Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Panel dividing saws SAWTEQ O-100

Panel dividing saws SAWTEQ O-100

Simply better, right from the start.

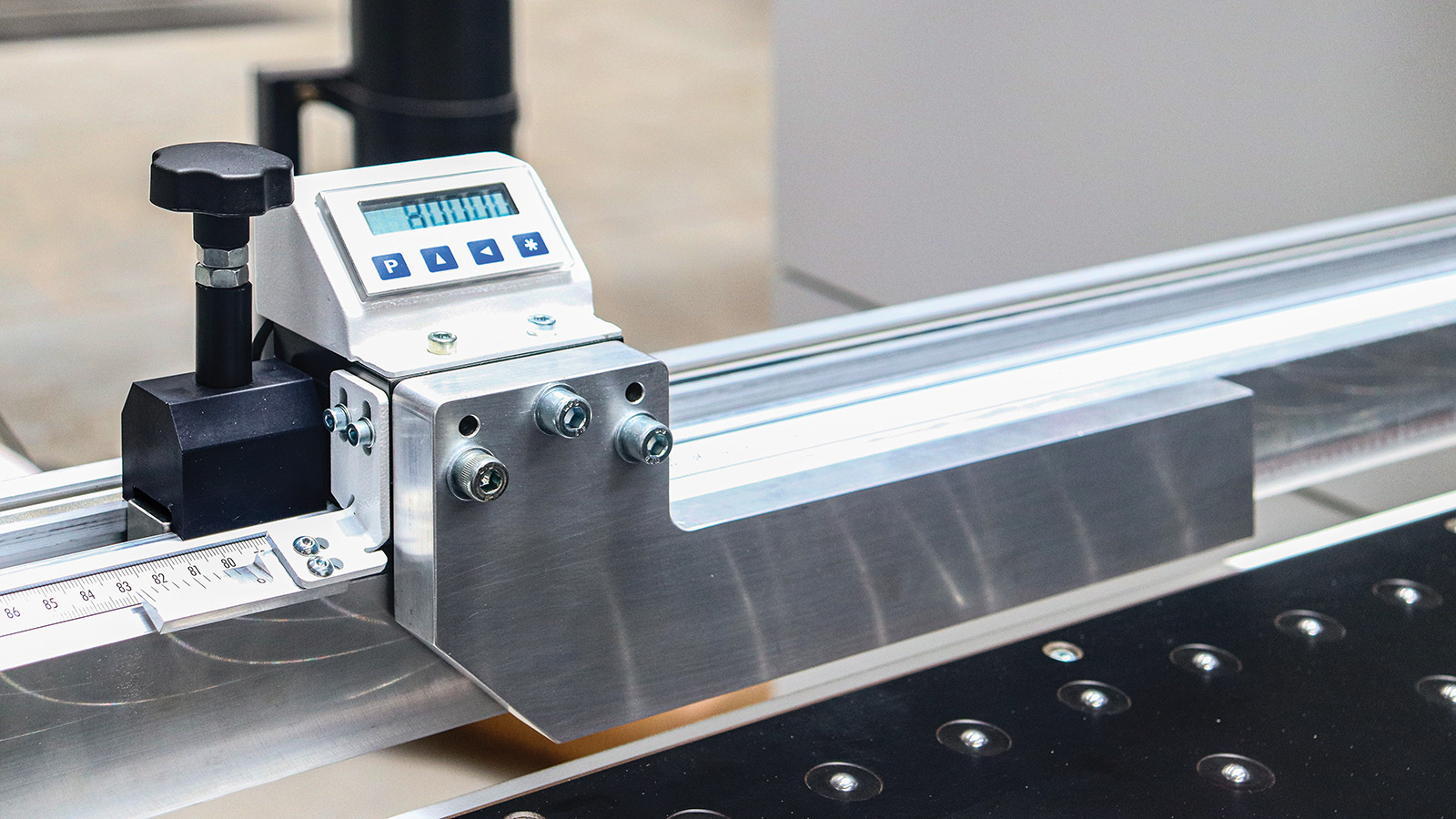

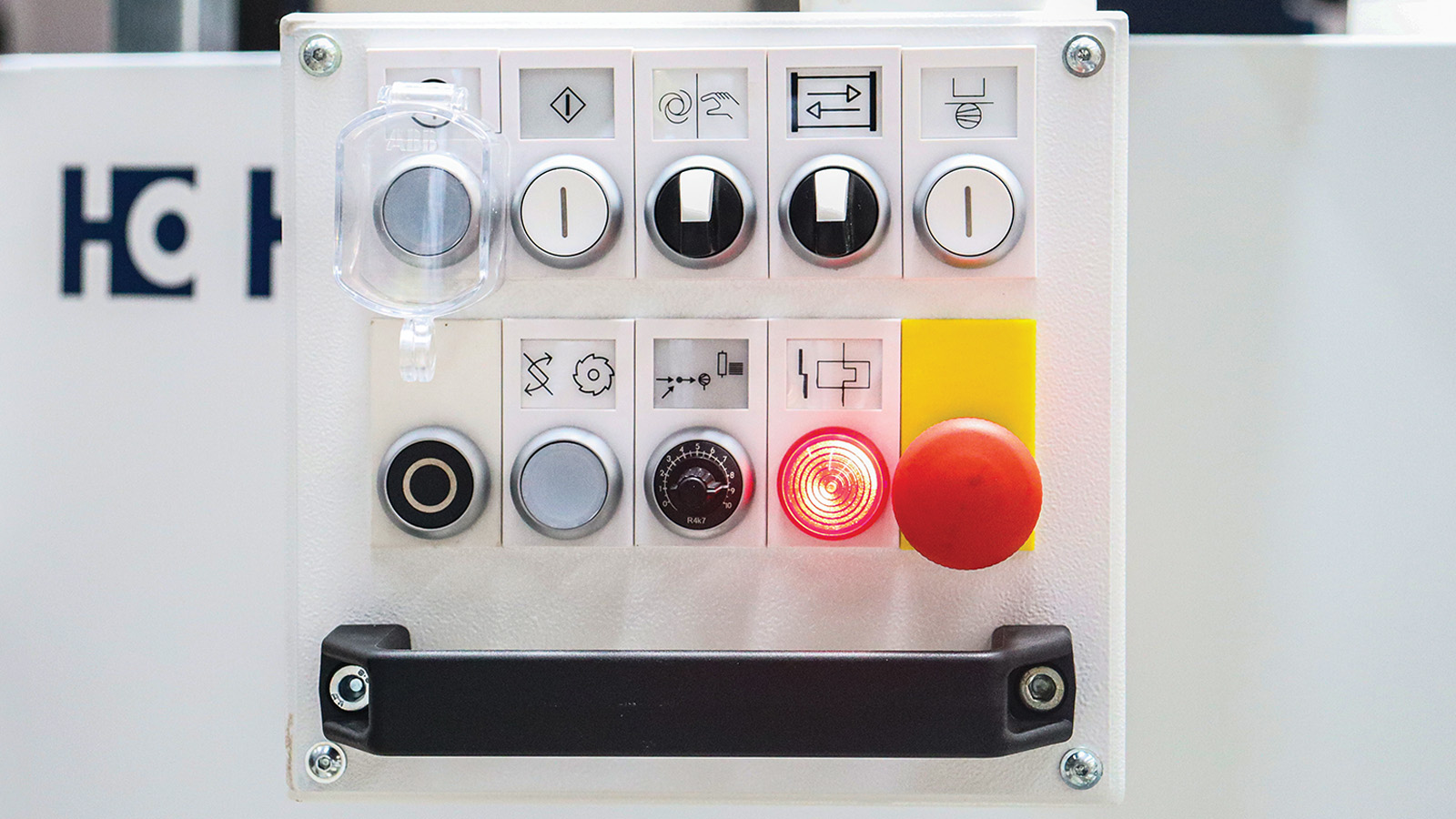

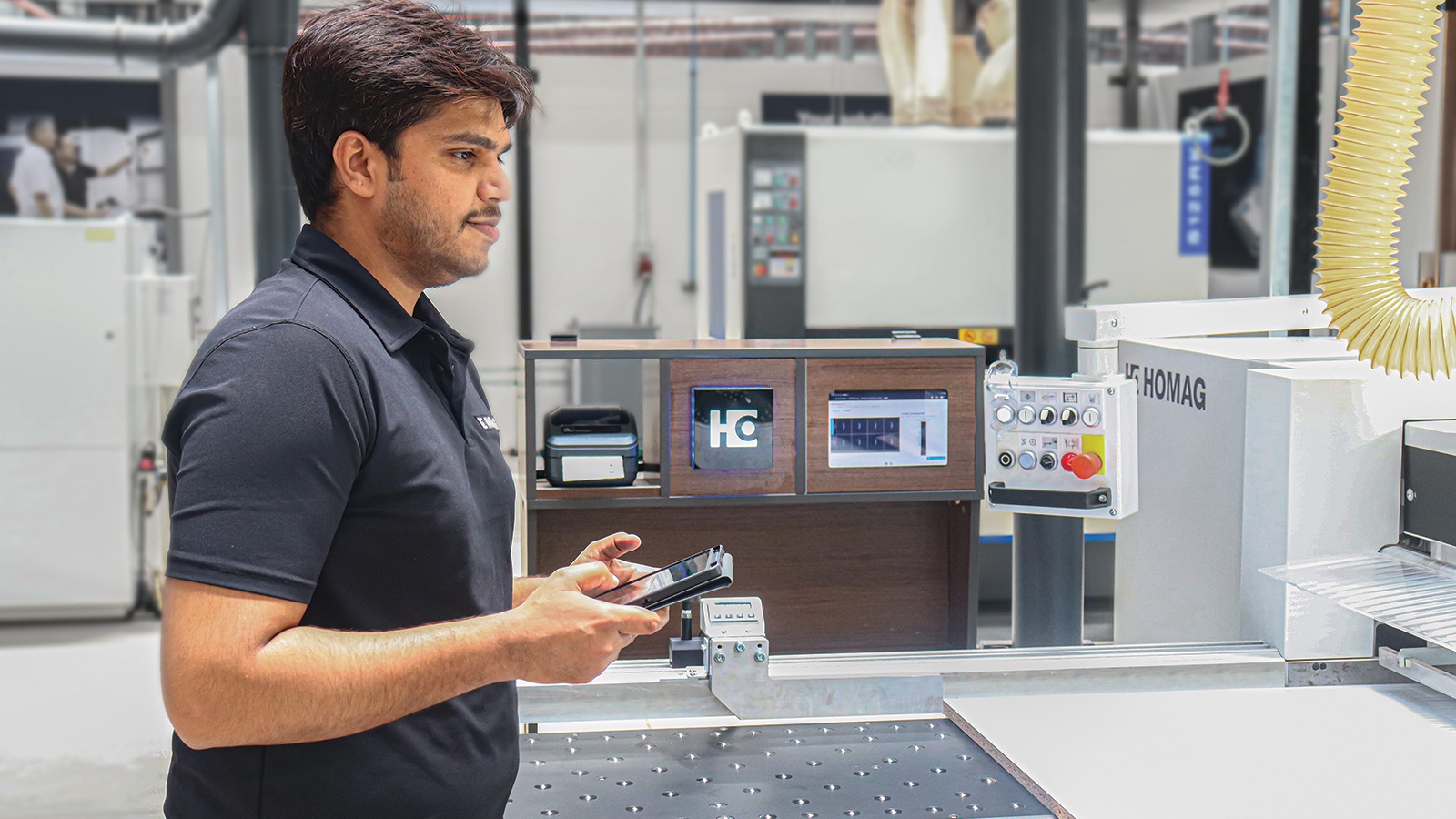

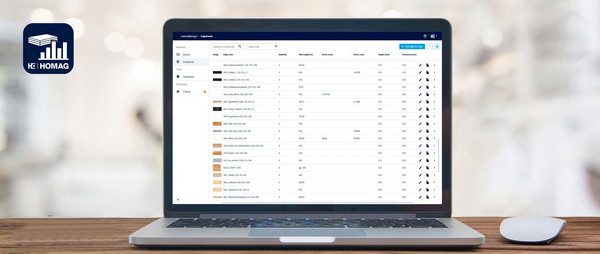

The SAWTEQ O-100 is highly suitable for woodworking shops that are ambitious. This model of the HOMAG panel dividing saws is equipped with everything needed for cutting single panels & small batches. A clear material flow around the saw & material handling working at the saw further increases the capacity. In addition, digital assistants help the operator to optimize the entire cutting process in terms of quality, quantity, and sustainability. This is achieved by proven HOMAG technologies. In short, the SAWTEQ O-100 is the solution for ambitious woodworking shops to improve productivity, and precise manufacturing at a reasonable price!

Product available exclusively in Bangladesh, Brazil, Bhutan, India, Sri Lanka, Nepal .

Images

Technical Data

| Model | SAWTEQ O-100 |

|---|---|

| Saw blade projection [mm] | 60 |

| Cutting length [mm] | 2,900 |

| Working height [mm] | 920 |

| Saw carriage speed [m/min] | 0 - 30 |

| Main saw blade [mm] | 300 x 4.4 x 60 |

| Scoring saw blade [mm] | 150 x 4.4-5.25 x 45 |

| Main saw motor [kW] | 5.5 (7.5 kW as an option) |

| Connected load [kW] | 8.5 (11.5 kW as an option) |

| Required compressed air supply [bar] | 6 |

| Air consumption [NL/min] | 100 |

| Dust extraction port size [mm] | 2 ports Ø 160 and Ø 100 |

| Extraction system [m3/h] | 2,600 |

| Machine weight [kg] | 1,500(Approx.) |

| Air blower volume [m3/h] | 1,000 |

Software

Brochures