Treffs 21: What's new in woodworking and timber construction?

HOMAG and WEINMANN give the answers

From Oct. 25 to Nov. 19, 2021 HOMAG and WEINMANN will be providing interesting news about machines, cell solutions, digital products and production methods in woodworking and timber construction at their HOMAG Treff and WEINMANN Treff 2021.

The face-to-face events and demonstrations in Holzbronn, Herzebrock and St. Johann will be accompanied by the well-known online format Live.HOMAG at live.homag.com with webinars and promotion videos on key topics and highlights. You will learn more about the HOMAG Treff and the WEINMANN Treff as well as the online formats soon. Below is a brief overview of the planned topics.

Among other things, HOMAG will be presenting the topics intelligent automation, process optimization and further development of mobile operation. Visitors will also get to know how they can use digital assistants from HOMAG to increase performance and efficiency while ensuring sustainability at the same time.

Automation sets new standards

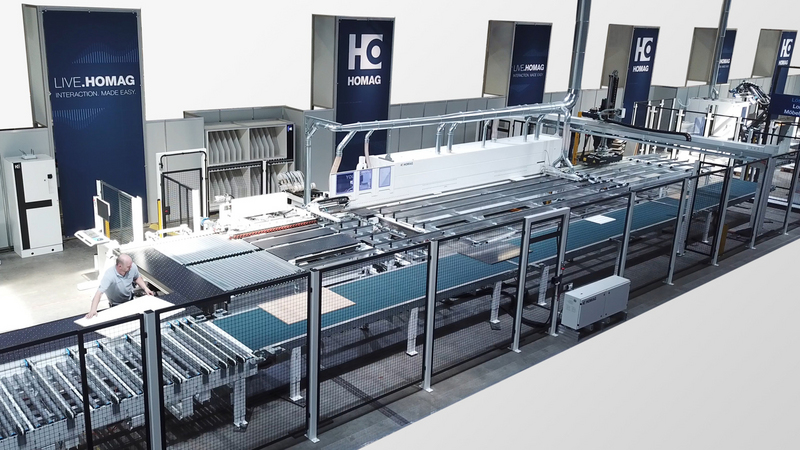

Fully automated installations, such as the SAWTEQ B-320 flexTec panel dividing cell for batch-size 1 production or WEINMANN's autonomously operating cells for the fully automated production of building components with industrial robots, set new standards in terms of performance and flexibility.

Intelligent automation creates an interlinked material flow with high performance. This is the case, for example, with the LOOPTEQ O-600 gantry return system as a supplement to the edge banding machines of the EDGETEQ S-500 series.

Equipment thought through

New equipment variants and clever software assistants increase efficiency and create more transparency in production, e.g. with the latest version of the storage management system, woodStore8.

Another new addition to HOMAG's equipment portfolio is a specially designed interchangeable container for fast and unmixed switching between EVA and PUR hotmelt adhesives in edge banding machines.

Sustainability and conservation of resources

HOMAG does not neglect the issue of sustainability either. Digital assistants such as the "Cutting Production Set" support the user in optimizing cutting and reusing offcuts. Thus, not only saving costs and materials, but also helping to protect the environment.

And that's not all

There will also be news in the CNC area this coming autumn. These are so current that they were not yet allowed to be published at the time of going to press.

In the following weeks we will provide more information on the various contents, dates and venues as well as registration for the online formats.