The production tachometer: Keeping an eye on production with MMR.

Software for analyzing machine data

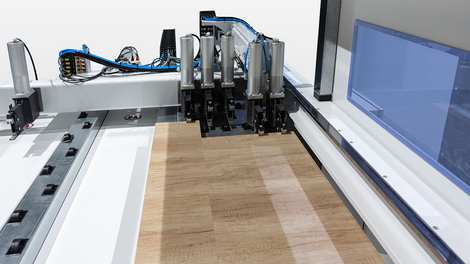

Anyone who invests in modern machine technology today wants to unlock the full potential of their production environment. Manufacturers of furniture, components and prefabricated houses often face the same questions: Am I making full use of my production capacity? On what machines is there potential to be more efficient? What measures can be taken to do this?

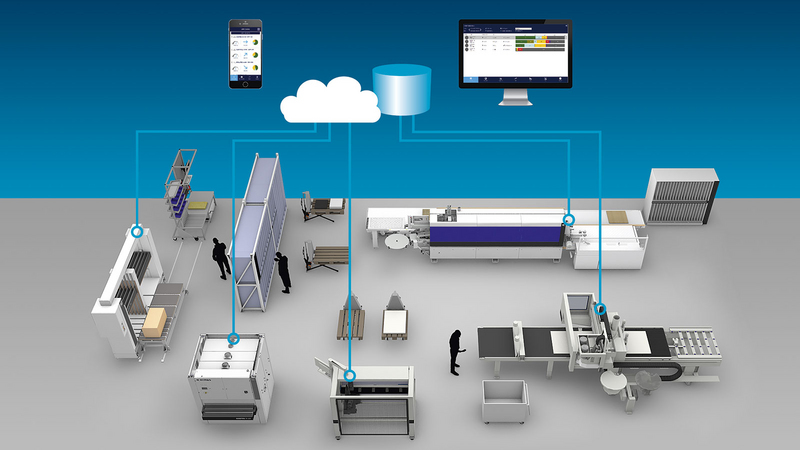

To embed different machines in the production sequence in the optimum way, the performance and efficient operation of each individual machine is crucial. This is where MMR Office (Machine Monitoring & Reporting) in the form of an app and software provides an essential overview. Parts, cycles, changeover gaps and much more — MMR Office gives wood processing businesses real data, thus allowing easy analysis of production and the opportunity to become better and more efficient. And the best thing is that MMR Office can also connect old machines and machines from third-party manufacturers.

MMR: The machine data reporter.

At a time in which delivery deadlines, optimally defined processes and sustainable production are becoming increasingly important in companies, detailed machine data is also gaining in importance. With the right data as a basis, companies can analyze their production quickly and easily, make informed decisions and ensure an efficient production standard for the future.

Did you know that older machines and machines not made by HOMAG can be connected to MMR Office easily via OPC-UA and REST interfaces?

.

MMR Office Software...

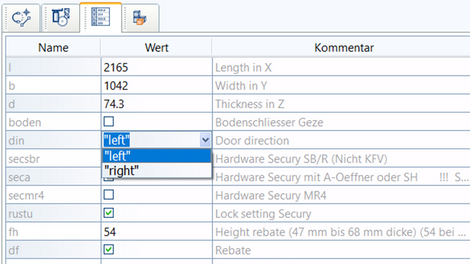

- ...can count parts, stock movements, cuts, panels and much more.

- ...knows the optimal cycle time for each part (e.g. for throughfeed machines).

- ...knows necessary handling times in the machine process (e.g. for saws).

- ...can record automatic setup processes (e.g. for batch size 1).

- ...saves error messages with text.

- ...can provide the data from the MMR database via an interface.

The right tool for every job: MMR grows with you.

The free smartphone app delivered with every new machine gives production managers an overview of production at any time, even when they're on the move. If they want detailed analyses and to be able to analyze and process data further in the office, they can use MMR Office. It's also possible to select different analysis periods and the number of machines to be connected, meaning every production manager can now find the right solution for their requirements.

MMR Mobile: The production tachometer for your pocket

- With the smartphone app, you always have your machine pool in your pocket. A glance is enough to show what the machines have achieved over specific periods.

- The app displays selected key figures in fixed analysis periods.

- It is supplied free of charge with every new machine purchased.

MMR Office Lite: The machine data supplier

- Quick and easy to install (access to the database on the machine).

- Makes the analyses provided by MMR Office available in work preparation.

- Detailed analyses (going back up to 30 days).

- Up to three machines can be connected.

MMR Office: The efficiency driver

- Copies the data from multiple machines to a separate database in the office.

- Can also connect old machines or machines from other manufacturers.

- The data in MMR Office can be made available for further analysis.

- Detailed analyses (going back up to two years).

- Two expansion levels: up to five or up to 20 machines can be connected.