Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Robot Solutions for the Furniture Industry FEEDBOT

Robot Solutions for the Furniture Industry FEEDBOT

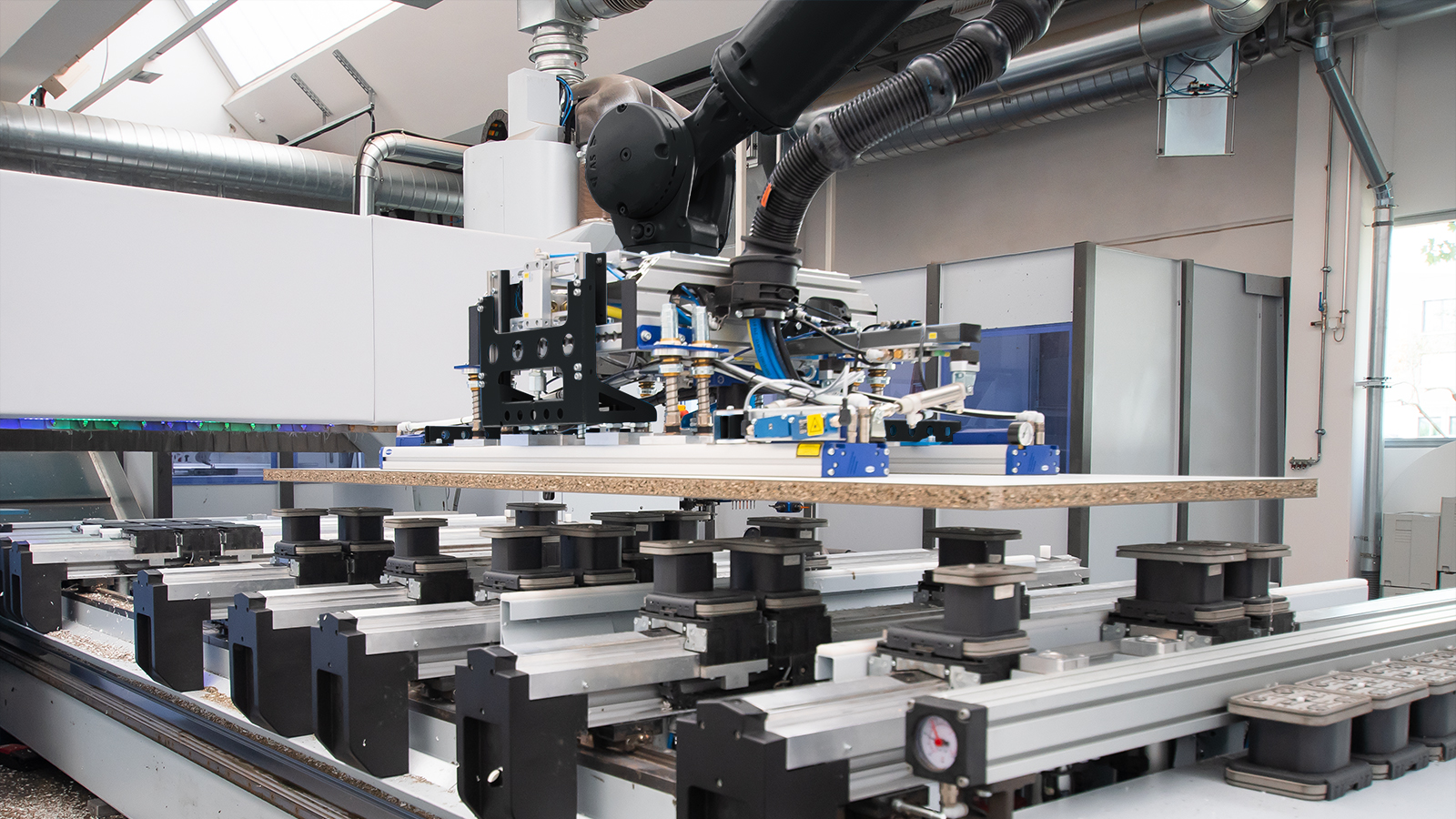

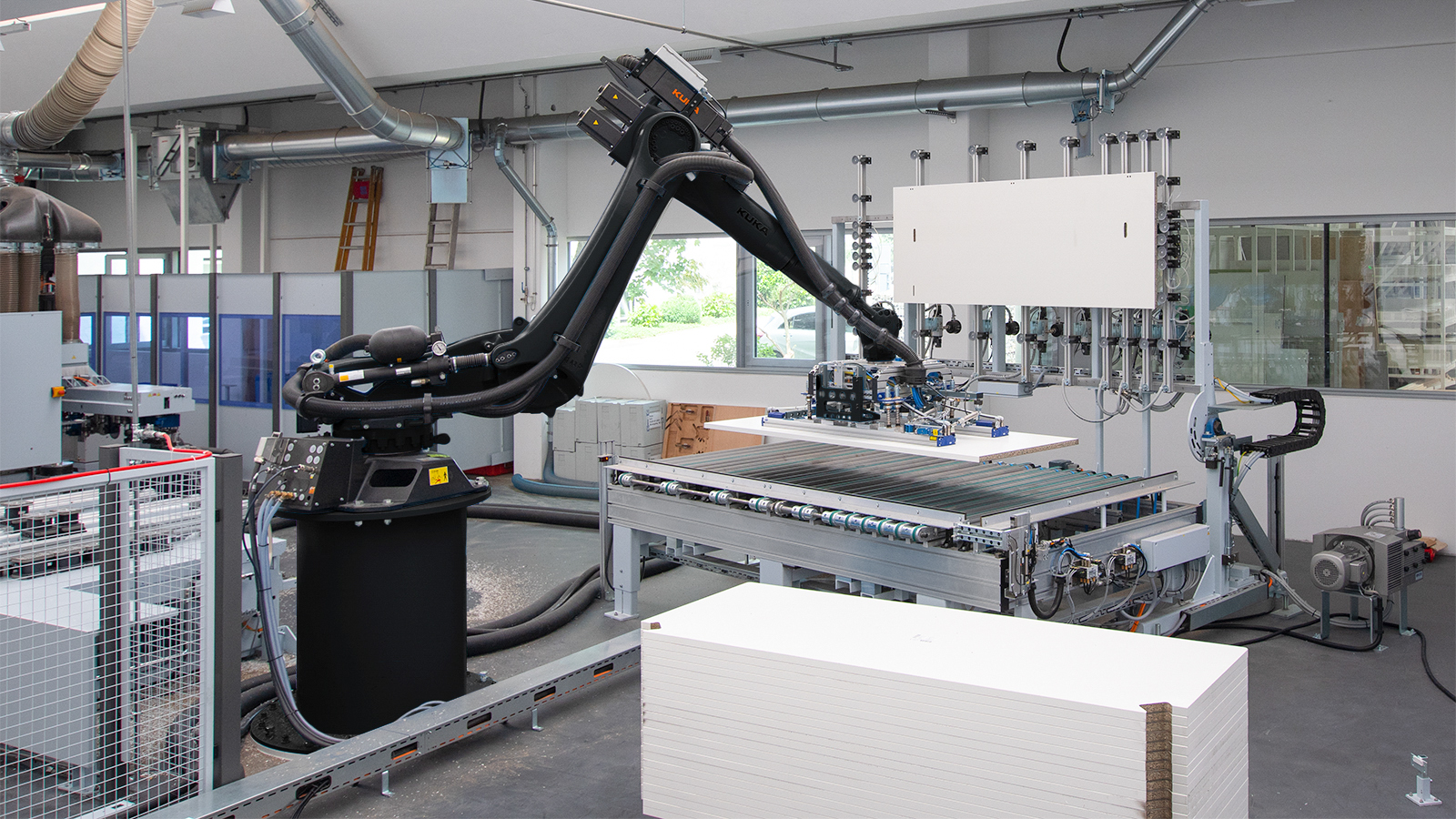

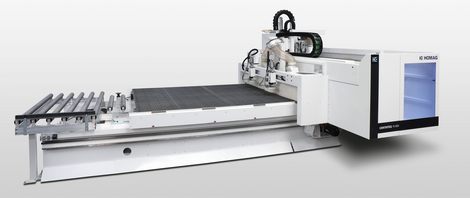

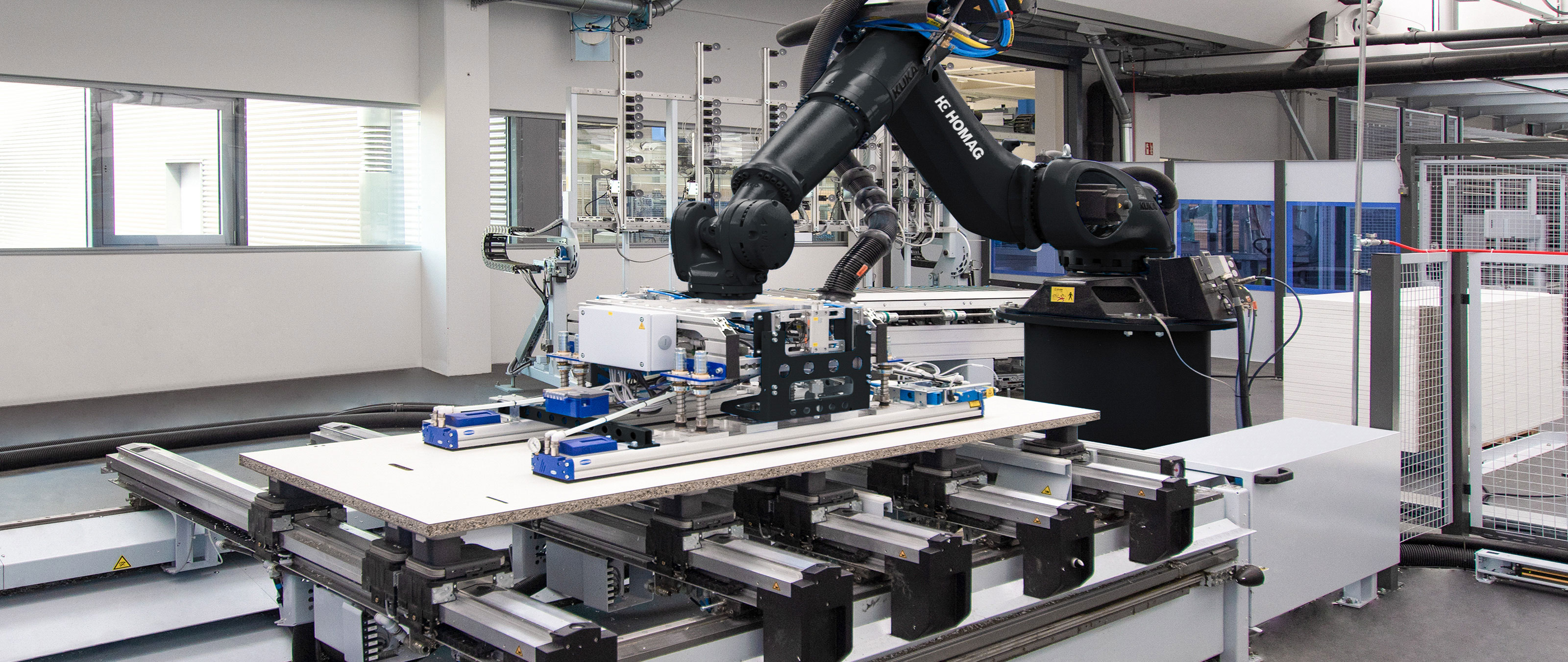

Production cell with a robot for automatic material handling

Availability of almost 100%, high repetition accuracy, and precise workpiece handling — robots are reliable partners and increase the cost-effectiveness of production automatically. The reliable supply of workpieces by the robot system makes every CNC machine a high-performance processing center, ensuring an optimal manufacturing production cell for wood and furniture production.

Images

Features

-

Five- or six-axis robot as the central element of the CNC processing cell

-

Easy and intuitive operation through integration of the robot in the cell control system and system display of the CNC processing center

-

New workpieces are produced without extensive training as the travel movements of the robot are automatically adjusted to the workpiece sizes

-

Part identification by a barcode reader is possible

-

Quiet, energy-efficient handling as energy is consumed only when a part is moved

Technical Data

| Workpiece length [mm] | 300 - 3.050 |

| Workpiece width [mm] | 300 - 1.675 |

| Workpiece thickness [mm] | 13 - 60 |

| Workpiece weight [kg] | max. 70 |

| Stack height (incl. subassembly) [mm] | max. 1.500 |

| Stack subassembly [mm] | EURO pallet (1.200 x 800 x 144) |

Here's how your colleagues produce

Brochures