in performance of up to 25% in the basic equipment.

With the newly developed materialManager Advanced and the Measuring System Cutting Quality (MSQ), HOMAG also ensures the quality level of the manufactured parts on a long-term basis.

materialManager Advanced — HOMAG innovation for automatic adjustment of the optimal machine parameters for cutting

- Automatically proposes optimal parameters for feed, saw blade projection and speed*

- Consistently good setting, depending on the material, saw blade and quality requirements

- Warning if the saw blade does not match the current cutting pattern

- The recommended parameters can be readjusted at any time

The benefits at a glance:

- Efficient and simple machine operation: The best possible saw parameters are automatically proposed

- Fewer sources of error: Automatic setting of saw parameters and warning if the tool is unsuitable

- Up to 8% performance potential due to optimized feed speed

- Up to 20% lower tool costs

* In conjunction with optional speed control

Measuring System Cutting Quality (MSQ)

- Cutting quality is monitored automatically through regular checks on edge breaks

- Material-specific warning and limit values are observed

Your benefits at a glance:

- Objective and regular evaluation: more frequent quality measurement and clear interpretation of results with fewer operator interventions

- Demand-based saw blade change: use of maximum saw blade service life and increased availability

- Avoid reject parts: less post-production effort since specified, material-specific limit values are observed

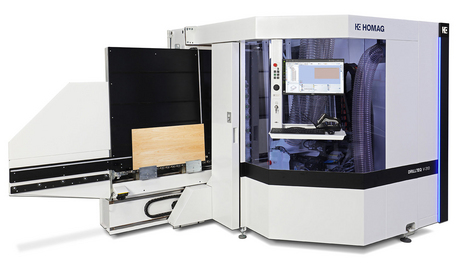

NEW: Cut Rite V12 – it's the software that makes the difference.

HOMAG presents the Cut Rite V12 in a new design and with new functions. The latest version of the proven optimization software makes processes efficient and flexible and makes data handling considerably easier.

When creating patterns for nesting machines, single part programs in different formats (e.g. MPRX, DXF) can now be mixed. In addition, each program can be edited on a job-specific basis without having to change its basic program.

With nesting, up to three trimming cycles ensure that even thick or heavy materials or small parts can be processed reliably in a way that protects tools and materials.

With the new software release, customers also benefit from an optimization in cutting. Improvements have been made in this area, particularly in the areas of labeling and reporting, as well as in algorithms that make the cutting for series production more efficient, especially on larger systems.

Good to know: the new version 12 is now available to all customers with an update and service contract free of charge.

woodStore 8 — storage management system for transparent information and material flow: More performance and greater flexibility.

If the bridge is the heart of a HOMAG storage system, then woodStore is the brain. The software links order management with job processing, manages materials down to panel waste, analyzes movements, controls material flow and optimizes all material movements.

One advantage is the automatic storage optimization: If the material composition of an order changes, the software issues the appropriate command. Stacks that are required immediately are automatically stored near the machine for quick removal. woodStore Analyzer also shows possible efficiency improvements in the storage facility. It recognizes, for example, which panel materials have to be disposed of or relocated based on frequency of use.

Another feature is the possibility to operate it via Wi-Fi with a smartphone or tablet. You can access production duration, material equipment, job overviews or information about missing panels very conveniently. This allows a direct estimation of when additional panels need to be transported from the block storage facility to the storage return position. The operator can then start the storage return process directly from the forklift truck. Using predefined barcodes, the operator scans materials, defines the number of panels to be stored and starts the storage process — conveniently, quickly and easily using a mobile end device.