Production Management ControllerMES

Production Management ControllerMES

Full control for production: The manufacturing execution system ControllerMES

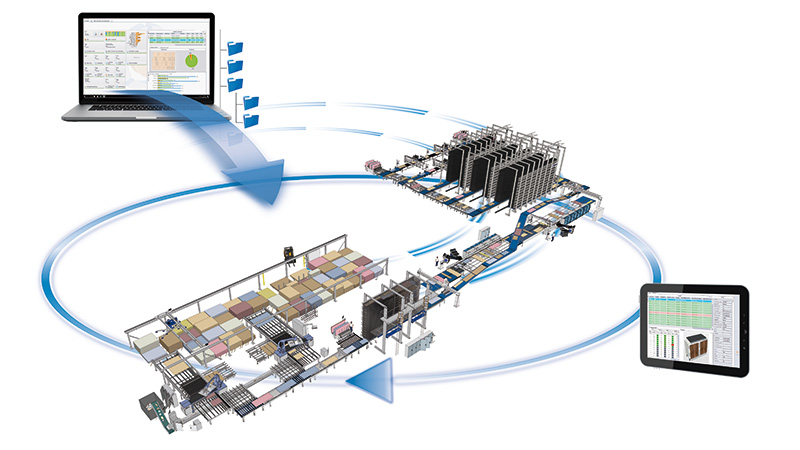

The networking of machines and production processes in times of digitalization makes a production control system indispensable. ControllerMES offers a modular, scalable and flexible software package for optimal production planning, control and monitoring. From the acceptance of your job data to the completeness check after final assembly.

Highlights

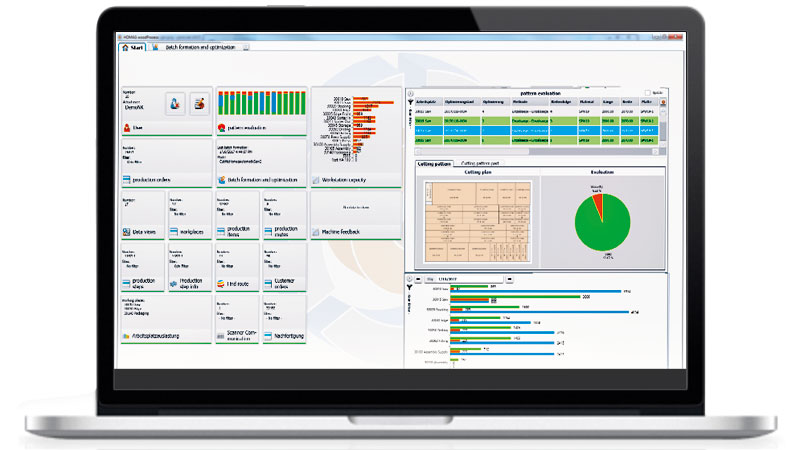

Flexible batch formation: Flexible batch formation not only saves time and material, but also optimizes production processes, as orders enter production more quickly and manual intervention is reduced.

Automatic stack layout: Automatic stack layout ensures optimally stacked components in the required production sequence and significantly reduces the search times for components.

Customized dashboards: Complete and comprehensive visibility as to your production performance through the use of simple and flexible dashboards.

Images

Features

-

Complete control over the production process

ControllerMES automatically reports back the production key figures for the entire production process, fully compiles the information and makes it available to the production control system to ensure a timely intervention at all times. Dashboards—also known as cockpits—visualize the production status using key figures. In this way, you can immediately detect bottlenecks and irregularities and react immediately. The production progress and job progress are displayed at all times. You can see at a glance where your customer job is and whether it is complete. A presentation can be created in flexible dashboards for employees, team and plant management, including analyses of material consumption at part or job level. -

Simple interfaces to other systems

ControllerMES ensures intelligently networked information flows — both within production and for your job entry, for example your ERP. With ControllerMES, the data from the upstream system is adapted to your production system and completed based on rules. Interfaces to all standard CAD/CAM systems, such as HOMAG iX, are available for this purpose and can be customized to suit individual customers. It is also possible to connect working hours or machine data recording systems so that all necessary information is available in one system. -

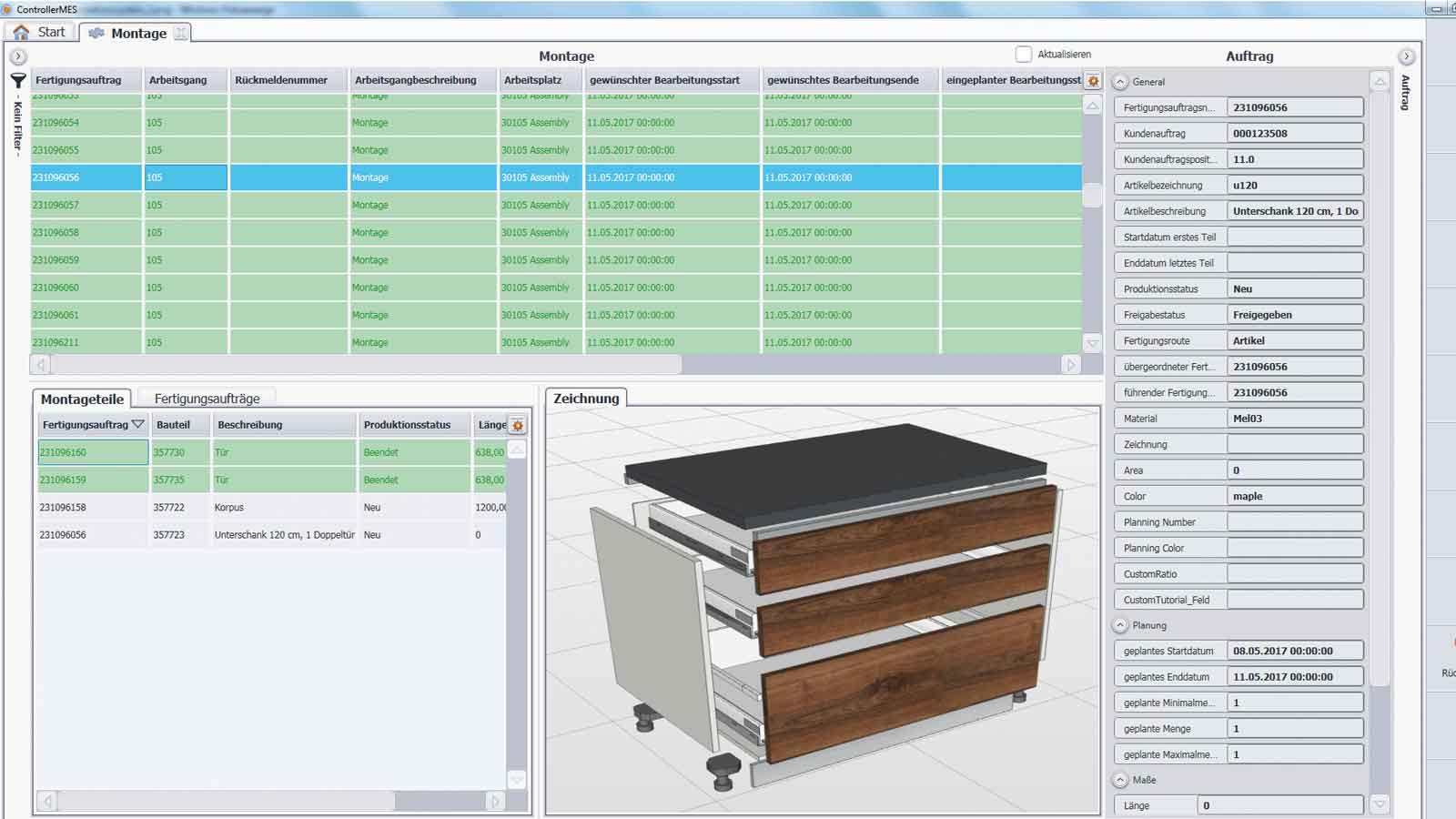

Automatic and manual feedback

The ControllerMES enables direct feedback on the production progress of networked machines (e.g. panel dividing saw, nesting, edge banding machine, CNC machine, sorting and buffer storage and more). Machines from all manufacturers can be connected with bidirectional communication points. What's more, feedback at workstations is also obtainable, e.g. for checking the completeness of component groups in manual sorting processes by scanning barcodes.

Further Solutions

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

Automatisch Produktionsdaten generieren

Find out here why the ControllerMES and HOMAG iX software is indispensable for the production of DeinSchrank.de.

Brochures

Product Comparison

Product comparison: productionManager and ControllerMES