Technology, Sustainability, and the Future of Woodworking in India

Inside HOMAG India: Keshav Murthy discusses technology, sustainability, and the future of woodworking in India.

An interview with Keshav Murthy, Director Sales, Marketing and LCS HOMAG India.

The woodworking industry in India is undergoing significant transformation, spurred by urbanization, expansion in the real estate and furniture sectors, and the rapid adoption of advanced manufacturing technologies. At the intersection of these developments is HOMAG India, part of the global HOMAG Group, recognized for engineering expertise and integrated solutions for woodworking and furniture production.

As one of the fastest-growing markets within the HOMAG Group, India presents both opportunities and challenges: a rising need for sustainable materials, demand for precision manufacturing, workforce upskilling, and technological modernization. HOMAG India’s role extends beyond supplying machinery to fostering innovation, contributing to global knowledge networks, and supporting manufacturers of all sizes in adapting to evolving industry conditions.

In this interview, Keshav Murthy, Director Sales, Marketing and LCS HOMAG India, provides insights into the company’s strategic position, changing customer requirements, operational challenges, technological priorities, and future plans. His perspectives shed light on the dynamics shaping India’s woodworking industry and its place in the broader Asia-Pacific region.

Can you describe your experience settling into your role at HOMAG India and your key priorities moving forward?

Murthy: Settling in has been smooth, thanks to a strong team and supportive culture at HOMAG India. Serving in the same industry for close to two decades has helped me gain significant industry exposure and experience. My focus is on aligning our strategies with customer needs and driving growth while strengthening our position in the woodworking industry.

How does HOMAG India contribute to the HOMAG Group’s operations and what is its strategic role moving forward?

Murthy: HOMAG India plays a vital role as the Group’s hub for one of the fastest-growing woodworking markets. We not only serve local customers but also contribute through engineering, service, and knowledge sharing within the Group. Going forward, our role will expand as a center for growth, innovation, and customer-centric solutions in Asia.

What differentiates HOMAG India in the Indian woodworking industry?

Murthy: HOMAG India stands out for combining German technology with local expertise. We not only deliver world-class machines but also provide strong after-sales service, training, and localized solutions, which makes us a trusted partner for the Indian woodworking industry.

What distinguishes HOMAG India’s approach to serving its customers in the woodworking industry?

Murthy: What sets HOMAG India apart is our ability to deliver end-to-end solutions - from world-class German technology to local application support, training, and service. We don’t just sell machines; we partner with our customers to improve productivity, quality, and long-term success.

What key trends do you foresee shaping the Indian woodworking industry over the next 3 to 5 years?

Murthy: In the next 3–5 years, the Indian woodworking industry will be shaped by automation and digital manufacturing, rising demand for sustainable and engineered wood, modular and space-saving designs, and stronger export opportunities supported by global quality standards. Above all, the industry will be driven by increased domestic demand through real estate growth and urbanization.

How are customer preferences evolving in the Indian woodworking market?

Murthy: Customer demand in India is moving towards sustainable materials, modular and space-saving designs, higher quality finishes, and greater customization, with strong growth coming from both metros and emerging cities.

What are the main challenges facing the Indian woodworking industry and how is HOMAG India addressing them?

Murthy: Main challenges for the Indian woodworking industry in the coming years include rapid market growth, raw material supply constraints, demand for sustainable products, the need for digitalization and automation, and workforce upskilling. HOMAG India supports customers with advanced Industry 4.0 solutions, real-time monitoring, energy-efficient machinery, and comprehensive training programs to optimize production and meet market demands. Trade platforms like INDIAWOOD also help spread innovation and collaboration within the industry.

How is digitalization impacting the Indian woodworking industry, and what digital solutions does HOMAG Group offer to support this transformation?

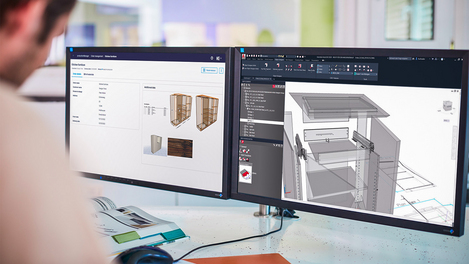

Murthy: Digitalization is crucial for India’s woodworking industry as it improves productivity, efficiency, and competitiveness. HOMAG Group’s digital products - such as smartWOP for easy programming, HOMAG iX for design, Production Manager and MES for streamlined workflow, and cloud-based platforms like pulseCloud and Tapio - enable Indian manufacturers to optimize processes and remain competitive in a fast-evolving market.

What Industry 4.0 innovations is HOMAG India introducing to support the Indian woodworking market?

Murthy: HOMAG India is focusing on Industry 4.0 innovations for the Indian market - especially IoT, artificial intelligence, cloud-based solutions, and digital factory concepts. Key advances include the Intelligent Virtual Platform (iVP) for immersive 3D factory planning, “digital twin” solutions, predictive maintenance using AI, real-time monitoring, and integration of powerful software with smart machines to streamline production and increase efficiency.

Can you describe the range of woodworking machinery and solutions that HOMAG India provides to its customers?

Murthy: HOMAG India’s core daily business revolves around supplying advanced woodworking machinery, including panel sizing beam saws, edge banders, CNC routers and machining centers, drilling machines, sanding solutions, automation systems, solutions for solid wood machines, and digital products. These machines support a range of tasks including cutting, edge processing, routing, drilling, and finishing.

What is the customer profile of HOMAG India in terms of business size and market segments?

Murthy: HOMAG India typically serves a broad mix: approximately 60% smaller and mid-size manufacturers, and 40% large-scale or premium customers. This reflects strong demand from SME workshops as well as large furniture, panel, and modular construction companies seeking advanced production solutions.

What are HOMAG India’s growth plans for the coming years, and how does the new Bengaluru production site support these objectives?

Murthy: HOMAG India aims to grow three-fold by 2030 alongside the expanding Indian furniture market, projected to reach $27 billion. The new production site near Bengaluru enables local manufacturing of new product lines, supports exports, and provides advanced customer training through its large experience center. The facility’s capacity allows HOMAG India to serve Tier-2 and Tier-3 towns more effectively and respond quickly to customer needs.

Can you share the key features and significance of the HOMAG India production site near Bengaluru?

Murthy: The production site spans over 100,000 square feet, with a large manufacturing area, advanced training facilities, and a 6,000+ square feet Experience Centre where customers can see machines and digital solutions in operation. The facility serves both local and export markets and incorporates a “local for local” and “local for global” manufacturing approach.

What training and service programs does HOMAG India provide to support its customers?

Murthy: HOMAG India offers a range of programs to help customers maximize machine performance, including:

- HOMAG Academy: Over 100 tailored training courses globally, with classroom sessions in Bangalore, live online courses, and eLearning options.

- Showroom Workshops: Hands-on training and process optimization sessions at the Bangalore showroom.

- Life Cycle Service (LCS): Technical support, maintenance programs, spare parts supply, and quick repair services.

- Customer Connect App: A platform for monitoring machine status, creating service requests, ordering spare parts, tracking maintenance, and accessing real-time support.

India’s woodworking industry is evolving rapidly, shaped by automation, digital manufacturing, and rising demand for sustainable, high-quality, and customized products. In this interview, Keshav Murthy, Managing Director of HOMAG India, discusses the company’s strategic role within the HOMAG Group, its integration of German engineering with local expertise, and its commitment to supporting customers through advanced technologies, training programs, and extensive after-sales service. He also outlines market trends, challenges, and growth plans - including the significance of HOMAG India’s new production site near Bengaluru in driving innovation, capacity expansion, and support for manufacturers across India and the Asia-Pacific region.