You are interested in

Discover our knowledge and solutions for Furniture Production - Industry

From individual machines and automated cells to fully interlinked systems — we help you to find the right solution for panel processing to meet your specific needs, and to ensure your success in the long term.

“For the production of individual household furniture and closets we rely on a complete solution from the HOMAG Group.”Ting Zhang, Vice President of Suofeiya Home Collection Co. Ltd., China

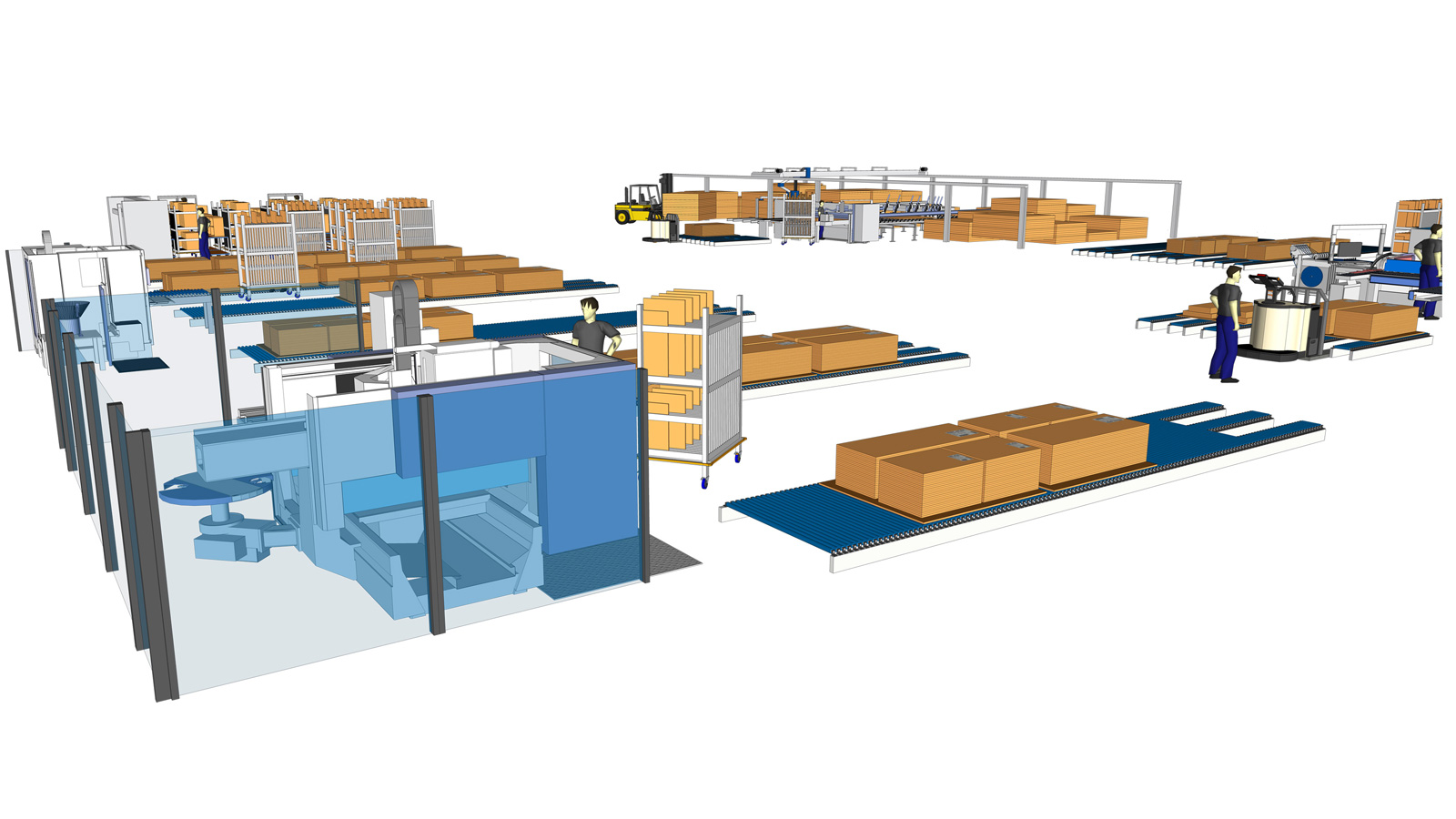

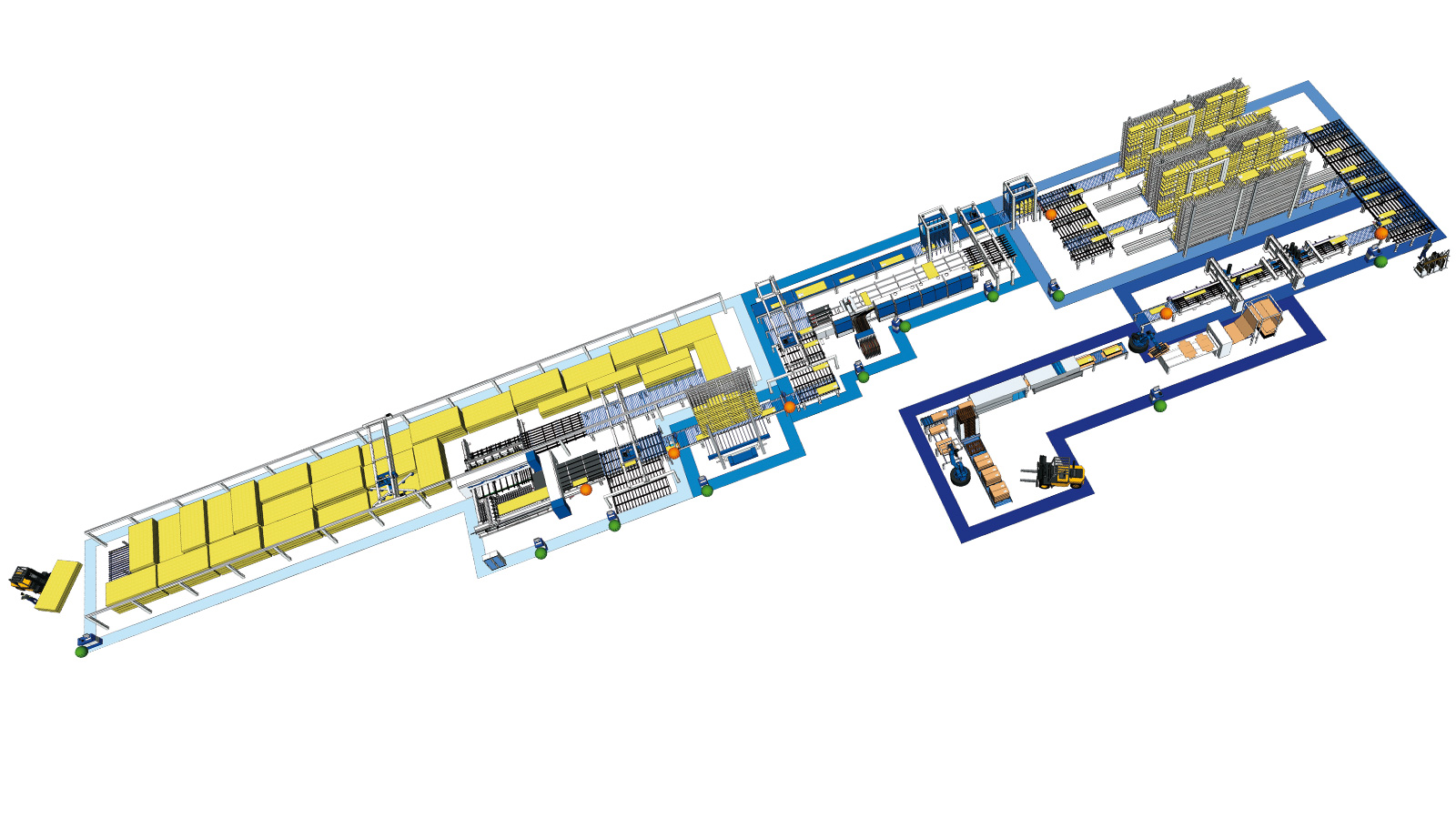

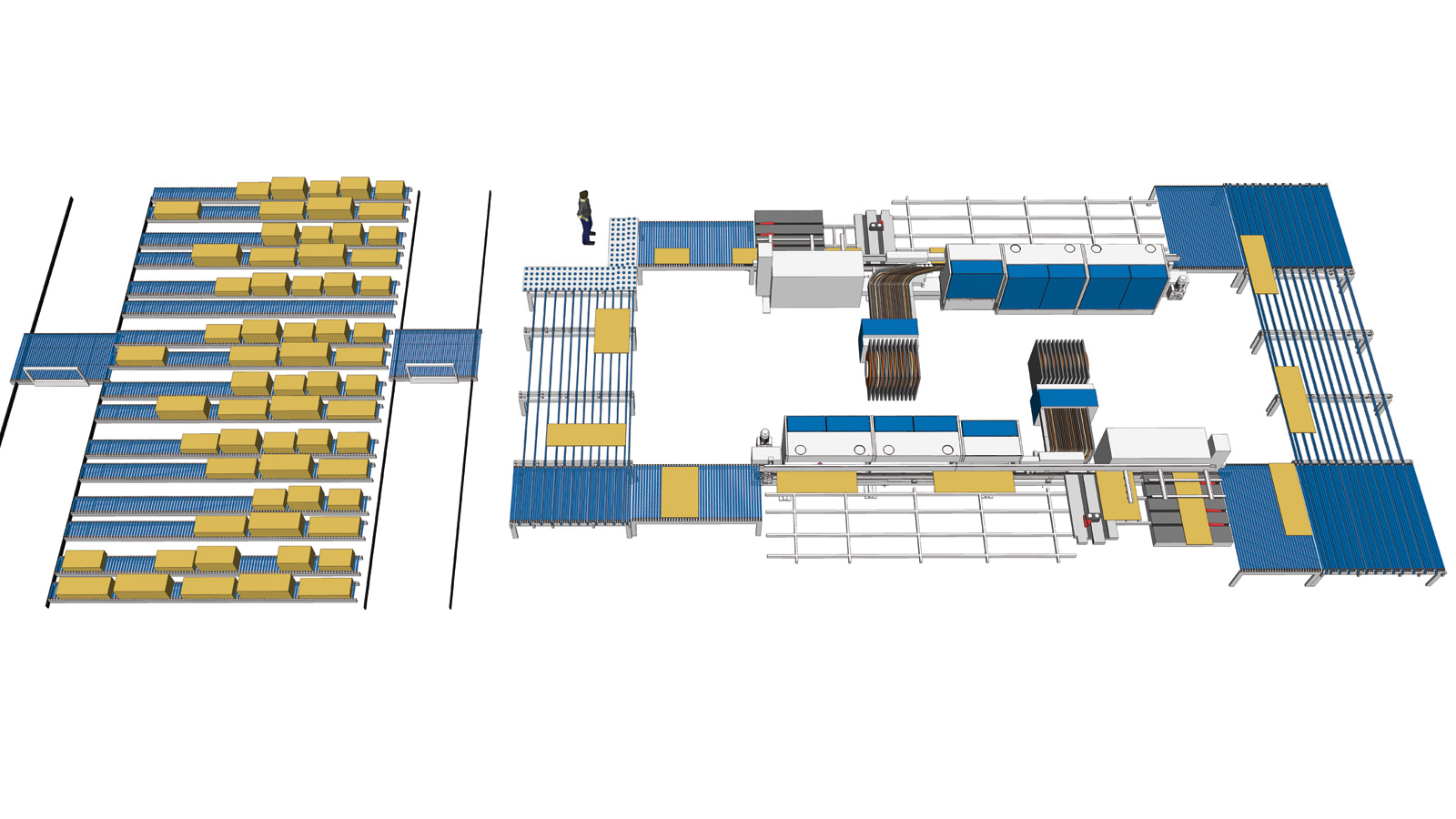

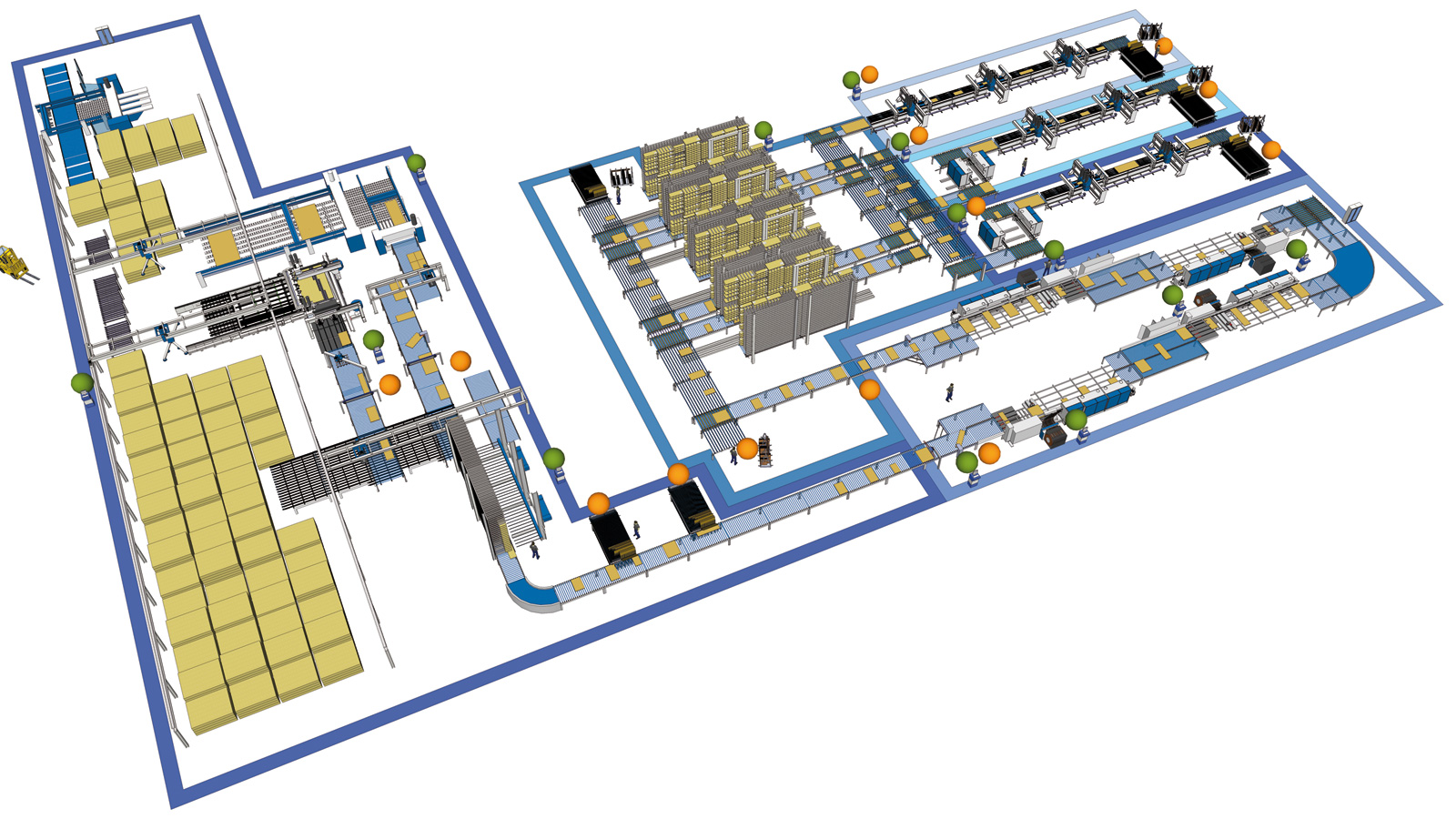

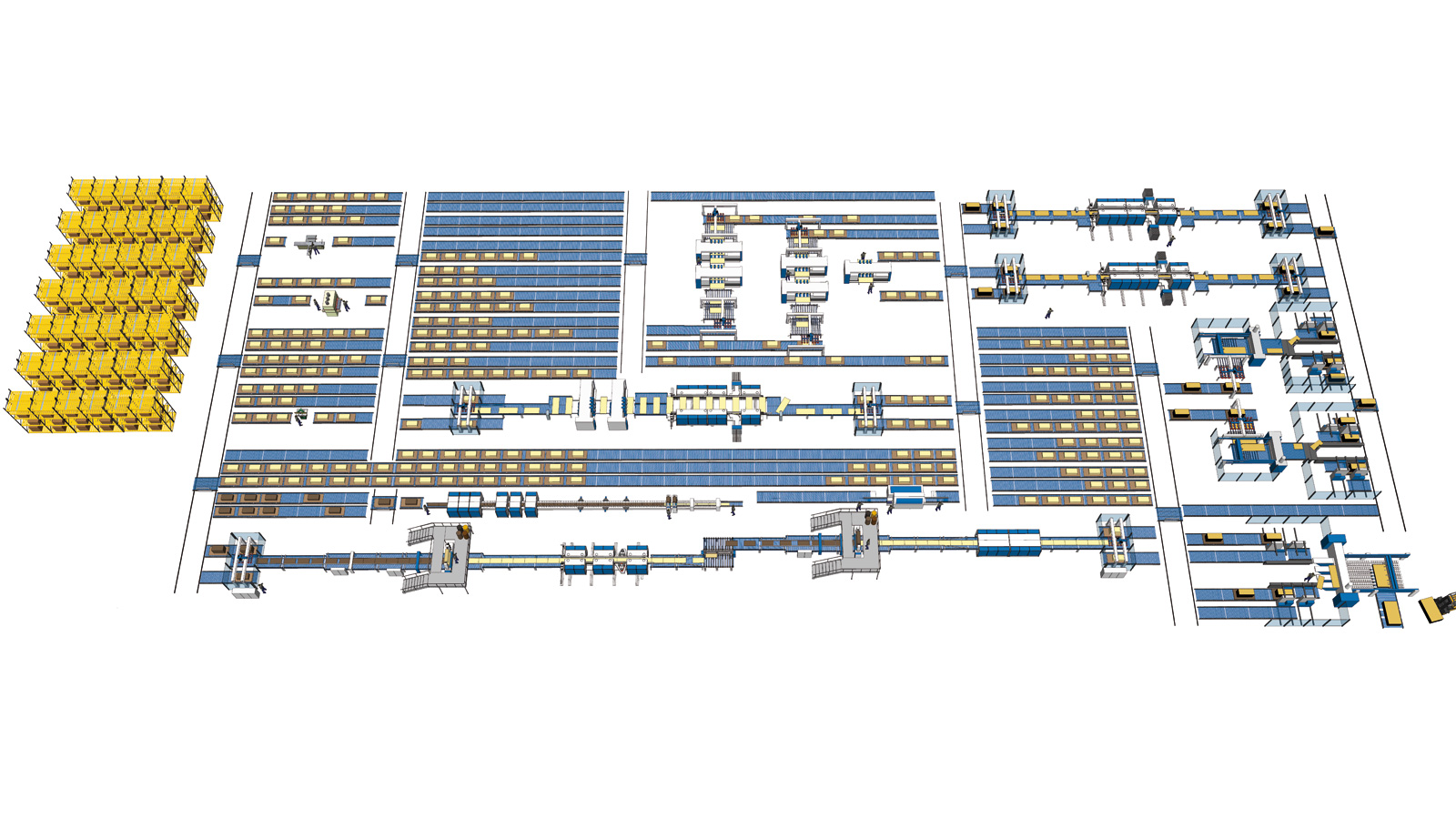

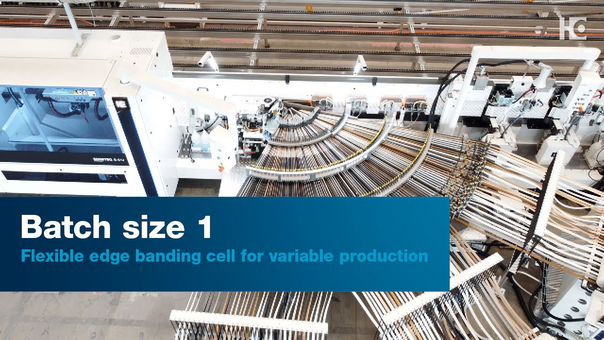

Your individual interlinked production combines the storage, handling, transport and processing of workpieces. Whether you need the flexibility of batch size 1 production to produce a wide range of product variants or want the efficiency of series production, we will find the right solution for you.

Batch size 1 production and order manufacturing

Market-driven production costs resulting from an optimum use of resources, short throughfeed times and low stocks are crucial factors, particularly if you have a wide variety of products. Benefit from our industry expertise, our many years of experience and our in-depth knowledge of the widest product range from a single source.

We have the perfect solution for you in the performance class you want!

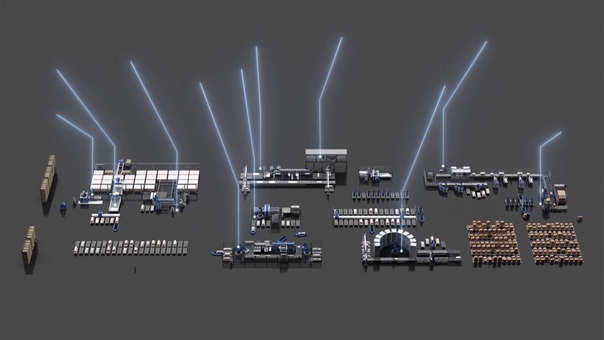

Series production

Today, manufacturing furniture panels without powerful and reliable machinery is no longer conceivable. We offer a system that is ideally suited to your needs. The ideal solution combining storage, handling, transport and processing of workpieces ensures a reliable production process that will put you on the path to success. For series-manufactured furniture with an attractive price-performance ratio for your customers.

Parts per shift is a figure that you will know only too well, as it defines the level of efficiency achieved. Mass production and identical parts per shift increase your return on investment (ROI).

We precisely define this unit for your machines and categorize them in performance classes:

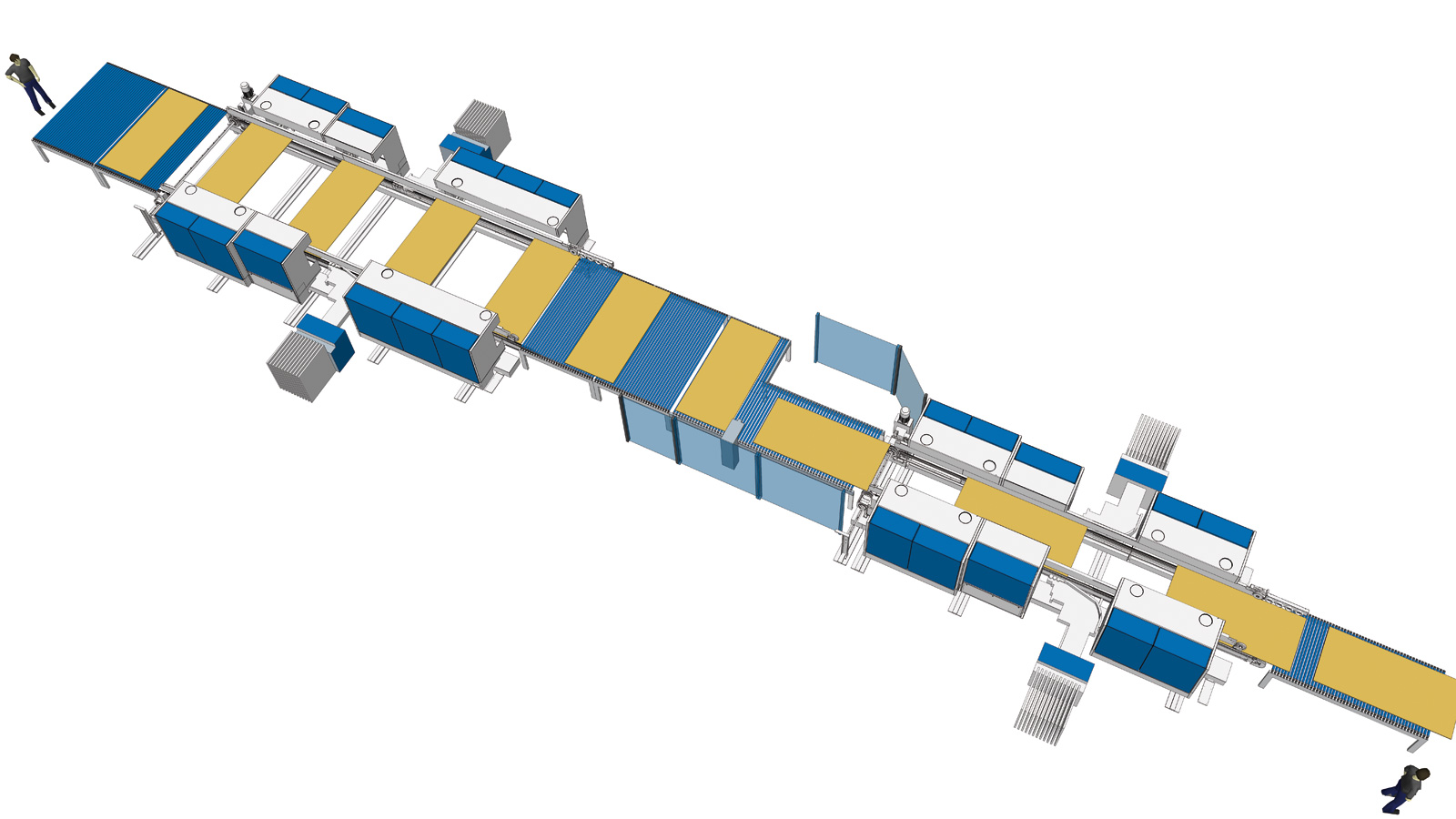

- Line for 3,000 parts/shift

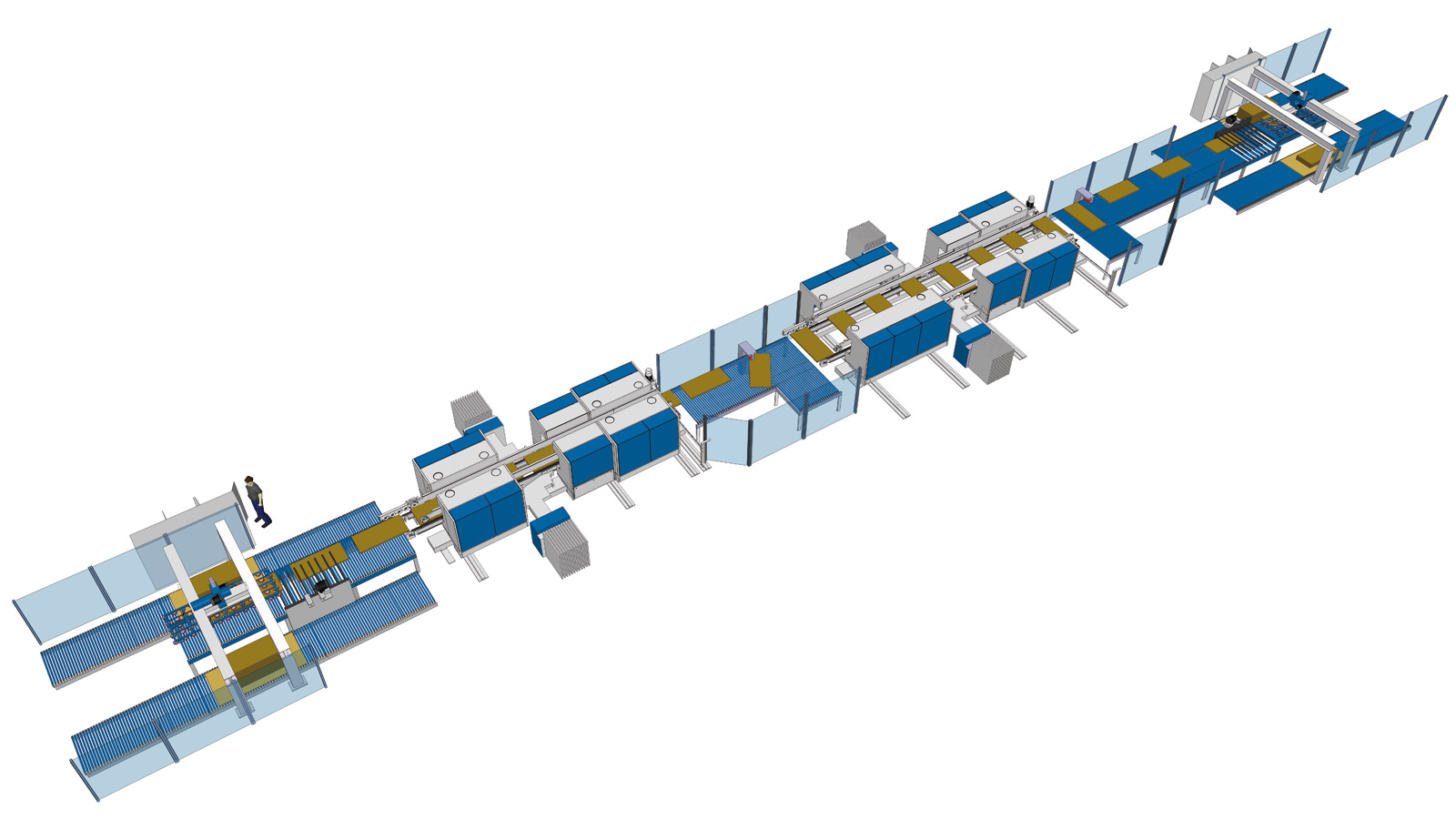

- Longitudinal and transverse line for 8,000 parts/shift

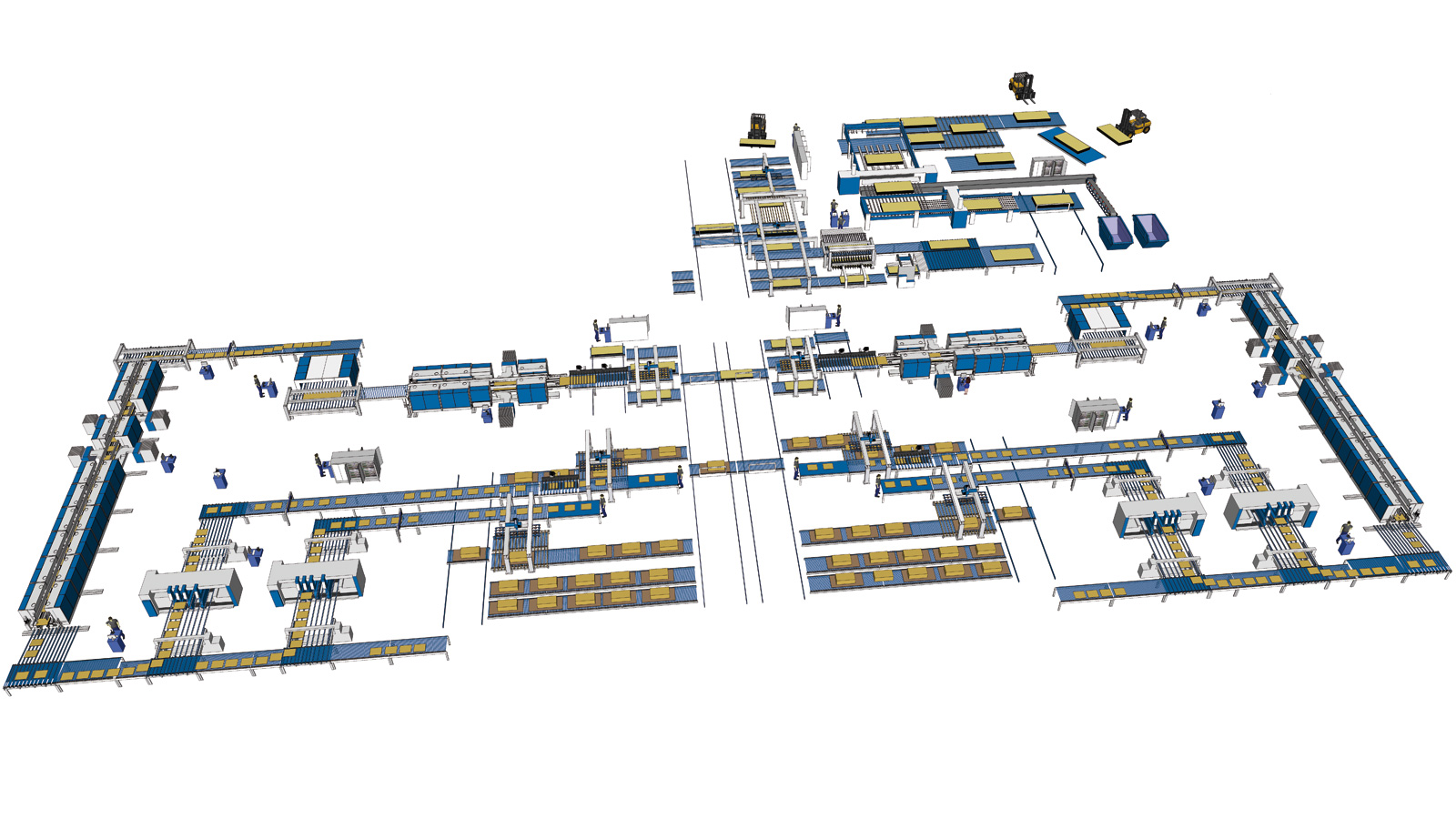

- Series production of up to 25,000 parts/shift

Project planning by HOMAG

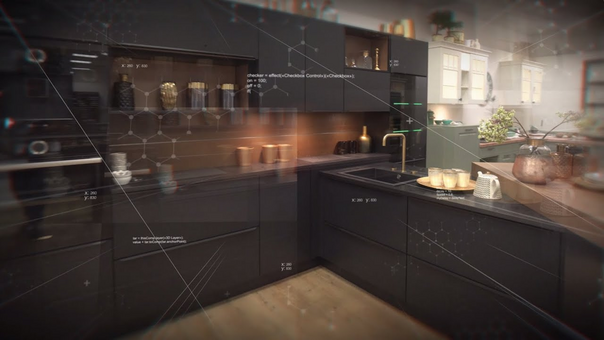

We develop suitable solutions for the production of your bathroom, kitchen, office or home furniture. Right up to a fully networked system. From design to delivery. From the first meeting to completion of the project.

More InformationThat's how your colleagues produce

Videos

HOMAG: Global market leader for wood processing machines