Automation Transforming India’s Woodworking Industry

Automation is transforming India’s woodworking sector. Learn how HOMAG’s customized automation solutions and digital platforms support manufacturers in achieving sustainable growth.

The primary goal of automation in woodworking production is to increase operational efficiency and accuracy while reducing labor costs and material waste. Keshav Murthy, Director Sales, Marketing and LCS at HOMAG India, brings extensive insight into how automation technologies are being adopted across the sector - from small workshops to large manufacturers. His perspective sheds light on the practical benefits and growing importance of integrated automation solutions, as well as the role of digitalization in transforming production processes.

Automation offering a pathway to enhanced efficiency, improved quality, and safer working environments. Machines equipped with automation technology can perform repetitive, precise tasks rapidly and consistently, which leads to better product quality and higher throughput. Keshav Murthy, Director Sales, Marketing and LCS at HOMAG India, emphasizes, “Automation is not just about replacing manual labor; it’s about enabling manufacturers to meet growing demand with consistent output and improved safety standards.”

Currently, the Indian woodworking sector predominantly relies on conventional standalone machines, especially among small and medium enterprises. Estimates suggest that only about 20 to 30 percent of production is automated, with the remaining 70 to 80 percent still dependent on traditional methods. Murthy notes, “While cost and skill barriers have slowed automation adoption among smaller businesses, we are witnessing a rapid shift as more manufacturers recognize the long-term benefits of integrated automation solutions.” Larger manufacturers are increasingly investing in automation to enhance efficiency and product quality, a trend that is expected to accelerate with the growing influence of Industry 4.0 technologies.

The Growing Role of Automation in Indian Woodworking

Automation in woodworking encompasses several key technologies. CNC machines automate drilling, and routing with high precision, making them indispensable in furniture and component manufacturing. Robotics assist in tasks such as sizing, sanding, painting, loading, unloading, and material handling, increasing speed and consistency while reducing labor intensity. Conveyor systems streamline the transport of materials and products within production lines, improving workflow efficiency. Automated storage and retrieval systems use computer-controlled cranes to manage material storage and retrieval, reducing manual labor and optimizing space. These technologies can be integrated across all stages of production, from raw material processing to finishing, resulting in higher productivity, better quality, and lower operational costs.

The Indian market demands automation solutions that deliver high productivity and precision, particularly through CNC and automated beam saw machines. Energy efficiency and eco-friendliness are increasingly important, aligning with broader sustainability goals. Integration of AI and IoT enables real-time monitoring, predictive maintenance, and process optimization. User-friendly smart controls that allow remote operation and flexibility are also critical. Murthy explains, “Our customers are looking for solutions that not only improve output but also reduce energy consumption and environmental impact. Digitalization and automation go hand in hand in achieving these objectives.” Additionally, cost-effective local manufacturing and specialized training programs are essential to overcome skill shortages and facilitate technology adoption.

Automated manufacturing offers clear advantages over standalone machines. Production speed and efficiency increase significantly through continuous, programmable processes. Precision and consistency improve, reducing defects and rework. Labor costs decrease as repetitive and labor-intensive tasks are automated. Safety is enhanced by sensors and automatic shutoffs, minimizing workplace accidents. Material waste is lowered due to optimized cutting and handling. Furthermore, automation provides greater flexibility to scale production according to demand. Murthy highlights, “Automation allows manufacturers to be agile. Whether producing large volumes or customized batches, they can maintain quality and efficiency.”

Many woodworking processes can be automated, regardless of production scale. These include cutting, edge banding, routing, drilling, sanding, finishing, material handling, assembly, sorting, packing, and dispatch. Essentially, the entire production process can be automated, benefiting both mass production and small batch sizes. Mass production involves continuous manufacturing of large volumes of standardized products, focusing on economies of scale and uniform quality. Automation supports this by enabling high efficiency and low unit costs but offers limited customization. Batch-size one production, produces goods in smaller quantities or customized batches, allowing flexibility and easier adjustments between batches. This approach suits varied or personalized products but - without automation - typically involves higher setup times and costs per unit. Murthy observes, “The Indian market is unique in its diversity. Automation solutions must be flexible enough to handle both mass production and highly customized orders.”

A typical example of automated woodworking production is the integration of CNC machining centers with robotic systems. CNC machines perform precise drilling, and routing tasks, ensuring high accuracy and repeatability. Robotic arms handle material loading, unloading, and assembly, boosting productivity and reducing labor intensity. An automated production line may include panel dividing saws, edge banders, and CNC processing machines working sequentially, with conveyor systems transporting materials between stations. This integration enables continuous flow with minimal manual intervention, resulting in lower waste and consistent product quality. Such systems are suitable for both large-scale and flexible batch production.

HOMAG India plays a significant role in supporting automation adoption across the country. The company serves a broad range of clients, from large industrial manufacturers to craft businesses, offering tailored automation, software, and digital solutions. Murthy states, “Our approach is collaborative. We work closely with customers to deliver customized end-to-end automation solutions, backed by expert consulting and comprehensive after-sales service - everything from a single source.”

Automation Across Woodworking Processes

Automation is relevant for companies of all sizes. Small and medium woodworking businesses benefit from improved precision, faster production, reduced waste, and enhanced safety. Modern automated solutions are scalable and flexible, ranging from CNC routers to robotic saws, adaptable to different production volumes and product complexities. Murthy points out, “Even small workshops can now access automation technologies that were once only affordable for large manufacturers. This levels the playing field and helps all businesses stay competitive.”

Determining when automation becomes economically viable depends on several factors, including product complexity, labor costs, and investment capacity. There is no fixed daily output threshold universally applicable. However, automation generally becomes cost-effective when production volume justifies the upfront investment by reducing labor and material costs. For simpler, repetitive products with stable demand, volumes of a few hundred to a thousand parts per shift can make automation sensible.

Beyond increasing output, automation offers additional benefits. Time savings and productivity improve as machines perform repetitive tasks faster and continuously, reducing production times and downtime. Consistent quality results from precise, repeatable automated processes, which reduce variability, defects, and material waste. Occupational safety improves by minimizing manual handling and exposure to hazardous tasks, with safety sensors, barriers, and automatic shutoffs reducing workplace injuries. Automation also optimizes personnel deployment, allowing skilled workers to focus on programming, quality control, and innovation rather than routine tasks.

Tailored Automation Solutions by HOMAG

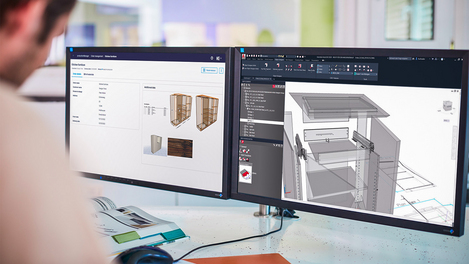

HOMAG provides tailored automation solutions across all segments of the woodworking industry. For the entry-level segment, including small carpenters, compact and space-optimized machines such as the SAWTEQ S-160 beam saw, and EDGETEQ S-230 edge bander are offered. These integrate with CAD/CAM software and barcode scanners to provide flexible automation. The mid-range segment, serving commercial builders, interior designers, and trade fair builders, benefits from machines like the SAWTEQ S-180/200/300 beam saws with various loading systems, EDGETEQ edge banders, and DRILLTEQ drilling machines. Integrated storage systems and digital products such as production managers and material tracking enhance efficiency. For the industrial segment, large manufacturers receive fully integrated production lines featuring high-speed angular saws, robotic saws, nesting lines, routing and edge banding machines, and robotic material handling. HOMAG’s digital platform Tapio connects machines and workflows for Industry 4.0, enabling real-time monitoring and predictive maintenance. Murthy explains, “Our portfolio covers the entire wood processing chain with scalable automation and digital solutions designed to meet diverse customer needs efficiently and sustainably.”

The Impact of Digitalization on Automation

Digitalization plays a critical role in modern woodworking automation. It enables seamless machine control, efficient work preparation, and streamlined order processing. HOMAG’s Tapio platform connects machines, tools, materials, and workflows in a unified IoT ecosystem. This connectivity allows remote monitoring, predictive maintenance, and real-time performance analytics, reducing unexpected downtime and improving machine utilization. Digital tools support automated job scheduling, cutting optimization, and workflow coordination, minimizing manual planning errors and setup times. Order processing benefits from continuous data flow from sales to production planning and machine operation, reducing redundancies and manual data entry while increasing transparency and speed. Murthy highlights, “Digitalization transforms automation from isolated machine tasks into fully connected, intelligent production ecosystems. This enhances productivity, flexibility, and responsiveness for woodworking businesses of all sizes.”

Outlook for Automation in India’s Woodworking Industry

Looking ahead, the increased use of automation is poised to transform the Indian woodworking industry significantly. Automated, precise machines and integrated production lines will enable faster manufacturing with less manual intervention and waste. This will help meet the growing demand for furniture and interiors driven by urbanization and rising incomes. Automation combined with digital technologies will ensure consistent, high-quality output and support flexible batch size one production, allowing manufacturers to offer personalized and complex designs. Automation will address skilled labor shortages and improve occupational safety by automating hazardous and repetitive tasks, freeing personnel for higher-value roles. Industry 4.0 integration will increase digitalization and connectivity of machines, production planning, and supply chains, enhancing transparency, predictive maintenance, and agile responses to market changes.

Keshav Murthy sums up the strategic importance of automation in India’s woodworking sector: “Automation is essential for driving sustainable growth and enhancing competitiveness. It helps manufacturers of all sizes produce efficiently while meeting evolving customer demands. Beyond cost reduction, automation is a catalyst for innovation, quality, and resilience in a rapidly changing market. The future belongs to those who embrace these technologies and integrate them into their production ecosystems.”

Automation is no longer a luxury but a necessity for the Indian woodworking industry. It offers a comprehensive solution to challenges such as labor shortages, quality consistency, and safety concerns. By combining automation with digitalization, manufacturers can build smarter, more agile production systems capable of handling diverse product requirements. This positions the woodworking industry to compete effectively on both domestic and global stages, unlocking new opportunities for growth and excellence.