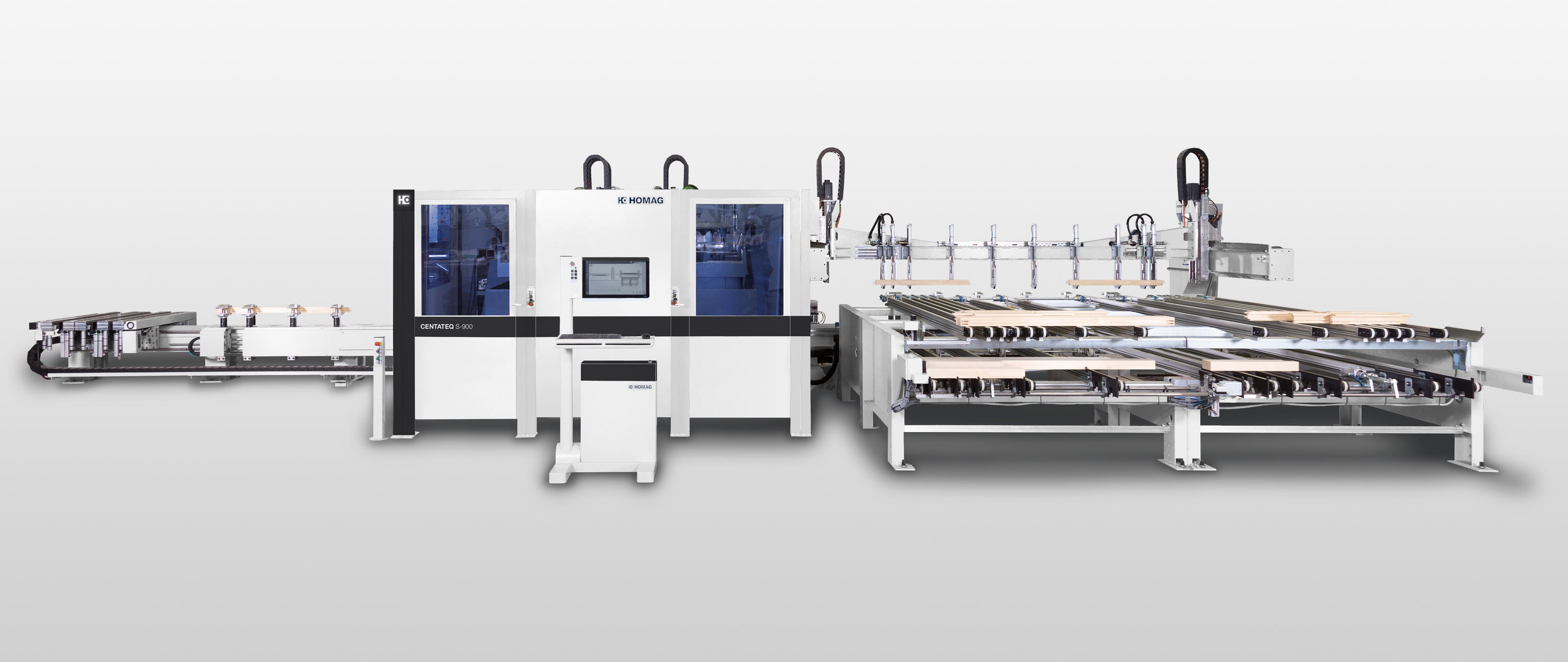

CNC Machining Centers CENTATEQ S-800|900

CNC Machining Centers CENTATEQ S-800|900

A firm "grip" on window production

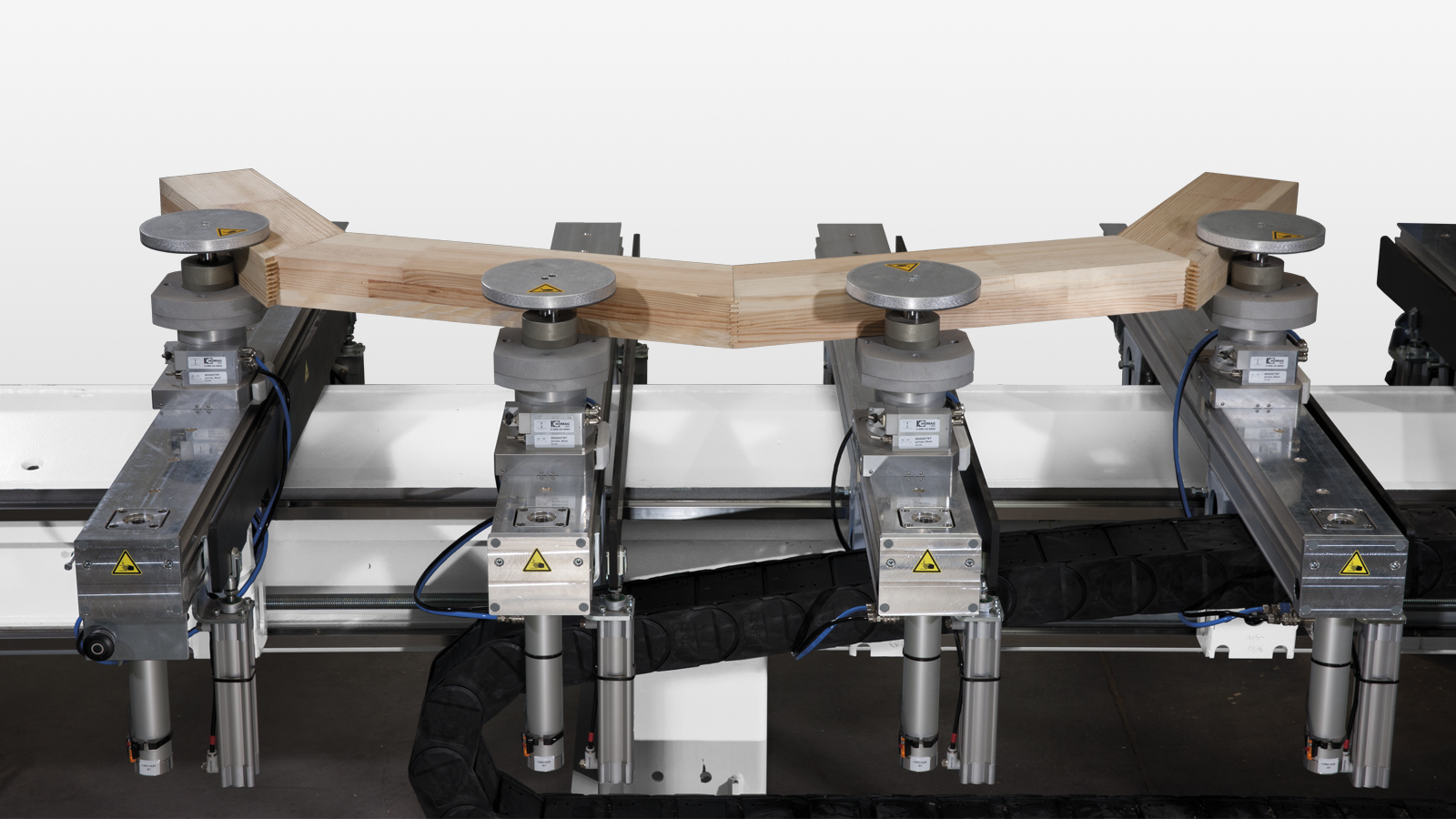

This series offers automated window production solutions – from entry-level machines to individual plant concepts for industrial multi-shift operation. With automated feed and removal, these solutions work independently. The additional console table also enables you to process curved and surface parts. The result: One machine for all components.

Highlights

Free clamping in all directions

Processing, loading, reclamping, unloading: Up to 2 parts each on 2 tables independently of each other

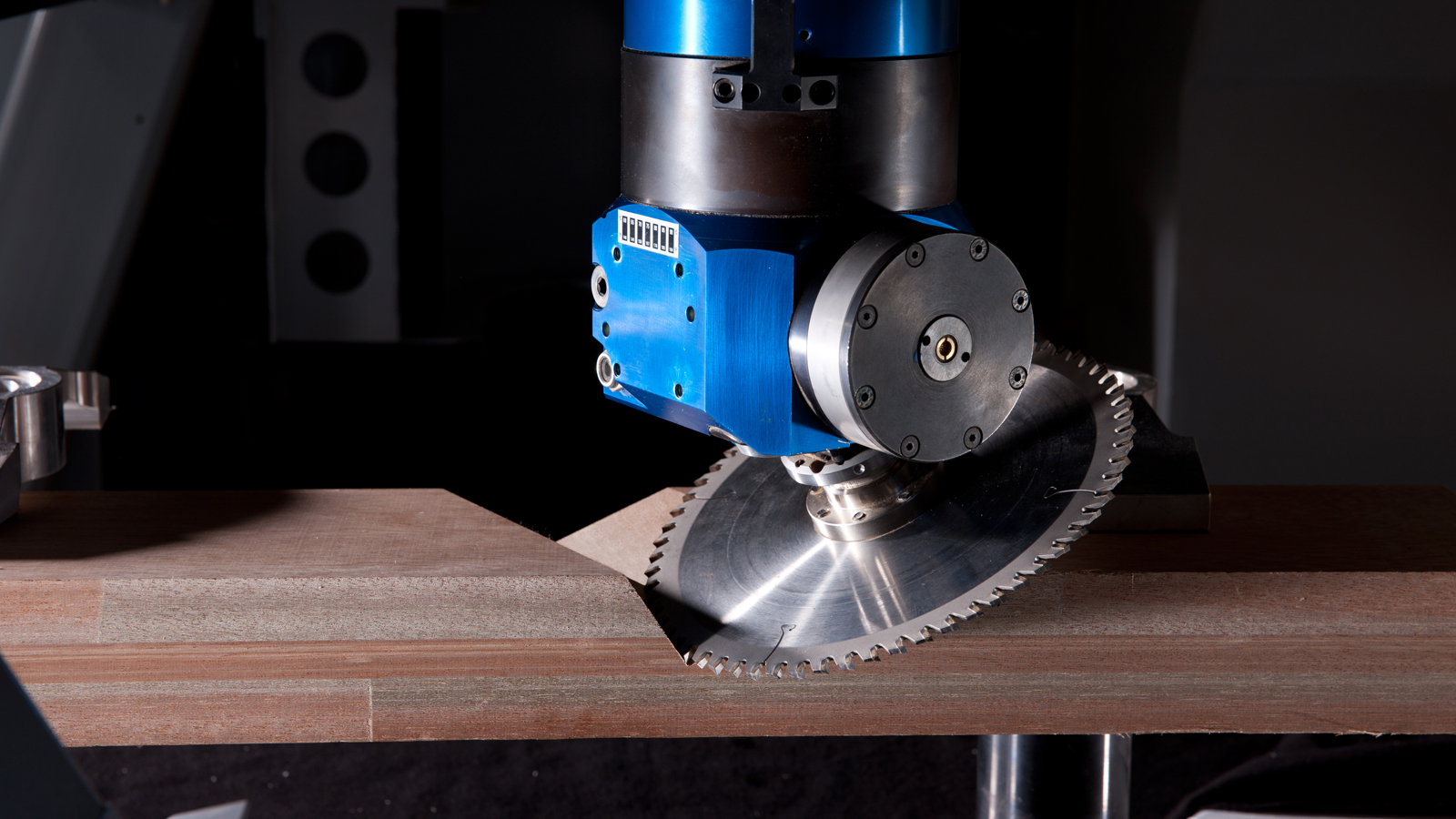

5-axis technology - DRIVE5 spindle or FLEX5 unit

Images

Features

-

Optimum processing quality with the basic machine comprising a heavy-duty gantry bridge plus compact, rigid guide track for the clamping tables

-

Dual-level infeed and outfeed for centralized workpiece handling

-

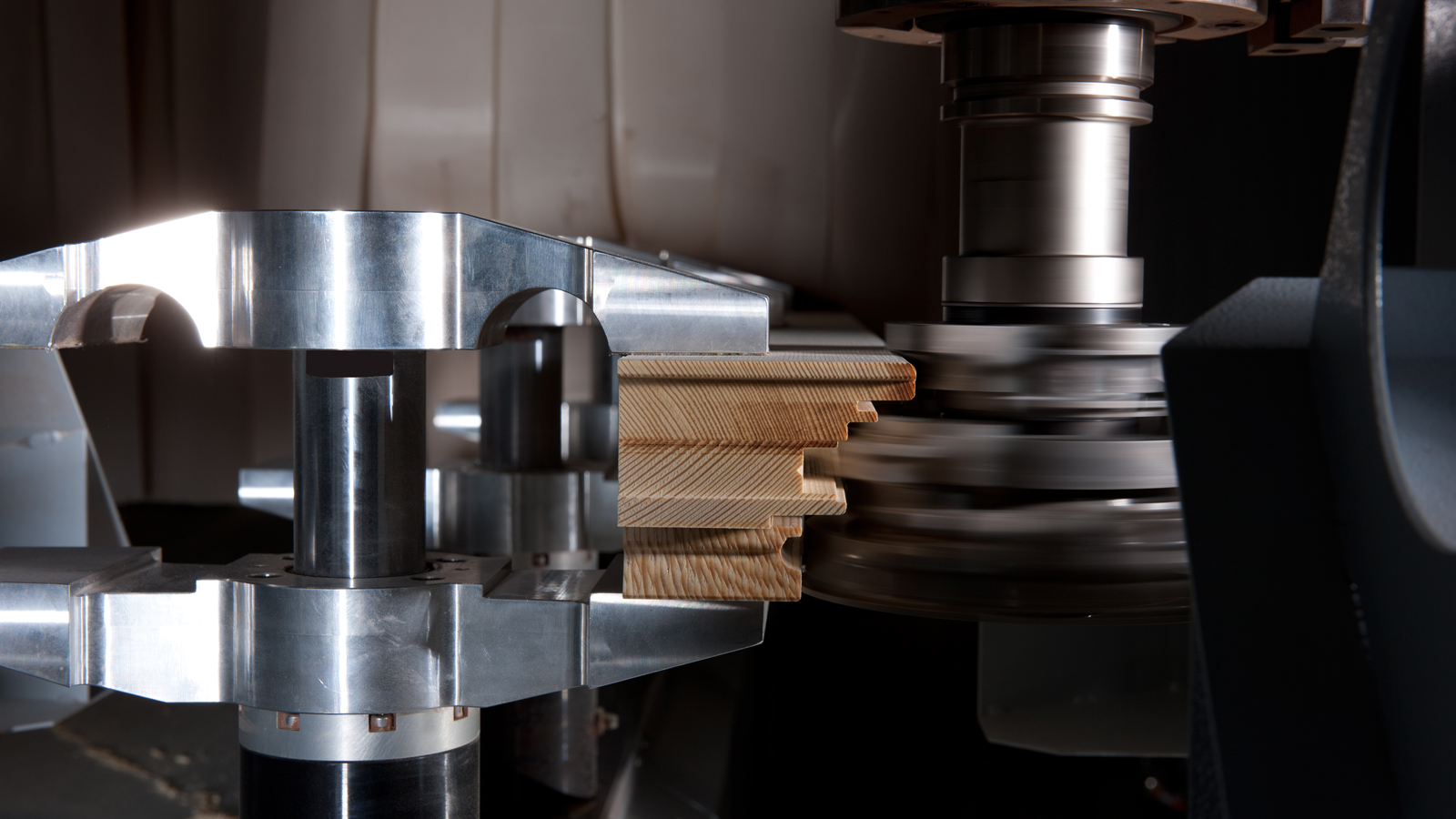

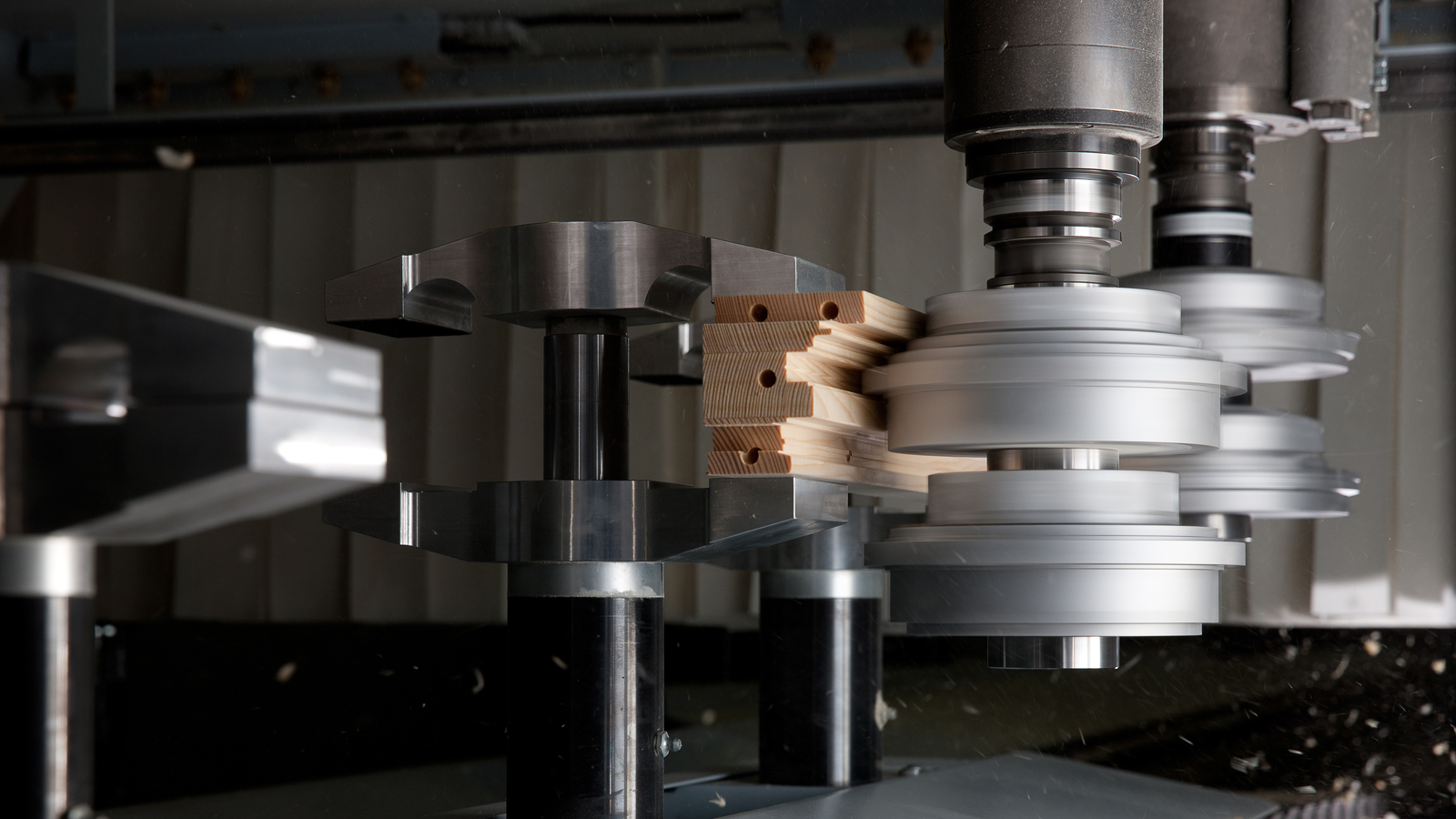

Precise clamping of components in all directions thanks to gripper system that pivots on both sides

-

High-performance processing spindles with liquid cooling, a variable speed range, vector control and a spindle sensor that detects imbalances and vibrations, thus protecting the spindle

-

Minimal clamp-to-clamp time thanks to compact tool magazines in different sizes with inte-grated pre-changing system

Technical Data

| Workpiece parameters | |

|---|---|

| Workpiece width [mm] | 20 - 300 |

| Workpiece height [mm] | 25 - 150 |

| Workpiece length [mm] | up to 4,200 for automatic operation up to 6,000 with reclamping |

(Previous product name: BMB 800|900 processing centers)

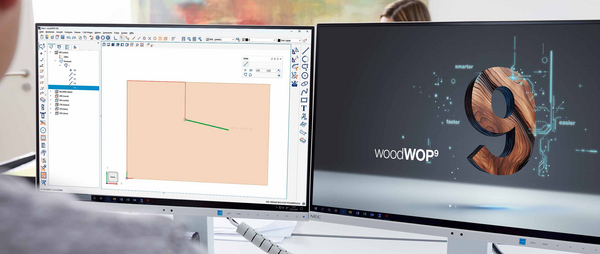

Software

Here's how your colleagues produce

Videos

Please confirm that when you use YouTube, data such as your IP address, browser identifier and similar may be transmitted to Google.

» Privacy Policy

CENTATEQ S-800|900 processing centers

Window production: The 3rd generation of the powerProfiler - dynamic, fast, precise and flexible

Brochures