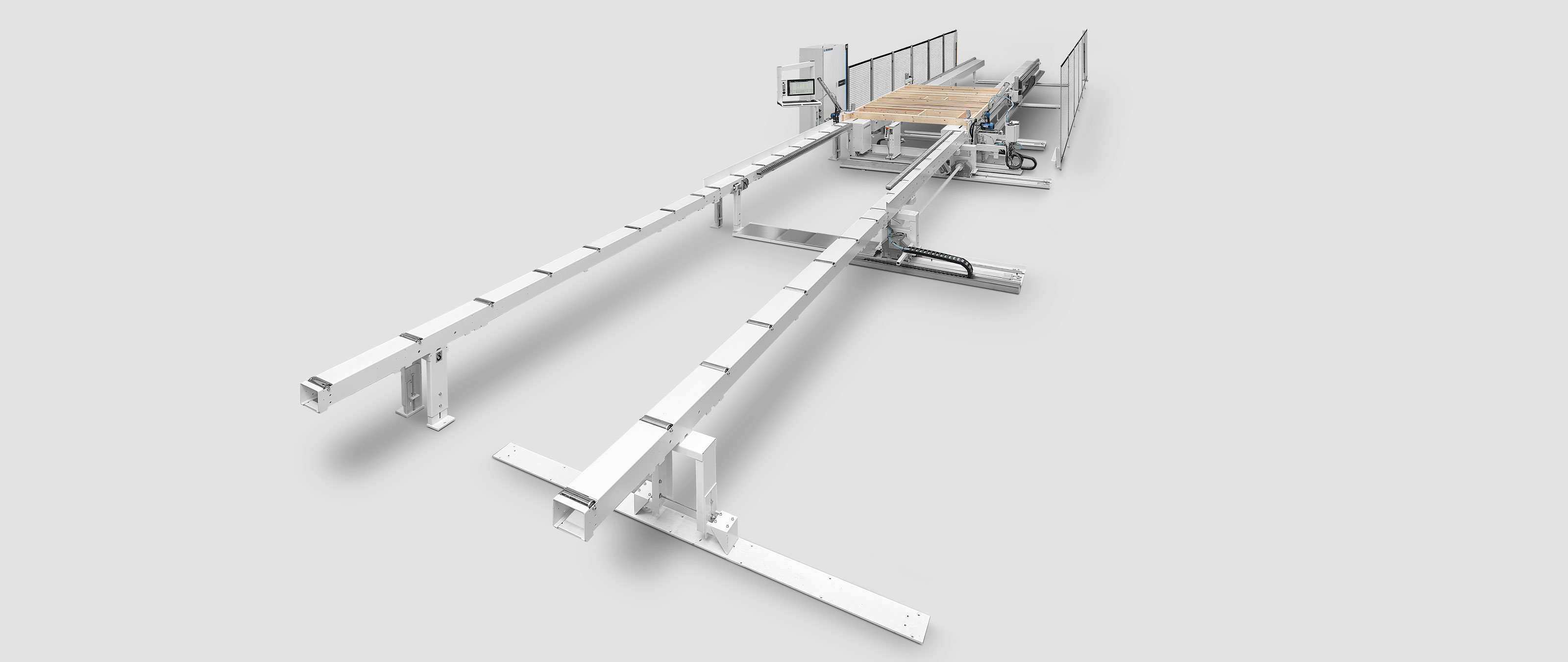

Framing Station FRAMETEQ F-300

Framing Station FRAMETEQ F-300

Frame work production in batch size 1

The WEINMANN FRAMETEQ F-300 simplifies and automates the manufacture of frame works. The distances between the studs are determined automatically, meaning that the operator only needs to place the studs and plates in the corresponding position. The studs and plates are then secured automatically. The FRAMETEQ F-300 frame work station is particularly well-suited to production capacities of 80 houses or more per year.

Benefits

Images

Features

-

Infinitely variable wall heights

-

Convenient installation of longitudinal studs using a special device

-

Innovative and convenient powerTouch operating concept

-

A wide range of additional options: module station, stud provision units and many more

-

Fully automatic transfer of data from all popular CAD programs for timber work

Technical Data

| Wall thickness [mm] | 75 - 200 Optional: 300 |

| Wall height [m] | 1.5 - 3.2 Optional: 3.8 |

| Wall length [m] | 6/ 8/ 10/ 12 |

| Production capacity [mm / min] | 500 - 1,000 |

(Previous product name: Frame Work Station WEM 100)

You might also like

Brochures